NoiseKen INS-4020 User manual

INSTRUCTIONMANUAL

IMPULSENOISESIMULATOR

MODELINS-4020/4040

NOISE LABORATORY CO., LTD.

Edition 2.03

AEB00319-00E -1 D

NOTICE

The contents of this booklet are subject to change without prior notice.

No part of this booklet may be reproduced or transferred, in any form, for any

purpose, without the permission of Noise Laboratory Co., Ltd.

The contents of this booklet have been thoroughly checked. However, if a doubtful

point, an error in writing or a missing is found, please contact us.

Noise Laboratory Co., Ltd. shall have no liability for any trouble resulting from the

misuse or improper handling of this product regardless of the contents of this

booklet or arising from the repair or remodeling of this product by a third party other

than Noise Laboratory Co., Ltd. or its authorized person.

Noise Laboratory Co., Ltd. shall have no liability for any trouble resulting from the

remodeling or modification of this product.

In no event shall Noise Laboratory Co., Ltd. be liable for any results arising from the

use of this product.

1

The instrument may only be used by trained EMC technicians

(electrical technicians)

Failure to follow this rule risks death or serious injury.

The instrument may not be used by people fitted with

electronic medical devices such as pacemakers and

such people may not enter the testing site while the

instrument is operating

The medical device may malfunction since the instrument emits more

electromagnetic wave than the regulated value.

Do not use the instrument for any purposes other than

the EMC testing purposes described in this instruction

manual

.

The instrument is not supposed to be used in manufacturing process

of a factory.

The instrument may not be used in a location where fire

is prohibited or there is a risk of explosion

Failure to follow this rule risks igniting a fire due to an electrical

discharge.

The supplied AC power cable of the instrument is

intended only for Japan and North America.

In case of using the instrument in other countries than the above, use

an AC power cable that is certified for use under the safety rules of

the country in which the instrument is being used.

Before building test set up, connecting the instrument,

power supply or EUT, or starting testing, be sure to read

Section 4 BASIC SAFETY PRECAUTIONS.

1 IMPORTANT SAFETY PRECAUTIONS

This manual contains important information pertaining to the operation and

maintenance of your Impulse Noise Simulator Model: INS-4020/4040. In order to

obtain the highest performance from this simulator, it is recommended that the

contents of this manual be thoroughly understood and used as ready reference

for operation and maintenance.

The "Important Safety Precautions" explain rules that must be followed to prevent

any risk of harm or injury to the user of the instrument or to other people.

2

3

2 APPLICATION FORM FOR INSTRUCTION MANUAL

We place an order for an instruction manual.

Model: INS-4020/4040

Serial No.:

Applicant:

Company name:

Address:

Department:

Person in charge:

Tel No.:

Fax No.:

Cut off this page "application form for instruction manual" from this volume and keep it for future

use with care.

When an INSTRUCTION MANUAL is required, fill in the above Application Form and

mail or fax it to your nearest sales agent of Noise Laboratory or Noise Laboratory.

Your sales agent:

NOISE LABORATORY CO., LTD.

1-4-4 CHIYODA, CHUO-KU, SAGAMIHARA-CITY, KANAGAWA PREF. 252-0237 JAPAN

TEL +81-42-712-2051 FAX +81-42-712-2050

Cut line

Cut line

4

Memorandum

5

3 CONTENTS

1 IMPORTANT SAFETY PRECAUTIONS .............................................................. 1

2 APPLICATION FORM FOR INSTRUCTION MANUAL ........................................ 3

3 CONTENTS ....................................................................................................... 5

4 PREFACE ......................................................................................................... 7

5 BASIC SAFETY PRECAUTIONS ........................................................................ 8

5.1 Warning signs and their meanings....................................................................8

5.2 Basic safety precautions..................................................................................8

5.3 When warning label is missing .......................................................................11

5.4 Restrictions to comply with CE marking requirements ...................................... 11

5.5 Coaxial connectors used for this product......................................................... 12

6 GENERAL DESCRIPTION ................................................................................ 13

6.1 Features.......................................................................................................13

6.2 Pulse generation principle..............................................................................14

6.3 For perfect matching .....................................................................................15

6.4 Range of settings for pulse and other parameters ............................................ 16

7 INCLUDED ACCESSORIES .............................................................................. 17

8 CONTROLS AND DISPLAY FUNCTIONS .......................................................... 18

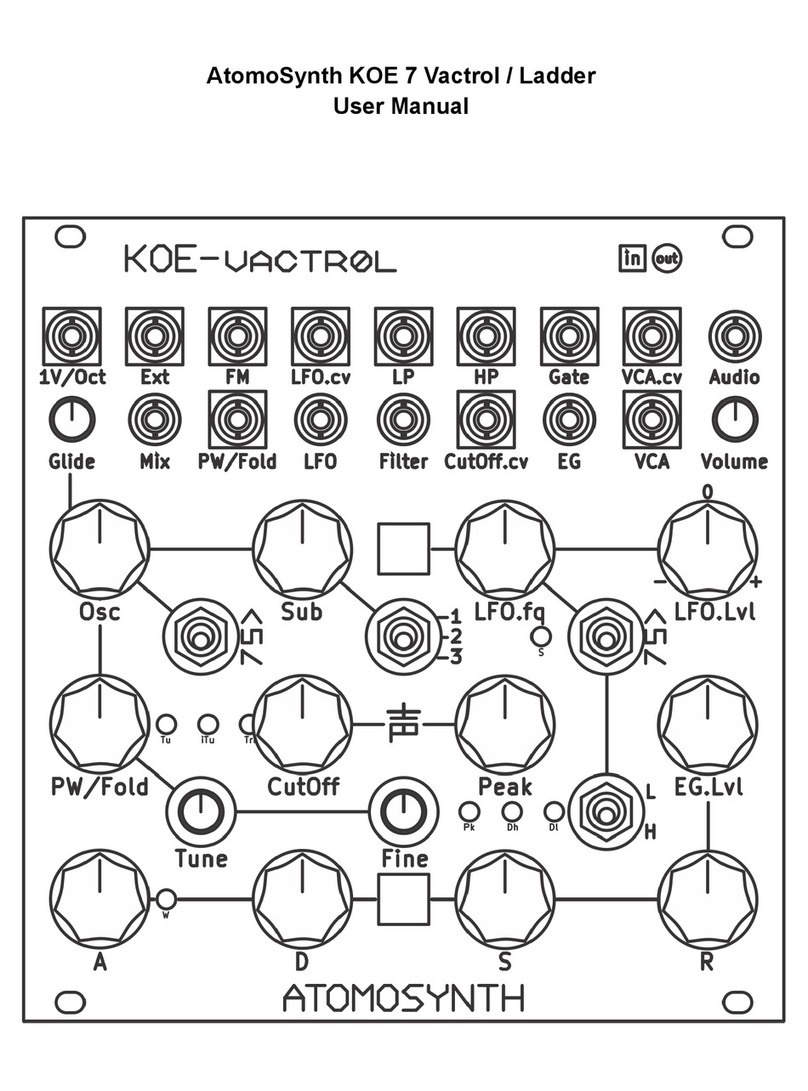

8.1 Front panel connecters and terminals .............................................................18

8.2 Front panel controls and displays ...................................................................20

8.3 Rear panel....................................................................................................22

9 OPERATION .................................................................................................... 23

9.1 Operating precautions ...................................................................................23

9.2 Turning ON and OFF power ...........................................................................23

9.3 Setting the pulse width ..................................................................................24

9.3.1 Setting for 50ns ....................................................................................... 25

9.3.2 Setting for 350ns ..................................................................................... 25

9.3.3 Setting for 800ns ..................................................................................... 26

9.3.4 Setting for 10ns ....................................................................................... 26

9.4 Connecting termination resistance..................................................................27

9.5 Select injection line.......................................................................................28

9.6 EUT line input connection..............................................................................30

9.7 Mount and dismount Outlet panel ...................................................................31

9.8 EUT connection ............................................................................................31

9.9 Connection of signal ground (SG) terminal ...................................................... 31

9.10 Operation in PHASE mode ..........................................................................32

9.11 Operation in VARIABLE mode .....................................................................34

9.12 Operation in 1 SHOT mode .........................................................................35

9.13 Operation in EXTernal Trigger mode............................................................ 36

9.13.1 Synchronization with inputs from an external signal generator ........... 36

9.13.2 Synchronization with zero-cross reference signal inputs form an

external Coupling Unit ...................................................................................... 37

9.13.3 Control by using a contact switch ....................................................... 38

9.14 Stop the unit..............................................................................................39

10 OPERATION FOR WIDE APPLICATION ........................................................ 40

10.1 VOLTAGE ramp setting...............................................................................40

10.2 VOLTAGE ramp test run .............................................................................42

6

10.3 VARIABLE ramp setting..............................................................................43

10.4 VARIABLE ramp test run.............................................................................45

10.5 PHASE ramp setting...................................................................................46

10.6 PHASE ramp test run..................................................................................48

10.7 Combined ramp mode.................................................................................50

10.8 Remote START and STOP ..........................................................................51

10.9 Memory function.........................................................................................52

10.10 Terminating resistor....................................................................................53

10.10.1 Voltage indicator correction ............................................................... 53

10.10.2 Setting of voltage indicator correction .................................................. 54

10.10.3 Maximum voltage for different models and different settings ............... 55

11 TEST SET UPS AND ENVIRONMENT ........................................................... 56

11.1 Precautions for use ....................................................................................56

11.2 Test parameters.........................................................................................56

11.3 Coupling modes .........................................................................................56

11.4 Test set-ups...............................................................................................56

11.5 Test set-up ................................................................................................58

11.5.1 Line to ground mode (common mode) for AC operated equipment ............ 58

11.5.2 Line to line (normal mode) for AC operated equipment ............................ 59

11.5.3 Line to ground mode (common mode) for DC operated equipment ............ 60

11.5.4 Line to line mode (normal mode) for DC operated equipment ................... 61

11.5.5 Capacitive coupling test for signal lines (by using CA-805B coupling

adapter) 62

11.5.6 Test by using a radiation probe (optional accessory) ............................... 63

12 SPECIFICATIONS ......................................................................................... 64

12.1 Specifications ............................................................................................64

12.2 Consumable parts ......................................................................................65

13 WAVEFORM CHECK ..................................................................................... 66

13.1 Instrument required ....................................................................................66

13.2 Oscilloscope settings..................................................................................66

13.3 Settings on this unit....................................................................................66

13.4 Checking the waveform...............................................................................67

14 RELAY UNIT ................................................................................................ 68

14.1 2kV relay unit and 4kV relay unit .................................................................68

14.2 How to replace the relay unit.......................................................................68

15 PHASE ANGLE CORRECTION ....................................................................... 70

15.1 Equipment required ....................................................................................70

15.2 Connections and settings............................................................................70

15.3 Setting up Correcting phase angle...............................................................71

15.4 Releasing Phase Angle Correction...............................................................72

16 WARRANTY .................................................................................................. 74

17 MAINTENANCE ............................................................................................ 76

18 NOISE LABORATORY SUPPORT NETWORK ................................................. 77

7

4 Preface

This manual contains important information pertaining to the operation and maintenance

of your Impulse Noise Simulator Model: INS-4020/4040. In order to obtain the highest

performance from this simulator, it is recommended that the contents of this manual be

thoroughly understood and used as ready reference for operation and maintenance

.

8

5 BASIC SAFETY PRECAUTIONS

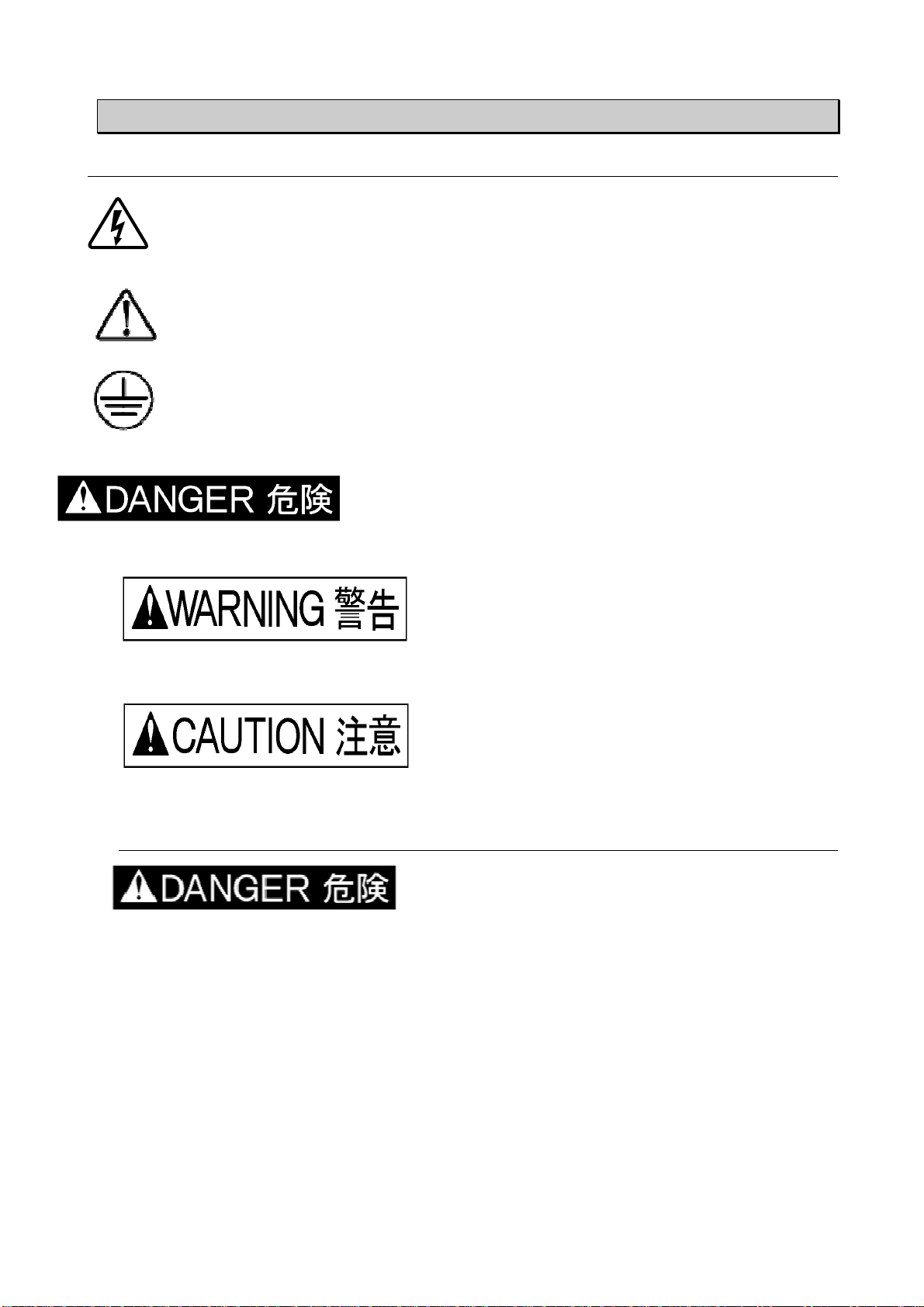

5.1 Warning signs and their meanings

This sign is shown at areas where HV voltages potentially hazardous to human

are present.

Sign for caution. For potential dangers or mishandling that could cause injuries

or material damage, this instruction manual shall be referred to.

Sign for a protective earth terminal.

Means

a danger.

If such a danger is not avoided, it leads to a state of

critical urgency, which

should result in a death or serious injury.

Means

a warning.

If such a danger is not avoided, a potential danger

which may result in a death or serious injury will

be caused.

Means

a caution.

If such a danger is not avoided, a potential

danger which may result in a minor or medium

degree of injury will be caused.

5.2 Basic safety precautions

1. Any person who has an implanted pacemaker in the body should not

operate this unit. Furthermore, such a person should not enter the test area

while this unit is operating.

【

【【

【Precautions for human body and operation】

】】

】

2. Use of this unit in an explosive area such as "No fire" area etc. is

prohibited. If used in such an area, it is liable to cause combustion or

ignition due to discharge.

【

【【

【Precautions for human body and environments】

】】

】

3. The AC INPUT (AC inlet) terminal on the rear panel has a conductor for

safety grounding connection. This unit shall be connected to a properly

grounded service outlet through the AC INPUT. When this unit is not

grounded through the AC INPUT, PE terminal positioned next to it shall be

used.

9

【

【【

【Precautions for connection】

】】

】

4. Before connecting the EUT LINE INPUT to a power supply, be sure to turn

off the power supply, otherwise supply power voltage may cause an electric

shock hazard.

【

【【

【Precautions for human body and connections】

】】

】

5. High voltages exist inside the unit. Never open the covers, except when a

mercury relay replacement is required. 【

【【

【Precautions for human body】

】】

】

6. Mishandling and careless operation of this unit will result in a deadly injury.

【

【【

【Precautions for human body, operation, environment and connection】

】】

】

1. The test rig used in conjunction with this unit should be insulated against a

minimum voltage of 8kV (when the built-in 50Ωterminator disconnected from

the test circuit).

【

【【

【Precautions for environments】

】】

】

2. Be sure to connect the ground plane to the safety ground.

【

【【

【Precautions for operation and safety】

】】

】

3. When connecting cables and carrying out settings, place the unit in the

STOP conditions and interrupt the EUT supply beforehand, otherwise, an

electric shock due to high voltage may be caused or the unit may be damaged.

Even in the STOP conditions, allow 5 seconds to elapse, as residual voltages

may exist.

【

【【

【Precautions for human body and connection】

】】

】

4. The coaxial connectors used for this unit is of NoiseKen original design. Use

of other type of connectors may cause electric shock hazards or malfunctions

of the unit.

【

【【

【Precautions for handling and safety】

】】

】

5. Fully put in each coaxial connector and make sure connections by rotating it clockwise

until a “click” is heard. Insufficient connection leads to unwanted discharges inside the

coaxial connectors. 【

【【

【Precautions for human body and connection】

】】

】

6.

Any other connection than the supplied SG short plug shall not be

connected to the SG connector of this unit. Wrong connections may apply HV

pulses to the ground plane, causing a shock hazard.

【

【【

【Precautions for human body and connection】

】】

】

7. To ensure safety in operation, use the accessories (use power cord and LINE

input cable with relevant safety agency approval) and optional equipment

supplied by our company. Use of others may degrade the safety and

performance of this unit.

【

【【

【Precaution for handling and safety】

】】

】

8. This unit has no built-in protection circuit for EUT supply. An external protective device

such as fuses, circuit breaker or protector meeting the EUT rating shall be installed.

9. When conducting coupling tests to the EUT LINE, the signal ground of the HV

pulse generator circuit and one line of the EUT LINE may be connected, causing a

shock hazard if the users touch the outer conductor of the HV coaxial connectors.

In addition, if the outer conductor of the HV coaxial connectors is connected to

any grounded object, leak current will flow, tripping the ground fault interrupter

10

embedded in the facilities. To avoid these two types of events, use of an isolation

transformer is indispensable. Be sure to connect the EUT LINE INPUT to the

isolation transformer secondary. 【

【【

【Precautions for human body and connection】

】】

】

10. When connecting cables and carrying out settings, place the unit in the STOP

conditions and interrupt the EUT supply beforehand, otherwise, an electric shock

due to high voltage may be caused or the unit may be damaged. Even in the STOP

conditions, allow 5 seconds to elapse, as residual voltages may exist.

【

【【

【Precautions for human body and connection】

】】

】

11. While this unit is producing pulses or EUT power is being supplied to the EUT

LINE INPUT, do not touch the HV coaxial connectors. Touching them may cause a

shock hazard.

【

【【

【Precautions for human body and operation】

】】

】

12. NOISE LABORATORY and its sales agents shall have no liability against any

accident resulting in injury or death, any damage to equipment or any resultant

damage thereof, which is caused by abuse or careless handling of this unit.

【

【【

【Precautions for human body, operation, environments and connection】

】】

】

1. As this unit employs a mercury relay, it shall be positioned horizontally only.

【

【【

【Precautions for handling】

】】

】

2. Do not supply voltage exceeding the rated voltage range. Do not connect the

EUT exceeding the rated power capacity of this unit.

【

【【

【Precautions for installation and connection】

】】

】

3. The SG terminal provided on the front panel of this unit functions as the

signal reference ground for testing. The PE terminal (EUT) is for the protective

earth conductor for the EUT. The protective earth terminals for this unit itself are

the AC inlet earth pin (AC INPUT) and PE positioned in close proximity to it. These

SG, EUT PE, the simulator PE are independent each other. When conducting tests,

make connections according to Section 10 test Set-ups.

【

【【

【Precautions for operation and connection】

】】

】

4. The supplied SG short plug shall not be connected to any other port than

L1, L2, PE injection connector or SG coaxial connectors. Connection to the

wrong port may damage the unit.

【

【【

【Precautions for operation and connection】

】】

】

5. The PE terminals of EUT LINE INPUT and EUT LINE OUTPUT are floating from the

chassis of this unit similarly to L1 and L2 terminals. When using the PE line, use an

appropriate power cord meeting your country’s safety regulations and EUT power rating.

6. During test, high level of electromagnetic radiation may be generated

depending on the type or nature of the EUT and thus causing interference with

nearby electronic equipment and radio communication equipment. In such case,

the user may have to take measures such as a faraday cage, shielded room,

and shielded cable and so on. 【

【【

【Precaution for environments】

】】

】

7. Do not use nor keep the unit in a hot or cold environment (Operating

temperature: 15°C~35°C/Operating humidity range: 25~75%) otherwise, the unit

may be damaged or only exhibit limited performance. 【

【【

【Precaution for

11

environments】

】】

】

8. If condensation is found, fully dry the unit before operating it, otherwise,

the unit may be damaged or only exhibit limited performance. 【

【【

【Precautions for

environments】

】】

】

9. The coaxial connectors used for this unit may have a shortened life due to a

poor insulation capability caused by a metal powder accumulation on the

connecting part, generated by a frictional wear with insertion and removal.

Clean the connectors by blowing a high pressure air. 【

【【

【Precautions for

handling】

】】

】

10. When installing the unit, do not block the vent. 【

【【

【Precaution for

environments】

】】

】

11. Do not drop the unit or do not give strong shock to the unit.

【

【【

【Precaution for handling】

】】

】

12. Do not wipe off the body and peripheral equipment with thinner, alcohol or

other solvent. When the unit is dirty, soak a cloth in a detergent, wring it and

wipe the unit with this cloth. Using solvents may spoil the appearance.

【

【【

【Precautions for handling】

】】

】

13. Only a service engineer authorized by our company should perform repair,

maintenance work and internal adjustment.

【

【【

【Precaution for handling and safety】

】】

】

14.

This unit employs a user-replaceable mercury switch. The component shall

be disposed of in conformity to the local regulations. Similarly, when scrapping

the product, follow the regulations.

5.3 When warning label is missing

1. When warning label is lost, or peeled off or dirty, put up a new one for extra safety.

2. When warning label is lost, contact our company's sales dept. or maintenance dept. for

issuance.

5.4 Restrictions to comply with CE marking requirements

1. Restrictions to comply with Low Voltage Directive (EN61010-1).

Use an AC cord and LINE Input cord with European Safety Agency approvals.

2. Installation category (for details, refer to IEC 664)

Installation category II: local level, appliances, portable equipment etc., with smaller

transient over voltages than installation category III.

3. Pollution degree

Pollution degree 2: Normally only non-conductive pollution occurs. Occasionally,

however, a temporary conductivity caused by condensation must be expected.

12

5.5 Coaxial connectors used for this product

The coaxial connectors used for this unit is of NoiseKen original design. Use of

other type of connectors may cause electric shock hazards or malfunctions of

the unit. Be sure to use accessories and options supplied by our company.

We have updated coaxial connector specifications to match the output pulse voltage

from the NoiseKen INS. This product (INS-4020/4040) uses a custom design

connector called NMHV which our company designed for 3kV or higher voltage

application. In the market, there are some other types of coaxial connectors similar to

the NMHV. Even when they have similar appearances, they are different from the

NMVH in terms of the inner conductor projection and length of the insulator.

Misconnection of a different type of connector to the NMHV may cause internal

discharges, leading to an unexpected shock hazard or a failure of this product. For

avoiding this kind of misuse, a marking of “NMHV-P-55U” is given on the fringe of the

leading edge of a connector lock. If NMHV connectors have been mixed up with other

types of connectors, discriminate NMHV connectors and use them only. Before

adoption of the NMHV, our company used the other type connector called MHV for

INS-400 series (2kV pulse output) such as model INS-410, INS-420 etc. and their

options. The MHV connector cannot be used for this product (INS-4020/4040) for the

above mentioned reason. The NMHV and MHV connectors are quite different in

appearance and thus they can be easily identified.

When using an external coupling unit such as IJ-4050 or other optional products,

check the connector type and use accessory and cables supplied by our company.

MHV:INS-400 seris

N M H V

-

P

-

5 5 U

NMHV:INS-4020/4040

13

6 GENERAL DESCRIPTION

This unit generates fast rise time square wave pulses and couples them to the power

supply lines of the EUT for noise testing purpose.

6.1 Features

• Generates pulses of less than 1ns rise time up to 4kV (INS-4040) or up to 2kV (INS-4020).

• Selectable pulse widths from 50ns to 1000ns at a step of 50ns, 10ns available as the shortest

width.

• Easily selectable coupling modes to EUT power lines.

• Maximum EUT voltage and current rating: 240V AC, 16A.

• Generates pulses in synchronization with EUT power line frequency. Placement phase angle can

be controlled from 0 to 360 degrees.

• Capability for a single pulse by using the manual trigger and for synchronization with external

signals.

• Automatic ramp capability provided for the output voltage, placement phase angle and pulse

repetition period.

• 3 phases coupling unit (415V/50A) is optionally available and operation in synchronization with

the relevant supply is also available.

• Triangular wave pulse unit is optionally available.

• Built-in terminator.

• Optional outlet panels are available for an easy connection of the EUT to this unit and for

better reproducibility in testing. Various receptacle types are available.

• Optionally provided are radiation probes, coupling clamps and others.

14

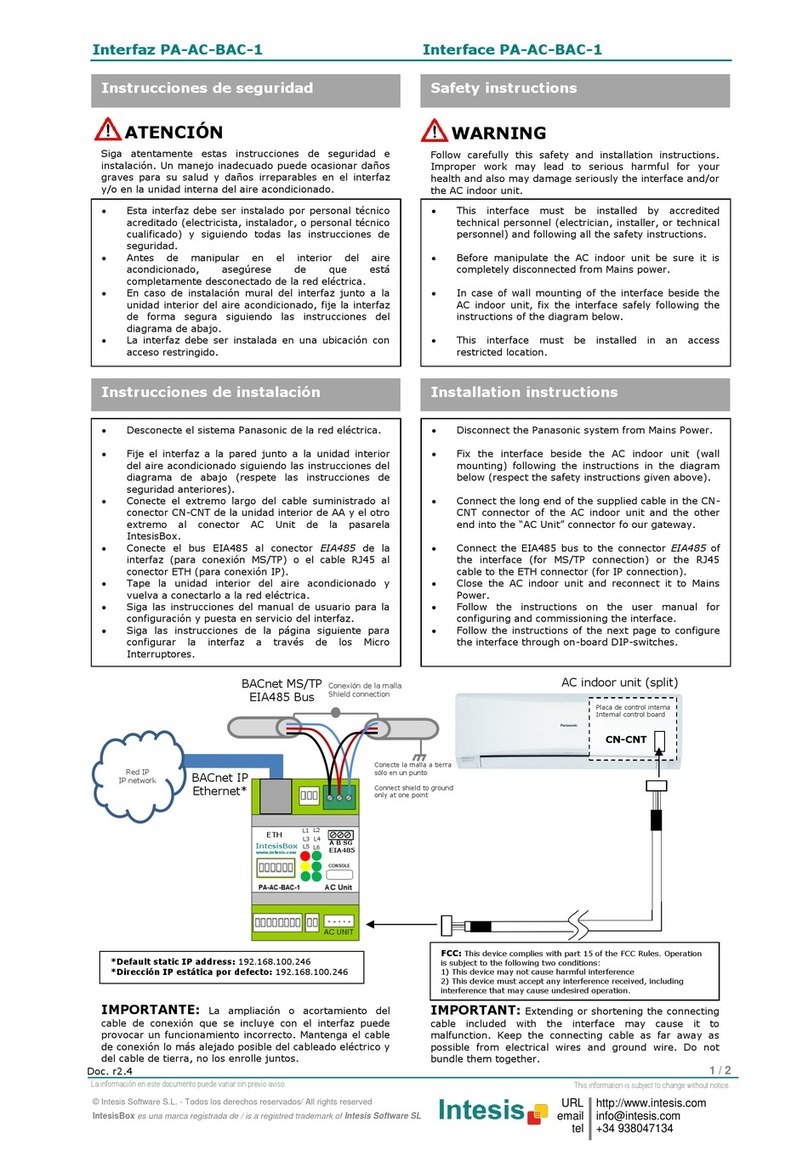

6.2 Pulse generation principle

The main components of the pulse generator circuitry of this unit are coaxial cables,

HV power supply, charging resistor, mercury relay and terminating resistor. The

coaxial cables form a distributed constant circuit consisting of the inductance of the

inner conductor and capacitance of the inner conductor to outer conductor. When a

50Ωresistance terminates this line, it works as a square wave pulse generator.

Pulse widths vary depending on the delay time of the coaxial line (length of the

cable). The proportion of pulse widths to the length is approximately 10 ns per meter.

Pulse waveforms and voltages depend on the relation between terminator resistance

and coaxial cable characteristic impedance. The HV power supply charges up the

capacitance component of the coaxial line through the charging resistor when the

mercury relay is in off status. The stored energy is discharged when the mercury

relay contacts turn on, generating a HV square wave pulse across the terminating

resistor. The injection unit couples this pulse through a capacitor to a EUT LINE.

Also provided is a Decoupling circuit consisting of an inductor and capacitor, working

as a high impedance circuit when seen from the injection point. This enables to

effectively couple the interference signals to the EUT and to reduce them to leak into

the power supply side (LINE IN).

CC

R2

HV

S1

EUT L1

EUT L2

EUT PE

SG

EUT L2

EUT L1

EUT PE

L1

L2

L3

C1

C2

C3

R1

LINE IN

LINE OUT

DC OUT

PULSE IN

PULSE OUT

50ΩTERM IN

50ΩTERM OUT

C4

C5

C6

HV:

HV power supply R1:

Charging resistor CC: Coaxial cable

S1: Mercury relay R2:

Termination resistor C4,5,6: Coupling capacitor

L1/C1,L2/C2,L3/C3: Filter

15

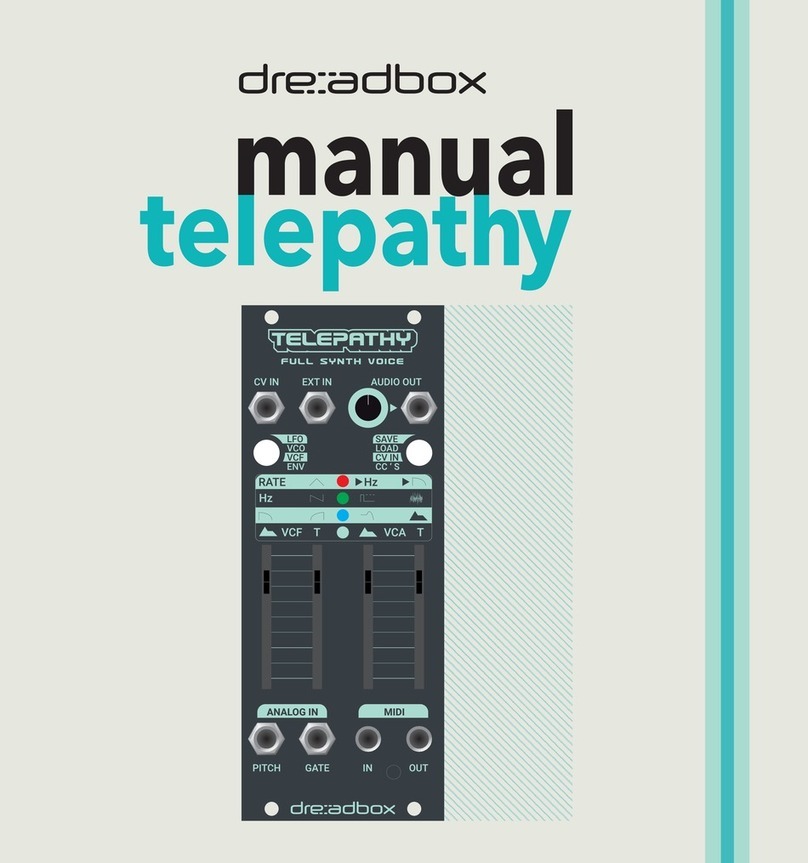

6.3 For perfect matching

Pulse waveforms and amplitudes are dependent on the value of a termination resistor being

connected to the PULSE OUT terminal. The figures and equation shown below describe these

relations. To generate square wave pulses, this unit adopts a 50Ω(strictly, 53.5Ω), equal value to

the characteristic impedance of the coaxial cables.

E E E

t t

R2=Zo

R2=ZoR2=Zo

R2=Zo R2=3Zo

R2=3ZoR2=3Zo

R2=3Zo R2=1/3Zo

R2=1/3ZoR2=1/3Zo

R2=1/3Zo

1/2E

3/4E

3/8E

3/16E 1/4E

1/8E

1/16E

t

Vp=R

2

÷( Z

0

+R

2

) ×E・・・・・・・・・・・ (equation 1)

E

: Output voltage from the HV power supply

Vp

: voltage being measured across the terminating resistor

Z0

: characteristics impedance of the cable cables

R2

: value of terminating resistor

16

6.4 Range of settings for pulse and other parameters

This unit can be set in the range in the table shown below.

Table 1 Range of settings

Parameters Specifications

Output voltage 0.01kV~2kV (INS-4020) at 0.01kV step

0.01kV~4kV (INS-4040) at 0.01kV step

Pulse polarity Positive/Negative

Pulse width 50ns~1µs (50ns step) and 10ns

Trigger mode PHASE (EUT line synchronization)

VARIABLE (asynchronization)

Placement phase angle in

PHASE mode 0~359° at 0° step

Pulse repetition in

VARIABLE mode 10~999ms(INS-4020) at 1ms step

16~999ms (INS-4040) at 1ms step

(Note 1) The output voltage display reads the correct pulse voltage only when the

built-in terminating resistor terminates the coaxial line (at the PULSE OUT)

When the terminating resistor is disconnected from the test circuit, the

actual pulse amplitude is approximately 1.8 times of output voltage display

reading and its waveform no longer square (damped). An automatic

correction for the voltage indicator is available by means of turning on the

unit with a different key operation. For details, refer to Section 9.10.

(Note 2) The fastest repetition of generated pulses (VARIABLE) is 10ms for INS-4020

and 16ms for INS-4040. This comes from different construction of the two

types of mercury relay.

17

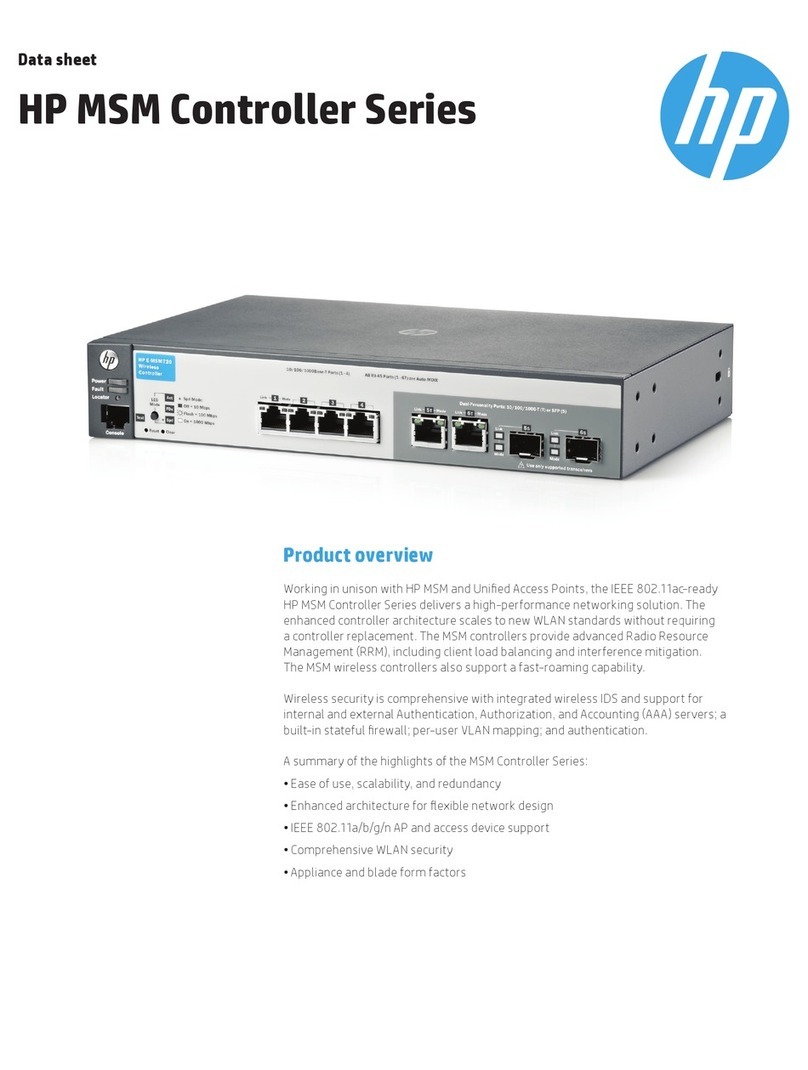

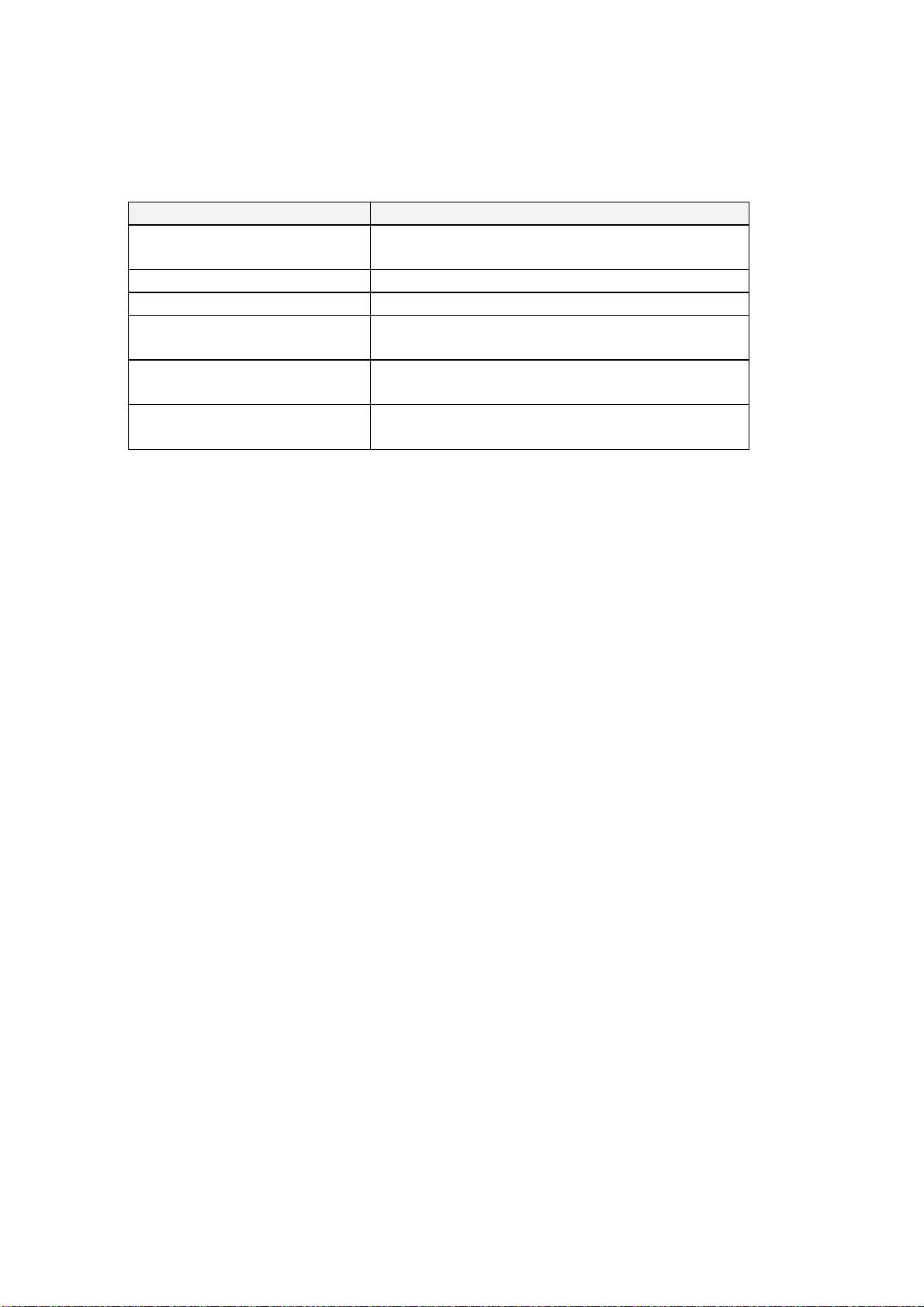

7 INCLUDEDACCESSORIES

This product includes the following accessories.

A B C

D E

List of the included accessories

Description Quantity

Note

A

Coaxial cable 02-00013A 8 30cm length

B

SG short plug 02-000106A

1

C

Outlet panel

(Terminal block

type)

18-00061B 1 AC240V/16A

DC60V/16A maximum

Leaves the factory with this panel

attached to the main unit.

D

AC cable 1 AC100-115V 3-p, 2.4m

E

Instruction manual 1

18

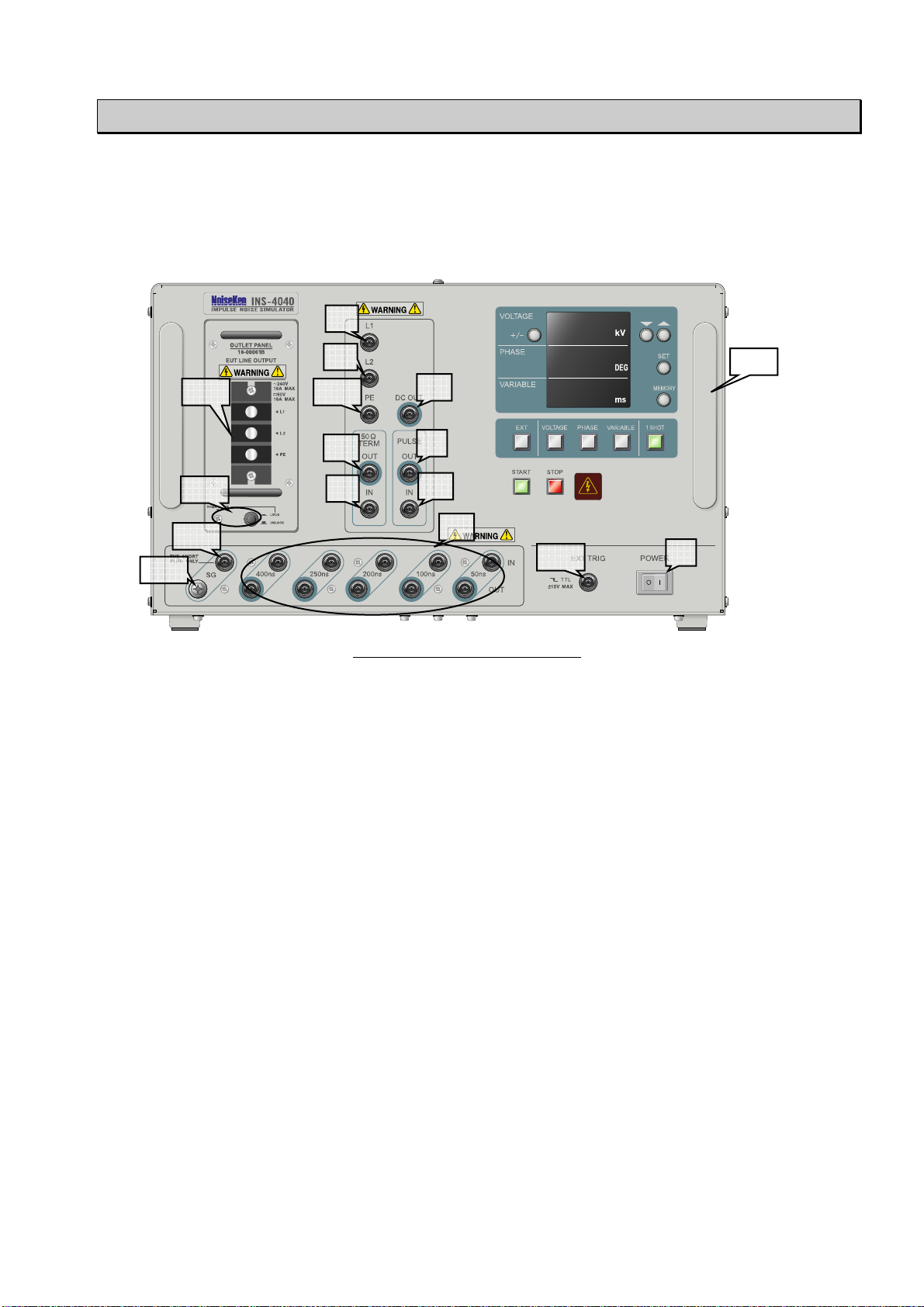

8 CONTROLSAND DISPLAY FUNCTIONS

On the front of the simulator, control, setting and output sections are provided. On the rear, mains

input terminals for the simulator and mains input terminals for EUT are provided.

8.1

8.1 8.1

8.1 Front panel connecters and terminals

INS-4020/4040 front panel

1. POWER key

Controls main POWER on and off. The | side is on position and the 0 side is off position.

2. DC OUT

HV DC OUTPUT connector. This terminal shall be connected to PULSE WIDTH terminal by

using a supplied coaxial cable.

3. PULSE WIDTH

Selects a pulse width among 50ns, 100ns, 200ns, 250ns, 400ns and any

combination thereof. Pulse width can be set from 50ns to 1000ns at a 50ns step by

using supplied coaxial cables. For more details, refer to Chapter 8 Operation.

4. PULSE OUT

PULSE OUTPUT connector. Outputs the pulses set through PULSE WIDTH section.

5. PULSE IN

PULSE INPUT connector. The DC output set through PULSE WIDTH section is input to this

terminal through a supplied coaxial cable.

6. 50ΩTERM OUT

Output at 50Ωtermination resistance. The pulse output with the selected peak amplitude exists

across this terminal.

7. 50ΩTERM IN

Input connector for 50Ωtermination resistor. The HV output pulses from PULSE OUT terminal

are input to this terminal through a supplied coaxial cable.

8. L1

1

2

3

4

5

6

7

8

10

9

11

12

13

14

15

16

This manual suits for next models

1

Table of contents