NOCRY Jig Set User manual

Jig Set

Instruction Manual

We've worked very hard on making this manual useful, simple, and understandable.

Please read it carefully, and keep it safe for future reference.

1

WHAT'S INSIDE THIS MANUAL

THE ABC'S OF CLAMP AND JIG SET SAFETY 3

Basics of power tool safety 3

Basics of your work area safety 5

Basics of electrical safety 6

Basics of personal safety 7

Basics of servicing your power tools 8

JIG SET KIT PACKAGE CONTENTS 9

HOW TO USE YOUR JIG SET 10

How to create pocket holes 11

How to select the correct screw type 12

How to measure the drill depth 14

How to set the drill depth for drilling pocket holes 14

When using ½ inch and ⅝ material thickness 15

When using ¾ inch material thickness 16

When using 1 inch and above material thickness 17

When using 1 ½ inch and above wood thickness 18

How to conceal pocket holes 18

How to create dowel holes 19

How to set the drill depth for drilling dowel holes 20

How to set the collar stop 22

How to secure the jigset to the workpiece 22

How to join two work pieces 25

TIPS AND TROUBLESHOOTING 26

Drilling tips 26

Reducing wood splitting 26

Gluing workpieces 27

MAINTENANCE 27

JIG SET LIABILITY 28

RESPONSIBLE DISPOSAL 29

WARRANTY 29

HOW TO CONTACT NOCRY 31

2

THE ABC'S OF CLAMP AND JIG SET SAFETY

These are the basic precautions you should take before, during, and after working

with your NoCry clamp and jig set. We've tried to include any safety precautions

that need to be adhered to when using any tools or equipment needed when using

the clamp and jig set kit.

Please read all safety warnings and instructions before

using your clamp and jig

set. They're pretty reasonable, and neglecting them may result in electric shock

and/or serious personal injury. There are other (and much better) ways to get your

adrenaline going.

Save this manual for future reference, review in between uses, and make sure

that anyone who's going to test your new smart charger has read and fully

understood all the information in here as well.

In case this manual disappears into the black hole that all manuals seem to fall

into, you can get a digital version of it at https://nocry.com/pages/instructions,or

by letting us know at [email protected].

Basics of power tool safety

✔

✔

✔

Only use your power tool for its intended use. Would you use a screwdriver

to hammer a nail? Exactly. A suitable tool will do a job a thousand times

better and safer than one that wasn't designed for the task at hand.

Don't force the tool. No one is fond of having to do something they're forced

to do - same goes for your power tools. Do not overload them, and use the

right one for the job.

Do not operate power tools in dusty or explosive areas, such as in the

presence of flammable liquids or gases, for a very simple reason - power

tools may create sparks which could ignite dust or fumes.

3

✔

✔

✔

✔

✔

✔

✔

✔

✔

✔

Your power tools aren’t waterproof or splash proof. Under no

circumstances should you use them in the rain, spray with water, or

immerse in liquid or risk the danger of explosion or electrocution.

Be sure to have a solid grip when drilling long screws, nuts or bolts as

tools can slide off the fastener head and cause you injury.

Remove any adjusting key or wrench before turning your power tool on, if

your power tool requires one. A wrench or a key left attached to a rotating

part of a power tool will ruin your day real fast.

Always wait until the power tool has come to a complete stop before

placing it down, changing the rotational direction, moving onto the next task,

or inserting a drill bit.

Should the tool insert jam, release the trigger switch immediately to stop

the drill and get it sorted. The tool insert jams either when the power tool is

subject to overload or it becomes wedged in the workpiece.

Do not use a malfunctioning power tool. If the switch doesn't turn on

and/or off, it's a pretty clear sign to not use the power tool and to get it

repaired or replaced.

Regularly check screw or drill bits for wear, cracks, or damage before

putting them into the chuck of your power tool.

Keep your cutting tools sharp and clean. Cutting tools that have been

carefully maintained and have sharp cutting edges will jam less and be

easier to control. If you think that more injuries are caused by sharp tools

than dull ones, you'd be surprised.

Disconnect the tool from the power source and/or the battery pack before

making any adjustments, changing accessories, or putting it in storage.

This way, you'll ensure it will not turn on accidentally.

Keep your power tools away from others. Store it away from children and

do not allow anyone unfamiliar with your power tool or this manual, to

operate it.

4

Basics of your work area safety

✔

✔

✔

✔

✔

✔

✔

Keep your working area tidy and well lit. Accidents are much more likely to

happen in dirty, unorganized, or poorly lit workspaces and can be easily

avoided with basic upkeep.

Secure any movable workpiece(s) you're working on. A workpiece secured

with suitable clamps or in a vice is much more likely to be steady and stay in

place than one held by hand.

Ensure your working area is well ventilated. If you smell fumes or feel

other than your usual self, stop working, ventilate the area properly by

opening a window or a door, and seek medical help.

Keep children and bystanders away. Distractions can easily cause you to

lose control, so consider operating your power tools a solo venture. You'll

catch up with everyone later, when you've made progress with your project.

If you absolutely must have children in the working area, ensure that

they're always closely supervised by another, responsible

, adult, and do

not interfere with your work.

Familiarise yourself with your local general rules of occupational health

and safety. The sooner you do that, the sooner you can start using your

clamp and jig set.

Only use your clamp and jig set accessories, tool bits, screws, plugs etc. in

accordance with these instructions. Use of them for anything other than

their intended use could result in a hazardous situation, personal injury AND

voids your warranty (see page 29 for warranty details). In short, we really,

really don’t want you to have an accident. Really.

5

Basics of electrical safety

✔

✔

✔

✔

✔

✔

✔

If you are using an electric drill with a power cord, do not modify plugs,

and make sure that the power tools you use correctly match the power

outlet to reduce your chances on getting an electric shock. Also, adapter

plugs and earthed (grounded) power tools are a really bad combo.

Do not abuse the power cord. The cord isn't the reason you're having a bad

day - and it won't be, if you won't use it for carrying, pulling, or unplugging

the power tool, and will keep it away from heat, oil, sharp edges, and moving

parts.

If the power supply is interrupted (for example, in case of a power failure or

when the mains plug is pulled), immediately set your power tool to its ‘off’

position to prevent uncontrolled restarting.

Find out if there are any utility lines hidden in the work area. Use suitable

detectors or call the local utility company for assistance. It's totally worth it -

only imagine the level of booms and ouchies that coming in contact with

electric lines, damaging a gas line, or penetrating a water line can bring.

When working outside, use an extension cord meant specifically for

outdoors use. It's going to be much more convenient, and will reduce the

risk of an electric shock.

Do not expose your power tools to rain, moisture or wet conditions. Search

“water and electricity don't mix” on YouTube, and you'll see why.

If damp conditions are unavoidable, use a residual current device (RCD)

protected supply.

6

Basics of personal safety

✔

✔

✔

✔

✔

✔

✔

Don't underestimate the power of safety gear. No one has ever felt sorry

about using safety glasses, gloves, dust masks, non skid safety shoes, hard

hats, and/or hearing protection when operating power tools. But there's A

LOT of people who feel sorry they didn't. On that note…

Dress appropriately. Your power tools strongly prefer clothing and

accessories that are tight on your body. Do not wear loose clothing or

jewellery, keep hair tied back and clothing and gloves away from moving

parts, and you'll never have to experience your power tools trying to rip them

off you.

To avoid unintentionally starting a power tool, make sure the power tool is

effectively switch off, before connecting the tool to a power source and/or

battery pack, or before picking up or carrying the tool. Also, learn to never

carry power tools with your finger on the power switch.

Hold your power tools by their insulated handle grip when using in

situations where the fastener or drill bit may come into contact hidden

wiring.

Don't touch drill bits, screws or fasteners after using them at high speeds.

They get hot. Let them cool down first, or use suitable work gloves before

handling.

Dust safely. Some dust created from drilling and other construction

activities on certain materials may contain chemicals known to cause

cancer, birth defects or other harm. If you're using a specific device for dust

extraction and collection, ensure that it's connected, cleaned and maintained

regularly.

Do not take unnecessary risks by trying to reach areas that are obviously

too far away to reach safely. Keep proper footing and balance at all times -

it'll help you keep control in unexpected circumstances, would it be the

power tool slipping out of your hands, or someone deciding it would be fun

to attempt to pull a jumpscare on you in your workshop.

7

✔

Common sense is the best protection, isn't it? Stay alert and take regular

breaks. Exercise common sense, and do not operate your cordless drill when

you're tired, under the influence of drugs, alcohol, or strong medication. It

only takes a split second of inattention to get into major medical bills that

could have easily been avoided.

Basics of servicing your power tools

✔

✔

✔

To keep your drill well-maintained, regularly check if any parts are

misaligned, damaged or broken, or if there's anything else that might affect

its performance. If you notice anything odd, definitely take it for repair

BEFORE using it.

Work or repairs on any power tool should only be carried out by a

professional. It’s best to leave the really serious stuff to a qualified repair

technician who only uses original replacement parts.

Find a qualified repair person who only uses replacement parts identical to

the original to service and repair your power tools. This will ensure that the

safety of the power tool is maintained, and there will be no unpleasant

surprises.

Pro tip:

Take this manual with you to the service point, just in case.

NB! NoCry Work & Safety Gear and the manufacturing plant shall not be liable for

any changes made to the tool, nor for any damage resulting from such changes.

8

JIG SET KIT PACKAGE CONTENTS

Here's what you can find in the package. If there's anything missing, let us know to

1 Jig

1 F Clamp

1 Square drill bit

Dowel function kit contents

1 Handle

1 Dowel stop block

1 Square hex key

3/32 inch

4 Dowel drill bits

¼, 5/16,

⅜

, ½ inch

30 Wood dowel pins

¼,

5/16

,

⅜

inch

4 Collar stops

¼, 5/16,

⅜

, ½ inch

9

Jig Set kit contents

1 Jig stop block

1 Jig drill bit

⅜

inch

1 Collar stop

⅜

inch

1 Square hex key

⅛

inch

10 Concealing plugs

20 Wood screws

1 inch

HOW TO USE YOUR JIG SET

Your jig set has two functions; as a jig to create pocket holes for joining two

workpieces together with screws and, a doweling jig, used to drill holes in wood

vertically and joined together with little pieces of wood, called ‘dowels’ (think Ikea

furniture).

To get right to using your jig to create pocket holes or dowles, go to page 15.

To use your jig set for either its dowelling and pocket hole functions, you will need

the following tools and equipment to hand:

✔

✔

✔

A portable drill with hex chuck capacity of between ¼ in and ½ in.

Suitable screws or dowels.

Holding clamps (an F clamp has been included in your jig set kit).

10

✔

✔

✔

Wood glue (if concealing pocket holes with included wooden plugs).

Sandpaper or electric sander tool if required.

Phillips head screwdriver to change the jig’s block stop.

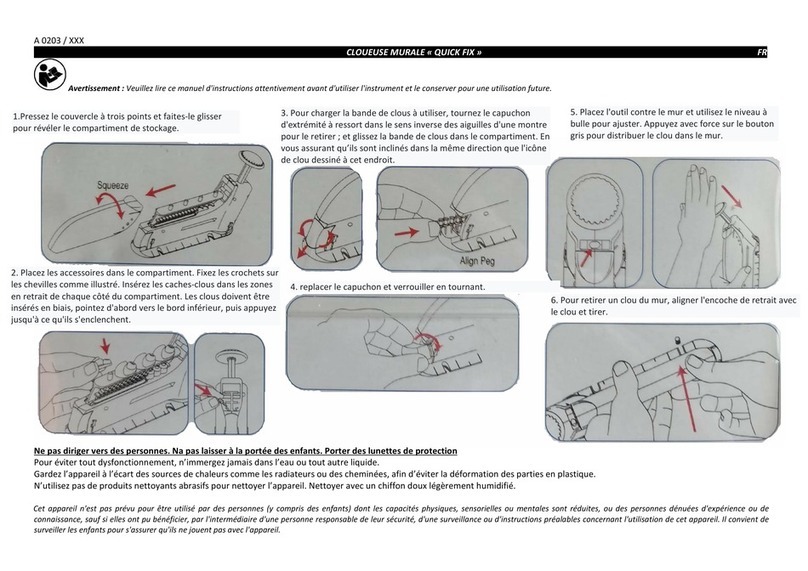

1.

Dowel drill guide hole

2.

Tightening dial

3.

Handle release button

4.

Drill guide

holes

5.

Measuring ruler

6.

Pocket hole depth marker and dowel mid point arrow

How to create pocket holes

Drilling pocket holes is fairly straightforward. However, there are a number of

steps that must be done before you can begin drilling pocket holes and joining

workpieces together.

11

1

2

3

4

5

6

7

Select the correct screw for the job.

Set the jig up for use with the appropriate wood thickness (very

important!).

Secure the workpiece to the jig and workbench using a suitable clamp.

Set the collar stop depth on the drill bit.

Drill the workpiece using the drill guide holes.

Join the workpieces together.

Conceal the pocket holes (if necessary).

How to select the correct screw type

Selecting the correct screw for the project or job you are working on is important -

it’s so much more than just selecting any old screw and hoping for the best. Here's

what you do.

First, select the correct screw length. The screw length you use will very much

depend on the thickness of the workpiece you are working on. Before you do

anything, be sure you know exactly what material thickness you will be working

with.

The table tells you exactly what screw length to use in relation to the material

thickness you are working with...

Material Thickness

Screw Length

½”

¾”

⅝”

1”

¾”

1 ¼ ”

⅞”

1 ½ ”

12

1”

1 ½ ”

1 ⅛”

1 ½ ”

1 ¼”

2”

1 ⅜”

2”

1 ½”

2 ½”

Then, select the correct screw thread and head type. Generally the type of

workpiece you are going to be working with will determine which type of screw

thread to use.

Screws come in two types, fine and coarse thread. Fine thread screws are usually

used for hardwoods and coarse thread screws for softer woods.

Fine thread screws are less aggressive, but ensure great holding power without

splitting the workpiece. Softwoods like pine and spruce are soft and not very

dense meaning they need a screw with deep, wider threads that will bite into their

soft fibers.

Use the table below to see which screw thread type is best for the workpiece

material your are working with...

Type of

thread

Material Type

Fine

Mahogany, Maple, Cherry, Ash, Walnut, Teak, Oak, Silver & red

beech, Hickory

Coarse

Plywood, MDF, Pine, Cedar, Particle board, Fir, Spruce, Aspen,

Basswood, Butternut, Melamine.

When it comes to choosing the screw head type, use washer head screws for

softwoods and pan head screws for harder woods.

13

If you know or regularly work with a certain type of material or workpiece

thickness, keep a supply of the matching screw type and length to hand at all

times.

Pro tip:

Using self-tapping screws will mean your workpieces won’t split when

driven in.

How to measure the drill depth

Listen up - this next part is perhaps the most crucial part of setting up your jig.

Get this wrong and you might end up in tears and your jig, along with your project,

in the bin.

Setting the correct drill depth means that the screw will exit at the centre of the

first workpiece, so you get a perfectly centered hole for your screw, ensuring the

strongest possible join.

Use the measurement markings along side of the jig for measuring the thickness

of your workpiece, setting the drill bit collar stop and most importantly to set the

jig to the correct drill depth measurement.

Once you know your material thickness, set the dowel and pocket hole indicator

arrow to the correct measurement marking (either 1/2 in, 3/4 in, 1 in, and 1 1/2 in)

to set your jig to the correct depth settings for your pocket holes.

How to set the drill depth based on material thickness

We thought we would make it easy for you and give you the exact jig setup

settings broken down by workpiece thickness, aren’t we kind.

Before setting your jig up, ensure that the front block stop is correctly positioned

and that you have already measured and know the thickness of your workpiece

material.

14

As long as you follow the steps taken in each of the following images, you

shouldn’t have any problems at all, but if there is anything that still isn’t clear or

that you don’t understand, email us at [email protected].

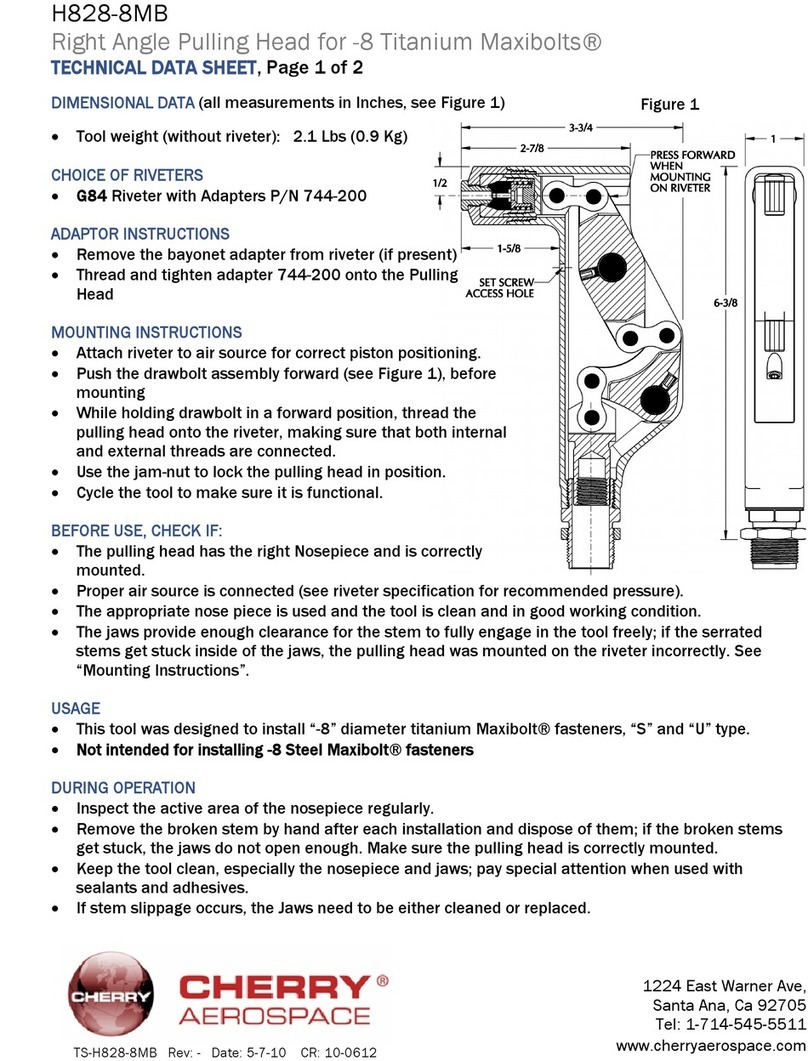

When using ½ inch and

⅝⅝

material thickness

1.

Set your jig to the ‘-3/8’ mark

(pictured above) at the edge of the

wood using the side measurement.

2.

Set your jig to ‘0 in’ setting using the

pocket hole indicator arrow.

3.

Set your drill collar stop 4 and ¼ in

back from the shoulder of the drill. See

page 23 for how to do this.

4

. Use 1 inch length screws.

15

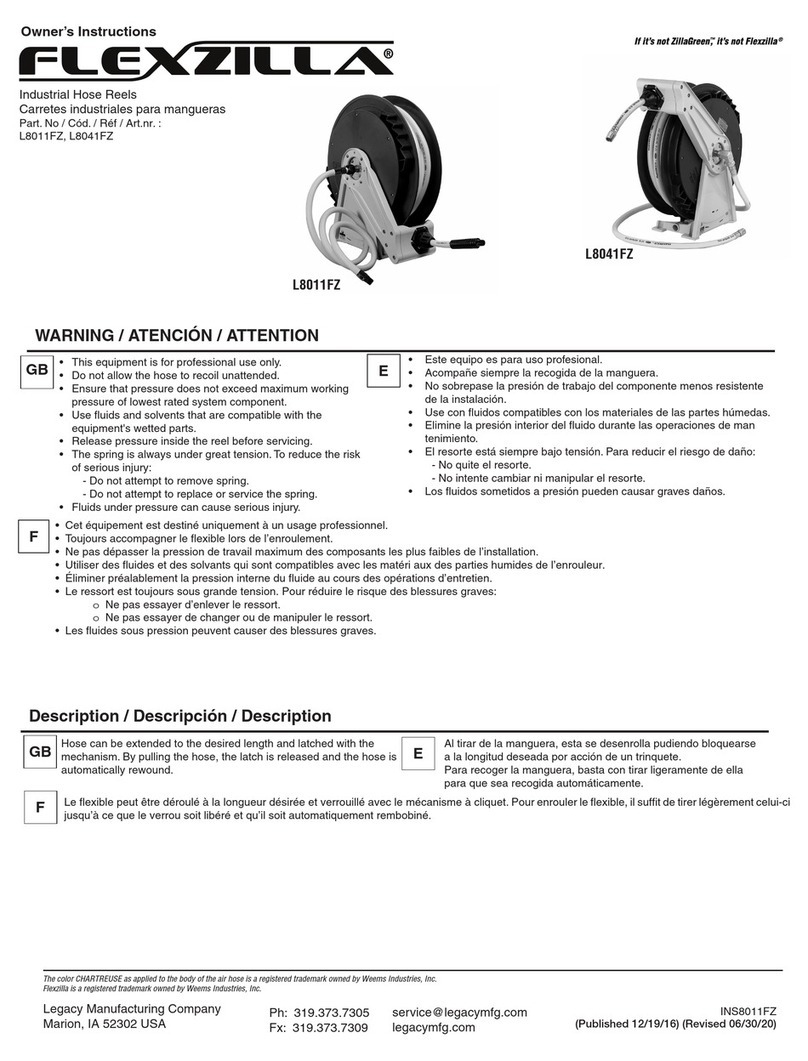

When using ¾ inch material thickness

1.

Set your jig to the ‘-5/8 in’ mark at

the edge of the wood using the side

measurement.

2.

Set your jig to ‘1/2 in’ using the

pocket hole indicator arrow.

3.

Set your drill collar stop 4 and ⅜ in

back from the shoulder of the drill. See

page 22 for how to do this.

4.

Use 1 ¼ ” length screws.

16

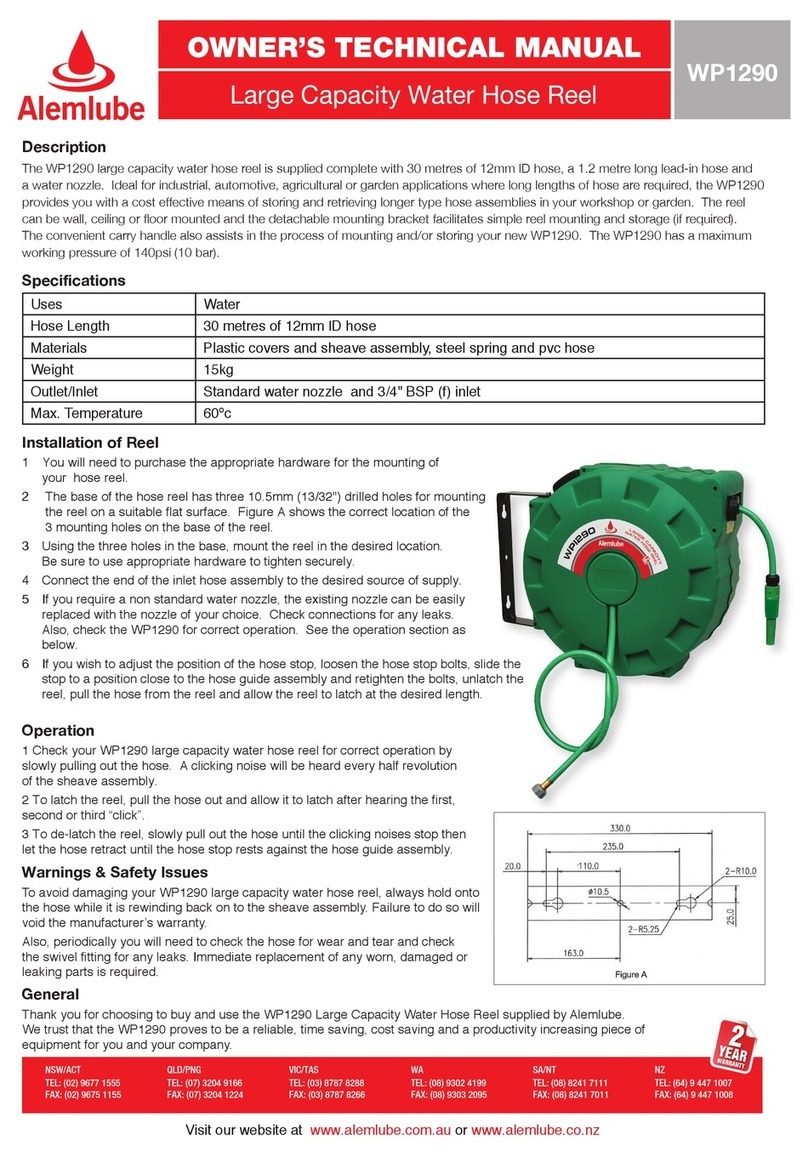

When using 1 inch and above material thickness

1.

Set your jig to the ‘-1 in’ mark at the

edge of the wood using the side

measurement.

2.

Set your jig to ‘⅝ in’ using the pocket

hole indicator arrow.

3.

Take the stop collar off of the drill

bit and instead use the end of the drill

chuck as a stop collar. Measure on the

drill bit 4 ¾ inches from the shoulder

and tighten.

4.

Use 1 ½ ” length screws.

17

When using 1 ½ inch and above wood thickness

1.

Set your jig to the ‘0 in’ mark at the

edge of the wood using the side

measurement.

2.

Set your jig to ‘1 ½ inch’ using the

pocket hole indicator arrow.

3.

Take the stop collar off of the drill

bit and instead use the end of the drill

chuck as a stop collar. Measure on the

drill bit 4 ¾ inches from the shoulder

and tighten.

4.

Use 2” length screws.

How to conceal pocket holes

You can finish your joining job by concealing your drilled pocket holes using the

included wooden plugs. These allow you to quickly fill all exposed pocket holes and

can be sanded down afterwards to fully conceal them - no one will ever know.

18

1.

Be sure that your

driven in screws are

tightened all the way

into the pocket hole to

get the best fit before

you fill the hole with a

wooden plug.

2.

Insert the wooden

plug into the pocket hole

and firmly tap the plug

until it is tight in the

pocket hole.

3.

For a more permanent

fix, apply glue around

the pocket hole before

inserting the wooden

plug. Allow the glue to

fully set before sanding.

How to create dowel holes

The second function of your pocket jig is creating dowel holes. Dowels are the

short wooden plugs or pins often used to construct flat pack furniture.

But why choose to use dowel holes over drilled pocket holes, we hear you say?

Dowel pins make for surprisingly strong, secure and versatile joints given how

quick and straightforward they are to make and yet also have a neat finish. Used

more in home workshops or for home DIY projects, as you also don't need nails,

screws or any expensive drilling equipment.

The main drawbacks to using a dowel type joint over a screwed pocket hole is that

given that there isn’t actually any face to face grain contact between the

workpieces, the joints are a bit weaker.

19

Table of contents