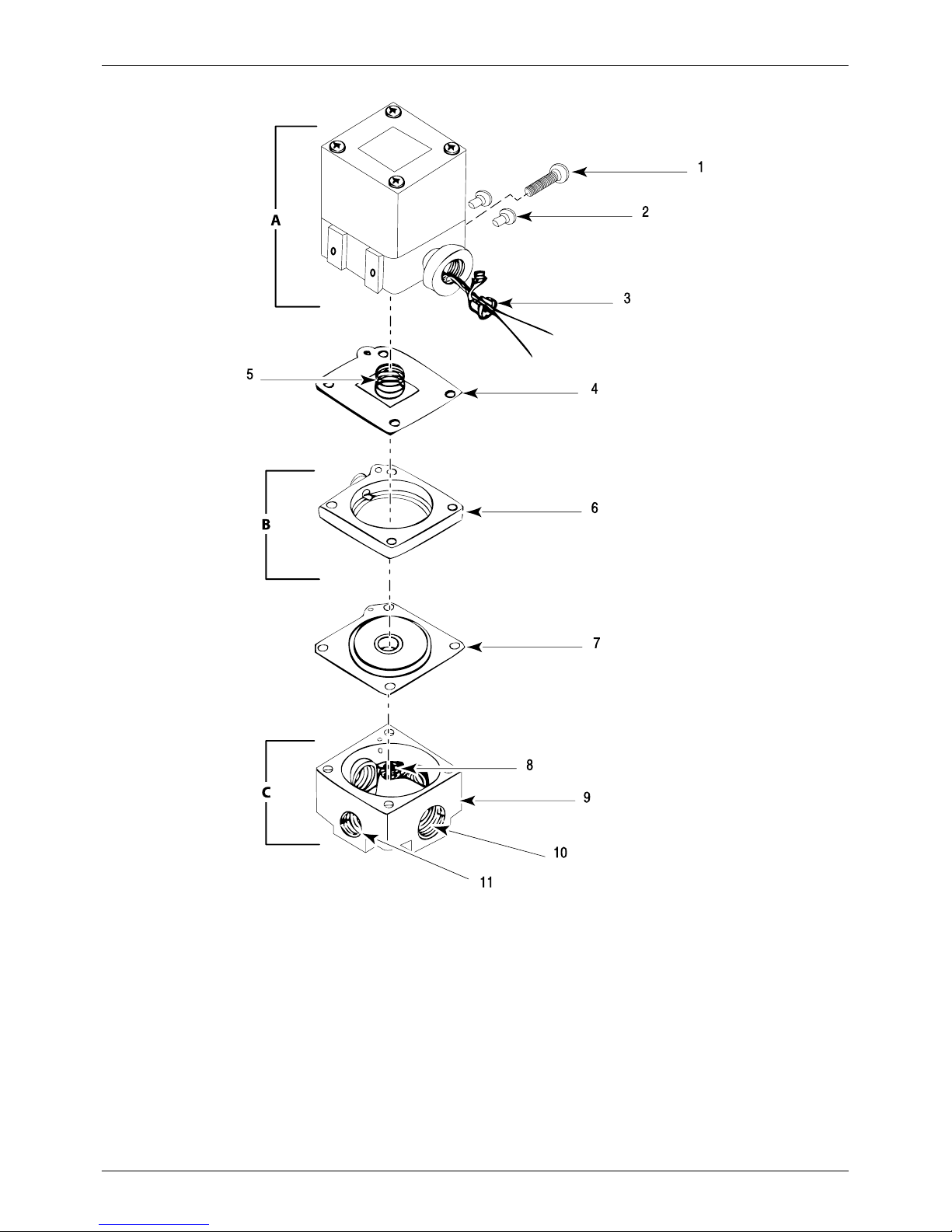

Series EPC-30 Current-to-Pressure (I/P) Transducer 9

Part 331276B02

E2010 Nordson Corporation

SPAN Adjustment

The SPAN adjustment potentiometer is located on the front of the

transducer. It is used to set the maximum pressure output. The minimum

and maximum pressure outputs must be checked each time an adjustment

is made. Follow these steps to calibrate the transducer:

1. Set the input signal to 4 mA.

2. Adjust the ZERO potentiometer until a proper setting is attained.

3. Set the input signal to 20 mA.

4. Adjust the SPAN potentiometer until a proper setting is attained.

5. Repeat steps 1−4 until the transducer is calibrated.

Field Troubleshooting

1. Verify that the supply air pressure is higher than the maximum output

pressure and the supply air is free to flow to the transducer.

2. Cycle the transducer from 4−20 mA several times and observe the

pressure output.

3. Apply 4 mA to the transducer and disconnect one or both of the leads.

After reconnecting the leads, make sure that there is a slight metallic

sound. This sound is caused when the coil jumps in the magnet, and it

indicates that the transducer has continuity.

4. Examine the SPAN potentiometer. If it does not show signs of damage,

then the electronic portion of the transducer is in good working

condition.

5. Apply 4 mA to the transducer and turn the ZERO potentiometer either

CW or CCW until the output pressure is 2 psi. The total deflection of the

coil from 4−20 mA is about .002”.

NOTE: If the ZERO potentiometer is turned CW (causing the nozzle to

move away from the flexure) to a point where the nozzle bottoms out

(approximately 1.00” away from the coil/flexure), it will take 30−50 turns

in the CCW direction before the pressure starts to climb.