Nolatron TB-2SR User manual

Model TB-2SR

Two-Hand Start Bar

Anti-Tiedown Switch Monitor

Owner's Manual

The Start Bar is an ergonomic starting system used to reduce operator stress

that can lead to carpal-tunnel syndrome. An internal anti-tiedown control

monitors both start sensors for concurrent operation. The output utilizes

redundant positive guided relays which are monitored to ensure proper

operation.

This product meets the OSHA 1910.217(b)(13) definition of "Control

Reliability ".

1

Introduction:

The Nolatron Two-Hand Start Bar has been tested to meet requirements regarding

safety devices. Before installing, refer to ANSI B11.1, B11.19, and OSHA 1910.217.

ANSI Standard B11.19-1990 gives the following definition: 2.60 Two-Hand Trip. A

device that requires concurrent operation of the trip controls or levers by the

operator’s hands to initiate the machine cycle.

Each Nolatron hand control is protected against unintended operation and arranged

by design, construction, and separation so the concurrent use of both hands is

required to initiate the machine cycle.

The Nolatron Start Bar incorporates an anti-repeat feature and is designed to require

the release of all operator’s hand controls before an interrupted machine cycle can be

resumed.

2

Safety:

The Nolatron Start Bar is not intended for use without adequate “point of operation”

safety guards, which must be provided following OSHA regulations and ANSI

standards to protect the operator. The operator must ensure the bar is properly

installed, inspected and operated. Failure to comply could result in serious bodily

injury and/or property damage.

When properly installed, the Nolatron Start Bar

meets all OSHA requirements for a two-hand

trip device.

Note: The information contained in this manual is for reference purposes only. The

use must determine the compatibility and safety of the Start Bar’s wiring for each

particular machine application.

Do not connect the output from the Start Bar to an input of any other control device

unless it is of a control reliable design. General purpose programmable controllers

(PLCs) are not intended for such an application. Please call Nolatron at 717-564-3398

for technical assistance on how a PLC can be configured to operate in conjunction

with the Start Bar.

Warning! This product may cause substantial personal injury or property

damage if it is not installed, maintained and used in accordance with

the manufacturer’s instructions and in accordance with regulations

of the Occupational Safety and Health Administration Part 1910.217,

the procedures prescribed by the American National Standards

Institute B11.1 and B11.19, and all other applicable regulations,

procedures, and codes. The manufacturer shall not be responsible

nor liable for any injury or damage resulting from use of the product

in any such applications or the failure to comply with any such

regulation, procedure, or code.

Warning!

Never install a suppression device across output contacts. If a

suppressor should fail, the load may unexpectedly become

energized.

3

Warning!

It is necessary to locate and install the Start Bar in accordance with

OSHA machine guarding distance calculations which can be found in

29 CFR 1910.217. Users must also install point of operation guarding

devices, compliant with OSHA regulations, ANSI standards, and any

other machine safety standard that applies to the specific industry

such as light curtains, pressure mats, etc. to fully protect personnel

from accessing the machine during cycle operations

Installation:

The Start Bar can be mounted to the back or to the bottom using the mounting holes

in the housing. Do not add additional mounting holes by drilling into the center

chamber that contains the anti-tie-down control. Metal shavings, caused by drilling,

may cause an internal electrical short circuit. This chamber is sealed to keep out

contaminants such as oil, drilling additional holes may allow these contaminants to

enter the chamber and damage the

anti-tie-down control circuit.

Mounting to the back:

When mounting to the back use a

bolt or screw with a diameter of

1/4". The mounting flange is 1/2"

thick. The holes are 19 1/2" apart

measured from center to center. The

use of a lock washer or locknut is

recommended. Be sure that the

wiring hole on the back of the Start

Bar is not blocked.

Mounting to the bottom:

When mounting to the bottom use a bolt

with a diameter of 1/4" and 20 TPI (1/4-

20). The mounting flange is tapped to a

depth of 1/2". The holes are 17" apart

measured from center to center. The use

of a lock washer and thread-locking fluid is

recommended.

4

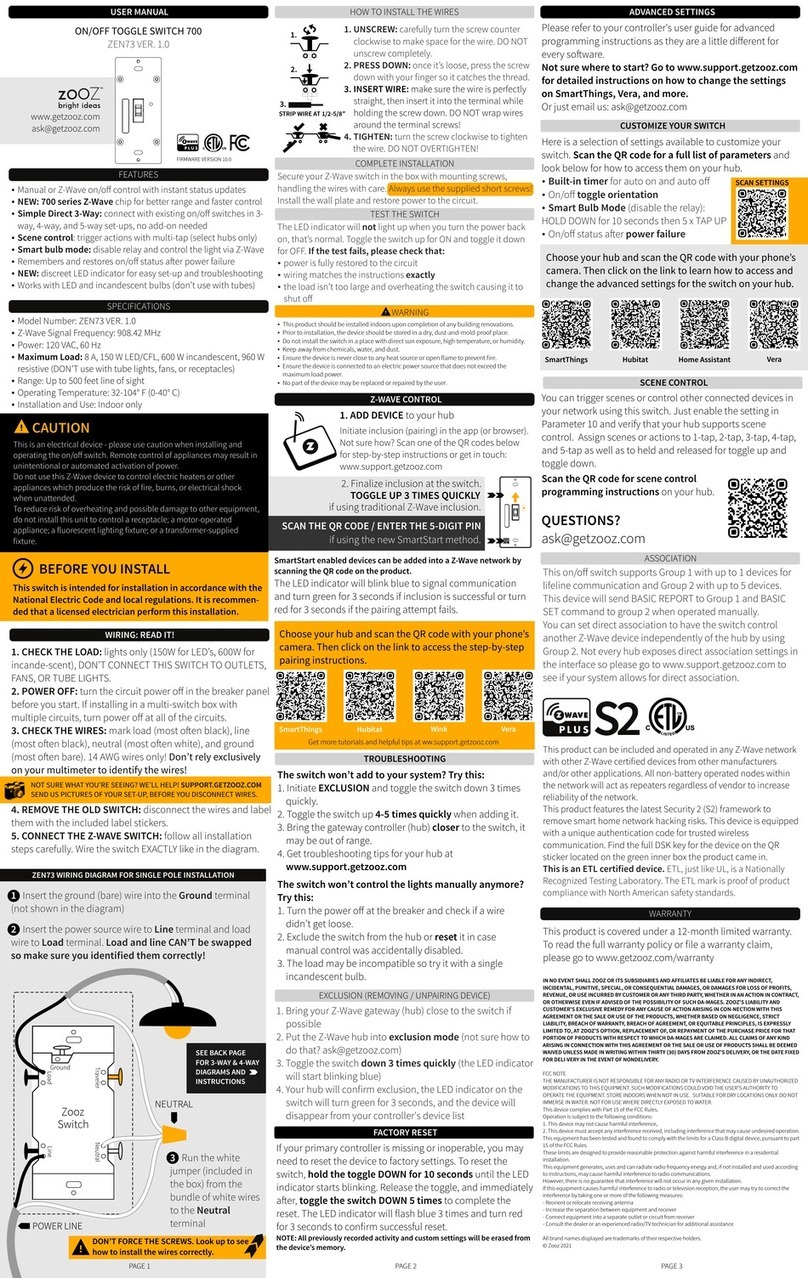

Wiring the Bar:

Input X1 (Hold Input):

This input is for a limit switch that tells the bar when the press is in the down position.

Connect a Normally Open switch across pins 1 and 2.

A 3-wire proximity sensor of the NPN (sinking) type may also be used.

Output X2:

When the output is on, 24VDC will appear across pins 1 and 2.

Connect the load device to these two pins.

Input X3 (Reset Input):

This input is for a limit switch that tells the bar when to end the machine cycle. As an

alternate, it can tell the bar when the part is in place in the press. Connect a Normally

Open switch across pins 1 and 3.

A 3-wire proximity sensor of the PNP (sourcing) type may also be used.

X1

Button

Switch

X2

Output

X3

Pressure

Switch

Fuse: 1 Amp

Pin 1

Signal

Pin 2

GND

Pin 3

24VDC

Pin 2

Output

-

Pin 1

Output

+

Pin 4

N/C

Pin 3

N/C

Pin 1

Signal

Pin 2

GND

Pin 3

24VDC

X1

X2

X3

5

Operation:

The Start Bar will perform a system test on power-up. This test will take

approximately one to two seconds to complete. During this time, the display will turn

on all digits and indicator lights. At the conclusion of this test, the display will show

the current Cycle Count. The Ready light will turn on indicating that the bar is ready to

begin a machine cycle.

In order to begin a machine cycle, both start switches must be touched concurrently

within a half a second. The Ready light will turn off and the Output light will turn on.

The output will remain ON until one or both start switches are released.

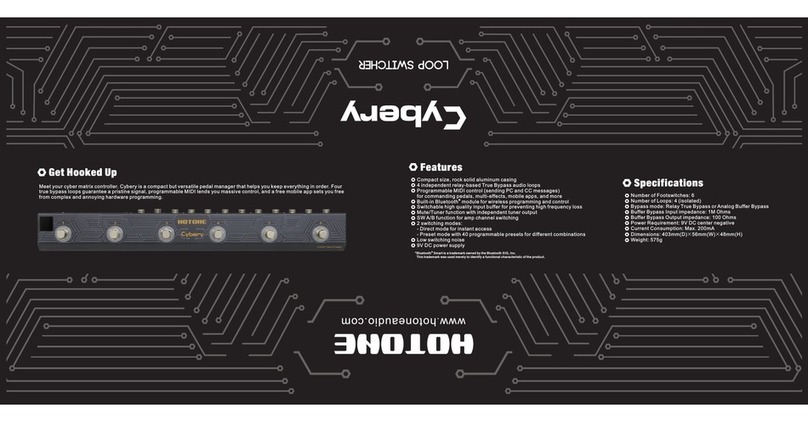

Front of Bar Features:

To Reset Cycle Count:

Press and release the Reset/Select button. The cycle count will reset to zero.

To View Output Dwell Time:

Press and release one of the Time Adjust buttons. The dwell time will show for about

two seconds and return to the Cycle Count display.

To Adjust Output Dwell Time:

While the dwell time is shown, press the Select button. The leftmost digit will begin to

blink. Use the Time Adjust buttons to change the digit. (Note that the leftmost digit

has an adjustment range from 0 to 5, all other digits have a range from 0 to 9). Press

the Select button to advance to the next digit. After adjusting the rightmost digit,

press the Select button to accept the setting. The new dwell time will show for about

two seconds, and then return to the cycle count display.

Power

On/Off

Cycle

Stop

Reset/Select

Button

Display

Window

Time

Adjust

Buttons

Right

Start

Switch

Left

Start Switch

Ready

Light

Output

Light Hold

Light

6

Modes of Operation:

The Start Bar has several modes it will operate in. They are controlled by setting

options in the Setup Menu.

Momentary Output:

The output will remain ON until one or both start switches are released.

To use this mode, set option bit F4 to 0 and set dwell time to zero.

Maintained Output:

After the external Hold switch is closed, the output will remain ON after the start

switches are released. The output will stay on until the external Reset switch is closed.

To use this mode, set option bit F4 to 1 and set dwell time to zero.

Timed Output:

The output will remain ON until one or both start switches are released, or until the

dwell timer reaches zero. Timing starts when the output turns on.

To use this mode, set option bit F3 to 0 and bit F4 to 0.

Maintained Timed Output:

After the external Hold switch is closed, the output will remain ON after the start

switches are released. The output will stay on until the dwell timer reaches zero or

until the external Hold switch is opened. Timing starts when the output turns on.

To use this mode, set option bit F3 to 0 and bit F4 to 1.

Delayed Timed Output:

The output will remain ON until one or both start switches are released, or until the

dwell timer reaches zero. Timing starts when external the Hold switch is closed.

To use this mode, set option bit F3 to 1 and bit F4 to 0.

Maintained Delayed Timed Output:

After the external Hold switch is closed, the output will remain ON after the start

switches are released. The output will stay on until the dwell timer reaches zero or

the external Hold switch is opened. Timing starts when external Hold switch is closed.

To use this mode, set option bit F3 to 1 and bit F4 to 1.

Part-in-Place Mode:

The bar will not respond to the start switches until the external Reset switch is closed.

In this mode, the external Reset switch cannot be used to end the machine cycle, and

the Hold feature will only work with a timed output.

To use this mode, set option bit F5 to 1.

7

Setup Menu:

To enter the Setup menu, hold the Cycle Stop button while turning on power to the

bar. At the end of the power-up test, the display will show "F0 n.n". This is the first

item in the Setup menu. Press Select to move to the next item in the menu. Press the

Up or Down buttons to toggle the settings for each function. At the last item, pressing

Select will return to the Cycle Count display.

Setup Menu Functions:

"F0 n.n" Software version number.

"F1 X" Cycle count reset lock

X = 0 Cycle count can be reset.

X = 1 Cycle count is locked.

"F2 X" Time adjust lock

X = 0 Dwell time can be adjusted.

X = 1 Dwell time is locked.

"F3 X" Timing start option

X = 0 Dwell timer starts when ouput contacts close.

X = 1 Dwell timer starts on signal from the Hold input.

"F4 X" Maintained output option

X = 0 Maintained output is disabled, the output will turn off if

the operator removes their hands during the cycle.

X = 1 Maintained output is enabled, the output will stay on if

the operator removes their hands during the cycle.

"F5 X" Input X3 option

X = 0 Input X3 functions as an end-of-cycle signal.

X = 1 Input X3 functions as a part-in-place signal.

In this mode, Input X3 must be made to start a cycle.

8

Safety Testing Procedure:

After the Start Bar is installed, an initial safety test must be performed by a qualified

person who is appointed by the employer. This testing procedure is used to ensure

that the Start Bar has been wired and is functioning properly. The testing procedure

should be carried out periodically and the machine must not be used if the Start Bar

ever fails the test. A copy of the test results should be placed on or near the machine.

1. Prepare the machine for normal operation. Be sure that all maintenance and setup

work was completed and that all point of operation guards are in place before

proceeding with this test.

2. Turn on the power to the Start Bar.

3. Verify that the Ready light is on.

4. Activate the left start switch.

5. Wait for at least a second, then activate the right start switch.

6. Verify that there is no output and the Output light is off.

7. Release both start switches and verify that the Ready light is on.

8. Activate the right start switch.

9. Wait for at least a second, then activate the left start switch.

10. Verify that there is no output and the Output light is off.

11. Release both start switches and wait for a second.

12. Activate both start switches simultaneously.

13. Verify that the Ready light is off and that the Output light is on.

14. Release both start switches.

9

Specifications:

Physical Size 50cm (20") long, 9cm (3.75") high, 5.5cm (2.15") deep

Mounting Holes 2 vertical / 2 horizontal, 1/4" diameter

Weight 3 kg (6.5 lbs)

Power Supply 115 VAC 50/60 Hz or

220 VAC 50/60 Hz

Power Consumption 5 watts standby, 8 watts output energized

Input X1 NPN (sinking) type, 24VDC, 15mA (p/n TB-2SR)

PNP (sourcing) type, 24VDC, 15mA (p/n TB-2SRPNP)

Input X3 PNP (sourcing) type, 24VDC, 15mA

Output X2 24VDC, .1Amps

2 positive guided relay contacts in series,

Life: 50 million cycles (mechanical)

Concurrency Timer Factory set at .5 sec.

Environmental 0 –50° C (32 - 120° F) ambient temp.

Origin Made in USA

Start Switches Electronic infrared photo sensors

approximately 80 millisecond response time

Warranty:

Nolatron LLC warrants the Start Bar against defects in material and workmanship

under normal and proper use for a period of one year from the date of shipment.

Nolatron's obligation under this warranty is limited to furnishing, without charge and

at our discretion, either replacement or repair of any defective part. This warranty

does not apply when the Start Bar has: (1) been damaged due to excessive vibration

(2) sustained contact damage due to load transients (3) been subjected to abuse or

has otherwise been tampered with. The foregoing warranty is exclusive and in lieu of

all other warranties of quality whether written, oral or implied. Nolatron is not liable

for any damage or injury which may result from the use of its products.

5198 Richmond Rd, Bedford Heights, Ohio 44146

Phone (717)564-3398 Fax (216)274-9262

www.nolatron.com sales@nolatron.com

© 2018 Nolatron, LLC

P/N: APPTB2-SR

Printed in USA

Rev Date: 2-Oct-18

Table of contents

Popular Switch manuals by other brands

Ametek

Ametek Magnetrol3 Series Installation and operating manual

CTC Union

CTC Union IFS+402GSM-4PHE24 Quick installation guide

D-Link

D-Link DGS-2208 - Desktop Switch user manual

Allied Telesis

Allied Telesis AT-8000S/48 datasheet

Extron electronics

Extron electronics MLS 406 Series brochure

Unifore

Unifore POE4100P user guide