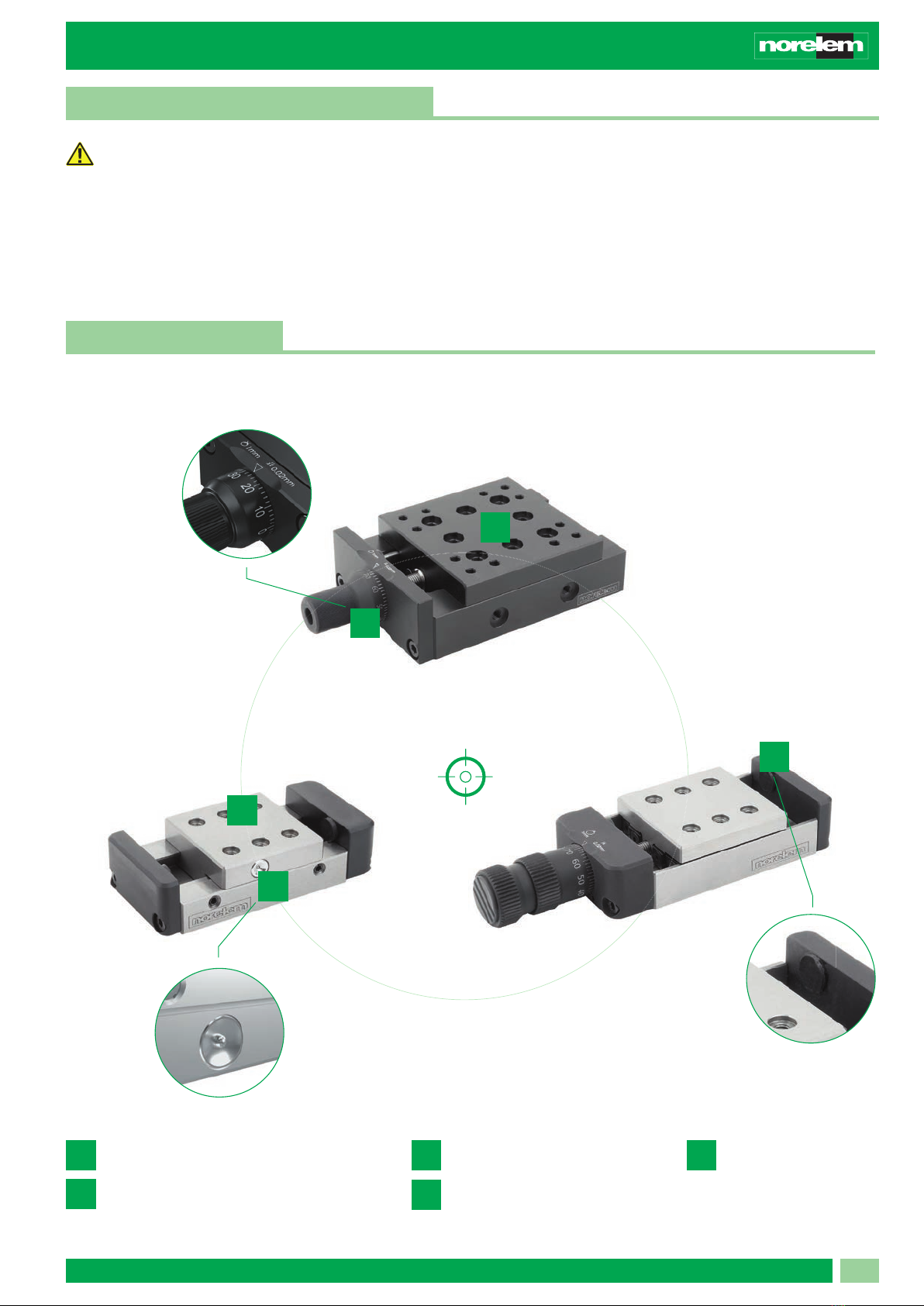

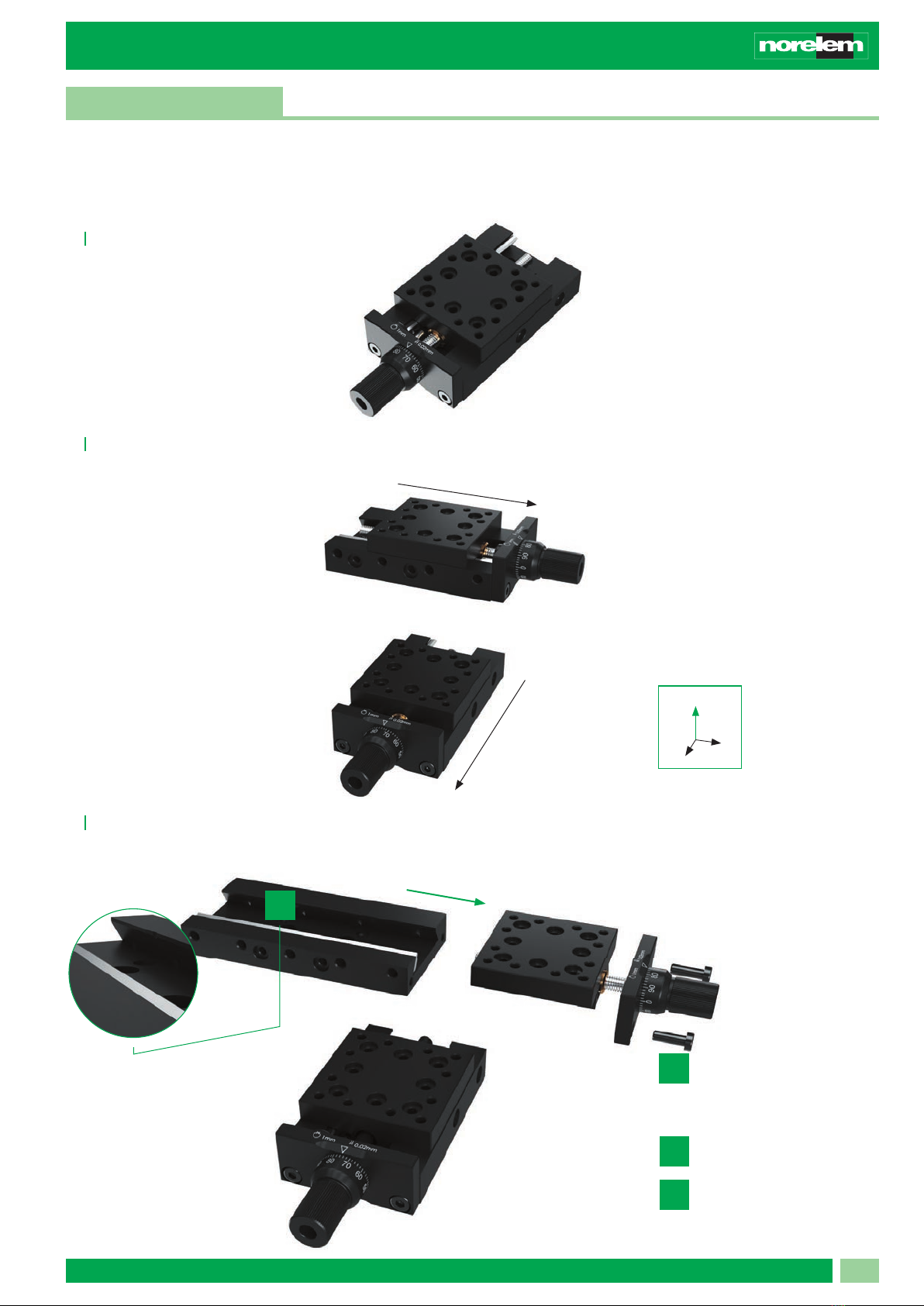

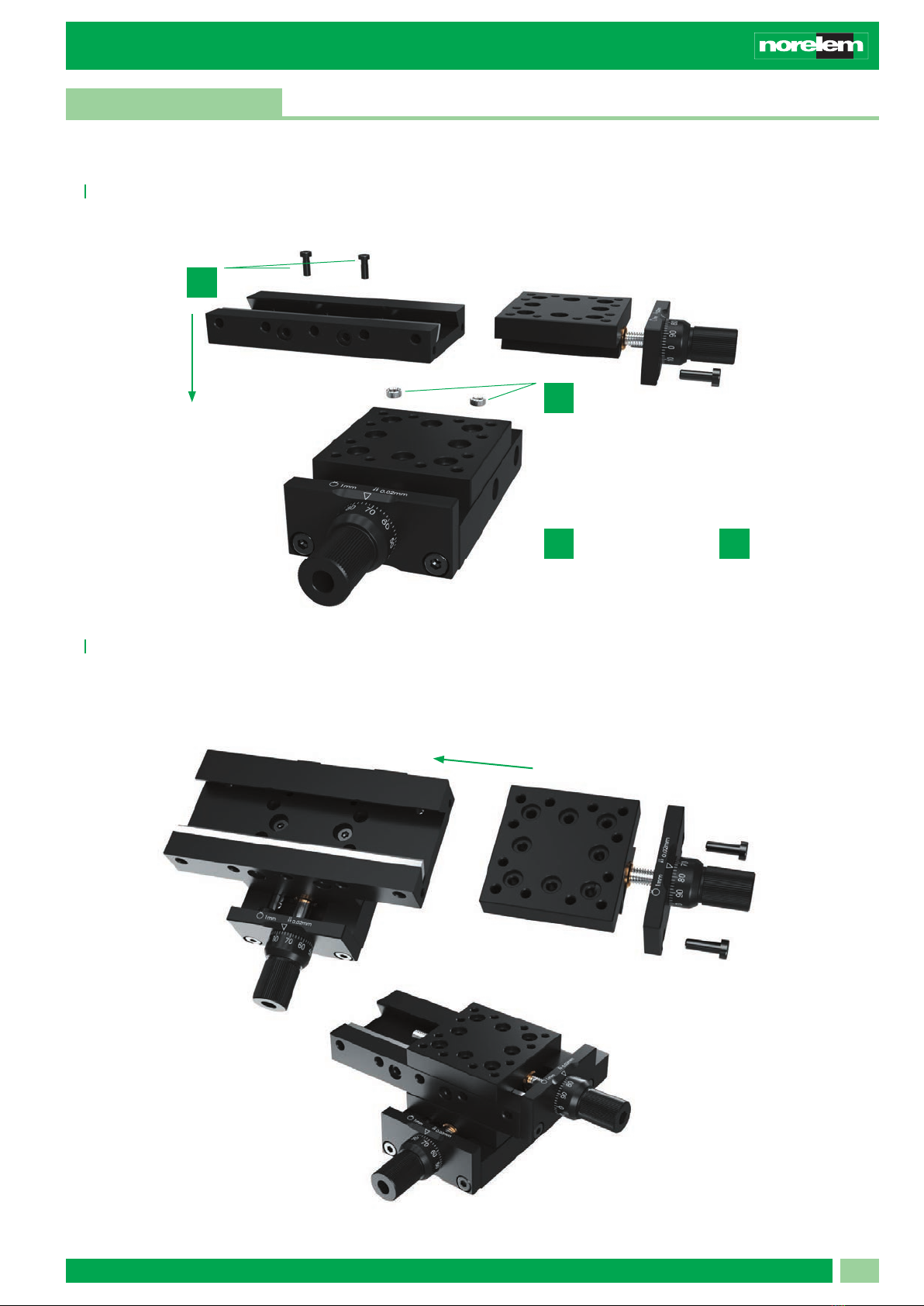

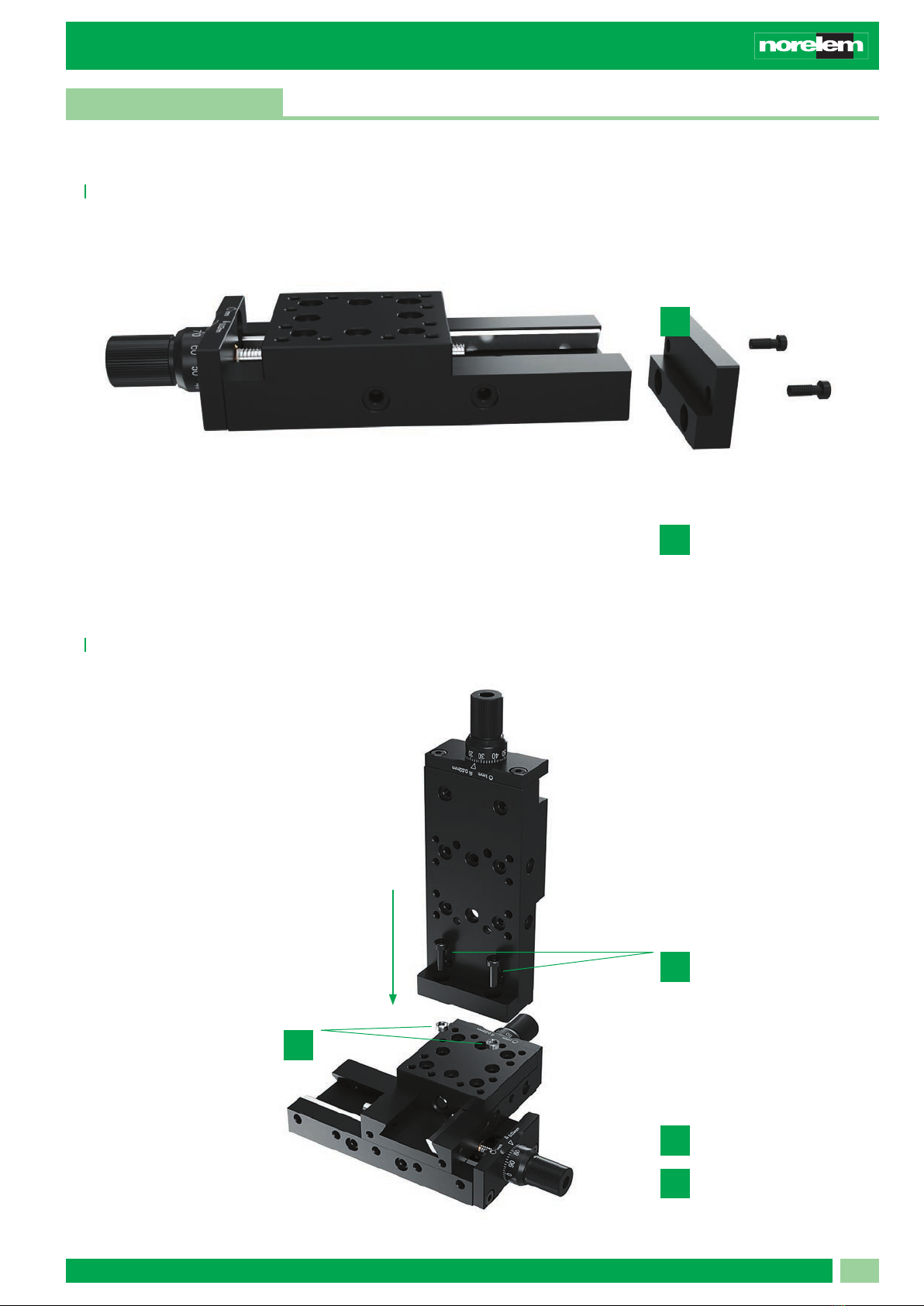

norelem 21010 Operating instructions

Popular Industrial Equipment manuals by other brands

Grundfos

Grundfos Control DC Safety instructions and other important information

Siemens

Siemens SIPROTEC 7VU681 user manual

Hitachi

Hitachi ABB RELION REB500 Communication protocol manual

Graco

Graco 25C483 Instructions-parts list

Fein

Fein GRIT GIB instruction manual

ABB

ABB Relion SMU615 Applications manual

Rittal

Rittal VX25 Ri4Power System Assembly instructions

TECHNOLOG

TECHNOLOG Cello 6S product manual

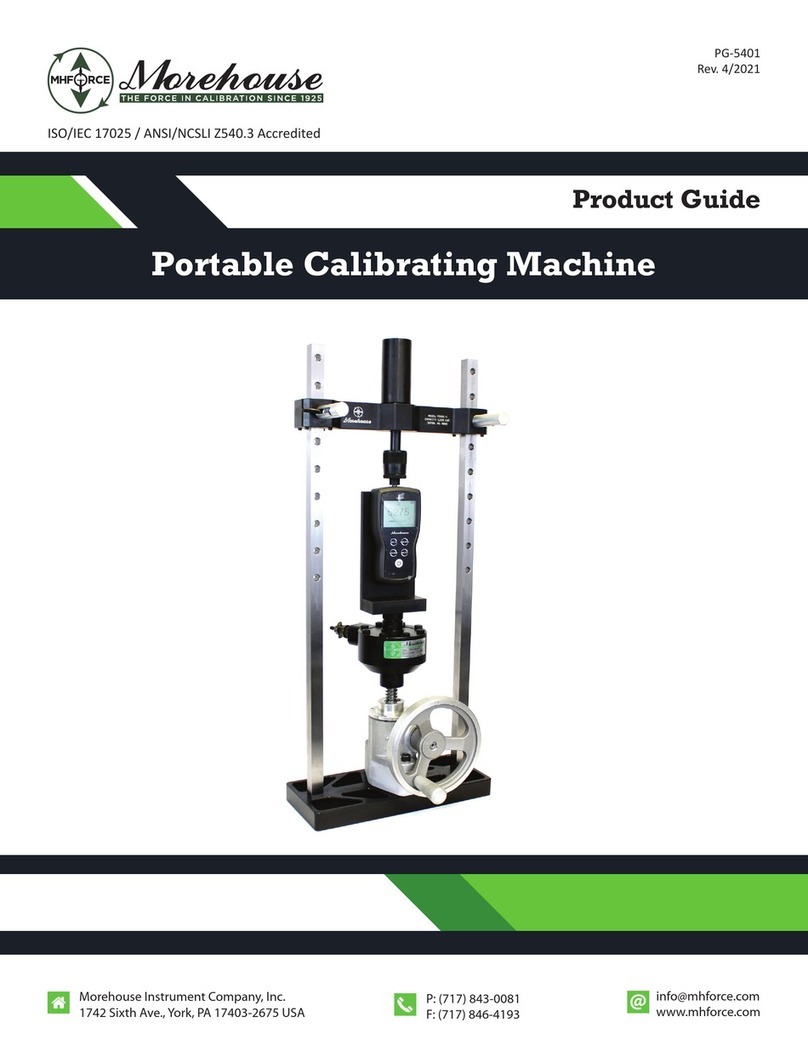

Morehouse

Morehouse PCM2K-2 Product guide

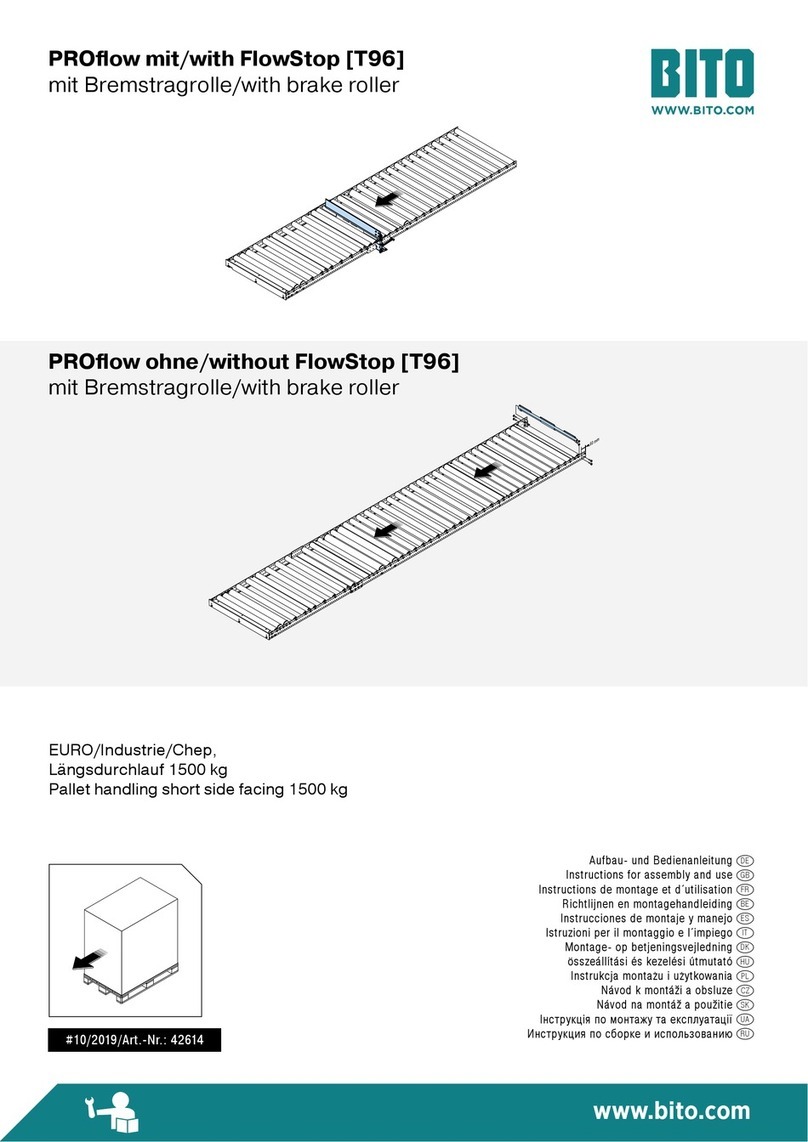

BITO

BITO PROflow with FlowStop T96 Instructions for assembly and use

Vestil

Vestil P-HOP Series quick start guide

Mitsubishi Electric

Mitsubishi Electric UBC75 Installation, operation & maintenance manual

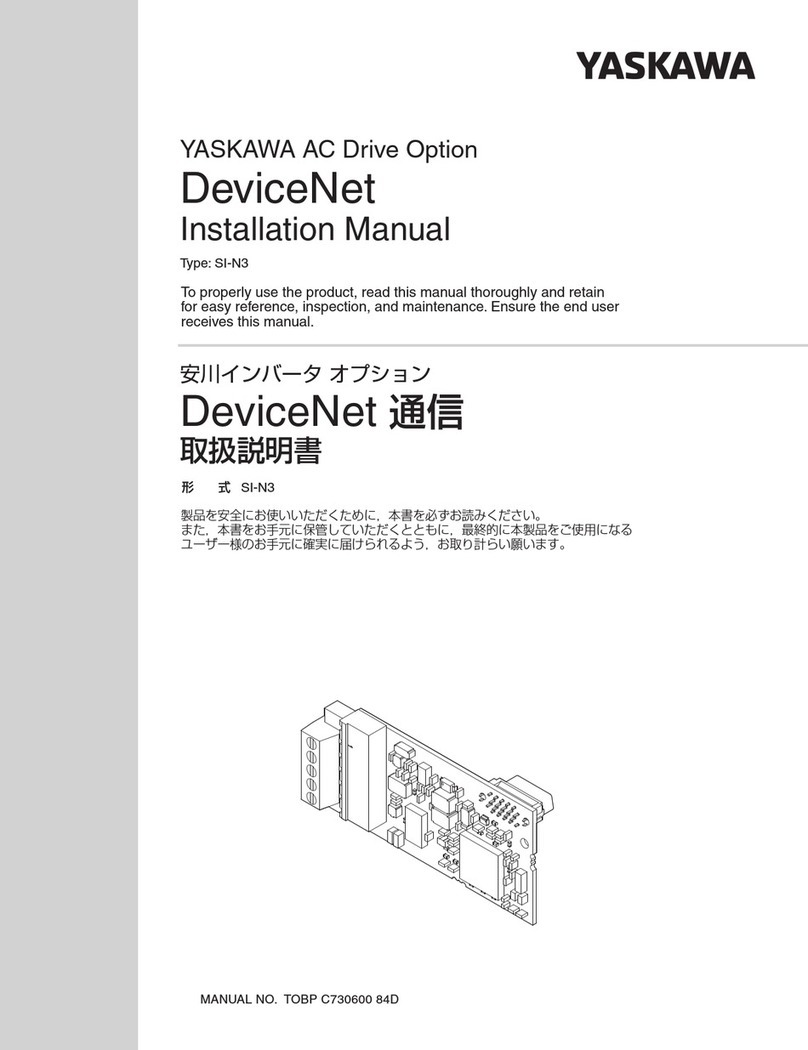

YASKAWA

YASKAWA DeviceNet SI-N3 installation manual

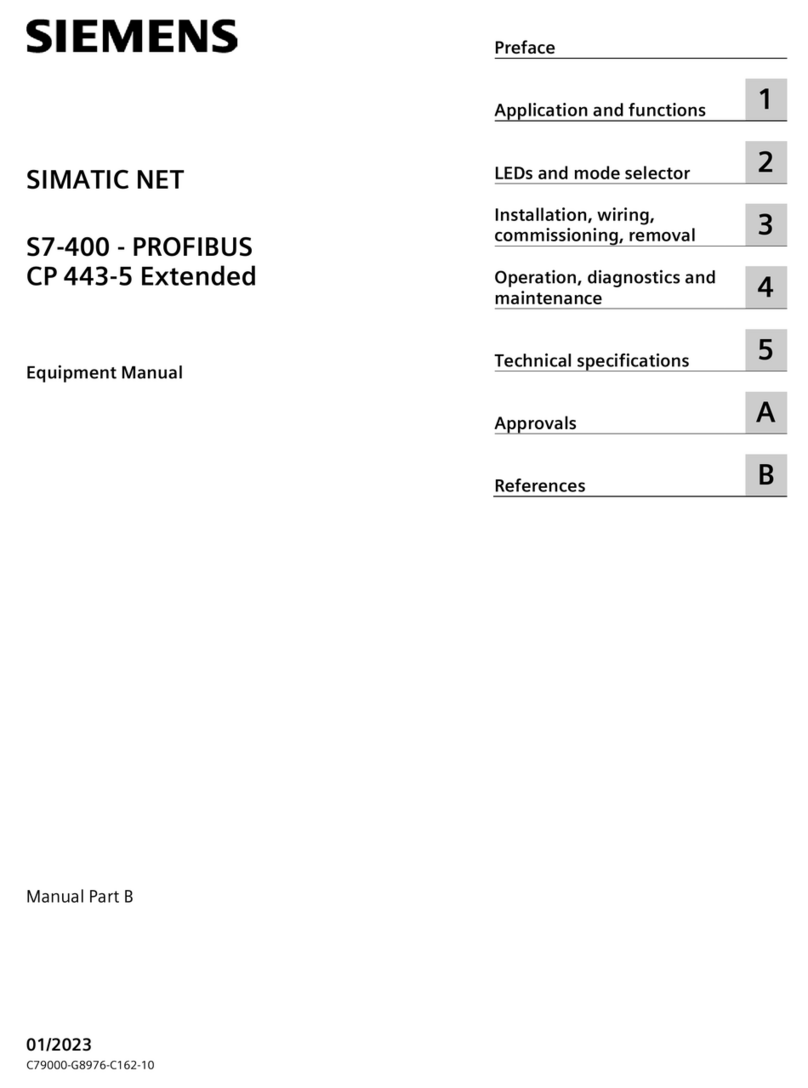

Siemens

Siemens SIMATIC NET S7-400 Equipment manual

ARS

ARS Flexibowl 200 Instructions for use and warnings

Eaton

Eaton Cooper Power VFI SF6 Installation, operation and maintenance instructions

IEMCA

IEMCA KID 80-IV Touch instruction manual

SCHUNK

SCHUNK ROTA FSW Series Assembly and operating manual