NORCAL NC2030 User manual

Norcal NC2030 v5 12-18-05

Page 1 of 128

Norcal NC2030

Low power, High Performance

20m or 30m DC Transceiver

Norcal NC2030 v5 12-18-05

Page 2 of 128

Table of Contents

A Bit of History and Recognition............................................................................................................... 8

Specifications............................................................................................................................................ 10

Receiver ................................................................................................................................................ 10

Transmitter............................................................................................................................................ 10

Building the Kit......................................................................................................................................... 12

Things you will need............................................................................................................................. 12

Parts List ............................................................................................................................................... 14

Tools and Construction Hints ............................................................................................................... 21

Power Supply........................................................................................................................................ 23

Switching Regulator Tests.................................................................................................................... 29

Main Board Temporary Power Connections ........................................................................................ 30

Main Board 3v and 5v Regulators........................................................................................................ 31

3v and 5v LDO Regulator Tests ....................................................................................................... 35

HPF, Audio Amp, Mute, Audio Limiter and Headphone Drivers........................................................ 37

Audio Section Partial Tests............................................................................................................... 39

SCAF Variable Low Pass Filter............................................................................................................ 39

SCAF and Additional Audio Section Tests...................................................................................... 40

CW Keyer ............................................................................................................................................. 42

Audio Frequency Annunciator.............................................................................................................. 44

Adding external controls for functionality tests.................................................................................... 45

Keyer, AFA and Additional Audio Section Tests ............................................................................ 51

VXO and T/R Offset............................................................................................................................. 52

AFA RF Buffer and Phase Splitter ....................................................................................................... 55

Band Specific Parts............................................................................................................................... 56

VXO and AFA Buffer Tests................................................................................................................. 57

LO Mixer and PTO............................................................................................................................... 59

LO Filter and LO amp........................................................................................................................... 67

First time LO filter tune up............................................................................................................... 69

Quadrature detector/front end filter...................................................................................................... 70

Detector Tests ................................................................................................................................... 73

Audio Pre-amp and Audio Phasing....................................................................................................... 74

Audio Pre-amp and Audio Phasing Tests......................................................................................... 76

Main Audio filter .................................................................................................................................. 76

Main Audio Filter Tests.................................................................................................................... 78

Transmitter............................................................................................................................................ 79

Transmitter Tests .................................................................................................................................. 82

Mounting into the case.......................................................................................................................... 85

Bolt down the PC board.................................................................................................................... 85

Add front panel hardware ................................................................................................................. 85

Add rear panel hardware................................................................................................................... 89

Receiver alignment section................................................................................................................... 96

LO Filter tune up............................................................................................................................... 96

PTO Frequency Alignment................................................................................................................... 97

PTO tuning for the 20m version (2.941 to 3.006 MHz) ....................................................................... 97

Norcal NC2030 v5 12-18-05

Page 3 of 128

PTO tuning for the 30m version (2.850 to 2.900 MHz) ....................................................................... 98

Mixer/LO Amp Gain selection ............................................................................................................. 98

RF front end tune up........................................................................................................................... 100

Opposite sideband suppression........................................................................................................... 102

Setting RX/TX offset.......................................................................................................................... 104

Transmitter Test...................................................................................................................................... 106

Operating the NC2030............................................................................................................................ 106

Principles of operation............................................................................................................................ 109

Transceiver Block Diagram................................................................................................................ 109

Receiver .............................................................................................................................................. 109

T/R switch....................................................................................................................................... 109

Detector/ AF pre-amp..................................................................................................................... 110

Phasing strip.................................................................................................................................... 113

R/C Audio Filter – Low pass.......................................................................................................... 114

R/C Audio Filter – High pass.......................................................................................................... 115

Audio Amplifier, Mute Switch & Audio Limiter........................................................................... 116

SCAF Variable Low Pass Filter & Headphone Drivers ................................................................. 117

PTO Circuit..................................................................................................................................... 118

VXO Circuit (20m - 11.059 MHz, 30m – 13.0 MHz).................................................................... 118

LO Mixer and IF Filter ................................................................................................................... 120

LO IF amp and Phase Splitter......................................................................................................... 120

Transmitter.......................................................................................................................................... 121

Class E PA finals ............................................................................................................................ 121

CW Waveform shaping................................................................................................................... 122

High Voltage/High Current PA protection..................................................................................... 122

AFA Frequency Counter Instructions..................................................................................................... 122

Introduction......................................................................................................................................... 122

Counter Modes.................................................................................................................................... 122

Mode............................................................................................................................................... 123

Digits Announced ........................................................................................................................... 123

Counter Usage..................................................................................................................................... 123

Keyer Instructions................................................................................................................................... 124

List of Figures

Figure 1. Working over an oversized cookie sheet is highly recommended to catch stray surface

mounted parts.................................................................................................................................... 13

Figure 2. A temperature controlled soldering helps a lot. 650 to 700 degrees is recommended............ 13

Figure 3. A very pointed soldering iron tip is a very big help for small surface mounted components.. 13

Figure 4. Headband Magnifiers. “Mag-eyes” from JoAnn Fabrics......................................................... 14

Figure 5. Parts in bag pockets are accessed via slit cut into the packet just larger enough to get the part

out. .................................................................................................................................................... 15

Figure 6. Close up of a surface mount parts strip and the bag slit just large enough to access the strip.. 15

Figure 7. A sample bag pocket layout diagram vs. a real bag of parts.................................................... 16

Norcal NC2030 v5 12-18-05

Page 4 of 128

Figure 8. Layout of the power supply and the first three bags ................................................................ 17

Figure 9. Layout of bags # 3 to # 6.......................................................................................................... 18

Figure 10. Contents of bags #7 - #9.......................................................................................................... 19

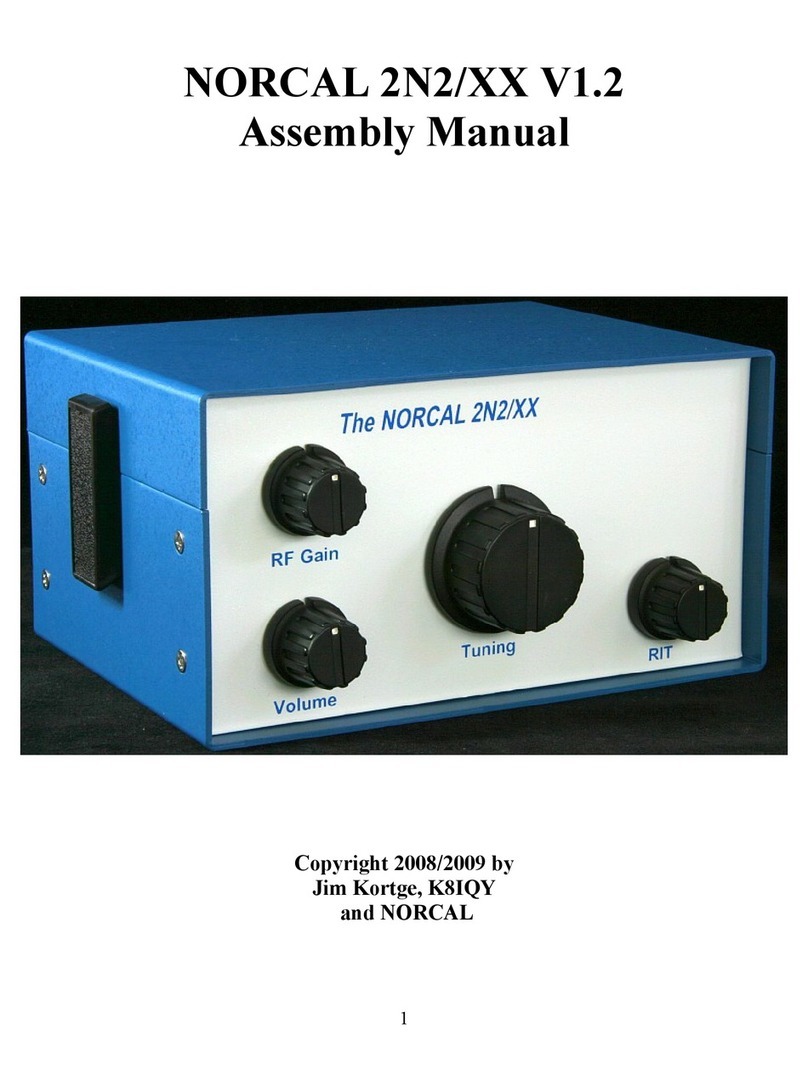

Figure 11. Completed Switching PS with Temporary 9v Power Connection and 100 ohm 3.3v Dummy

Load .................................................................................................................................................. 23

Figure 12. Board layout of the switching power supply......................................................................... 23

Figure 13. Switching supply built up....................................................................................................... 24

Figure 14. Orientation of U1. Mount with the markings “AANY” upside down as shown................... 24

Figure 15. PS with 0.1 Caps, 47 uH inductors, Schottky diodes, and Switching IC............................... 25

Figure 16. PS and Electrolytic Caps Polarity Details.............................................................................. 25

Figure 17. L2 mounting details................................................................................................................ 26

Figure 18. L2 details. After first 24 turns, add a twisted loop for later center tap. Add 27 more turns

after this. ........................................................................................................................................... 27

Figure 19. Form 1N4001 Diode as Shown .............................................................................................. 27

Figure 20. 100 ohm Temporary 3v Load Resistor Formed as Shown..................................................... 27

Figure 21. 1N4001 Mounted and 9v Battery Clip Connected................................................................. 28

Figure 22. 3v Temporary 100 Ohm Load Resistor Connected to Bottom of Board................................ 28

Figure 23. Power Output Connection Details (Load resistor not shown)................................................. 29

Figure 24. Temporary 9v power connection and connections between switching supply and main board

........................................................................................................................................................... 30

Figure 25. Close up of power connections on the main board and switching supply, bypass caps, and

polarity diode.................................................................................................................................... 31

Figure 26. Location of the two 3v and 5v regulator sections................................................................... 31

Figure 27. Close up of first two 3v LDO regulators................................................................................ 32

Figure 28. Parts layout of first two 2.9v LDO regulators. Note the black band orientation of the

electrolytic caps. ............................................................................................................................... 32

Figure 29. Location of the one 3v and two 5v LDO regulator sections................................................... 33

Figure 30. Installed parts for this section of LDO regulators. Note the black band orientation on the

electrolytic caps. ............................................................................................................................... 34

Figure 31. Ground reference for voltage measurements are upper 2 corners, the lower 2 are not

connected .......................................................................................................................................... 35

Figure 32. SCAF, HPF, Audio Amp, and Headphone driver section of the board.................................. 37

Figure 33. HPF, Audio Amp, Headphone Drivers portion...................................................................... 37

Figure 34. Picture shows orientation of U11 with stripe on upper end. ................................................... 38

Figure 35. General location of the SCAF circuit...................................................................................... 39

Figure 36. Close up component view of the SCAF section of the board.................................................. 39

Figure 37. U13 and D10 mounted. IC notch and D10 flat side in the vertical direction........................ 40

Figure 38. Location of the CW Keyer section of the board..................................................................... 42

Figure 39. Close up of the CW Keyer section......................................................................................... 42

Figure 40. Picture showing correct orientation of Norcal Keyer Chip (optional socket not shown) ...... 43

Figure 41. General Location of AFA circuit............................................................................................. 44

Figure 42. Close up view of the AFA section........................................................................................... 44

Figure 43. Correct orientation of both the 8 pin 12C508 AFA chip and 14 pin 74ACT00 ICs. ............. 45

Figure 44. Connect buttons keyer and AFA buttons S2 and S3 as shown................................................ 46

Figure 45. Prepare R88 100K Cw speed pot as shown. The left and middle terminals are connected to

the white lead.................................................................................................................................... 47

Norcal NC2030 v5 12-18-05

Page 5 of 128

Figure 46. Connect R88 CW speed pot to the R88 pads as shown. Keep black and white in order shown.

........................................................................................................................................................... 47

Figure 47. Use Brown/Red/Orange wire and connect up the paddle jack in the color order shown........ 47

Figure 48. Attach paddle jack to JP5 using the color order shown.......................................................... 48

Figure 49. Use Brown/Red/Orange wire and connect up the headphone jack in the color order shown 48

Figure 50. Connect the headphone jack to JP4 in the color order shown................................................ 48

Figure 51. Use Yellow/Green/Blue wire to connect to R83, the 50k SCAF pot in the color order shown

........................................................................................................................................................... 49

Figure 52. Connect the 50K SCAF pot to the R83 header pads in the color order shown....................... 49

Figure 53. Use Yellow/Green/Blue wire to connect to R77, the 5K volume control pot in the color order

shown................................................................................................................................................ 49

Figure 54. Connect the 5K volume control pot to the R77 header pads in the color order shown.......... 50

Figure 55. All controls attached thus far.................................................................................................. 50

Figure 56. Location of VXO and T/R offset circuit.................................................................................. 52

Figure 57. Close up of VXO and T/R offset circuit.................................................................................. 52

Figure 58. Proper orientation of U8, D2, and D3 .................................................................................... 53

Figure 59. Yellow/Green/Blue wire to connect to R52, the 25k RIT pot in the color order shown......... 54

Figure 60. Connect the 25K RIT pot to the R52 header in the color order shown. Also attach a SPDT

switch to S1....................................................................................................................................... 54

Figure 61. General location of the AFA RF Buffer and Phase Splitter................................................... 55

Figure 62. Close up view of the AFA RF Buffer and Phase Splitter Area............................................... 55

Figure 63. Orientation of U9 labeling as installed.................................................................................... 56

Figure 64. Temporary connection from C72 to C54................................................................................. 57

Figure 65. Board Location of the LO mixer and PTO circuitry .............................................................. 59

Figure 66. Close up of the PTO and Mixer section of the board.............................................................. 59

Figure 67. PTO and PTO/VXO mixer sections as built........................................................................... 60

Figure 68. Temporary soda straw PTO coil L13 connected to the PTO oscillator circuit. ...................... 61

Figure 69. Anchoring the first turn of the temporary PTO coil................................................................ 62

Figure 70. Finished temporary PTO coil with 82T. Tie off holes placed on both ends ......................... 62

Figure 71. McDonald’s straw diameter. .................................................................................................. 63

Figure 72. Main tuning PTO coil L13 shown mounted to the front panel. This is used only when the rig

is finished.......................................................................................................................................... 63

Figure 73. Wrap first turn on the PTO coil. Position ¾” back from front, twist single turn in place..... 64

Figure 74. First turn is glued (epoxy) into place to make it easier to wrap the rest of the turns ............. 64

Figure 75. Coil with completed 105 turns. Turns wound tight and “shoulder to shoulder”.................... 65

Figure 76. PTO coil coated in clear nail polish. The wife recommends “Sally Hansen Diamond

Strength”........................................................................................................................................... 65

Figure 77. 2” brass screw cut back to a total length of 1 ¾ inches.......................................................... 66

Figure 78. Final screw with mounted spacer............................................................................................ 66

Figure 79. General location of LO Filter and Amp .................................................................................. 67

Figure 80. Close up of the LO Filter and Amp components..................................................................... 67

Figure 81. LO Filter and amplifier as built. Both trim caps must have proper orientation ..................... 68

Figure 82. Coils L6 and L7 are prepared to be mounted surface mount style on the top of the board on

the coil holes..................................................................................................................................... 68

Figure 83. General location of the Detector and Front End Filter............................................................ 70

Figure 84. Close up of the detector and the RF tuned front end............................................................... 70

Norcal NC2030 v5 12-18-05

Page 6 of 128

Figure 85. Picture of detector and RF front end with parts installed. Note trim cap orientation and

jumper on JP3!.................................................................................................................................. 71

Figure 86. Detail on T1. Two turn # 32 to pads 1 & 2. Main winding connect to pads 3 & 4.............. 72

Figure 87. L2 leads formed to prepare for surface mounting on the top of the through hole pads

provided. ........................................................................................................................................... 72

Figure 88. Location of Audio Preamp and Phasing sections.................................................................... 74

Figure 89. Close up of Audio Preamp and Phasing sections.................................................................... 74

Figure 90. Component alignment of U4, and U5. Note C30, R22 locations........................................... 75

Figure 91. General location of the Audio 750 Hz LPF............................................................................ 76

Figure 92. Close up of the 750 Hz Audio LPF section............................................................................. 77

Figure 93. Component placement and alignment of U7 and polarization of caps C47, C48, C49........... 77

Figure 94. General location of the Transmitter section............................................................................ 79

Figure 95. Close up of the transmitter section portion.............................................................................. 79

Figure 96. All transmitter parts except for the inductors. Note TS912 orientation, BS170 flat side

orientation......................................................................................................................................... 80

Figure 97. L19 mounted. 3T tap location shown.................................................................................... 81

Figure 98. Location of U9 and pins voltages to check. In receive mode, check, U9 pins 11 (0v), 12 &13

(2.9v)................................................................................................................................................. 82

Figure 99. Location of U15 between AFA and Keyer chips. Test pins 11, 12, and 13........................... 83

Figure 100. Location of R95 and R96. Voltages on transmit/receive switches....................................... 84

Figure 101. Mount all four corners of the main board using the mounting hardware as shown............. 85

Figure 102. NC2030 with all front panel hardware mounted in prototype chassis. Case will be silk

screened............................................................................................................................................. 85

Figure 103. Mount the paddle jack.......................................................................................................... 86

Figure 104. Mount the headphone jack..................................................................................................... 86

Figure 105. Add Keyer button (upper left), AFA button (lower right).................................................... 87

Figure 106. Mount the volume control pot (upper right) and the spot switch (lower middle)................. 87

Figure 107. Another view of the spot switch. The two terminals are orientated in the “up” position. .. 88

Figure 108. Add keyer speed pot, SCAF Pot, and RIT pot. .................................................................... 88

Figure 109. Rear panel of prototype NC2030. Final case will be silk screened....................................... 89

Figure 110. Antenna jack added .............................................................................................................. 89

Figure 111. Rear power connections: Power switch, leads to rear switching supply, power jack (not

shown)............................................................................................................................................... 90

Figure 112. Power jack connections, +12v to power switch (red wire) and ground (green) to JP2 ground

pad..................................................................................................................................................... 90

Figure 113. Placement of the switching supply tin on the back chassis, power jack not installed........... 91

Figure 114. Place the switching supply board in the tin, center it top & bottom, and mark the mounting

holes.................................................................................................................................................. 92

Figure 115. Connect the power wires to the switching supply in the color order shown......................... 93

Figure 116. PTO L13 mounting detail. Coil connections shown. Front PTO coil wire must connect as

shown................................................................................................................................................ 93

Figure 117. Connections for the PTO coil L13......................................................................................... 94

Figure 118. Front side of the PTO coil (prototype chassis) showing epoxy ridge from the front side .. 94

Figure 119. Tuning knob with PTO screw partially inserted................................................................... 95

Figure 120. PTO brass screw full inserted into the PTO coil.................................................................. 95

Norcal NC2030 v5 12-18-05

Page 7 of 128

Figure 121. With PTO screw fully inserted, adjust tuning knob to have a small amount of front panel

clearance. .......................................................................................................................................... 96

Figure 122. Location of LO trim caps C58, C60 and TP3 in the upper left corner of the board.............. 96

Figure 123. L13 PTO tuning coil as mounted. Remove turns off the end simply by pulling on the wire.

........................................................................................................................................................... 97

Figure 124. Location of R63, PTO/VXO mixer gain adjust located in bottom left corner of board....... 99

Figure 125. Location of optional LO amplifier gain adjust resistor R50............................................... 100

Figure 126. Location of RF front end band pass filter adjust trim caps, C23 and C25 on top middle of

the board.......................................................................................................................................... 100

Figure 127. Adjustment points for nulling out the opposite sideband.................................................... 102

Figure 128. Picture of simulated opposite sideband rejection when optimally tuned up...................... 103

Figure 129. Location of the T/R offset trim pot, R53............................................................................. 105

Figure 130. Tayloe quadrature detector and I/Q audio preamplifier schematic..................................... 110

Figure 131. Audio phasing section schematic ....................................................................................... 113

Figure 132. Main brick wall filter. 800 Hz active R/C low pass filter. ................................................ 114

Figure 133. 400 Hz High pass filter schematic...................................................................................... 115

Figure 134. SCAF Low Pass Filter and Headphone Amplifier............................................................. 117

Figure 135. PTO schematic.................................................................................................................... 118

Figure 136. VXO schematic and transmit/receive offset switching....................................................... 118

Figure 137. LO Mixer and IF Filter schematic...................................................................................... 120

Figure 138. Schematic of LO amplifier and detector clock phase splitter............................................. 120

Figure 139. Schematic of Class E Transmitter....................................................................................... 121

Figure 140. A Function Table of the Keypress Combinations .............................................................. 124

Figure 141. Mem + dit menu (PAR mem to advance to the next menu item)...................................... 125

Figure 142. Mem + dah menu (PAR mem to exit)................................................................................ 126

Figure 143. Mem switch menu (PAR mem to advance to the next menu item).................................... 127

Figure 144. Mem + both menu (PAR mem to exit)............................................................................... 127

Norcal NC2030 v5 12-18-05

Page 8 of 128

A Bit of History and Recognition

The basic design of the detector used in this transceiver first came about in 1998, a bit over seven years

ago. I came up with the idea for the detector during a 5000+ mile road trip with the family from

Phoenix to Newark, New Jersey, down to Disney in Florida, and back home again to Phoenix.

When I got back home, I bread boarded the detector idea using some then newly released bus switching

ICs and discovered that it not only worked, but that it had other interesting properties such as a band

pass characteristic and very low loss detection.

As soon as I found that the detector worked, I quickly built a simple image rejection receiver around it

and brought the transceiver to Norcal’s Pacificon QRP convention. At the Pacificon Friday evening

QRP dinner, I found myself talking to Doug Hendricks about the design. Doug picked up interest in the

design and offered some development money if I allowed Norcal to produce a kit based on the design. I

accepted, and the rest is history.

This is my 7th design in a string of designs where incremental improvements have been made over time.

The NC2030 design attempted to maximize receiver performance give a receiver current drain constraint

of roughly 10 ma at 12v. The NC2030 draws roughly 12ma in its current form, while providing 140+ db

of blocking dynamic range and 107+ db of third order intercept dynamic range while operating at full

receiver sensitivity. This receiver performance is unmatched by anything commercially available today.

Across this seven year span of time, there were many folks that helped me in my pursuit of this design

and I want to take a moment and recognize a few of them.

Kent Torrel for calculating the theoretical detection loss of the detector. In addition, he helped me

measure the performance of my first receiver prototype before I had my own test equipment.

Brian Kessel was a ScQRPion member that gave me my first pair of signal generators. This enabled me

to measure sensitivity (one generator needed) as well as blocking and third order intercept (two

generators needed) and started me down this path of high performance receivers.

Dave Fifield offered me a pair of 8640Bs to allow me to the testing required for very high receiver

performance. Brian’s generators were a start, but the testing of very high performance receivers requires

a very clean signal source with extremely low sideband noise and these two generators were not quite

good enough. The HP 8640Bs were just what I needed. There is no way of knowing where a design

stands without testing. High performance receivers do not happen by accident. Performance must be

designed in.

Trevor Jacobs for laying out the NC2030 PC board.The single largest difficulty in getting this project

kited was getting the PC board laid out. The design has a lot of parts! Trev did an excellent job as

evidenced by this kit. Trev also ran the PTO temperature compensation experiments using a home made

temperature chamber.

Norcal NC2030 v5 12-18-05

Page 9 of 128

Dean Davis has been managing the web site for Norcal. I appreciate the work he has done in set up the

NC2030 page and linking the presentations to the web page. By the time this is finished, he will also

probably be tired of proof reading and fine tuning the format of this manual.

Vicki Tayloe my long suffering wife. Thanks for putting up with this project for the last seven years.

NC2030 Kit Crew: I do not know who you are (I know Doug was involved), but my hats off to you!

Finally, big thanks to Doug Hendricks for encouragement and support all through this saga!

Without him, this would not have gotten to this point.

Norcal NC2030 v5 12-18-05

Page 10 of 128

Specifications

As measured from current prototypes, some variance in performance is expected from unit to unit.

Receiver

Tuning range: 20m – 14.0 to 14.065 MHz 30m – 10.1 to 10.15 MHz

Curent Drain: ~11.5 ma at 12v. Current drain is lower at higher voltages, higher at lower voltages due

to the use of a switching supply converting the input voltage to the required current drain at 3v and 5v.

Supply voltage range: 7 to 15v

Receiver 6 db bandwidth: ~ 350 to 850 Hz. Fixed 400 Hz 3 pole high pass filter (HPF); Fixed 750 Hz

9 pole low pass filter (LPF) plus variable frequency 5 pole SCAF LPF (14 poles total low pass filter).

SCAF audio low pass filter tuning range: ~300 Hz to 900 Hz

Audio limiting: The headphone audio output is diode limited to ~0.28v peak to peak. For full volume

conditions, the audio will limit for signals above –95 dbm.

Sideband: LSB using audio phasing techniques.

Opposite sideband rejection: ~ -45 db

MDS receiver sensitivity: -133 dbm (30m) to -135 dbm (20m), measured for a 3db signal rise over the

receiver noise floor.

Third order distortion dynamic range (IP3DR): 93 db at 2 KHz, 108 db at 10 KHz

Blocking Dynamic Range (BDR): 130 db at 5 KHz, 142 db at 20 KHz

Suggested headphone sensitivity: at least 104 dbm minimum sensitivity (106 to 110 is better)

Transmitter

20m: Power Output: ~4w at 12v, ~500 mA current drain; ~5w at 13.8v; ~1.5w at 7v;

30m: Power Output: ~3w at 12v; ~4w at 13.8v

Norcal NC2030 v5 12-18-05

Page 11 of 128

Norcal NC2030 v5 12-18-05

Page 12 of 128

Building the Kit

Things you will need

- 9v battery clip (for temporary power connection for testing)

- Fresh 9v battery (for a low current power source for testing)

- Teflon plumbing tape (for wrapping PTO coil and temporary PTO coil)

- Clear nail polish (“Sally Hansen Diamond Strength” highly recommended for hardness. Source: Ulta)

- McDonald’s straw (for constructing a temporary PTO coil)

- Two part epoxy (for use on PTO coil)

- Thin super glue (as opposed to “thick” super glue). Used for the PTO tuning screw assembly

- Tweezers

- Solder sucker (highly recommended) or solder wick

- Temperature control soldering iron with a fine tip

- Two 8 pin sockets for the AFA and the keyer chip (optional)

- Magnifying headpiece and/or magnifying glass

- Cookie sheet (highly recommended for building on top of in order to catch stray parts)

Norcal NC2030 v5 12-18-05

Page 13 of 128

Figure 1. Working over an oversized cookie sheet is highly recommended to catch stray surface mounted parts

Figure 2. A temperature controlled soldering helps a lot. 650 to 700 degrees is recommended.

Figure 3. A very pointed soldering iron tip is a very big help for small surface mounted components

Norcal NC2030 v5 12-18-05

Page 14 of 128

Figure 4. Headband Magnifiers. “Mag-eyes” from JoAnn Fabrics

Parts List

The bags are broken into a series of pockets that contain the surface mounted parts.

Caution! The surface mount part values are not always marked!

The bags pockets will be used for parts storage through out the

building process.

When you need to access a part, cut a slit into the bag pocket just large enough to access the part. When

the parts are in a strip as shown below, peel back the top plastic portion of the strip just enough to dump

out one part. When finished, slide the remainder of the strip back into the bag pocket for storage.

Norcal NC2030 v5 12-18-05

Page 15 of 128

Figure 5. Parts in bag pockets are accessed via slit cut into the packet just larger enough to get the part out.

Figure 6. Close up of a surface mount parts strip and the bag slit just large enough to access the strip.

Below is an example of a bag layout as compared to a real bag. Notice the correspondence of the three

single resistor pockets at the top of the real bag compared to the bag layout.

Norcal NC2030 v5 12-18-05

Page 16 of 128

Figure 7. A sample bag pocket layout diagram vs. a real bag of parts.

Below are all the bag parts diagram. You will need these diagrams in order to determine where to find

which bag and bag pocket in which to find any part that you need. I suggest printing out these bag

layouts and keeping them with these bags.

The only bag diagram not shown below is the hardware bag. That bag contains the screws, nuts, jacks,

knobs, switches, connectors, wire, solder, etc. needed in the kit.

Norcal NC2030 v5 12-18-05

Page 17 of 128

Figure 8. Layout of the power supply and the first three bags

Norcal NC2030 v5 12-18-05

Page 18 of 128

Figure 9. Layout of bags # 3 to # 6

Norcal NC2030 v5 12-18-05

Page 19 of 128

Figure 10. Contents of bags #7 - #9

In addition to the above bags, there are two more bags. One is a bag of wire, and the other is a bag of

miscellaneous parts. The contents are listed below:

Misc bag:

1 - 1.25" knob (Main tuning. 1.25" fits per silk screen layout)

4 - 0.75" knobs (Control knobs. 0.75" fits per silk screen layout)

2 - Sub-miniature push buttons plus nuts and lock washers

2 - SPST miniature switches plus nuts and lock washers

2 - headphone jacks plus nuts and lock washers

1 - 100 pf N220 Temperature compensation disc cap

1 - 1N4001 diode

1 - 5K pot plus nut and lock washer (Volume control)

1 - 25K pot with center detent plus nut and lock washer (RIT control)

Norcal NC2030 v5 12-18-05

Page 20 of 128

1 - 50K pot plus nut and lock washer (SCAF Low Pass Filter cutoff control)

1 - 100K pot plus nut and lock washer (CW speed control)

1 - BNC antenna connector plus nut and lock washer

1 - Power connector plus nut and lock washer

1 - Switching supply tin

1 - PTO coil form

1 - Nylon nut for PTO coil form

1 - ¼-20 thin nuts

1 - 2" brass 6-32 screw

1 - 0.5" aluminum spacer threaded for 6-32

6 - 4-40 screws 3/8"

6 - 4-40 nuts with lock washers (used for board standoffs, lock washers give additional height)

6 - 4-40 nuts

Wire bag:

#26 wire - 8 feet

#30 wire - 16 feet

#32 wire - 3 feet

10 conductor ribbon cable

Tube of solder

Status 12-12-05: Two other missing parts are being shipped out, five 100 uf capacitors for the main

receiver board and a 30 pf trimmer cap. These are being shipped separately and are not included in

the above bags.

Table of contents

Other NORCAL Transceiver manuals