For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all necessary

risk assessments have been completed prior to the use

of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by his/her

employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from the

work area. Cordon off a NO GO area using either cones,

barriers or tape, available for hire from your local HSS Hire

Shop.

This Cartridge Hammer must only be operated by

adults over 18

who have read and understood these instructions.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Safety goggles MUST be worn by everyone in the

work area.

This equipment generates potentially harmful

noise levels. To comply with health and safety at work

regulations, ear defenders must be worn by everyone in

the vicinity.

Wear practical, protective clothing, gloves and

footwear. Avoid loose garments and jewellery that

could catch in moving parts, tie back long hair.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at your

local HSS Hire Shop.

Do not work near flammable gases or liquids, petrol or

paint thinner fumes for example. Keep combustible

materials at a safe distance - at least 5m.

Make sure that everyone is warned of what you are

doing.

Never load the Cartridge Hammer until you are ready

to use it to make a fixing and, once loaded, never point

it at anyone – including yourself.

Never use the Cartridge Hammer if anyone is close

enough to be at risk from flying debris or misfires.

Never use the Cartridge Hammer in fume/gas-laden

atmospheres where there is a risk of explosion or fire – for

example, in paint stores and sewers.

Make sure of your footing before operating the

Cartridge Hammer. Never work from an unstable

platform such as ladders, steps or anywhere else where

there is a risk of slipping or falling – the recoil could throw you

off balance.

Never make fixings in anything containing hidden

pipes or electrical wiring. If in doubt, use a metal detector

or Cable Avoiding Tool to locate such hazards.

Before cleaning or making any adjustments to the

Cartridge Hammer, unload it by pulling the cartridge strip

out through the top.

Never leave the Cartridge Hammer loaded and

unattended – even for a moment.

Store the Cartridge Hammer (together with spare

cartridges and fixings) in its case, somewhere it cannot be

reached by children or unauthorised users.

Check the condition of the equipment before use. If it

shows signs of damage or excessive wear, return it to your

local HSS Hire Shop.

COSHH information sheets are available from your local HSS

Hire Shop.

It is essential to familiarise yourself with all the

controls before starting.

Ensure the method of fixing is appropriate to the

object being fixed. The base material should be at least

4mm thick for steel, 100mm for concrete and resistant to

impact damage.

Ensure the method of fixing is suitable for the

surface you are fixing to, for example concrete,

brick and steel. In particular, the tool must not be used

to make fixings in partition walls, ceilings, soffits.

Select the appropriate cartridge for the job. In most

cases, standard red cartridges are more than adequate.

However, there may be times (when fixing into steel) when

the more powerful black cartridges are needed. If in

doubt, contact your local HSS Hire Shop for advice.

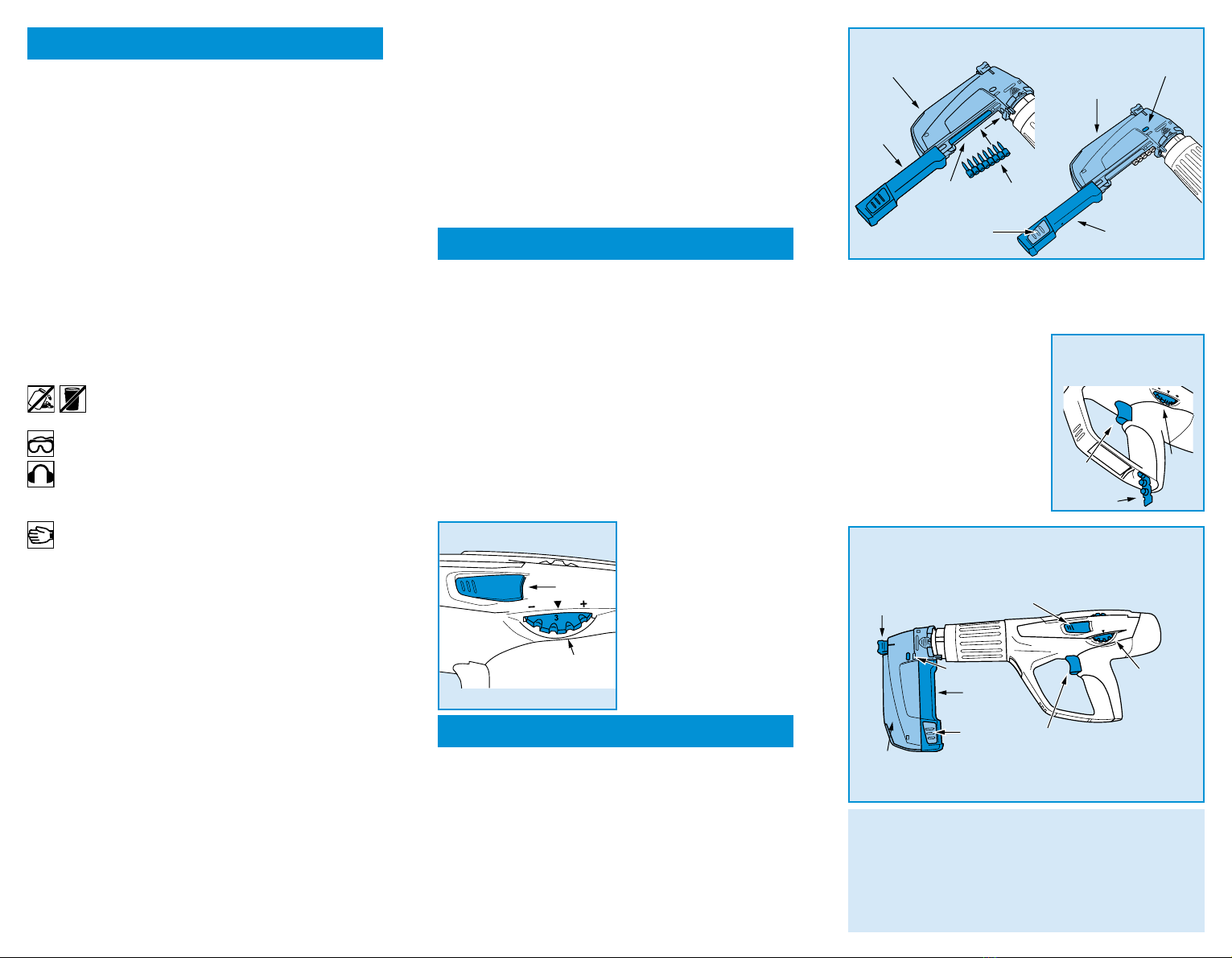

Adjust the Cartridge Hammer’s power regulator to

give the required penetration.

Start at the number 1

setting, make a test fixing

(see Basic Techniques) then

reset the regulator dial if

required and re-test until

you have an acceptable

fixing.

To adjust the setting,

depress the dial lock,

turn dial anticlockwise

to increase and clockwise

to decrease then release

the dial lock.

To load the Cartridge Hammer, open the magazine.

Push in the release button and slide the cover down.

Carefully insert the strip of nails into the guide with

points facing forward. Firstly, insert and raise the strip, then

slide the cover up until it clicks in place.

There is an indicator fitted to the magazine, which shows

a red marker when down to the last two nails.

Feed the cartridge strip into the bottom of the tool’s

grip as far as it will go. You are now ready to fire.

To make the fixing, hold the Cartridge Hammer with

both hands and press the fastener guide against the

work until the nosepiece is fully compressed – you may

hear a click as the fastener guide slides back and arms the

firing mechanism.

Now, having braced yourself against the recoil, squeeze

the trigger and the tool should fire.

Release the trigger and

move the tool away from

the surface. Note that the

mechanism will automatically

load the next cartridge and

fixing ready for firing.

Do not drive nails near the

edges or corners. In steel,

edges should be at least

15mm away; 80mm in

concrete. Do not try to make

a fixing twice in the same

place.

GENERAL SAFETY

GETTING STARTED

BASIC TECHNIQUES

Power Regulator

Power Regulator

Dial

Dial Lock

Loading the Magazine

Loading

Cartridges

Guide

Magazine

Cover

Strip of

Nails

Magazine

Red Indicator

Cover

Release

Button

Cartridge

Trigger Power

Dial