NORCAL QRP Club SMK-1 Instructions for use

2000, Red Hot Radio – Unauthorized Copying or Publication Prohibited

1

The NorCal QRP Club

SMK-1 Construction Manual

A Learning Tool For

Surface Mount Construction

Kit Building

By Dave Fifield, AD6A

Revision 0.1

April 2000

WARNING – DO NOT OPEN ANY OF THE PARTS BAGS YET!

2000, Red Hot Radio – Unauthorized Copying or Publication Prohibited

2

The SMK-1 Construction Manual

Introduction

Thank you for buying a NorCal QRP Club SMK-1 kit.

We’re sure you will enjoy learning/practicing surface

mount construction techniques by building the SMK-1.

As a bonus, when built, the SMK-1 is a fully working 40m

CW transceiver that you will be able to use on the air to

make contacts!

The idea to produce the SMK-1 kit came from Doug

Hendricks, KI6DS, who thought it would be a good idea

to have a cheap learning tool to get hams used to doing

surface mount construction, since that’s the way virtually

the whole electronic industry has gone and will inevitably

become the technique of necessity for ham kits in the

future.

All you will need to turn the SMK-1 into a fully working rig

is a case, some knobs, an antenna jack, a power jack, a

key jack and an earphone jack. Fortunately, the New

Jersey QRP Club has come to your rescue here! They

are supplying a custom designed PCB construction

case, knobs and connectors kit for the SMK-1 for only

$10 including shipping to anywhere. You can order one

from them by sending a check or money order for $10

made payable to George Heron to:

George Heron, N2APB

2419 Feather Mae Court

Forest Hill

MD 21050

USA

The SMK-1 contains over 80 components. Most of them

are surface mount parts. Some parts, like crystals,

trimcaps and pots, are either too expensive or not easily

obtained in surface mount packages so through hole

parts are used.

The surface mount parts used in the SMK-1 were

chosen to be large enough for most hams to be able to

handle them with a small pair of tweezers and solder

them in place using a fine-tip soldering iron. They are not

the smallest surface mount parts by a long way, but they

are small. I have personally built several kits now without

using a magnifier, but I do recommend you use one if

you have one! It will make life a lot easier for you,

especially if your eyesight isn’t quite what it used to be!

I recommend that you use a 1/16th inch or smaller

soldering iron tip, preferably temperature controlled, and

use 0.020” silver solder (although just about any solder

will do!). You will need a small pair of angled tweezers to

be able to handle the components with dexterity and

without damage.

Have fun building your SMK-1 kit – please let us all know

your progress and give us your comments/feedback on

the QRP-L email reflector.

General Description

The SMK-1 circuit is basically a modified Tuna Tin 2

transmitter integrated with a modified MRX-40 receiver. It

is a further modification of the modified TT2/MRX-40 that

I built for the indoor foxhunt at Pacificon 1999. All this is

fitted onto a small 2.475” x 2.25” PCB.

The transmitter consists basically of the two 2N2222A

transistor lineup of the original TT2 but with electronic

keying. A key-switched crystal oscillator that has some

degree of VXO feeds a medium power packaged version

of the 2N2222A as a final in class A mode. After

harmonic filtering, the result is about 350mW of fairly

clean transmit power on 7.040MHz (+/- a bit).

The RX front end uses the ubiquitous NE602

mixer/oscillator with a crystal VXO. The RX is a direct

conversion receiver, so you will hear both sidebands as

you tune through a station. The input stage of the NE602

has been biased a bit harder than normal by R1, a 22K

resistor (this resistor may need tweaking, if your receiver

is overdriven, increase the value of this resistor. Try 27K

or 39K). This gives the device more conversion gain.

The audio output of the NE602 direct conversion front

end goes through a FET switch that serves to mute the

audio to an acceptable sidetone level during TX and then

on to a standard LM386 audio power amplifier running

as much gain as it can.

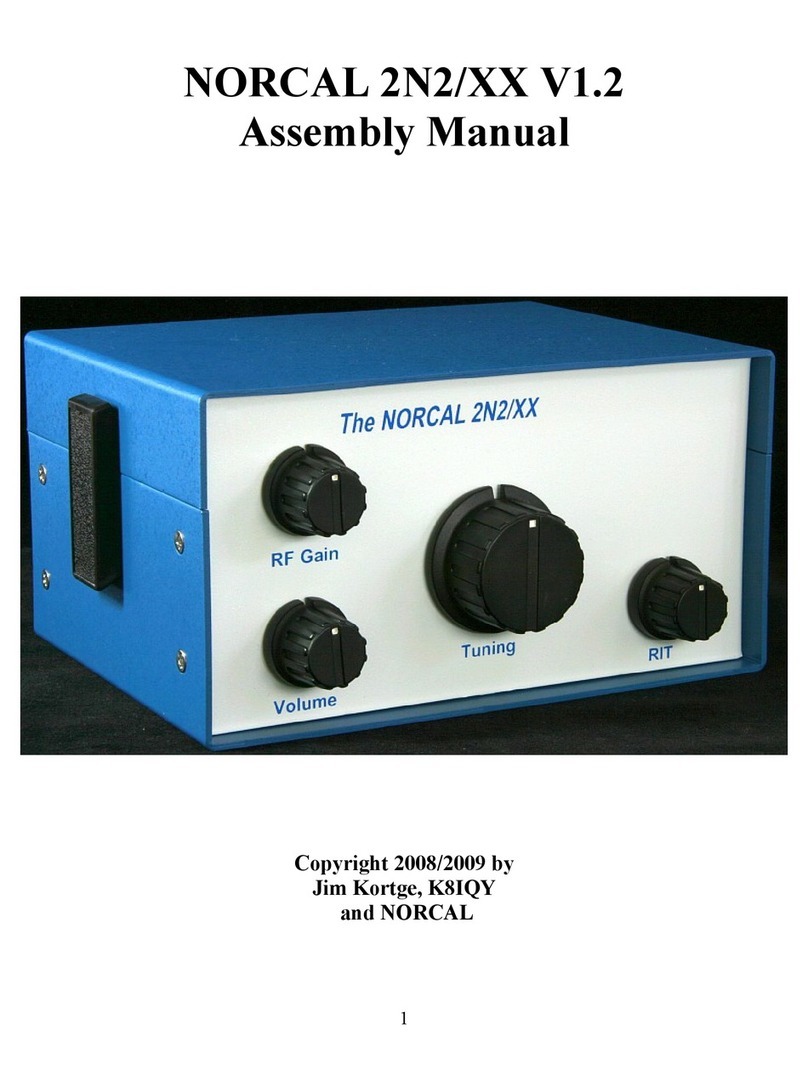

The three controls on the front panel of the SMK-1 are

(left to right as you look at it) RF attenuation, RX tuning,

TX tuning. Operating the SMK-1 requires a little

knowledge of where you are receiving and transmitting –

there will be more on this in a later section of this

manual.

2000, Red Hot Radio – Unauthorized Copying or Publication Prohibited

3

Don’t Open The Parts Bags Yet – MUST

READ!

The parts bags have been loaded with components in

the exact order that you should solder them onto the

SMK-1 PCB. Since the components are tiny and many of

them have no markings on them at all, you must only

open one component compartment at a time! Solder all

the parts from that compartment onto the PCB before

opening the next compartment. It is imperative that you

do it this way, so you only have one value open at a

time. If you get the parts mixed up, tough bananas! You

have been warned!!

In a few of the kits shipped, one of the small orange

trimmer capacitors was put into the wrong compartment

– it was placed in with the 4.7uH inductor. If your kit is

one of these, when you get to the stage where you fit the

4.7uH inductor, save the orange trimcap on one side

until you get to the one at the bottom of the bag and

solder them in together then.

The through-hole parts and the transmit output

transformer are fitted last. Save the crystals, pots and

trimcaps till the end before you solder them in – it will

make life much easier.

Missing/Defective Parts

Due to the care and methodology put into the kitting

process, it is virtually impossible that any parts will be

missing from your SMK-1 Kit. However, due to the nature

of the small surface mount components in the kit, it is

very easy for you to lose parts and we anticipate that

there will be some loss! NorCal will only be able to

replace parts for $2. Send your lost parts requirements

with a check or money order for $2 made payable to

Doug Hendricks to:

Doug Hendricks, KI6DS

862 Frank Avenue

Dos Palos

CA 93620

USA

Please include an SASE for the parts.

Technical Support

For simple questions please use email to obtain

technical support from your fellow QRP’ers on the QRP-

L email reflector. To subscribe, send an email to

listserv@lehigh.edu with the words “subscribe qrp-l <your

name> <your callsign>” on the first line of the email

body.

For more complex problems or issues or if you don’t

obtain satisfaction from the QRP-L email list, please

email me at ad6a@arrl.net

Surface Mount Soldering Technique

Use a fine soldering iron tip (1/16th inch or less) at about

700°F if possible. Use fine solder (0.020”), silver solder if

you can get it.

First, tin one PCB pad of the component you are going

to solder down. Don’t overdo the amount of solder – just

a slight bump of solder is enough – maybe a ¼” of solder

from your reel.

Next, pick up the component you are going to solder

down using your tweezers – carefully, lengthwise –

make sure you have it firmly, but not so firmly that it

goes “ping” and flies across the room! With your

soldering iron in one hand and the tweezers with the part

in the other, carefully place the part down onto the pads

in position – take care to line it up straight. Quickly dab

the wetted soldering iron onto the lead/pad that you

tinned previously to get it to stick nicely and sit flat.

Re-run the solder on this pad if you need to adjust the

position of the component. You must get it straight

and/or symmetrical across the pads at this time – once

you solder another pin, you will have no chance to re-

position it at all.

Once you are happy with its alignment on the pads (try

to get it right first time to minimize the possible heat

damage to the component), solder the other lead/s down

carefully. Go back and touch up the first lead if

necessary. That’s it – simple!

If you need to remove a part for any reason, the best

method is to use two soldering irons at once, one on

each end. If you only have one iron, add solder to both

sides of the part and heat them alternately until the part

comes away on the tip of the soldering iron. You will

need to use some solder wick to clean the PCB pads

before soldering down a new component. Surface mount

components that have been removed by this method are

usually good candidates for the trash can – try not to

reuse them unless you really have to.

2000, Red Hot Radio – Unauthorized Copying or Publication Prohibited

4

Getting Started With Bag #1

Turn Bag #1 around so that you are looking at it like this

with the “This Side Up” label in the bottom left hand

corner:

Item 6

13 x 0.1uF Item 1

3 x 82pF Item 2

1 x 100pF

Item 3

2 x 270pF Item 4

1 x 390pF Item 5

3 x 470pF

Item 22

1 x 10 Ohm Item 23

1 x 56 Ohm Item 24

1 x 100 Ohm

Item 25

1 x 220 Ohm Item 26

1 x 560 Ohm Item 27

2 x 1K

Item 28

2 x 2.2K Item 29

1 x 3.3K Item 30

1 x 4.7K

Item 31

1 x 5.6K Item 32

1 x 8.2K Item 33

5 x 10K

Bag #1

This Side Up Item 34

1 x 22K Item 335

1 x 47K

Using a sharp knife, cut open just the top left hand

compartment that contains Item #6, the thirteen 0.1uF

capacitors. Remove the capacitors from their containers

carefully, making sure that they do not fly off and get

lost!

Using the PCB legend on the board together with the

parts list and schematic, locate the 13 circuit references

for this component type and, one at a time, solder them

to the PCB.

When you have all 13 parts soldered down, move onto

the next compartment on the right that contains Item #1,

the three 82pF capacitors. Solder these parts to the

PCB.

Next do Item 2, Item 3, Item 4 …and so on down the bag

until you have fitted all the parts from Bag #1.

Continuing With Bag #2

Likewise, turn Bag #2 around so that you are looking at it

like this with the “This Side Up” label in the bottom left

hand corner:

Item 21

1 x PZT2222A Item 36

1 x 1M Item 37

1 x 2M

Item 18

2 x MMBF2222AL Item 19

1 x MMBF3906LT1 Item 20

1 x MMBFJ309LT1

Item 42

1 x SA602AD Item 43

1 x LM386 Item 12

5 x RLS4148

Item 44

1 x L78L06 Item 10

4 x SS16 Item 11

1 x GF1G

Item 13

1 x 1uH Item 14

1 x 4.7uH Item 15

1 x 12uH

Item 16

1 x 22uH Item 17

1 x 27uH Item 7

1 x 1uF

Bag #2

This Side Up Item 38

2 x 15-50pF Item 39

1 x FT37-43

Using the same technique as for Bag #1, solder the

parts to the PCB one compartment at a time. Some of

the parts in Bag #2 are polarized. Make sure you align

the bar ends of the diodes (items 12, 10 and 11) with the

bar marked on the PCB legend before soldering them

down. Item #7, the 1uF capacitor, has one side painted

black. This is the negative end and should be at the

opposite end from the + symbol that’s marked on the

PCB legend. Pay careful attention to the alignment of all

the polarized components or your kit will not work!

Identification of pin one for the 8 pin SOIC chips. Locate

the LM386 chip. You will note a small indentation or dot

in one corner. That is pin one. Also, note that the edge

of the IC is beveled on that size. That indicates the side

with pin 1. Use this information to find pin 1 on the

SA602 and the L78L06 chips. Be careful to place them

correctly.

2000, Red Hot Radio – Unauthorized Copying or Publication Prohibited

5

10uF & 100uF Capacitors

Next, locate the 10uF and 100uF capacitors, items 8 &

9. Solder them in place on the PCB paying careful

attention to the polarization. The black end of the

capacitor is negative (-) and should be at the opposite

end from the + symbol on the PCB legend.

TX Output Transformer (T1)

The output transformer is bifilar wound on the toroid. It

is quite easily done. Take the toroid and the two pieces

of red and green wire. Hold the two pieces of wire

parallel and wind 6 turns on the toroid, counting one turn

each time you go through the toroid. When you finish,

prepare the ends of the wire by trimming them about 1

inch long at first. Then burn the insulation off to the

edge of the core, use a piece of sandpaper to get all of

the insulation off and make sure that you have bright

copper wire showing. Tin each of the four leads. Now,

trim each of the leads so that they are ¼” long. Solder

the toroid on the pads, making sure that you solder the

red leads to pads 1 & 2 and the green leads to pads 3 &

4. You must do this correctly.

Crystals

The crystals are through hole parts. Place them in the

position indicated and solder them in. The cases must

be grounded and we have provided a place to do this.

Find a cutoff resistor lead (sorry, but there are no leaded

resistors here, but you should have one around). Solder

it in the hole next to the crystal. Bend the lead over the

crystal and solder it to the case of the crystal. Do this

quickly so as to not kill the crystal!!

Pots

Next, solder in the pots. Make sure that they are fully

seated to the board. This is important when you mount

your SMK-1 in its case (You did order the case and

connectors from the NJ QRP Club didn’t you??).

Finally, solder in the two trim caps. They are the little

square orange devices from Bag #2. When you solder

them in, make sure that you orient them exactly as

shown on the silkscreen of the board.

Wiring Up

Wiring the connectors is simple. Use small gauge

stranded hookup wire and connect the speaker jack, key

jack, power jack and antenna jack of your choice to the

back of the board.

Testing

Now it is time to test your efforts. Attach a dummy load.

Then apply 12 volts. Check for smoke, and hopefully

there won’t be any!! Replace the dummy load with an

antenna. We will start with the receiver section. Plug in

a set of headphones. Peak TC1 first to make sure that

you have 2 peaks. Go for highest noise level or signal.

Next peak TC2 for loudest signal. Next do the

transmitter, and that is the easy part. Plug in a key, and

transmit. Monitor on another receiver to make sure that

you are putting out power.

If you have problems, go to qrp-l, and post your problem.

There are literally thousands of fellow qrpers there who

will be more than happy to help with your problem.

Operation

Test units of the SMK-1 have tuned from about 7.035 to

7.039.7 on the receiver, and 7.0375 to 7.039 on the

transmitter. Thus the transmitter is the limiting factor on

making contacts. Use a transceiver to verify which side

of your signal that you want to tune the receiver to. You

will soon learn that a dc receiver has two sidebands, and

that you want to be on the correct one to make contacts.

Verify the correct sideband on a transceiver, and then

note which way that you tune the receiver in relation to

the tone, (whether it goes up or down in pitch as you

tune). Don’t worry, you will soon get the hang of it. If

you have questions, again, get on qrp-l, someone will be

there to assist you.

Again, the purpose of this kit was to assist you in

learning how to work with surface mount parts. We

believe that it succeeds, and for a very modest cost.

The transceiver does work, and it is capable of making

contacts. It is not an ICOM 706 by any means though.

We will be coming out with a full featured single band

surface mount kit later, this kit is just for training and we

hope that you have enjoyed it.

Table of contents

Other NORCAL Transceiver manuals

Popular Transceiver manuals by other brands

Kenwood

Kenwood ProTalk TK-3201 instruction manual

City Theatrical

City Theatrical SHoW DMX SHoW Baby user manual

Standart Horizont

Standart Horizont HX407 owner's manual

B&G

B&G V90S quick start guide

VictelGlobal

VictelGlobal ALK300 series Operation manual

Cactus

Cactus Wireless Flash Transceiver V6 user manual