NoiseKen ISS-7630-CUP User manual

R

INSTRUCTIONMANUAL

COUPLING CLAMP

MODEL

ISS-7630-CUP

Noise L a boratory Co., Ltd.

Edition 1.01

AEJ00362-001-0B

NOTICE

•

The contents of this instruction manual(the “Manual”)are subject to change without

prior notice.

•

No part of the Manual may be reproduced or transferred, in any form and for any

purpose, without the permission of Noise Laboratory Co., Ltd.(the “Company”).

•

The contents of the Manual have been thoroughly examined. However, if you find

any problems, misprints, or missing information, please contact our sales agent who

you purchased our product from.

•

The Company assumes no responsibility for any loss or damage resulting from

improper usage, failure to follow this manual, or any repair or modifications of this

product undertaken by a third party other than the Company or the agent authorized

by the Company.

•

The Company assumes no responsibility for any loss or damage resulting from

remodeling or conversion solely undertaken by the user.

•

Please note that the Company cannot be held responsible for any consequences

arising from the use of this product.

•

Product names and business names referred to in this manual are generally

trademarks or registered trademarks of third parties. And those trademarks have

nothing to do with the Company. ® and TM are not always referred to in this

manual.

1

1. IMPORTANT

SAFETY PRECAUTIONS

The following instructions are very important for safe handling of ISS-7630-CUP

(the “Unit”). Read them carefully before use.

1. Do not use the Unit near flammable materials or fire sources. When

used, there is a risk of fire due to pulses, etc

2. Any person with medical electronics such as a heart pacemaker is not

to operate the Unit. And, do not enter the test area while the Unit is

operating.

3. To avoid electric shock, be sure that the power of the Unit, the power

source, and the device under test ("DUT") are all turned OFF, and make

sure there is no residual voltage before making any connections.

4. A number of safety recommendations are listed in the later chapter

"BASIC SAFETY PRECAUTIONS". Be sure to read them before test

environment settings, connecting and testing.

5. A powerful magnetic field is generated by the Unit at the time of pulse

output. Give careful consideration to your testing environment to use

the Unit.

2

Memorandum

3

2.

A

PPLICATION

F

ORM INSTRUCTION

M

ANUAL

We place an order for an instruction manual.

Model: ISS-7630-CUP

Serial No.:

Applicant:

Company name:

Address:

Department:

Person in charge:

Tel No.:

Fax No.

Cut off this page “APPLICATION FORM FOR

INSTRUCTION MANUAL” from this volume and keep it

for future use with care.

When an INSTRUCTION MANUAL is required, fill in the above Application

Form and mail or fax it to the following sales department of our company.

To: Noise Laboratory Co., Ltd.

1-4-4 Chiyoda Sagamihara City,

Kanagawa Pref., 229-0037 Japan

Tel: +81-(0)42-712-2051 Fax: +81-(0)42-712-2050

Cut

line

4

Memorandum

5

3. CONTENTS

1. IMPORTANT SAFETY PRECAUTIONS..........................................................................1

2. APPLICATION FORM INSTRUCTION MANUAL............................................................3

3. CONTENTS.....................................................................................................................5

4. PREFACE........................................................................................................................6

5. BASIC SAFETY PRECAUTIONS....................................................................................7

5-1.

S

YMBOLS OF

H

AZARD

.........................................................................................................7

5-2.B

ASIC

S

AFETY

P

RECAUTIONS

...........................................................................................7

5-3.

L

OSS OF

W

ARNING

L

ABEL

..................................................................................................8

6. MAIN FEATURES ...........................................................................................................9

6-1.

F

EATURES

..........................................................................................................................9

6-2.

R

EGARDING

ISO7637-3

(1995-07-15) ...............................................................................9

7. PART NAMES AND FUNCTIONS.................................................................................10

8. TEST PROCEDURE......................................................................................................12

8-1.

T

EST

P

REPARATION

.........................................................................................................12

8-2.

R

UNNING

DUT .................................................................................................................13

8-3.

S

TARTING

T

EST

................................................................................................................13

8-4.

F

INISHING

T

EST

................................................................................................................13

9. PRODUCT SPECIFICATIONS ......................................................................................14

10. WAVEFORM VERIFICATION......................................................................................15

11. ACCESSORIES...........................................................................................................16

12. OPTIONS.....................................................................................................................17

13. WARRANTY................................................................................................................18

14. MAINTENANCE ..........................................................................................................20

15. NOISE LABORATORY SUPPORT NETWORK ..........................................................21

6

4. PREFACE

Thank you very much for purchasing ISS-7630-CUP (the "Unit"). Please read this instruction manual

(the "Manual") thoroughly prior to use of the Unit in order to attain the maximum and safe use of the

Unit.

The Manual will let you operate ISS-7630-CUP safely and make the most use of it if

you strictly follow the operational procedures and the safety instructions.

Keep the Manual handy whenever you operate ISS-7630-CUP.

7

5.

B

ASIC

S

AFETY

P

RECAUTIONS

5-1. Symbols of Hazard

This sign indicates the presence of "dangerous voltage/current" that may endanger

persons.

This sign indicates "handle with care".

Refer to the Manual to protect human bodies and devices.

5-2.Basic Safety Precautions

1. There is a risk of electric shock.

【Precautions regarding use and safety】

2. Do not supply the Unit with voltage or do not make any connections other than the

designated load (Accessory Terminator). The Unit may be damaged if this is not

obeyed

【Precautions regarding connection and use】

3. Before connecting the Unit, turn OFF the DC power source and the Unit, and make

sure that there is no residual voltage. Connect each cable securely. Nonobservance

may cause electric shock or damage to the internal parts of the Unit and connected

devices.

【Precautions regarding bodily injury and connection】

4. Use accessories and optional items supplied by the Company to ensure safe

operation.

【Precautions regarding connection and use】

5. Do not utilize or store the Unit under extremely high or low temperature

environment. (Operating environment: 23℃±5℃/ Operating Humidity Range:

25-75 %)

【Precautions regarding environment】

6. Do not use the Unit under high humidity or dusty conditions.

【Precautions regarding environment】

7. Should condensation form, fully dry the Unit before usage.

【Precautions regarding environment】

8. Do not wipe the body of the Unit with solvents such as lacquer thinner or alcohol.

When the Unit gets dirty, wipe it with a detergent moistened fabric etc.

【Precautions regarding use】

9. Do not use the Unit near flammable materials or fire sources. When used, there is a

risk of fire due to electric discharge, etc.

【Precautions regarding bodily injury and environment】

8

10. The Company and its sales agent assume no responsibility for any bodily injury,

loss, damage or resultant damage arising from derelict misuse of the Unit on the

part of the user.

【Precautions regarding bodily injury, use, environment, and connection】

11. Should the necessity of services such as repair, maintenance, or internal calibration

arise, leave them to qualified service personnel only.

【Precautions regarding use and safety】

5-3. Loss of Warning Label

1. If the warning label is peeled off and missing or it gets dirty, replace it with a new one for

safety.

2. If the warning label is lost, order a new one from our sales agent or the technical service

center of the Company.

9

6

. MAIN FEATURES

6-1. Features

This coupling clamp, ISS-7630-CUP (the “Unit”) complies with the ISO7637-3 (1995-07-15)

Standard.

The Unit allows easy testing when connected to pulse simulator (ISS-7630 or ISS-P3ab).

The Unit has a micro-strip line structure, and the characteristic impedance is 50Ω.

The waveform is not distorted because of well matched impedance..

The Unit is capable of handling fast rising waveforms of tr <3.5ns input from the pulse

simulator ISS-7630.

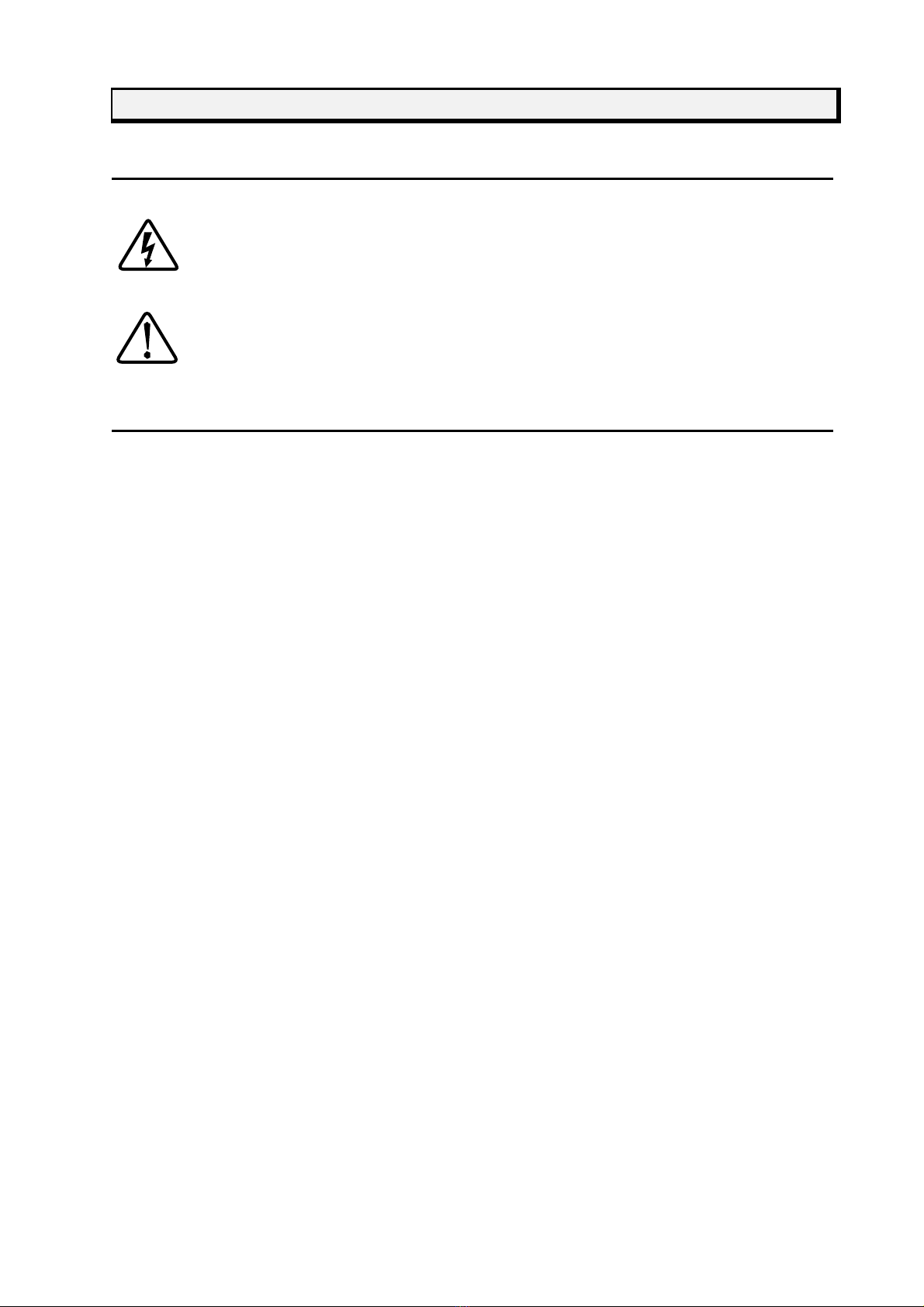

6-2. Regarding ISO7637-3 (1995-07-15)

ISO 7637-3 (1995-07-15) provides the standard for coupling tests. It specifies configuration of

the tests, pulse voltage waveform, test voltage level, and testing environment. The Unit is

designed in compliance with the ISO standard. Summary of the schematic circuit diagram

excerpted from the standard is shown below. Be sure to refer to the ISO standard for details.

供試機器

(ECU or EUT)

周辺装置

(センサ、負荷、装備品)

ATT(40dB)

50Ω

オシロ

50Ω

カップリング・クランプ

試験器

(ISS-7630,

ISS-P3ab)

バッテリ

DC電源

又は50Ωターミネータ④

同軸ケーブル③同軸ケーブル②

ハーネス ハーネス

グランドプレーン(2m × 1m以上 t=1mm以上)

Figure 1 Testing Configuration (for Coupling Clamp Tests)

Figure 1 is a schematic diagram. Run tests in accordance with the IS0 tandard or a test plan.

Harness Harness

ECU or DUT Peripheral

Equipment

Simulator

(ISS-7630,

ISS-P3ab)

Coupling clamp

Or 50Ω

Terminator

DC

Power

Supply

Battery

Oscilloscope

50Ω

ATT

(40dB)

50

Ω

Coaxial cable②Coaxial cable③

Ground plane (size: more than 2m x 1m, thickness: more than 1mm)

10

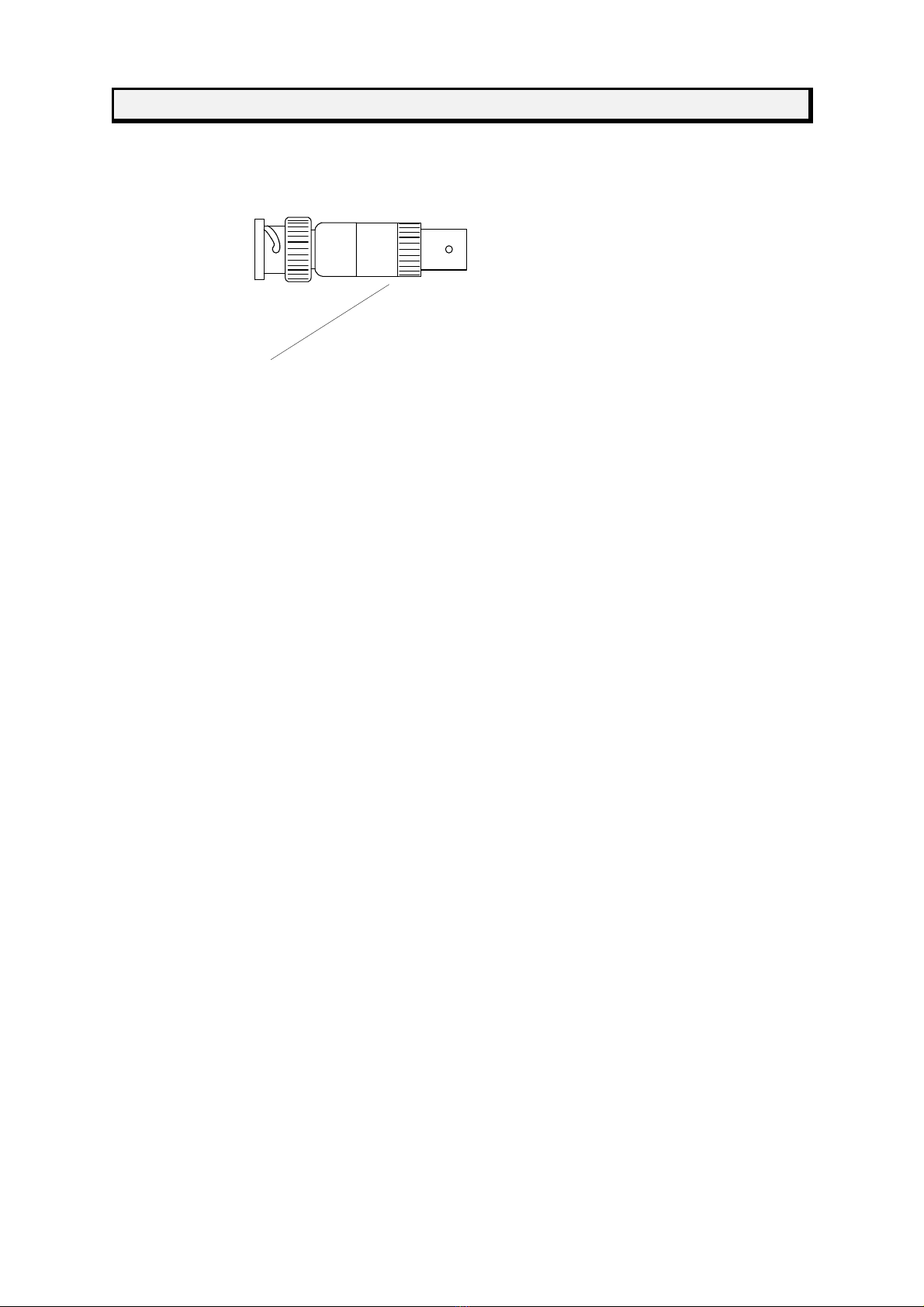

7. PART NAMES AND FUNCTIONS

② ① ③ ④

Figure 2

①Coupling Clamp

②Coaxial Connection Cable for a simulator.

③Coaxial Connection Cable for a terminator.

④Terminator

11

①Coupling Clamp

The coupling clamp main unit for coupling pulses to harnesses etc.

The unit is utilized by inserting a harness into the plates of the clump located on the

ceiling.

Stray capacity arisen between the harness and the plate transmits the high

frequency components onto the secondary side (harnesses) mainly by electrostatic

inductions. Therefore, the transmission gets harder as the noise components reach

a lower frequency range.

Since the transmission efficiency depends on the stray capacity between the

harness and the plate, the harness should be pinched by the plates as tight as

possible to increase the stray capacity.

The coupling would not take effect unless the coupling pulses have sufficient

energy of high frequency range.

Do not touch any portion of the clamp during pulse output. Otherwise you may get an

electric shock.

②Coaxial Cable (For Simulator Connection)

This is a 50Ωcoaxial cable with BNC connectors to connect the coupling clamp to

the simulator.

A BNC tangent line is attached.

One end is to be connected to the pulse simulator (ISS-7630 or ISS-P3ab), and the

other end is to be connected to the terminator.

③Coaxial Cable (For Terminator Connection)

A 50Ωcoaxial cable with BNC connectors to connect the coupling clamp to the

attached terminator

One end is to be connected to the coupling clamp, and the other end is to be

connected to the terminator.

④Terminator

A 50Ωterminal resistor for matching the transmission line (coupling clamp) with

50Ω.

The rated power of the terminator is 5W. Take every caution not to input the voltage

that gives higher effective power than the rating. In case of coupling pulses of the

ISS 7630 simulator or ISS-P3ab without DC voltage, It will be no problem.

⑤ Metal Fasteners

Metal pieces to fasten the simulator (ISS-7630) to the ground plane.

Attach them to 2 locations, at the FG terminals on the front and rear panes.

Refer to “8.1 Preparation of Testing”.

12

8. TEST PROCEDURE

8-1. Test Preparation

Before proceeding with the test, always carry out “10 Pre-Start Checkup (Waveform Verification).”

Prepare the installation environment and connect the cables. Set up according to the Standard

and/or other user requirements. An example is shown below.

・Installation

Place the Coupling Clamp, the simulator (ISS-7630 or ISS-P3ab), an

oscilloscope, and the power source (batteries) on the ground plane, and

secure each with screws. Use the Metal Fasteners attached to ISS-7360-Cup

to secure ISS-7630.

BNC変換アダプタ

(ISS-7630の添付品)

試験器固定金具⑤

(フロントパネル用)

試験器固定金具⑤

(リアパネル用)

Set DUT, peripheral DUT connecting devices, the harness.

・Wiring the Simulator (for ISS-7630)

Insert the BNC Conversion Adapter (accessory to ISS-7630) into the output connector

(DC LINE OUT/PULSE). Connect the BNC Conversion Adapter and the Coupling

Clamp ①with Coaxial Cable ②. Connect the Coupling Clamp ①and the Terminator

④with Coaxial Cable ③. In case of evaluating the waveform after passing the

Coupling Clamp, connect 20dB ATT in two series instead of the Terminator ④and

examine the waveform using an oscilloscope (50Ωtermination) after the 40dB

attenuation.

・Wiring the Simulator (for ISS-P3ab)

Connect the ISS-P3ab simulator’s Surge OUT BNC connector (Coupling Clamp) and

the Coupling Clamp ①with Coaxial Cable ②. Connect the Coupling Clamp ①and

the Terminator ④with Coaxial Cable ③. When evaluating the waveform after passing

the Coupling Clamp, connect 20dB ATT in two series instead of the Terminator ④and

examine the waveform using an oscilloscope (50Ωtermination) after the 40dB

attenuation.

・Connecting DUT

Connect DUT and peripheral connecting devices.

Insert the harness of DUT and the peripheral devices into the clamper portion

of the Coupling Clamp ①.

BNC conversion adaptor

(Accessory of ISS-7630)

Metal fittings to

fix the simulator

Metal fittings to fix

the simulator

13

Since the waveform contains high frequency components over the range of 200MHz, the

malfunction level cannot be measured quantitatively if the free capacity and the

electromagnetic field radiation deviate due to placement of the simulator and DUT,

types of cables used, and the height from ground plane. This highly depends on the

physical positioning of devices under the testing environment. Thus, devices must be

always positioned in the same locations in order to realize quantitative tests.

8-2. Running DUT

Run DUT as it is used. Input signals preliminarily if necessary.

8-3. Starting Test

When the simulator (ISS-7630, ISS-P3ab) begins to output pulses, the pulse is coupled to the

harness.

Proceed according to the Standard or test plan.

For operation procedures of the simulator, refer to its manual.

Do not touch the clamper portion on the ceiling when outputting pulse. There is a risk of electric

shock.

The Terminator may burn out when tests are carried out coupling pulses to DC.

Always couple pulses without DC voltage.

To avoid coupling pulses to DC, be sure to turn OFF the DC LINE of ISS-7630. As for ISS-P3ab,

always connect from the Surge OUT BNC connector (Coupling Clamp).

Since the waveform contains high frequency components over the range of 200MHz, the

malfunction level cannot be measured quantitatively if the free capacity and the

electromagnetic field radiation deviate due to placement of the simulator and DUT,

types of cables used, and the height from ground plane. This highly depends on the

physical positioning of devices under the testing environment. Thus, devices must be

always positioned in the same locations in order to realize quantitative tests.]

8-4. Finishing Test

To finish the test using ISS-7630, put it in STOP mode. As for ISS-P3ab, lower the

simulator output voltage to 0V and then put it into STOP mode.

Next, turn the power OFF.

Stop the operation (working status) of DUT, and shut the power supply off.

Remove the harness from the coupling clamp.

14

9. PRODUCT SPECIFICATIONS

・Coupling Harness Measurements····························· 4mm~40mm Diameter

・Pulse Voltage Insulator Strength ······························ over 600V

・VSWR (without Harness) ········································ less than 1.3 (~200MHz)

・Input/Output Connector ·········································· BNC-R

・Dimensions·························································· (approximately)

1200mm×H70mm×D300mm

・Weight ································································ (approximately) 3.5kg

・Terminator ··························································· 50Ω±5Ω

5W

・Run Time Temperature ·········································· 23ºC±5ºC

・Run Time Humidity ················································ 25%~75%

15

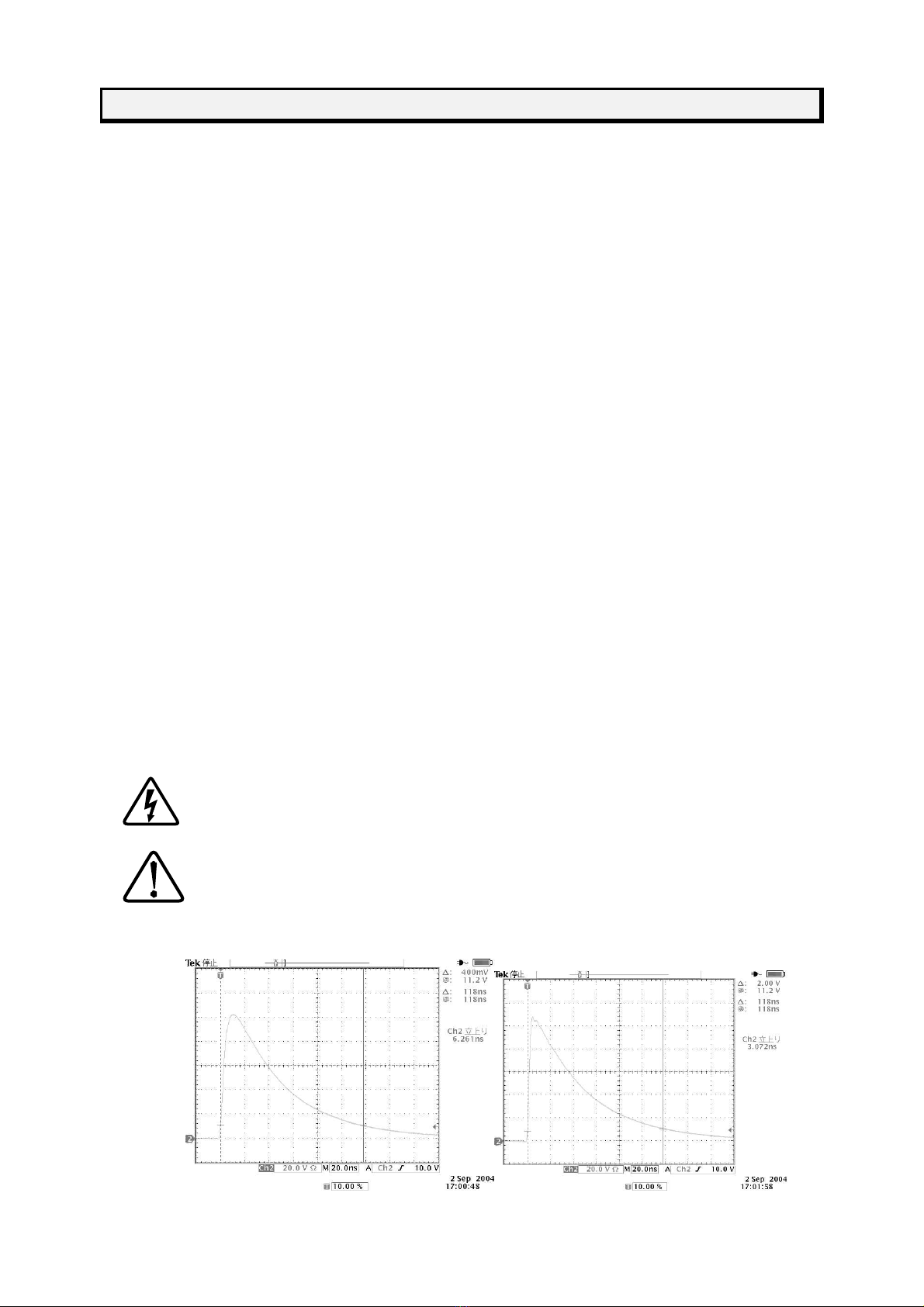

10. WAVEFORM VERIFICATION

Before proceeding to the coupling clamp tests, confirm that the simulator is transmitting pulses

normally. Refer to Figure 1. However, when verifying the waveform, harness must not be inserted

into the clamper portion. Insertion of the harness will alter the characteristic impedance and

cause reflections onto the waveform. The ISO complied procedure for waveform

verification is given below. Refer to ISO Standards for details.

・Place Coupling Clamp, the simulator (ISS-7630 or ISS-P3ab), and an oscilloscope on the

ground plane and screw fasten. Use Metal Fasteners ⑤for ISS-7630.

・Wiring the Simulator (for ISS-7630)

Insert the BNC Conversion Adapter (ISS-7630 accessory) into Output Connector (DC LINE

OUT/PULSE).

Connect the BNC Conversion Adaptor and Coupling Clamp ①with Coaxial Cable ②.

Connect the Coupling Clamp ①and 20dB ATT×2 (2 connected in series to attenuate 40dB) with

Coaxial Cable ③.

Connect 20dB ATT to oscilloscope (50Ωtermination) and verify the waveform.

・Wiring the Simulator (for ISS-P3ab)

Connect the simulator ISS-P3ab Surge Out BNC connector (Coupling Clamp) and Coupling Clamp

①with Coaxial Cable ②.

Connect the Coupling Clamp ①and 20dB ATT×2 (2 connected in series to attenuate 40dB) with

Coaxial Cable ③.

Connect 20dB ATT to oscilloscope (50Ωtermination) and verify the waveform.

・Output pulses from the simulator and verify that the oscilloscope waveform matches the 50Ωload

waveform shown in the specifications of the simulator.

Do not touch the clamper portion of the ceiling when outputting pulse.

There is a risk of electric shock.

The Terminator may burn out when tests are carried out coupling pulses to DC.

Always verify the waveform without DC injection.

Measured Waveforms (After Passing Coupling Clamp) tr < 3.5ns Setting

16

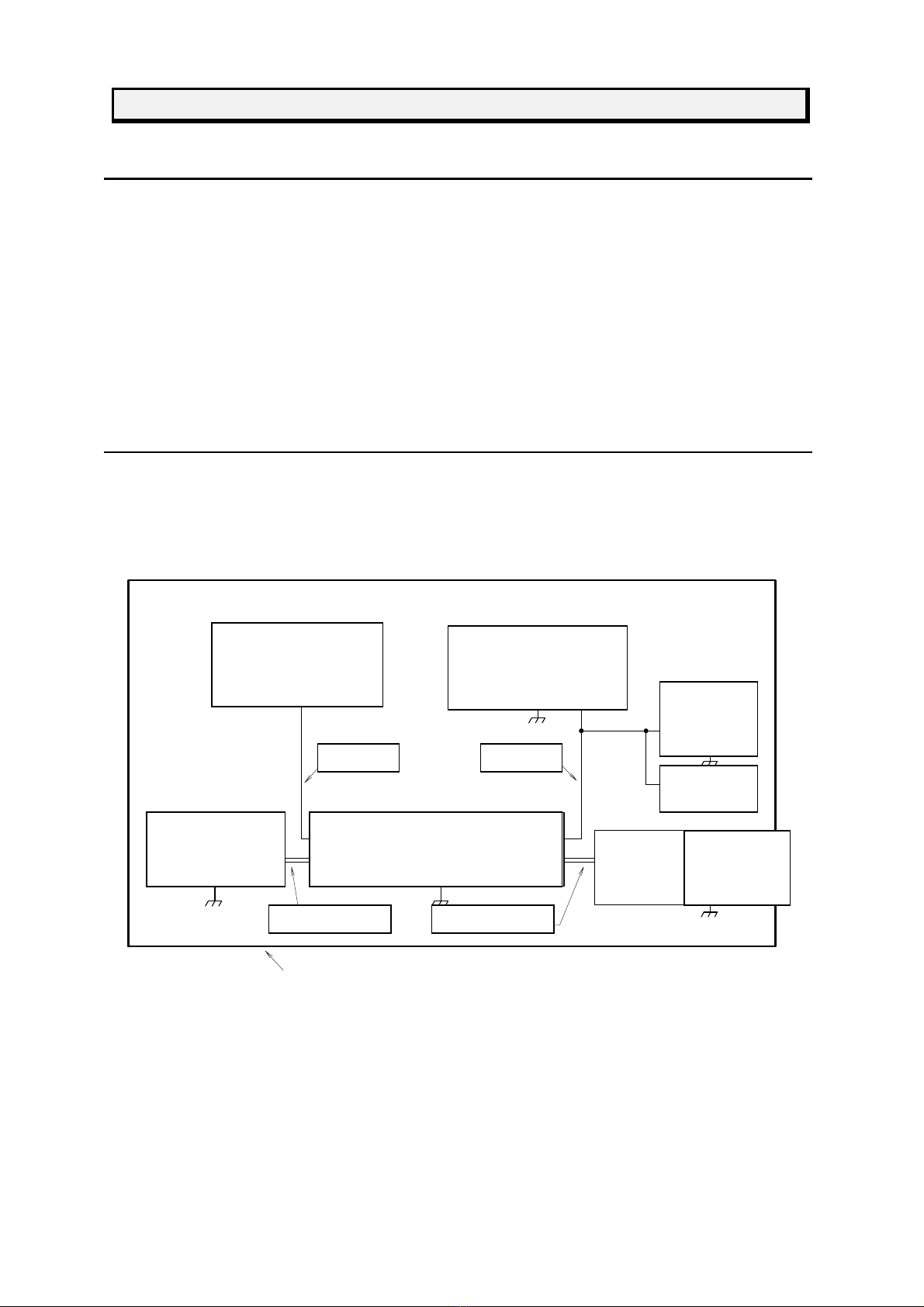

11. ACCESSORIES

Bag of

Accessories

Instruction

Manual

Coaxial Cable ①

(To Connect with Simulator)

Coaxial Cable②

(To connect to Terminator) Terminator ③

Metal Fittings ⑤(for ISS-7630)

フロントパネル用

リアパネル用

For front panel

For rear panel

17

12.

O

PTIONS

50ΩLoad Waveform Verification ATT 00-00006A

20dB 50Ω

20dB ATT Set of 2

18

13. WARRANTY

Services

The following terms are applicable to the services provided by the Company to maintain and

repair the Unit.

1.

Scope

The Unit and accessories and options provided by the Company are covered under this

section.

2.

Technical Service Fee

Any repairs provided by the Company during the warranty period will be free of charge in

accordance with the Limited Warranty. After expiration of the warranty period, actual cost

for the repair will be charged to the user.

3. Ownership of Defective Parts

All the defective parts replaced during the warranty period become the property of the

Company. For paid repairs, they also become the property of the Company unless

otherwise directed by the user.

4. Maximum Compensation

In the event the user incurs damage due to malfunction of the Unit arising solely from the

negligence and/or improper repair on the part of the Company, the Company will

compensate for the damage. The maximum compensation amount shall be limited to the

amount paid by the user at the time of purchase of the Unit. In no event, shall the company

be liable or in any way responsible for incidental or consequential damages such as loss of

profit or third party’s claims to the user.

5. Wrong Parts, Missing Parts and Damage

The company shall not be liable for loss of profit, business interruption, other incidental

damage, special loss, punitive damage or third party’s claims to the user directly or

indirectly arising from suspension of testing activities due to wrong parts, missing parts, or

damage of the Unit.

6. Service Refusal

The company may not accept a repair order in the following cases:

More than 5 years have passed since the product discontinued

More than 8 years have passed after delivery

Required component for servicing already discontinued and no alternative is available.

Product changed, repaired or remodeled without obtaining a prior permission from the

Company.

Product severely damaged to the extent it has lost its original form

Table of contents

Other NoiseKen Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Straightpoint

Straightpoint Radiolink Plus RLP user manual

Extech Instruments

Extech Instruments MO210 user guide

Endress+Hauser

Endress+Hauser Proline Promass E 200 operating instructions

Apache Technologies

Apache Technologies STORM Operator's manual

ProMinent

ProMinent DULCODOS DSWb SP10 Assembly and operating instructions

Lovibond

Lovibond SensoDirect pH110 instruction manual