Noark Electric ExATSN3/4 User manual

Thank you for your purchase of this Noark® ExATSN Automatic Transfer Switch devices. It

is important that you read this manual thoroughly before attempting to install, operate and

maintain this equipment not only for your personal safety, but to ensure the equipment is used

properly and the system runs safely and reliably.

Only the professionals should install and operate this equipment. The manufacturer will not

be liable for any consequences arising from your failure to follow the installation manual.

Warning

1 Turn ATSN power switch to "O" position before manual operation.

2 The main and spare neutral lines (N line) of three-pole products must be connected.

3 Do not wire and dismantle the product and contact its metal components while it is energized.

4 Do not alter the connecting wires between the equipment and its controller without permission.

5 The product is internally powered as standard. Do not connect it to an external power supply.

6 The product is equipped with interlocking mechanism which must not be operated improperly

or with a handle other than the one specified.

7 The product shall be grounded reliably or provided with appropriate equipotential protection

measures.

8 The user needs to provide fuses matched with the currents and voltages of the switch.

9 Operating under conditions beyond those specified in relevant standards could affect the

function and performance of the product. In such cases, appropriate measures shall be taken

or the manufacturer contacted.

10 Be sure to disconnect wires on the transfer switch before insulation test.

Table of Contents

I. Unpacking.........................................................................................01

II. Preparations .....................................................................................01

III. Operating instructions.......................................................................02

3.1 Manual debugging

3.2 Installation instructions

IV. Appearance and mounting dimensions............................................04

4.1 Appearance and mounting dimensions of the equipment

4.2 Appearance and mounting dimensions of the controller

V. Wiring................................................................................................06

5.1 Equipment wiring

5.2 Wiring of controller ports

5.3 Wiring between equipment and controller

VI. Operating conditions.........................................................................09

6.1 Normal operating conditions

6.2 Usage class

6.3 Compliance with standards

VII. Technical parameters........................................................................10

VIII. Troubleshooting of common faults....................................................11

I. Unpacking

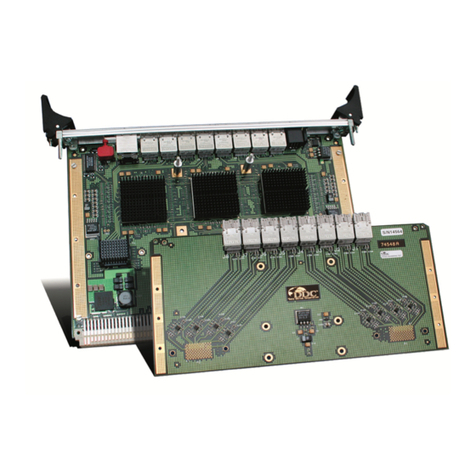

1. Transfer switch

2. Controller

3. Connecting wire

4. Handle

5. Mounting screw

Name ExATSN1/2 ExATSN3/4

Specification Quanity

1. Handle

2. OFF button

3. Switch button

4. Handle resting location

5. Power switch of controller

6. Grounding screw

7. Sight glass of main power

switch position

8. Sight glass of spare power

switch position

9. Mounting hole

6. Interphase insulating barrier (nine barriers for

four-pole product and six for three-pole product)

7. Installation manual

8. SU60 functionality manual

Mounting screw

Spring washer

Flat washer

Mounting nut

II. Preparations

OFF SWIT

MAIN MAIN

POWER

SPAR

SPAR

Noark Electric Europe s.r.o.

III. Operating instructions

3.1 Manual test

Before starting installation, the user shall conduct debugging by himself manually, with steps given below:

Verify that the switch is turned to the OFF position; if not, turn it to the OFF position (Figure 1);

Insert the handle into the revolving shaft (Figure 2) at an angle downward from the equipment

(Figure 4);

2))ĺ0DLQWXUQWKHVZLWFKIURPWKH2))WR0DLQSRVLWLRQFigures 4 and 5);

2))ĺ6SDUHSUHVVWKH³VZLWFK´EXWWRQFigure 3) and rotate the handle from the position shown

in Figure 4 to the position in Figure 5;

7KHKHDULQJRI³FOLFN´LQGLFDWHVFRPSOHWLRQRIWKHVZLWFKLQJ1RZWKHVZLWFKSRVLWLRQVLJKWJODVV

VKRZV³21´RIWKHPDLQRUVSDUH

Conformance with the above means the self-test is acceptable. In case of any abnormalities, do not

use the equipment and contact the manufacturer.

Figure 1

Figure 3

Figure 2

Figure 4 Figure 5

1RWH

Figure 3 is given for the step of manually switching to spare power.

Figure 1

3.2 Installation instructions

3.2.1 Installation instructions for equipment

Note:

Take out mounting screws

from the accessory bag.

Model

Torque

Installation tools: hex wrench

,QVWDOODWLRQSURFHVVPRXQWLQJVFUHZĺIODWZDVKHUĺIL[HG

VROHSODWHĺIODWZDVKHUĺVSULQJZDVKHUĺQXW

3.2.2 Installation instructions for controller

Installation instructions for

controller:

1. Before installation: remove

the four clips (Figure 1), and

insert the controller into the

perforated panel;

2. During installation: install the

four clips from the back of

the panel to fix the controller

to the panel.

Installation and fixing of four clips

IV. Appearance and mounting dimensions

4.1 Appearance and mounting dimensions of equipment

Size

Model

Note: please contact us if you need the physical dimensions of ExATSN5.

4.2 Appearance and opening size of controller

4.2.1 Physical size of controller

Installation with clips

4.2.2 Opening size of controller

V. Wiring

5.1 Equipment wiring

5.1.1 Wiring of main circuit

5.1.2 Size of the terminal block of main circuit

5.1.3 Wiring of secondary circuit

Spare power Main power

NoteśNoteś

NoteŚ

Output power

Warning

Noteķ: Be sure the product is reliably grounded.

Noteĸ: The inputs of main and spare power must

be provided with short-circuit protective device

meeting isolation requirements.

The secondary circuit is

located on the right side

of the equipment, and its

wiring is schematically

shown in pictures right.

Main position feedback signal

Auxiliary group (two groups)

Spare position feedback signal

Auxiliary group (two groups)

Voltage: AC230V

Current: <10A

Terminal screw: M3

Torque: 0.5 Nm

Terminal screw: M6

Torque: 7 Nm Terminal screw: M8

Torque: 10 Nm Terminal screw: M10

Torque: 18 Nm Terminal screw: M10

Torque: 18 Nm

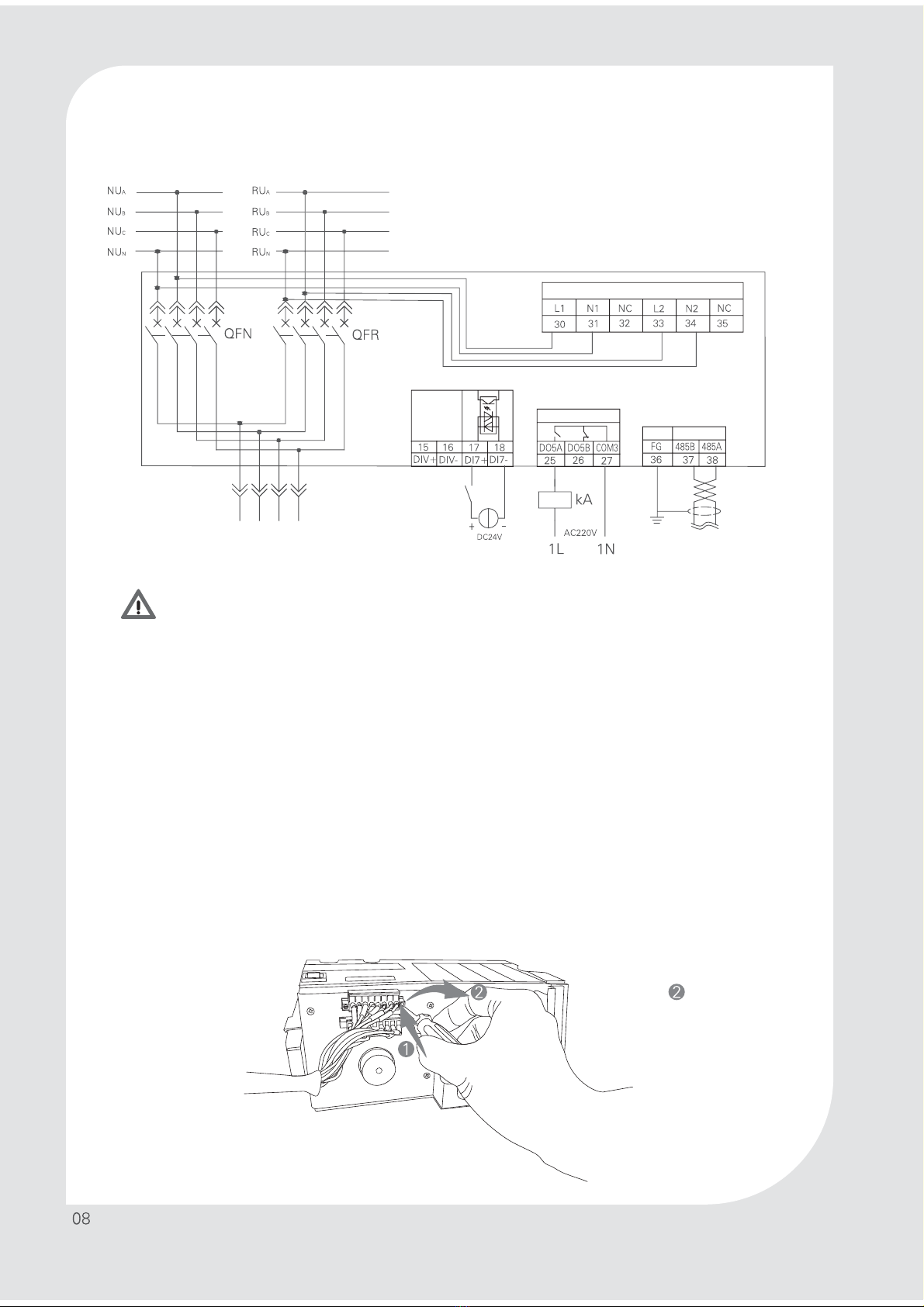

5.2 Wiring of controller port

5.2.1 Mode of external power supply (single auxiliary power)

5.2.2 Mode of external power supply (double-circuit auxiliary power)

Main power Spare power

Main power Spare power

Output power

Output power

NoteĹ

NoteĹ

NoteĹ

NoteĹ

NoteĻNoteĺ

Input of fire blocking signal

Output of generator signal

Input of auxiliary power supply

kA: intermediate relay

NoteĻ

NoteĺNoteĺ

Input of fire blocking signal

Output of generator signal

Input of auxiliary power supply Communication port

kA: intermediate relay

Communication port

5.2.3 Mode of internal power supply

Main power Spare power

Output power

NoteĹ

NoteĹ

Input of fire blocking signal

Output of generator signal

Communication port

Noteĺ

NoteĻ

Noteĺ

kA: intermediate relay

Warning

NoteĹ: Three-pole product needs to be connected to neutral lines (N-line), with the N-line of

main power to the terminal “NUN” and N-line of spare power to “RUN”.

Noteĺ: With AC220V power supply, the controller must not be connected to an external supply

if it is powered internally.

NoteĻ: The maximum voltage for generator output terminals is AC270V/DC30V. At the maximum

voltage, the output current must not exceed 1 A.

5.3 Connection between equipment and its controller

Connection instructions

1. The connection between equipment and its controller is of plug-in type. Take out wires from the

accessory bag, and securely connect them to the screws on both sides of a terminal block according to the

terminal number.

2. Before pulling or inserting wires from or into terminal, make sure the fastening screws on the terminal

block are loosened. Do not force wires into or out of terminal block.

(1) Rotate clockwise for

fastening screws;

(2) Rotate counterclockwise for

removing screws.

Note steps:

Terminal screw: M2.5

Torque: 0.4 Nm

Input of auxiliary power supply

VI. Operating conditions

6.1 Normal operating conditions

Ambient temperature: -5ć~+40ć, not greater than +35ćon average in 24h

Altitude: not greater than 2,000 m

Atmospheric condition: The relative humidity shall not exceed 50% at ambient air

temperature of +40℃; it can be higher than 50% at lower temperatures. In the wettest

month, the monthly average relative humidity is 90% as a maximum, and +20℃as a

minimum. Special measures are required for occasional condensation due to

temperature variations.

Pollution degree: 3

Installation category: III

6.2 Usage class

6.3 Standards

VII. Technical parameters

Model and specification

Electrical grade

Standard

Number of poles

Electrical performance

Switch operating position

Service life

Service life

(with maintenance)

Minimum switch time

Mechnical

Electrical

Controller

Type A (economical)

Type B (basic)

Type D (smart)

Control voltage

Installation and connection

Fixing/connection at the panel front

Auxiliary device for monitoring and indication

Fire linkage function

Alarm feedback signal

Position feedback signal

Standard Optional Unavailable

Noteķ: The front must be provided with short-circuit protective

device meeting isolation requirements.

Housing current

Rated current

Rated frequency

Rated insulation voltage

Rated impulse withstand

voltage

Rated voltage

Rated short-time withstand

current

Rated conditional

short-circuit current

Connection and breaking capacity

Usge class

PC class

Three positions

IEC/EN 60947-6-1

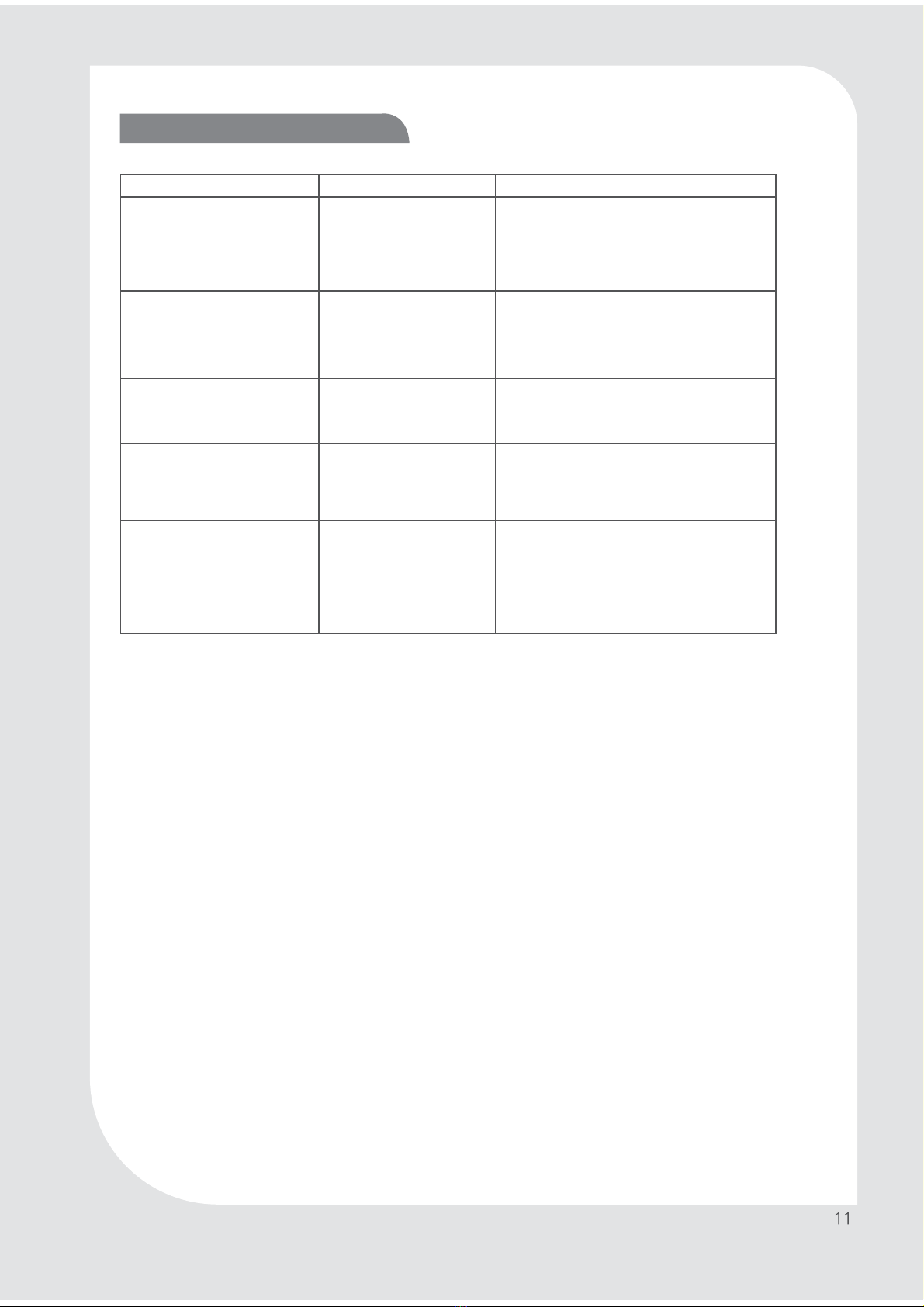

VIII. Troubleshooting of common faults

Common faults

No display on controller

The main (spare) power

indication lamp on controller

panel is not ON. The switch is at

the main (spare) power position,

and fails to act.

Failure of automatic switch

In automatic mode, the switch

fails to act upon a change to

power supply

Upon inputting a fire signal

1) The switch fails to act

2) The switch fails to return to the

previous status after its action.

Cuase

1) The controller is not

energized.

2) The terminals of connecting

wire are not securely attached

to both the transfer switch and

controller.

1) The terminals of connecting wire

are not securely attached to both

the transfer switch and controller.

2) The wires connected with the

transfer switch are loose at the

interface or come off.

The manual/auto mode is not

set correctly.

1) Both power supplies fail

2) The wires show poor

interface contact or come off

1) The fire signal wire is

improperly connected

2) The switch is set at

“manual” position.

Troubleshooting

1) Push the controller’s “power” button on

transfer switch to switch to “I” position

2) Reconnect the wire terminals as per the

steps given in Section 5.3, and secure

fastening screw

1) Reconnect the wire terminals as per the

steps given in Section 5.3, and secure

fastening screw

2) Fasten all wires connected with the switch

Push “manual/auto” button on the panel of

controller SU603 and switch to “auto” status,

in which the “auto” light is ON.

1) Provide normal main and spare power

2) Fasten all wires connected with the switch

1) Fasten all wires attached to the fire signal

terminal

2) Turn the switch to “auto” position

This document is prepared and printed by Noark,

and only covers information about this series of

products. It is subject to change at any time

without notice, for technical upgrade or application

of new technologies or for correction of misprint

and incorrect information.

Copyright©Noark Printed with eco-friendly paper

Noark Electric Europe s.r.o.

;"54/&6

Add: Sezemická 2757/2, 193 00 Praha 9, Czech Republic

Registered at Municipal Court in Prague, Section C,

Insert 181277

Tel: +420 226 203 120

Email: [email protected]

www.noark-electric.cz

This manual suits for next models

1

Table of contents