Table of contents

1 About this document ..................................................... 3

1.1 Target groups ................................................................3

1.2 Associated documents ..................................................3

1.3 Symbols.........................................................................3

1.3.1 Danger levels ....................................................3

1.3.2 Danger signs.....................................................3

1.3.3 Symbols in this document .................................4

2 Safety .............................................................................. 4

2.1 Proper use .....................................................................4

2.2 Foreseeable misuse ......................................................4

2.3 Fundamental safety instructions....................................4

3 Identification................................................................... 4

3.1 Rating plate ...................................................................4

4 Technical data ................................................................ 4

4.1 Ambient conditions ........................................................4

4.2 Dimensional drawing .....................................................5

4.3 Power supply .................................................................5

4.4 Modbus interface ...........................................................5

4.5 Cable specification ........................................................5

4.6 Pin assignment ..............................................................6

5 Function description...................................................... 6

5.1 Functional principle........................................................6

5.1.1 Usage................................................................6

5.1.2 Communication .................................................6

5.1.3 Volume measurement.......................................7

5.1.4 Linearization......................................................7

5.1.5 Density determination .......................................7

5.1.6 Mass measurement ..........................................7

5.1.7 Differential measurement and synchronization

..........................................................................7

5.1.8 Averaging..........................................................7

5.2 Modbus communication.................................................8

5.2.1 Supported Modbus functions ............................8

5.2.2 Sequence of the data values ............................8

5.2.3 Legend for the parameter tables.......................8

5.2.4 Protected parameters .......................................8

5.2.5 Automatically updated parameters ...................9

5.2.6 Parameters for configuration.............................9

5.2.7 K-factor table...................................................10

5.2.8 Density tables .................................................11

5.2.9 Error messages...............................................12

5.2.10 Parameter for clearing error messages ..........13

6 Transportation, storage............................................... 13

6.1 Unpacking and checking the state of delivery .............13

6.2 Transporting the processing unit .................................13

6.3 Storing the processing unit ..........................................13

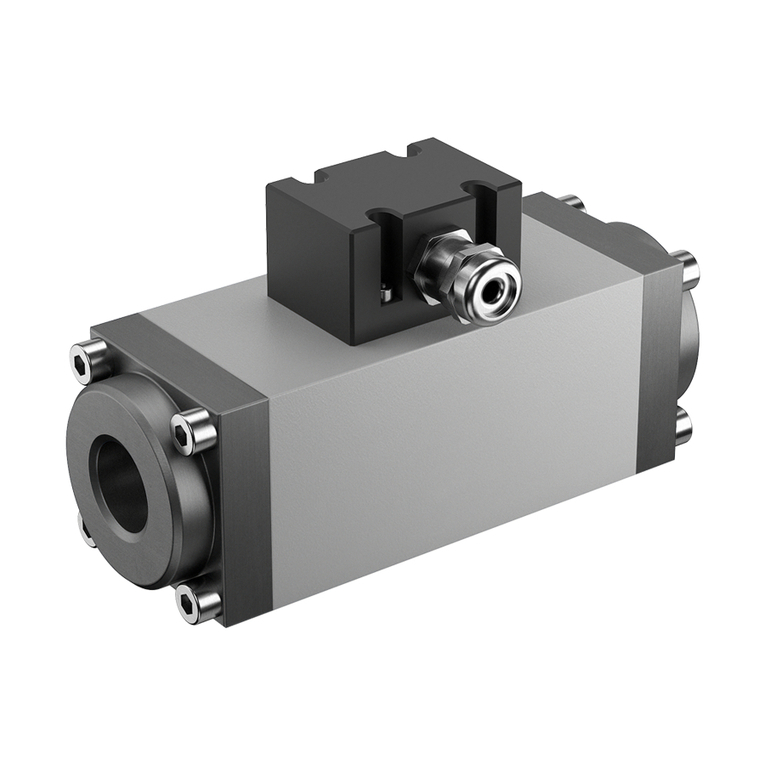

7 Installation, removal .................................................... 13

7.1 Dangers during installation, removal ...........................13

7.2 Installing the processing unit .......................................13

7.3 Removing the processing unit .....................................14

8 Connection ................................................................... 14

8.1 Dangers during connection work .................................14

8.2 Connecting the processing unit ...................................14

9 Operation ...................................................................... 16

9.1 Carrying out the basic settings ....................................16

9.1.1 Setting the Modbus address............................16

9.1.2 Managing the density table..............................16

9.1.3 Entering the density table ................................17

9.1.4 Selecting the mode for volume measurement

.........................................................................17

9.1.5 Specifying the reference temperature for tem-

perature compensation....................................18

9.1.6 Smoothing the indication .................................18

9.1.7 Selecting the mode for pulse evaluation..........18

9.1.8 Specifying the maximum flow rate...................18

9.1.9 Specifying the minimum flow rate....................19

9.2 Reading the measured values and status information

.....................................................................................19

9.2.1 Synchronizing measured values......................19

9.2.2 Clearing error messages .................................19

10 Maintenance...................................................................20

10.1 Required maintenance.................................................20

10.2 Cleaning the processing unit........................................20

11 Disposal..........................................................................20

11.1 Disposing of the processing unit ..................................20

12 Troubleshooting ............................................................21

12.1 Status LEDs .................................................................21

12.2 Fault table ....................................................................21

12.3 Error tree: No communication ......................................22

12.4 Error tree: No flow........................................................23

12.5 Error tree: Flow unusually high ....................................23

12.6 Error tree: Flow rate varies too much...........................23

2OIE 27en-GB Edition 2020-01 Operating instructions