Norfield 1020 User manual

1

1020/1020K DOUBLE END TRIM SAW

PRODUCTAND OPERATIONS MANUAL

DOCUMENT NUMBER 17-245

Eff. S/N TS-1902

Rev 6

Release 0

2

Norfield Industries

P.O. Box 459

Chico, CA 95927

SERVICE: (530) 891-4214 PARTS: (800) 824-6242

Serial No:

Date Sold:

Norfield Industries is the name that represents Quality, Reliability, Support, Innovation and

True Customer Service. We have been dedicated to providing quality products and excellent

customer service for more than 40 years. Norfield Industries has earned a reputation in the

pre-hanging industry for setting standards for reliable machinery, full technical support,

machine parts, full line industrial woodworking tools and supplies and a team of customer

care representatives to support you! Our factory-trained technical personnel are ready to

assist you on the telephone or in your shop.

3

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................................................................3

INTRODUCTION ........................................................................................................................................6

SAFETY INFORMATION...........................................................................................................................7

SPECIFICATIONS ....................................................................................................................................10

INSTALLATION........................................................................................................................................ 11

1.1 SHIPPING DAMAGE AND SHORTAGES............................................................................................11

1.2 INSTALLATION ....................................................................................................................................11

1.3 POSITIONING THE 1020 DOUBLE END TRIM SAW ........................................................................11

1.4 LEVELING .............................................................................................................................................12

1.5 ELECTRICAL ........................................................................................................................................12

1.6 AIR SUPPLY AND CONNECTION.......................................................................................................13

1.7 REGULATOR SETTING AND TYPE OF OIL .....................................................................................13

1.8 DUST COLLECTOR (OPTIONAL).......................................................................................................13

1.9 BASIC INSTALLATION ADJUSTMENTS...........................................................................................14

1.10 MAJOR COMPONENTS AND CONTROLS.......................................................................................16

OPERATIONAL SETTINGS..................................................................................................................... 17

2.1 QUICK-START GUIDE .........................................................................................................................17

2.2 SETTING THE MACHINE TO DO MITER CUTS OR END CUTS ....................................................19

2.3 SETTING UP TO CUT DIFFERENT LENGTHS OF MATERIAL......................................................19

2.4 SETTING UP TO CUT DIFFERENT WIDTH MATERIALS...............................................................20

2.5 RESETTING THE CRUTCH TIPS FOR DIFFERENT WIDTH MATERIAL.....................................21

2.6 SETTING UP TO CUT MATERIAL OVER 3" WIDE..........................................................................22

2.7 SETTING UP FOR DIFFERENT THICKNESS MATERIAL...............................................................23

2.8 SETTING THE UNDERCUT ANGLE OR SILL BEVEL......................................................................24

2.9 OPERATING THE KERFING UNIT.....................................................................................................24

2.10 RESETTING THE EMERGENCY STOP SWITCH............................................................................25

ADJUSTMENTS ........................................................................................................................................26

4

3.1 ADJUSTING THE MACHINE BACK TO FACTORY SETTINGS......................................................26

3.2 REESTABLISHING THE CENTER-MARK SCRIBE LINE ................................................................29

3.3 ADJUSTING THE SHOCK ABSORBER...............................................................................................31

3.4 ADJUSTMENT OF THE FEED ASSEMBLY STOPS...........................................................................31

3.5 ADJUSTING THE CYCLE RATE OF THE KERFING MOTORS. .....................................................32

3.6 ADJUSTING THE FEED ASSEMBLY CYCLES PER MINUTE .........................................................33

3.7 FEED START AND FEED RETURN PILOT VALVE ADJUSTMENT................................................36

3.8 ADJUSTING HEIGHT OF KERFING BLADES (OPTIONAL EQUIPMENT)....................................37

3.9 JET AIR PULSE ADJUSTMENT...........................................................................................................37

3.10 SAW DRIVE BELT ADJUSTMENT....................................................................................................38

3.11 FEED SYNC ASSEMBLY EQUALIZATION ADJUSTMENT............................................................39

3.12 ADJUSTMENT OF MITER OR SQUARE CUTS................................................................................40

MAINTENANCE........................................................................................................................................ 42

4.1 ROUTINE & PREVENTATIVE MAINTENANCE ...............................................................................42

4.2 DAILY CHECKS: (EVERY 6-8 HOURS OF OPERATION) ................................................................42

4.3 WEEKLY CHECKS: (EVERY 30-40 HOURS OF OPERATION)........................................................42

4.4 MONTHLY CHECKS: (EVERY 100-200 HOURS OF OPERATION) .................................................43

4.5 GENERAL MAINTENANCE COMMENTS..........................................................................................43

4.6 CHANGING THE SAW BLADES..........................................................................................................44

4.7 CHANGING THE KERFING BLADES (OPTIONAL EQUIPMENT)..................................................44

4.8 SAW DRIVE MANDREL REPLACEMENT .........................................................................................45

4.9 SAW DRIVE CYLINDER REPLACEMENT.........................................................................................46

4.10 SAW DRIVE BELT REPLACEMENT.................................................................................................47

TROUBLESHOOTING.............................................................................................................................. 49

5.1 TROUBLE CHECK LIST.......................................................................................................................49

APPENDIX A

ASSEMBLY DRAWINGS ............................................................................................................................52

APPENDIX B

5

SCHEMATICS................................................................................................................................. 73

1020 FLOOR LAYOUT................................................................................................................................77

APPENDIX C ............................................................................................................................................. 78

BASIC PRINCIPLES OF PNEUMATIC PLUMBING................................................................................78

6

INTRODUCTION

Congratulations on your purchase of your Norfield Industries 1020 Double End Trim Saw.

You can be assured that this machine was constructed and assembled to a set of rigid

specifications by trained workers who take pride in the quality of their work. To safely

operate this machine it is vital that you read and understand all safety and operator

instructions.

The Norfield Industries 1020 Double End Trim Saw is designed to quickly and efficiently

process door casings into the appropriate lengths for the door industry. Settings to adjust

length and select miters are quickly made to minimize set-up time. Head or side casings can

be processed with ease using front mounted controls. Undercuts of up to 15 degrees can be

quickly set if needed to match jamb edge profile. An Infeed Hopper allows standard profile

casing to be stacked and fed automatically into the machine. A moveable saw assembly

mirrors a stationary saw and is used to cut, simultaneously, both ends of the casing to the

desired length. Consistent operation at up to 30 pieces a minute can be sustained increasing

the throughput needed for today's high speed machining centers. Add more functionality to

the 1020 with the available Kerfing option.

A safety system including guards, saw-motor brakes, and mechanical/electrical E-stop

functions are designed to provide operator safety.

Prior to shipment from our factory each Norfield machine is put through a series of tests and

inspections to insure that you are provided with the highest quality product for your

business.

In order for this machine to provide you with a long period of continuous and trouble free

service, it is necessary that it be properly installed, operated, and maintained. We urge you

to study the contents of this manual and be guided by the suggestions herein. We strongly

recommend that a periodic review of the contents of this manual be made to maintain a high

level of competency when operating this machine.

I

NTRODUCTION

7

SAFETY INFORMATION

LABEL AND DEFINITIONS

Danger indicates an imminently hazardous situation, which if not

avoided, WILL result in death or serious injury.

Warning indicates a potentially hazardous situation which, if not

avoided, COULD result in death or serious injury.

Caution indicates a potentially hazardous situation which, if not

avoided MAY result in minor or moderate injury. It may also be used

to alert against unsafe practices.

Caution without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided may result in property

damage (i.e. not personal injury).

Notice indicates important information that if not followed may CAUSE

damage to the equipment.

Mandatory Action conveys an action step that should be taken to avoid

the hazard.

I

NTRODUCTION

STOP!

Protect Yourself

This manual contains information that is

important to the safe operation of your

Norfield e

q

ui

p

ment.

8

MUST READ SAFETY INFORMATION!

Read and understand the operator's manual before using this machine. Failure to

follow proper operating instructions could result in death or serious injury.

Do not operate this machine unless all guards are in place and working correctly.

If any guards or hazard labels are missing or damaged call Norfield's Service

department immediately and request a replacement at 800-824-6242.

Only trained personal that have read and understand the operator's manual and all

the safety precautions may operate this machine.

This machine, when in operation, produces wood chips and dust. The operator

and all persons in the work area MUST wear approved eye protection with

permanently attached, rigid plastic side shields. These safety glasses must

conform to ANSI Z87.1 standards and will have "Z87" printed on the lens.

This machine, when in operation, produces a noise level greater than 85dB. The

operator and all persons in the work area MUST wear approved hearing

protection. OSHA has determined that a noise level in excess of 85dB average in

8 hours can cause permanent hearing damage. We recommend that hearing

protection be worn even if the decibel level is below 85dBA.

Certain types of wood dust can cause allergic reactions, Sawdust has been

determined to be a Group Acarcinogen by the International Agency for

Research on Cancer (IARC). A dust collection system or an approved personal

dust mask MUST be used during the operation of this equipment.

This machine has moving parts that loose clothing and long hair can become

entangled in. Take care not to become caught between the work material and the

feed mechanisms or any other moving components.

Inspect the machine at the beginning and end of each shift for damaged or

cracked components such as, but not limited to, saw blades, router bits, drill bits,

and boring bits.

I

NTRODUCTION

9

MUST READ SAFETY INFORMATION! (CONTINUED)

Never leave this machine unattended while it is in operation. Make sure that

all electrical and air is in the off position when the machine is not in use or is

unattended and that any cutting blades have come to a complete stop.

Do not attempt to clean material from this machine until all the cutting blades

have come to a complete stop. Even when the machine has been turned to the

off position it may take up to several minutes for the blades to coast-down to

a complete stop.

Before beginning any service repairs, general maintenance, or adjustments

you MUST follow proper Lockout Tag-Out procedures. OSHA regulation

1910.147 establishes a minimal lockout tag-out procedure to assist employers

in development of their own procedures.

Woodworking machinery is inherently dangerous, common sense and good

safety practices are your best defense against injury.

If you have any questions regarding the correct operation of the machine and

safety procedures in this manual call the Norfield Industries Service

Department at 800-824-6242.

I

NTRODUCTION

10

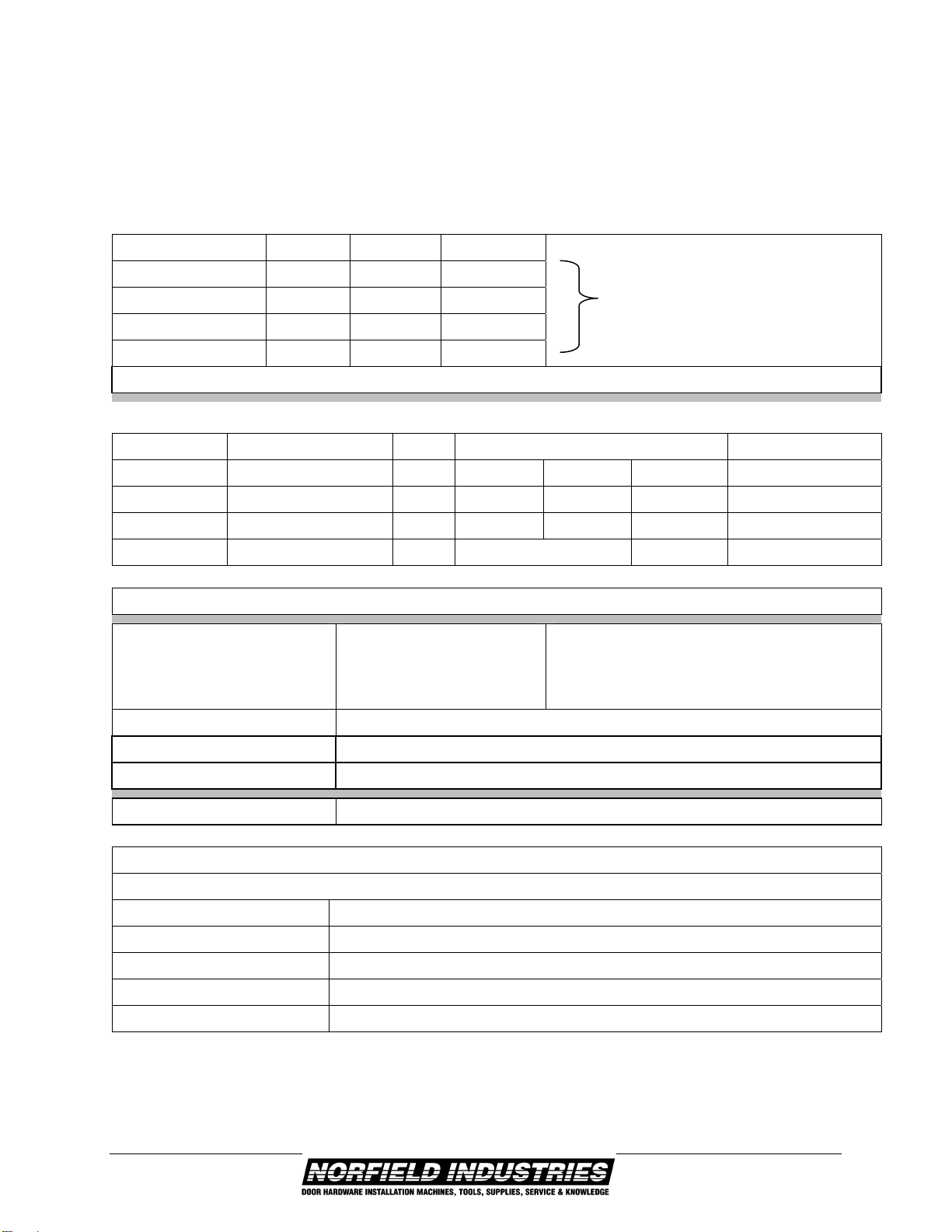

SPECIFICATIONS

Electrical Requirements:

AC Line Phase Hertz Amperage

Includes Vacuum

208V 3

60HZ 30 A*

230V 3

60HZ 30 A*

460V 3

60HZ 15 A*

575V 3

60HZ 15 A*

*Additional 115V-160HZ 20 Amps With Kerfing Option required

Motor Specifications:

Application Motor HP Amperage Norfield P/N

208V 3230V 3460V 3

Saws BALDOR M3550T l.5 4.3

4.2 2.1 0693-016

Vacuum JET DC1900 3 14.5

14.0 14.0 13-708

Routers DEWALT DW616 1 3/4 11A @120V 15-174

Note: For 575v Motor Specifications See Electrical Schematic

Air Requirements: 22 cfm @ 90 psi

1/2" I.D. Minimum air line when less than

20 feet from compressor OR 3/4" I.D.

minimum air line when more than 20 feet

from compressor

Vacuum Requirements: Min. 1900 cfm - 6" Duct

Approximate Weight: 1600 lbs.

Space requirements: Width 9'6" x Length 18'0"

Machine Capacity Rate: 30 Pieces Per Minute

Machine Capabilities:

1020 & 1020K (CASING & BRICKMOLD)

Length 1 '-6" To 8'-0"

Width TO 3-1/2"

Thickness 3/8" To 1-1/2"

Undercut Angle 0 To 15 Degrees for square end cuts, 0 to 1 degree for miter cuts

Angle Of Cut 90 And 45 Degrees

I

NTRODUCTION

11

SECTION 1

INSTALLATION

1.1 SHIPPING DAMAGE AND SHORTAGES

Before and after the crated machine is unloaded from the truck the create should be

inspected for any signs of damage. If suspected damage is found it must be noted on the bill

of lading and signed by the driver and the person receiving the shipment. After the machine

has been uncrated inspect it and all other contents of the crate for shipping damage. In the

event that damage has occurred in transit notify the freight carrier and Norfield Industries

immediately. Inspect the complete shipment against the packing slip to make sure all items

listed are accounted for. If any shortages are noticed, the freight carrier and Norfield

Industries should be notified immediately. While any shortages, other than back orders, or

freight damages are the complete responsibility of the freight carrier, Norfield Industries

desires to be notified so that the replacement of lost or damaged parts can be expedited.

1.2 INSTALLATION

The information in this chapter refers to the installation and setup of the Norfield 1020

Double End Trim Saw. Since the purchase of the machine includes a startup by a Field

Service Technician, the following six items must be accomplished before the Technician

arrives:

1. Review the pre-installation packet that was sent prior to the shipment of your new

machine.

2. Uncrate the machine and inspect for shipping damage and shortages.

3. Position the machine in its permanent location.

4. Provide the proper electrical supply and make connections.

5. Provide the proper air supply and make connections.

6. Install Lockout/tagout devices on all power sources at the machine.

7. DO NOT TURN ON POWER UNTIL THE SERVICE TECHNICIAN ARRIVES-doing

so may VOID your warranty.

1.3 POSITIONING THE 1020 DOUBLE END TRIM SAW

With the use of a forklift move the machine to its permanent position within your shop.

This space should have been predetermined and power and air must be installed prior to the

Service Technician's arrival.

I

NSTALLATION

12

1.4 LEVELING

It is important to level the machine across the two ends so that there is no twist or strain on

the frame rails. This machine will not function properly if the frame is twisted. It is also

desirable to level the machine from end to end.

1. Place the level down the length of the front frame rail. Level the machine by adjusting

either of the two front leveling feet until the machine is level.

2. Next level the machine across one of its two ends. Place a level across one end of the

frame as shown.

3. Adjust the back leveling foot of the end that you are working on until that end of the

machine is level.

4. Next move the level to the opposite end of the machine and place the level across the

frame as shown.

5. Adjust the back leveling foot of the end that you are working on until that end of the

machine is level.

6. Check the entire machine to make sure that it is level across its entire frame.

1.5 ELECTRICAL

Before connecting any electrical power to the main electrical enclosure, be sure that the

characteristics labeled on the enclosure match those of your service. Refer to the drawing

that was included in the pre-installation packet that was sent prior to this shipment or to the

electrical schematic in Appendix B of this manual.

I

NSTALLATION

13

Clean Dry Air (CDA) is important. Air operated tools and equipment require CDA for top performance

and low maintenance. Foreign material such as dirt, grit and pipe scale generally present in airlines can

cause severe abrasive wear in valves and cylinder walls.

1.6 AIR SUPPLY AND CONNECTION

In order for the machine to perform properly, the quick-disconnect to the machine must be

at least 3/8" inside diameter. Refer to specification section for further information.

A Filter-Regulator-Lubricator (FRL) unit has been installed on your machine to prolong the

life of the machine. The FRL is designed to work with adequate mainline filtration and

drainage (refer to Appendix C). We also recommend the use of an air drying system to

protect all your air tools and equipment.

1.7 FRL SETTINGS AND TYPE OF OIL

Adjust the regulator so that it maintains at least 90 psi during operation of the machine

(100-psi static). For approximately every 33 drops of oil observed at the drip tube in the

sight dome, only one drop of oil will remain in suspension for down stream lubrication,

therefore do not under lubricate. Set the drop-type lubricator so that one drop occurs for

every cycle of the machine. Adjustment of the drip rate is accomplished using a small

screwdriver. Turn the screw, located next to the lubricator filler cap, counterclockwise to

increase drip rate, clockwise to decrease the drip rate. Only use 10WT turbine oil in the

lubricator.

1.8 DUST COLLECTOR (OPTIONAL)

If the dust collection option was purchased with this Norfield 1020 Double End Trim Saw,

or if you wish to connect this machine to an existing in-house dust collector, an 8 inch

diameter hose is required. If the optional dust collector was purchased with this machine

refer to electrical schematic in Appendix B for additional power requirements.

I

NSTALLATION

Regulator Adjustment

Knob 90psi (100 psi

static).

Lubricator filler cap

Sight Dome

14

1.9 BASIC INSTALLATION ADJUSTMENTS

Your new Norfield Industries machine has been carefully

adjusted at the factory prior to shipment, however we

recommend that you check the following initial perimeters to

insure proper operation before running any material through

the machine for the first time.

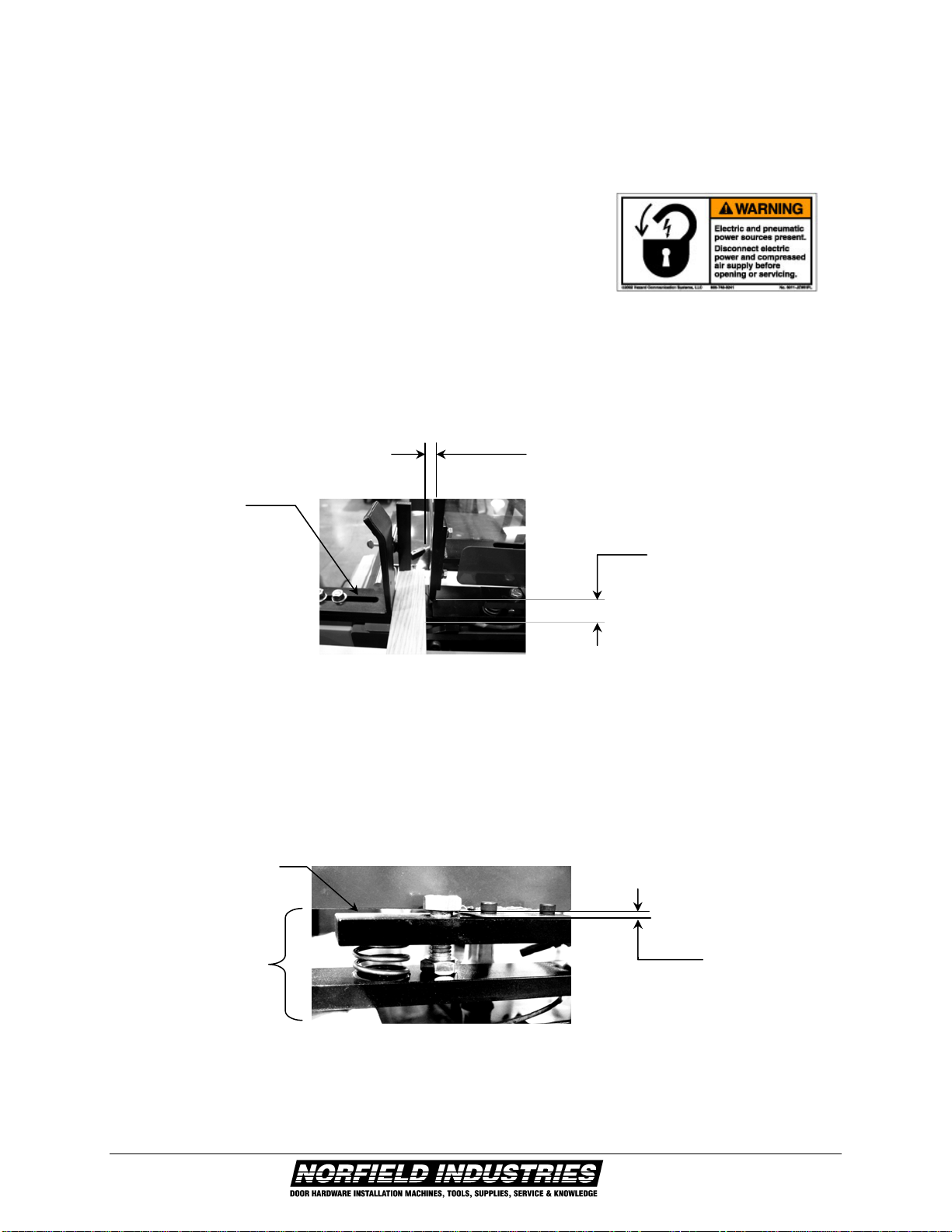

To check the Magazine width, place a piece of material into the Magazine and hold it

against the Feed Magazine, measure the distance between the material and the Material

Gate; there should be 1/16" to 3/32" clearance. Refer to Section 2 if any adjustment is

required.

To check the Material Gate height clearance. Manually push the material under the gate

opening. Measure the distance from the edge of the gate opening to the thickest part of the

material's profile; this distance should be 1/16" to 1/8" max. Refer to Section 2 if any

adjustment is required.

Next, check the Hold-down Ski heights. Manually push the material with the two feed

assemblies into the Hold-down Ski Assembly. Measure the distance from the bottom of the

1/2" hex head bolt to the top of the Ski Adjustment Bar. This distance should be 1/32 to

1/16" max. Refer to Section 2 if any adjustment is required.

I

NSTALLATION

Hold-Down

Ski Assembly 1/32" to

1/16" gap

Ski Adjustment Bar

Feed Magazine

Material Gate

Height 1/16" to 1/8"

gap

Material Gate clearance

1/16" to 3/32" gap

15

When re-energizing

the machine after the

E-Stop has been

depressed the

assemblies will move

back to their home

positions if the saw

cycle was interrupted

in mid cycle.

1.9 BASIC INSTALLATION ADJUSTMENTS (CONT.)

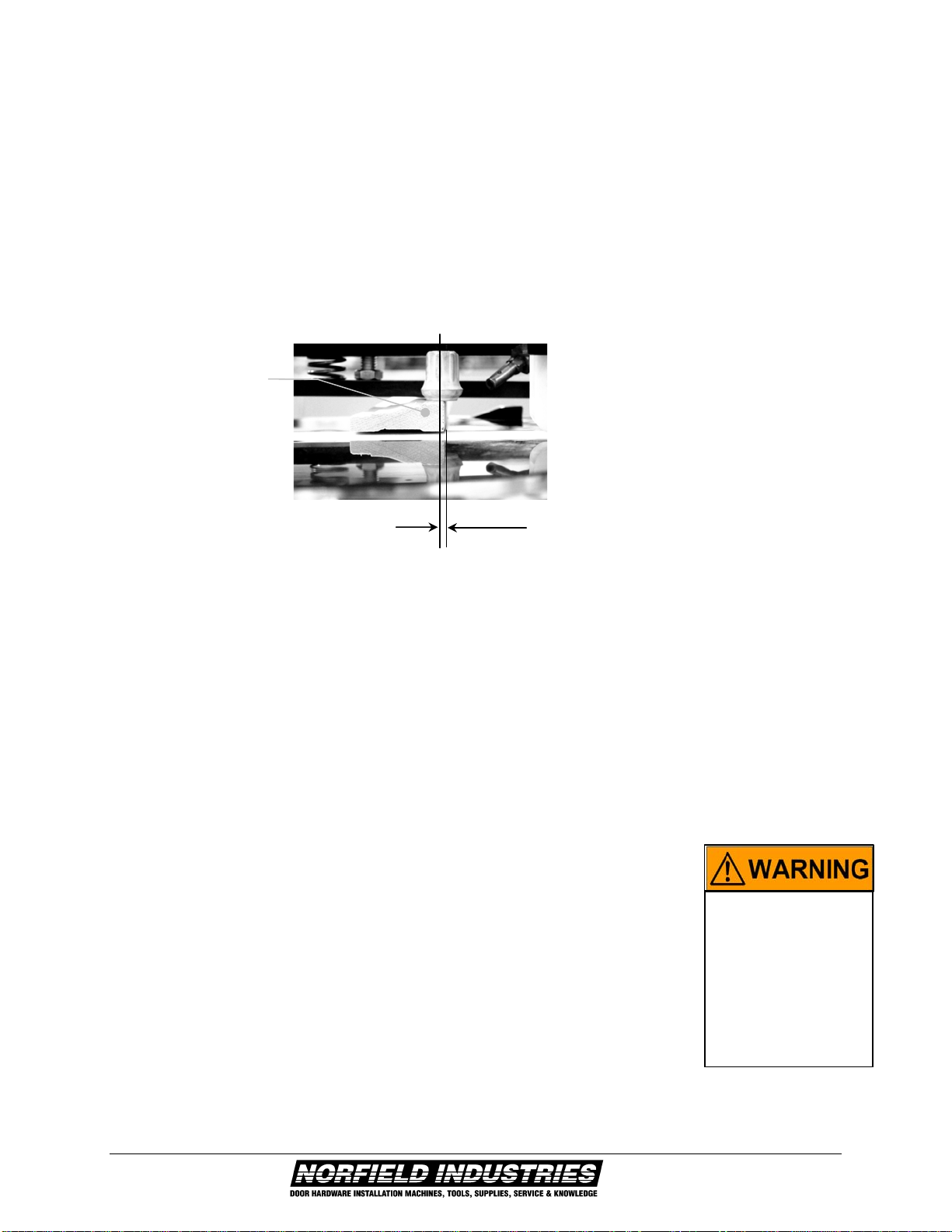

Next, check the position of the Crutch Tip. To do this, manually raise both Crutch Tips until

they stop. Using the two Feed Assemblies manually push the material forward until the feed

assembly comes into contact with the stop. Lower the crutch tips so that they contact the

material. The center of the Crutch Tip should contact the thickest part of the profile of the

material 1/16" to 1/8" in from the leading edge. Refer to Section 2 if any adjustment is

required.

After noting and checking all the above items and making any necessary changes, turn the

main air on, start the saws, start the kerfing unit (if applicable), and then lift the Cycle Start

Lever to begin operation. Let the machine cycle at least 6 times before loading the

magazine. Place material into the magazine only during the return stroke of the feed

mechanism, or after the feed dog has gone forward away from the magazine. If you wish at

any time to stop the machine operation, push the Cycle Start Lever back down to the off

position.

Using the Cycle Start Lever is the recommended way to stop normal

operation of the machine. This is not an Emergency Stop, as the saw will

complete the remainder of its present cycle.

The Emergency Stop switch is located on the Electrical Enclosure, and

when depressed will halt all operations. Both the air and electrical

systems will be interrupted until the switch is reset.

I

NSTALLATION

1/16 to 1/8

Thick part of

material profile

16

1.10 MAJOR COMPONENTS AND CONTROLS

I

NSTALLATION

17

SECTION 2

OPERATIONAL SETTINGS

2.1 QUICK-START GUIDE

The Norfield Industries 1020 DOUBLE END TRIM SAW consists of two saw canisters

supported on a common frame. The left or stationary saw canister is fixed and the right saw

canister is adjustable to allow setting for the desired length of cut. The following

instructions are intended to familiarize the operator with the normal operating settings.

Individual adjustments are covered in greater detail following this section.

1. Before removing any of the Lock-out Tag-out devices on either the main electrical panel

or air supply do the following 3 items:

I. Depress the Emergency Stop Button on the 1020's Electrical Enclosure.

II. Make sure that the Cycle Start Lever and Main Air Lever are in the off

position.

2. Remove the lock-out/tag-out devices.

3. Turn on the air valve located at the Filter/Regulator/Lubricator to supply air to the

machine.

4. Turn the Disconnect Switch to the on position

5. Release the two Head Lock Levers on the right Saw Canister, using the scale provided

set the right saw canister to cut the material to the desired length.

6. Retighten the Head Lock Levers.

7. Next, determine the miter cut needed. For headstock both saws are adjusted to 45

degrees. To cut side trim, one saw will be 45 degrees and the other 90 degrees. The

appropriate hand is achieved using the adjustments knobs located on the front of the

corresponding saw canister.

8. Turn the Turntable Lock Switch to the off position.

9. Select the desired cut, 45 or 90 degrees

10. After the saw has rotated to the set location, change Turntable Lock Switch to the ON

position.

O

PERATIONAL

S

ETTINGS

18

2.1 QUICK-START GUIDE (CONT.)

11. Turn the Main Air Lever to the ON position by moving the lever to the left. Stay clear of

the saw and feed assemblies as they may move unexpectedly when air is applied.

12. Set the Material Stop on the left side for the appropriate position based on that saws

rotational position.

13. If kerfing is desired, and your machine is equipped with this option, the appropriate

selector switch should be turned to the ON position on the Electrical Enclosure. Once

the Saw Motor Start Button is depressed the kerfing motors will start automatically.

14. Rest the Emergency Stop Switch by pulling it out.

15. Start the saw motors by depressing the Saw Motor Start Button on the Electrical

Enclosure.

16. Lift upwards on the Cycle Start Lever, this will activate the saws and the Feed

Assemblies will begin cycling.

17. Load one piece of material into the Magazine. Place material into the Magazine only

when the feed mechanism is returning to pick up material, or after the Feed Dog has

gone forward away from the magazine.

18. Once the material is cut and has passed through the machine return the Cycle Start Lever

to the off position.

19. Turn off the saw motors by depressing the Stop Button located on the electrical

enclosure.

20. Measure the length of material and check the miter for accuracy. If the material does not

meet your specification please proceed to the adjustment section of the manual.

21. Once these checks have been made and you are satisfied with the specifications you are

ready to begin using your new Norfield 1020 double end trim saw.

O

PERATIONAL

S

ETTINGS

19

2.2 SETTING THE MACHINE TO DO MITTER CUTS OR END CUTS

To adjust the saws to perform a 45-degree miter cut or a 90-degree end cut:

1. Unlock the turntable by turning the Turntable Lock Switch to the off position.

2. Switch the Turntable Indicator Knob to either 45 or 90 degrees. The turntable will

automatically rotate the selected angle as soon as the turntable has stopped so that the

spiral pin is in contact with the corresponding adjusting screw.

3. Change the Turntable Lock Switch back to the on position.

4. This completes the change over.

2.3 SETTING UP TO CUT DIFFERENT LENGTHS OF MATERIAL

To set the machine at any given length from 1'6" to 8' you must:

1. Loosen the two Headlock-levers.

2. Turn the adjustment crank clockwise for longer lengths of material, or counterclockwise

for shorter lengths of material.

3. Retighten the two Headlock-levers.

O

PERATIONAL

S

ETTINGS

Head Lock Levers

Length Adjustment crank

Stationary Canister Moveable Canister

Turntable Indicator Knob

Turntable Lock

Kerfing option not

shown

20

Loosen four 1/2"

b

olts

2.4 SETTING UP TO CUT DIFFERENT WIDTH MATERIALS

If the thickness of the material does not change there are only two adjustments to make

when setting the machine for different widths of materials, Please refer to the following:

1. Turn the Disconnect to the off position.

2. Loosen the four 1/2 inch bolts that hold down the Feed Magazine Weldment

3. Insert a piece of material into the magazine.

4. Holding the material against the back of the magazine.

5. Adjust the Feed Magazine Weldment such that the magazine opening has 1/16" to 3/32"

clearance between the material and the Material Gate as shown.

6. Tighten bolts and recheck the clearance at both ends of the machine.

O

PERATIONAL

S

ETTINGS

Material Gate

Feed Magazine

Weldment

1/16" to 1/32"

This manual suits for next models

1

Table of contents