NOREMAT AXIONA Series User manual

SIDE ARM FLAIL MOWERS

Operator’s

MANUAL

Axiona - Prodigia

Left Hand Version

Eco-friendly printing on 100% recycled paper.

This book contains pictures that are not contractual.

Translation of the operator’s manual original version

Book ref : 132524 Index : -

Operator’s manual

Axiona - Prodigia

2

INDEX

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RECOMMENDATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

RESPONSIBILITIES OF THE USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GENERAL SAFETY RULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. Contact with oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Noise/dust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Before tting to the tractor/cv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Before starting the rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. Before leaving the tractor/cv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CHAPTER 1 : TECHNICAL CHARACTERISTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1. Technical specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Power and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Manoeuvrability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Standard equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Transport of the machine by lorry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unloading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3. Attachment of the machine to the tractor/CV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. First-time operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

Starting the rotor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Stopping the rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. Safety instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

Operator’s manual

Axiona - Prodigia

3

CHAPTER 2: OPERATION AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1. Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

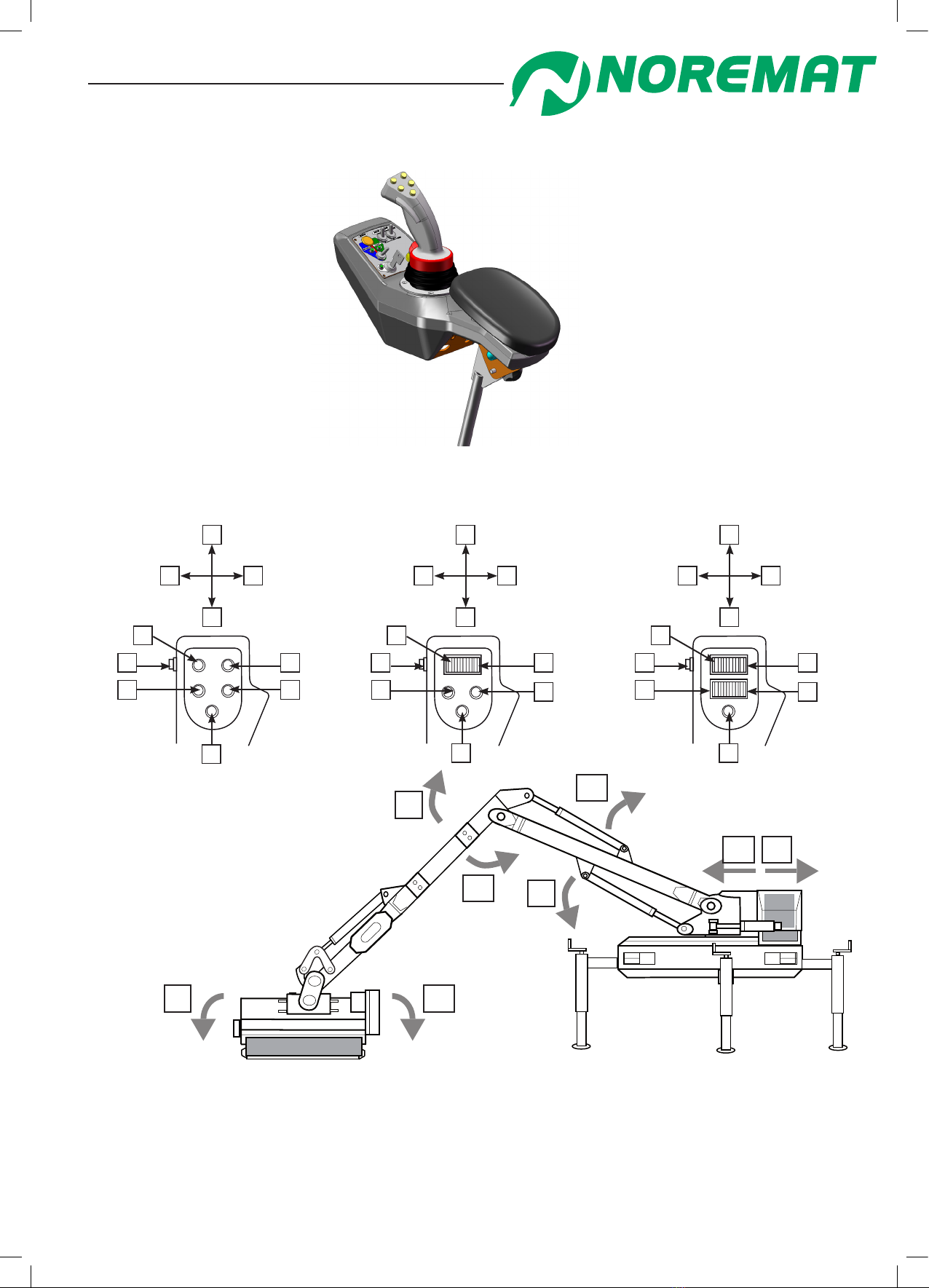

2. Identication of the control movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3. Identication of control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

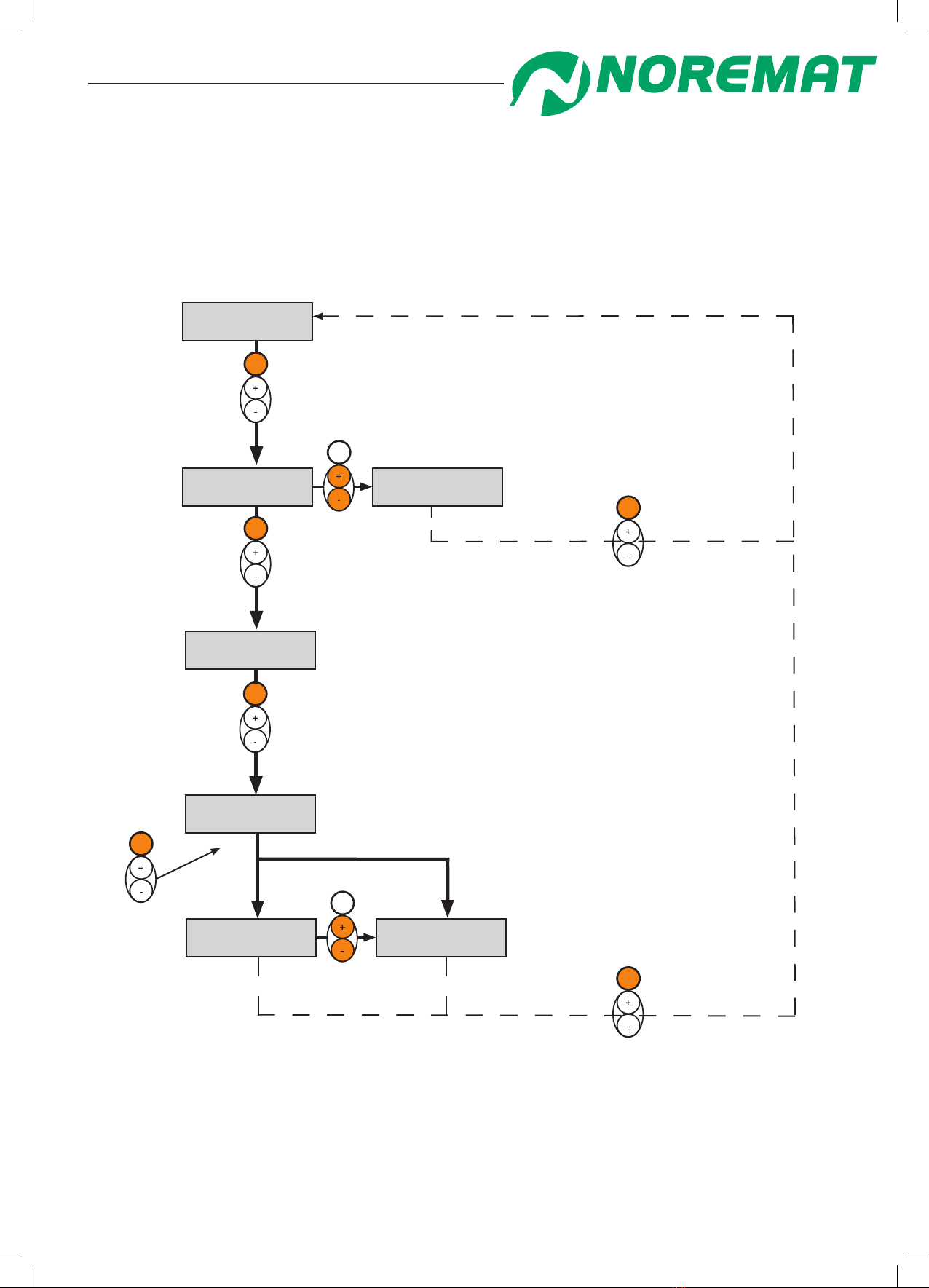

4. Use of the digital controls (Start - Joystick - Initialization - Measures - Hour counter). . . . . 18

5. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Transport position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Working position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.3 Choice of the working ground speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.4 Vibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.5 Work on the ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.6 Height work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6. Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Machine pressures adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Bolt tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7. Greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Recommendations about greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Greasing plan and intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.3 PTO driveshaft greasing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8. Oil changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1 Recommendations about oil changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8.2 Hydraulic circuit oil changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8.3 Oil lter cartridge replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.4 Gearbox oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.1 Daily maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.2 Replacement of the rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.3 Maintenance of the cutting tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

9.4 Maintenance of the accumulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

10. Attachment of the machine to the tractor/CV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11. Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13.1 Warranty application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operator’s manual

Axiona - Prodigia

4

INTRODUCTION

Congratulations on acquiring your new side-arm mower/ail-cutter*

Model

AXIONA - PRODIGIA

From it’s introduction, this machine has given the user, greater benets of ease of operation and

operating comfort not found in a rear mounted arm machine.

We hope that it will give you the satisfaction that you justiably expect and that motivated your

choice.

SAFETY ALERT SYMBOL

This symbol identies the important safety messages in the manual. When you

see it, take note about the risks, read the accompanying message carefully and

inform other users.

This specication and operation manual contains the information that will enable you to:

1.Familiarise yourself with your machine and take full advantage of it’s technical renements

in the best usage conditions.

2.Obtain optimum performance by simple, but strict observance of

the maintenance recommendations.

3.Deal with incidents that do not require the help of a specialist, without wasting time.

For the safety of any persons nearby, it is very important to follow

the advice given in this manual.

ATTENTION

Your side arm mower must NEVER be used as a lifting device.

*To help with the reading of this manual, the terms, ail mower and articulated side-arm mower are

covered by the word ‘machine’. Terms for ‘cutting head’, reciprocating knife etc will be referred to as

the ‘tool’.

This manual consists two chapters :

- Chapter 1 : Spare parts list Page 4 to 14

- Chapter 2 : Operator’s manual Page 15 to 27

Operator’s manual

Axiona - Prodigia

5

RECOMMENDATIONS

Your machine is likely to be tted to an agricultural tractor.

NOREMAT would like to draw your attention to the following points :

- Please refer to the relevant authority in your country or state for;

-required certicates of competence to drive and use a tractor/mower combination on

the public highway or other;

-related Health and Safety regulations and requirements.

Road trafc

In France, the driving of a tractor is subject to obtaining a HGV driving licence, except for drivers

working in agricultural or forestry environments such as agricultural contractors. (art. R221-20 from

the trafc rules)

Driving of Machines (directive 98-1084 from 02/12/1998)

The driving of a tractor equipped with a side-arm ail mower is subject to the express written

authorisation of the employer. The driver must attend and satisfactorily pass a training course to

establish his/her knowledge of the machine and competency to operate it. Obtaining the CACES

(certicate of professional competency) ensures that the driver is adequately trained.

The job in hand and the use of your machine, just like the whole tractor will necessitate a period of

acclimatization.

NOREMAT will assist you with information and advice.

It is recommended that you make contact with a NOREMAT technician to establish your informational

and instructional needs in relation to the machine and it’s use.

Furthermore, it is desirable that each user can benet from the experience and expertise of

NOREMAT, your Direct-Constructor.

Operator’s manual

Axiona - Prodigia

6

RESPONSIBILITIES OF THE USER

The user is responsible to adhere strictly to the safe-use regulations

and safety points which are dened in this manual.

As with the driving of all machines, the user must match his speed

of travel in the transport position or during work, to the condition of

the roadway or terrain.

Before carrying out any operation with your machine, you are advised to read this section carefully.

All modications carried out on the machine are the sole responsibility of the person instigating them.

To use the machine for mowing (rotor turning in the opposite direction to the tractor wheels), it is

imperative that the front hood and aps are tted to avoid the risk of debris being thrown from the

rotor.

example of

hood and aps

If these regulations are not respected, responsibility lies with the user alone.

Operator’s manual

Axiona - Prodigia

7

GENERAL SAFETY RULES

It is essential to follow the instructions in this manual to ensure the

safety of persons operating or in the vicinity of the machine.

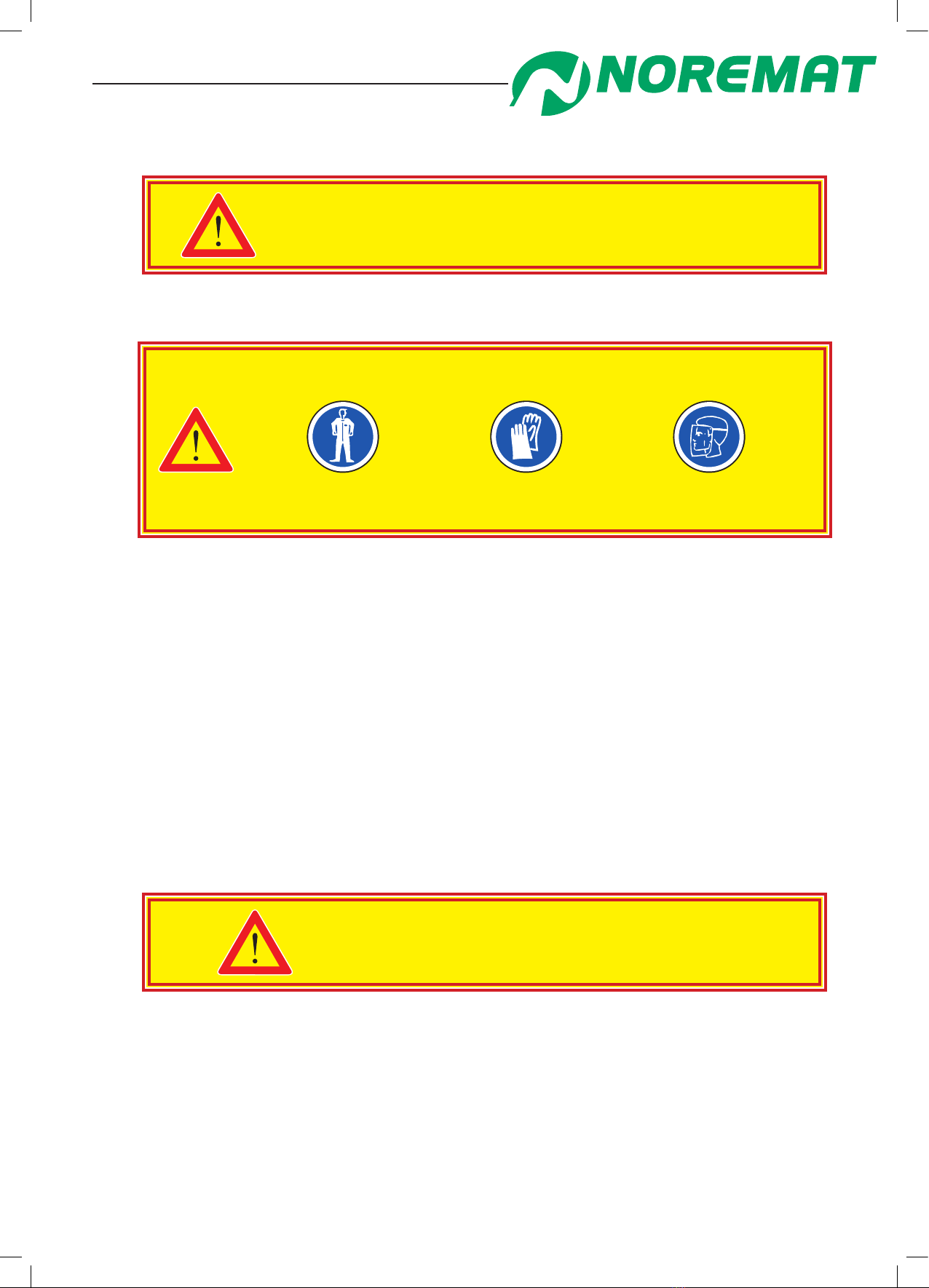

1. Contact with oil

At the time of oil changes or when working on any components which

may retain hydraulic pressure, ALWAYS wear adequate safety equipment

Body

Protection

Gloves Face

Visor

-In the event of contact with the skin:

If a high pressure jet of oil is applied to the skin there is a danger of the oil penetrating

the surface. The injured person should be taken to hospital even if no wound is apparent.

Remove all contaminated clothing. Wash the suspected area immediately with plenty of soap

and water.

-In the event of contact with the eyes:

Wash immediately with plenty of water. Hold the eyelids apart for at least 15 minutes.

-Ingestion:

Risk of vomiting and diarrhoea. Do not make the person drink to avoid the risk of inhalation by

the respiratory tracts. Do not drink water.

-Aspiration:

If there is a suspicion that the person may have inhaled oil into the lungs (when vomiting for

instance), take them to hospital immediately.

In all cases seek immediate medical attention

Operator’s manual

Axiona - Prodigia

8

2. Noise

Take necessary precautions against the risk

of exposure to noise and dust during working

and travelling periods.

Wear Ear

Defenders

3. Vibrations

To improve safety and health conditions of workers, the decree 2005-746 from July 4th, 2005 forces

the employer to evaluate the levels of exposure of its employees to the vibrations transmitted to the

whole body, and to start protection of the driver beyond exposure limit values.

These daily exposure limit values are precised in the article R 231-119 of the Labour regulation.

Noremat carried out trial runs to evaluate the level of vibrations emitted by a tractor /machine unit and

transmitted to the operator’s seat. As an indication, the median value recorded is 0.45m/s2 per eight

hours base period in normal work conditions as recommended by the manufacturer.

4. Heat

According to employment regulations, the employer must take measures to limit to the minimum,

employee’s exposure to noise.

Recommendations concerning employee’s exposure to noise.

Taking into account that the tractor cab noise level may vary;

- If the daily level of exposure to noise reaches or exceeds 80dB(A),

the employer must supply ear defenders to the driver to limit that noise.

- If the daily level of exposure to noise reaches or exceeds 85 dB(A)

the employer has to ensure that ear defenders are worn.

Take necessary precautions against the risks

due to the heat released by the hydraulic

components (hoses, pump, motor, gearbox,

valve block, rotor shaft).

Wear heat

protection

5. Delivery

Observe safety and handling rules, in particular:

-only use designated slinging points for all slings.

-never lift the machine with slings that are in poor condition or are too weak in lifting capacity.

-check that the means of lifting is satisfactory and suitable to lift the load.

-never stand or walk under the load.

-never attempt to remove the delivery supports (blue pieces) before tting

of the machine has been completed.

Operator’s manual

Axiona - Prodigia

9

6. Before tting to the tractor/cv

-It is necessary that the tractor is equipped with a cab or means of protecting the driver from possible

debris thrown from the tool.

-Check the condition of the PTO shaft guard on the tractor.

-Carefully read the tting instructions supplied with the drive shaft.

-Check all tyre pressures.

7. Before starting the rotor

-Read chapter 2, section 3, ‘Identication of controls’.

-Read the operator’s manual for the tool to be used.

-Do not start the machine in an explosive atmosphere or near inammable items.

-It is recommended that the rst trial be carried out on ground which is rm, at and without

obstacles.

-Ensure that the operator is familiar with the tractor/machine combination.

-Check that the control unit is mounted securely in the cab/on the tractor.

-Never start the rotor if anyone is standing within the trajectory of possible debris thrown from the

rotor.

-Ensure that all persons remain outside of the working area of the tractor and machine.

-Never remove the front hood of the cutting tool during work when mowing (direction of rotor opposite

to the forward motion of the carrying vehicle, see chapter ‘User responsibilities’).

8. Before leaving the tractor/cv

Before leaving that tractor/cv or allowing anyone to approach, it is imperative to:

- lower the tool to the ground.

- stop the rotor.

- stop the PTO.

- switch the machine off.

- apply the parking brake.

- stop the tractor engine.

General Safety Rules

As for all work, observe the safety instructions.At worksites it is recommended

that persons in the immediate vicinity do not approach the area of work, and in

particular from within the trajectory of possible projectiles thrown by the rotor.

10

Axiona - Prodigia

Technical Characteristics

1. Technical specications

1.1- POWER AND FEATURES :

1.2- WEIGHTS

Maximum tool weight at the end of arm : 300kg,

except with written permission from NOREMAT.

1.3- PERFORMANCES

4.5 m 5.0 m

L Maximum lateral reach* 4.5 m * 5.0 m *

VVertical reach 5.6 m * 6.1 m *

TBank reach 4.47 m * 5.0 m *

HOver-hedge reach 3.71 m 4.1 m

FDitch reach 3.0 m 3.5 m

I Minimum lateral reach 1.75 m

Orientation angle 102 °

Tool orientation 230°

Measured from the centreline of the tractor.

Average dimensions, variable according to the type of tractor.

1.4- MANOEUVRABILITY :

Type of pump 14cc geared (Axiona)

17cc geared (Prodigia)

Hydraulic ow : AXIONA 26 L/mn

PRODIGIA 36 L/mn for 540 rpm and 42 rpm for 1000 rpm

General pressure at work (pump exit) : AXIONA 210 bars

PRODIGIA 210 bars

NOTA :These indications of pressure are detailed in part 5.1, chapter 2.

1.5- STANDARD EQUIPMENT

Filtration, hydropneumatic suspension, adjustable stands, rear bumper with lights, oat.

AXIONA PRODIGIA

Gearbox ratio 3,45 4 2.5

Power Take Off speed 540 rpm 540 rpm 1000 rpm

Pump turning speed 1860 rpm 2160 rpm 2500 rpm

Type of pump Geared Axial pistons

Flow 81 L/mn 60 L/mn 70 L/mn

Maximum pressure 210 bars 345 bars

Power 31.6 kW (43 HP) 34 kW (47 HP) 40 kW (54 HP)

Tank capacity 80 L 80 L

Rotor control Mecanical Electrical

Time of rotor emergency stop Less than 3 sec.

45 Arm 50 Arm M45 Arm

850 kg 865 kg 875 kg

4.24

4.09

5.37

2.05

4.22

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

Echelle :1:50

Tolérance générale sauf

indications particulières :Js13

166, rue Ampère - ZI - BP 93

54714 LUDRES CEDEX

Tel: 03.83.25.69.60

Fax: 03.83.26.12.85

Ce plan est la propriété de la société NOREMATet ne

peut être reproduit ou communiqué sans son autorisation.

Désignation :

Format: A3

Planche: 1/1

Code :

Matière:

Date:

Poids: 6028.59 kg

C_PR2_MAN001

Indice:

E

F

5

6

7

8

Dess :

VOIR

DETAILS

Technical Characteristics

11

Axiona - Prodigia

2. Transport of the machine by lorry

The machine should be secured to the lorry in such a way as to

guarantee absolute safety for nearby persons and equipment.

See Safety Rules on Page 5.

Precautions for carriage when not tted to a tractor or carrying vehicle:

It is essential to lock the arm with the locking kit (blue supports)

supplied with the machine.

Contact NOREMAT who can supply you with the correct locking kit.

For safety reasons, the equipment is delivered in the ‘delivery’ position. In this position, machine

movements are locked by supports that serve both for lifting the machine and for anchoring it

to the lorry.

These supports are identied by their unusual blue colour.

When it is delivered, the machine is unloaded and placed on the ground on it’s stands at the correct

height to be tted to a standard tractor.

The supports should not be moved until the machine is tted to the tractor and started.

The locking bar may be equipped with a shackle (adapted to the weight it will lift).

Use only the indicated lifting point to lift the machine, necessary lifting capacity at that point is 1000kg

(1250kg with mowing head)

Loading:

- Move the arm to the back

- Place the mowing head in the recommended position.

- Place the rst-, and second arms so that you can install the locking bar.

- Adjust stands and then dismount the machine from the tractor

- Install parts tted for forklift ( kit available as an option)

- Lift the machine by the designated lifting point.

- Turn the stands to 90°, machine can then be loaded.

General Safety Rules

Technical Characteristics

12

Axiona - Prodigia

Unloading :

□ Lift the machine with the help of a suitable gantry crane (fork truck : use only if the necessary kit is

tted to the machine)

□ Move clear of the lorry and t the adjustable stands to the machine.

□ Lower the machine slowly. Before it touches the ground, adjust the stands so that it will remain

level.

□ Place the machine on the ground.

□ Remove the parts tted for adapting it to the fork truck lifting means.

□ Mount the machine on the tractor (stands can be removed, see procedure).

□ Remove locking kit (if necessary by moving lightly the arm).

Forklift kit : 109997

PRODIGIA M45 AXIONA-PRODIGIA 45/50

Lifting-means Lifting-means

Locking kit

110017

Technical Characteristics

13

Axiona - Prodigia

3. Attachment of the machine to the tractor/CV

See chapter 2, part 9, page 25.

4. First-time operation

As for all work, observe the safety instructions.

It is desirable for a new operator who may already be familiar with the operation of the tractor/cv to

acquire experience in an area which is smooth, at and free of obstacles where he may concentrate

fully on the operation of the machine.

It is essential to stop the rotor before stopping the PTO shaft (no warranty claims will

be considered if this procedure is not strictly adhered to).

PRODIGIA AXIONA

Starting the rotor

Engage the PTO.

Start the engine and set to a speed

approximately 500 rpm below the required

speed for your choice of PTO speed.

Extend the arm and lower the tool to the

ground in the working position.

Select the direction of rotation and engage

the rotor. Allow a warm up time of several

minutes.

Allow the machine to run at the speed

recommended by your NOREMAT technician

for several minutes. This is very important in

temperatures of less than 5 degrees C.

Increase the engine speed

PROGRESSIVELY to the gure given by

your NOREMAT technician at the time of

installation/test.

No warranty claims will be considered

if this procedure is not strictly adhered to.

Engage the PTO.

Extend the arm and lower the tool to the

ground in the working position..

Select the direction of rotation to the right

(scrub clearing) to the left (grass cutting), with

idled engine speed.

Allow the machine to run at the speed

recommended by your NOREMAT technician

for several minutes. This is very important in

temperatures of less than 5 degrees C.

Increase the engine speed

PROGRESSIVELY to the gure given by

your NOREMAT technician at the time of

installation/test.

No warranty claims will be considered

if this procedure is not strictly adhered to.

Stopping the rotor

Decrease engine speed by approximately

500 rpm.

Stop the rotor.

DECREASE the engine speed

PROGRESSIVELY until idle.

Put the rotor lever in the neutral position

(Stopping the rotor).

Technical Characteristics

14

Axiona - Prodigia

5. Safety instructions

□ Ensure that the operator knows and understands the operation of the machine and tractor.

The two have to be operated simultaneously what requires practice. If this is not the case, the operator

should choose a piece of at ground without people or obstacles on it to practice.

□ Never work in an explosive or inammable atmosphere.

□ Only work with good lighting, natural or articial.

□ Never work with any safety guards or covers removed.

□ Never start the machine if it is not in good working order and especially if any safety guards or covers are not

in place.

□ When using the machine for mowing. (ie rotor turning in opposite direction to forward travel of tractor wheels)

it is essential that the front hood and aps be tted to prevent the risk of any material being thrown by the

rotor.

□ Never leave the rotor turning if a person could be in the path of any material that could be thrown out by it.

□ Never move the arm if any person could be within the machine’s operating area.

□ Do not stand or walk under the machine.

□ Never insert branches or objects by hand during operation of the rotor.

□ Always make sure that all hydraulic components and ttings are not under pressure before removal.

BEFORE DOING ANY WORK ON THE MACHINE :

- lower the tool to the ground

- stop the rotor.

- stop the PTO.

- stop the tractor / cv’s engine.

- place the gear lever in neutral and apply the parking brake.

- ensure that all hydraulic cylinders, hoses etc are not under pressure.

- to be sure, operate all sections on the main valve block in both directions

with the manual lever provided.

Relieve any pressure in the accumulator before carrying out any maintenance.

To be sure, open the valve situated behind the reservoir in the case of machines not equipped with electric

accumulator command.

For machines equipped with electric command, the procedure is as follows:

- start the engine and engage the PTO.

- switch on the machine.

- lower the tool to the ground.

- switch on the <ACCU> switch on the control panel.

- move the control lever forward as if to lower the rst-arm.

- switch off the <ACCU> switch on the control panel.

ANY OTHER PROCEDURE IS NOT ACCEPTABLE OR SAFE

The oil tank is under 0.3 bar of pressure. Before any work on the machine, please make sure components are

no more under pressure by removing the tank cap, taking care about temperature and pressure.

ATTENTION, the machine uses a hydraulic accumulator which may still be under pressure

Before using your mower/ail-mower it is important to read these safety rules.

Operation and Maintenance

15

Axiona - Prodigia

1 - Frame

2 - Arm pivot assembly

3 - First-arm

4 - Second-arm

5 - Tool pivot bracket

6 - Transfer link bracket

7 - Angle transfer bracket

8 - Cutting tool

9 - Machine orientation cylinder

10 - First-arm cylinder

11 - Second-arm cylinder

12 - Tool orientation cylinder

AXIONA - PRODIGIA

1. Description of machine

1

2

3

4

5

6

7

12

10

11 9

8

REP

Production/Quantit

é

CODE

IND

DESIGNATION

EXTENSION

11

bati-s

21

pivot-s

31

fleche-s

41

balancier-s

51

pivot

groupe-s

61

116560-s

---

CONTREBIELLE

MOULEE

72

114061-s

---

DESI

-----

81

118827-s

---

DESI

-----

92

116615-s

10 2

116616-s

11 2

116617-s

12 2

116626-s

13 1

Reform

mounty

Pneus 425-55

R17

---

DESI

-----

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

Echelle :1:20

Tolérance générale sauf

indications particulières :Js13

166, rue Ampère - ZI - BP 93

54714 LUDRES CEDEX

Tel: 03.83.25.69.60

Fax: 03.83.26.12.85

Ce plan est la propriété de la société NOREMATet ne

peut être reproduit ou communiqué sans son autorisation.

Désignation :

Format: A3

Planche: 1/1

Code :

Matière:

Date:

Poids: 5977.88 kg

C_PR2_MAN002

Indice:

E

F

5

6

7

8

Dess :

VOIR

DETAILS

Operation and Maintenance

16

Axiona - Prodigia

2. Identication of the control movement

3B

3A

4B 4B 4B5A 5A

5A

4A 4A 4A

3A 3A 3A3B 3B 3B

2B 2B 2B

2A 2A 2A

1B 1B 1B

5B 5B5B

1A 1A 1A

4A 4B

2B

2A

1B 1A

Digital control

2 proportional

movements

Digital control*

3 proportional

movements

Digital control**

4 proportional

movements

*option : Thumbwheel for the head proportional movement (4A/4B)

Operation and Maintenance

17

Axiona - Prodigia

3. Identication of control

1 13

2

14

3

15

4

16

5

17

6

18

7

19

8

20

9

21

10

11

12

9

8

7

5

21

20

16

15

14 13 12 11 10

18

2

13 3

19

4

6

17

Power up light

Green = correct battery

Orange = low battery

Red = polarity inversion

Ignition

Option B light

Float light

Display

Accumulator switch

Float switch

Option B switch

Rotor switch

Option A switch

Sustentation switch

Rotor direction light

Rotor direction selection

Emergency stop

Fault indicator light

Sustentation adjustment

Buttons to browse in the menu

Selection and conrmation button

Sustentation light

Option A light

Accumulator light

Operation and Maintenance

18

Axiona - Prodigia

The use of your control is made by the Menu/OK button and the + and – scroll buttons.

Remark: At the rst start or by the change of a component, the joystick is maybe not initialized, there cane b an

error. Do not force the start (risk of uncontrolled movement). Follow the procedure «Joystick initialization»

START

Turn the ignition key. An auto-test is running to check the system, wait.

Before forcing the start, check the reason of the error by looking the events list and try to x it.

The 256 last events are viewable by browsing with the buttons + and -.

In case of problem, take contact with your NOREMAT technician/dealer to organize a visit.

*

There are 3 main check points with message change every 3 seconds.

*

4. Use of the controls

NOREMAT

VERSION 1.73

AUTO-TEST

RUNNING .A1

AUTO-TEST

OK .A3

VOLTAGE .C1

12.1 Volts

OIL T° .C3

23°C

AUTOMATIC RETURN

ON .R6

AUTO-TEST

ERROR .A2

FORCE START

A4

QUIT

B7

OK

OK

OK

OROR

OK OK

Operation and Maintenance

19

Axiona - Prodigia

JOYSTICK INITIALIZATION

It is necessary to initialize the joystick when it’s replaced or one of the components (thumbwheel).

To do this, the user access code (1111) has to be previously entered.

Move the joystick and the

optional thumbwheel.

SET UP

A6

JOYSTICK

INIT. .D8

KEEP IN NEUTRAL

AND CONFIRM .D8

MOVE PROP

AND CONFIRM .D9

CANCEL

B6

SAVE

B9

CANCEL

B6

OK

OK

OK

OK

OK

OK

OK

OK

Operation and Maintenance

20

Axiona - Prodigia

MEASURES (DEpENDINg ON OpTION)

It is possible to make some measures coming from the different sensors tted on the machine.

See details

page 23

Options

MEASURES

A5

HOUR COUNTER

A8

BATTERY VOLTAGE

MEASURE .CO

VOLTAGE .C1

14.20 VOLTS

OIL T°

MEASURE .C2

OIL T° .C3

00.0°C

OIL PRESSURE

MEASURE .C4

ROTOR PRESSURE

MEASURE .C5

ROTOR P .C6

BARS

MVT P .C8

BARS

MVT PRESSURE

MEASURE .C7

OK

OK

OK

OK

OK

OK

OK

OK OK

This manual suits for next models

6

Table of contents

Popular Lawn Mower manuals by other brands

Cub Cadet

Cub Cadet RZT 54 Limited warranty

AMBROGIO

AMBROGIO BASIC user manual

Walker Rider Lawnmowers

Walker Rider Lawnmowers MBS26 owner's manual

Cub Cadet

Cub Cadet CC 46 ES Operator's manual

Dixie Chopper

Dixie Chopper Vortex 2008 Installation & owner's manual

AGCO Allis

AGCO Allis 1691815 Operator's manual