Norgren Herion XSz User manual

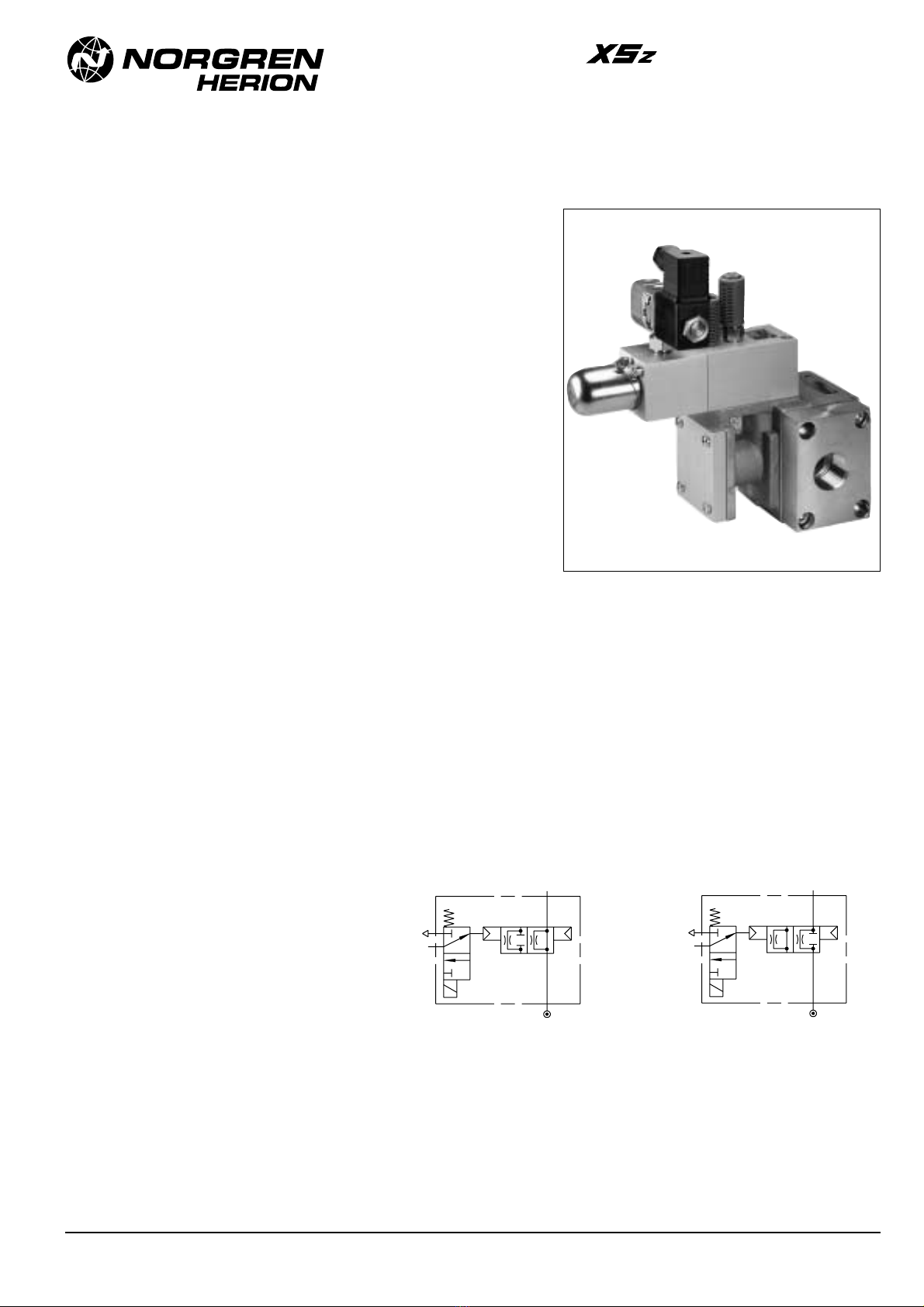

Damping modules

2/2 directional control valve, normally open or closed

for soft clutch engagement

●Compact design

●Simple installation

●Reduction wear and tear

●Noise reduction

Soft start valve can be used for soft engagement of a

pneumatically operated clutch on presses. It can be directly

flanged on port 1 (P) of the safety valve XS/XSz 32 and

with an adapter plate on the XS/XSz 50. It has a

interchangeable bypass orifice to adapt to individual

operating conditions.

Technical data

Operating pressure:

2 to 8 bar

Fluid:

Filtered and lubricated air 1)

Fluid temperature:

- 10 to + 40 °C 2)

Ambient temperature:

- 10 to + 60 °C 2)

Materials: Housing: Aluminium alloy

Seals: NBR (Perbunan)

AU (Vulkolan)

3 (R)

1 (P)

12 (Z)

2 (A)

1 (P)

3 (R)

1 (P)

12 (Z)

2 (A)

1 (P)

Symbol for Cat. No. 1020113 Symbol for Cat. No. 1020141

Soft start („soft clutch“) valve

1) Oil recommendation: Shell Hydrol DO 32, ESSO Febis K 32 (as of July 1992) or comparable oils with DVI

values < 8 (DIN 53521) and ISO viscosity class 32-46 (DIN 51519).

2) To secure the safety function of the valve at subzero temperatures, it is important that the air is dry

enough to prevent an icing of the valve.

Ordering example:

To order, quote part number, e.g.

1020113.0700 for nominal size 32 soft start

valve for XS/XSz 32 valve, soft starting from 2

bar up.

Caution:

For mounting soft start valve on a

XS/XSz 50 valve an adapter flange plate

(Cat.-No. 0557164) is necessary. It has to be

ordered in addition to the soft start valve.

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specifications given in this document. N/** 5.11.041•0103/01

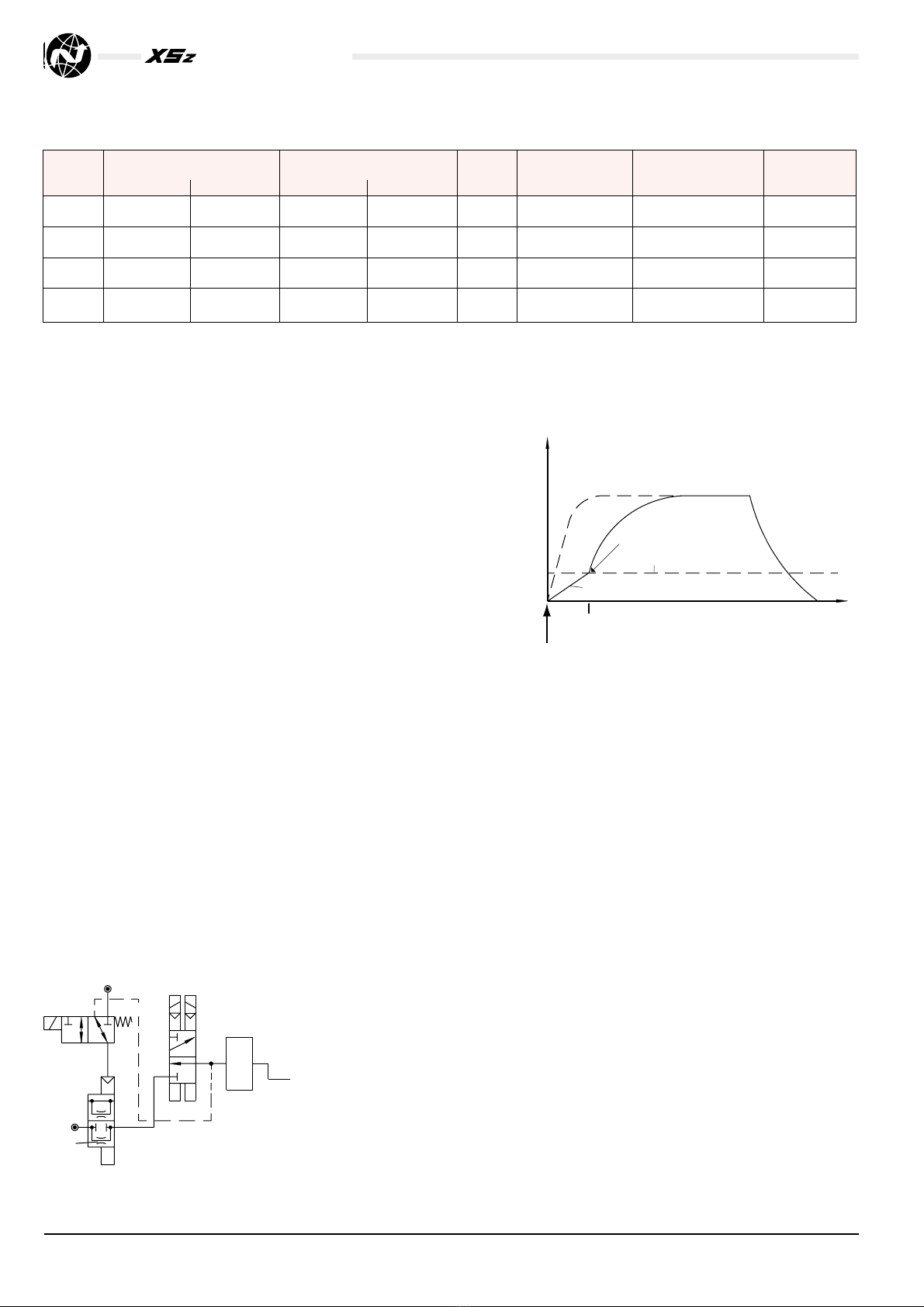

Damping modules

Threshold pressure of clutch from 0 to 2 bar

Switching diagram and characteristic curve

for pressure build-up

M1

2

D

XS / XSz

24

1

C

1

Z

2 (A)

1 (P)

3 (R)

1 (P)

M1energized

Sequence valve (2) closed (Orifice D

2

)

Sequence valve open

t

Threshold pressure of clutch

Stages ab

Pressure

in the

clutch

pe

1

E = Safety valve solenoids (1) are energized

Fig. 1

As shown in Fig. 1 the clutch (C) is vented via safety

valve (1). Pressure supply via filter, lubricator and the

2/2 control valve (2). However, the clutch is shut off by

the safety valve (1). As soon as the solenoids of the

safety valve (1) are energized, the clutch is pressurized

in following two stages:

a) The closed 2/2 directional control valve causes

slow pressure build-up in the clutch via orifice D2,

to a level where the acceleration phase between

flywheel and drive shaft is reached (clutch closes).

b) Via line 4 the 2/2 directional control valve (2) is

switched to the open position initiating a rapid

pressure build-up.

The clutch (C) exhaust through the safety valve (1) as

soon as safety valve solenoids are de-energized

the 2/2 directional control valve (2) is switched to

closed position.

The 3/2 solenoid valve (M1) allows a setup operation

of the press: after switching the solenoid valve (M1)

and the safety valve (1), pressure will build-up at port

2(A) from the safety valve (1).

This operation will cancel the soft engagement

function of the soft start valve.

Adapter plate for flanged versions, Types XS/XSz50, Cat. No. 0557164

General information

Nominal Operating pressure (bar) Control pressure (bar) Weight Cat. no. Notes Voltage

size

(bar) (min. max. min. max. (kg) Valve Solenoid

3 8 0,6 8 4,1 1020113. 0700 Valve for smooth starting DC

from 2 bar up

3 8 0,6 8 4,1 1020113. 3703 Valve for smooth starting AC

from 0 2 up

3 8 0,6 8 4,5 1020141. 0800 Valve for smooth starting DC

from 0 to 2 bar

3 8 0,6 8 4,5 1020141. 3803 Valve for smooth starting AC

from 0 to 2 bar

All solenoids are delivered without plugs. If you require plugs, please order them separately, Cat-No. 0570275.

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specifications given in this document.

N/** 5.11.041•02 03/01

Advantages of this control are:

●Soft application of the clutch disc, thus reducing the

noise

●Controlled torque transmission reducing clutch wear

and tear

●Due to pressure control, no change in

the performance characteristic caused by clutch wear

and tear

●No need to harmonize clutch volume and volume of

pipe lines between clutch and valve

●No pipe work due to flanged design

●Easy to handle

●Due to pressure adjustment, suited for all clutch

types

●No changes by fluctuations of operating pressure

●The solenoid valve M1 allows a setup operation of the

press.

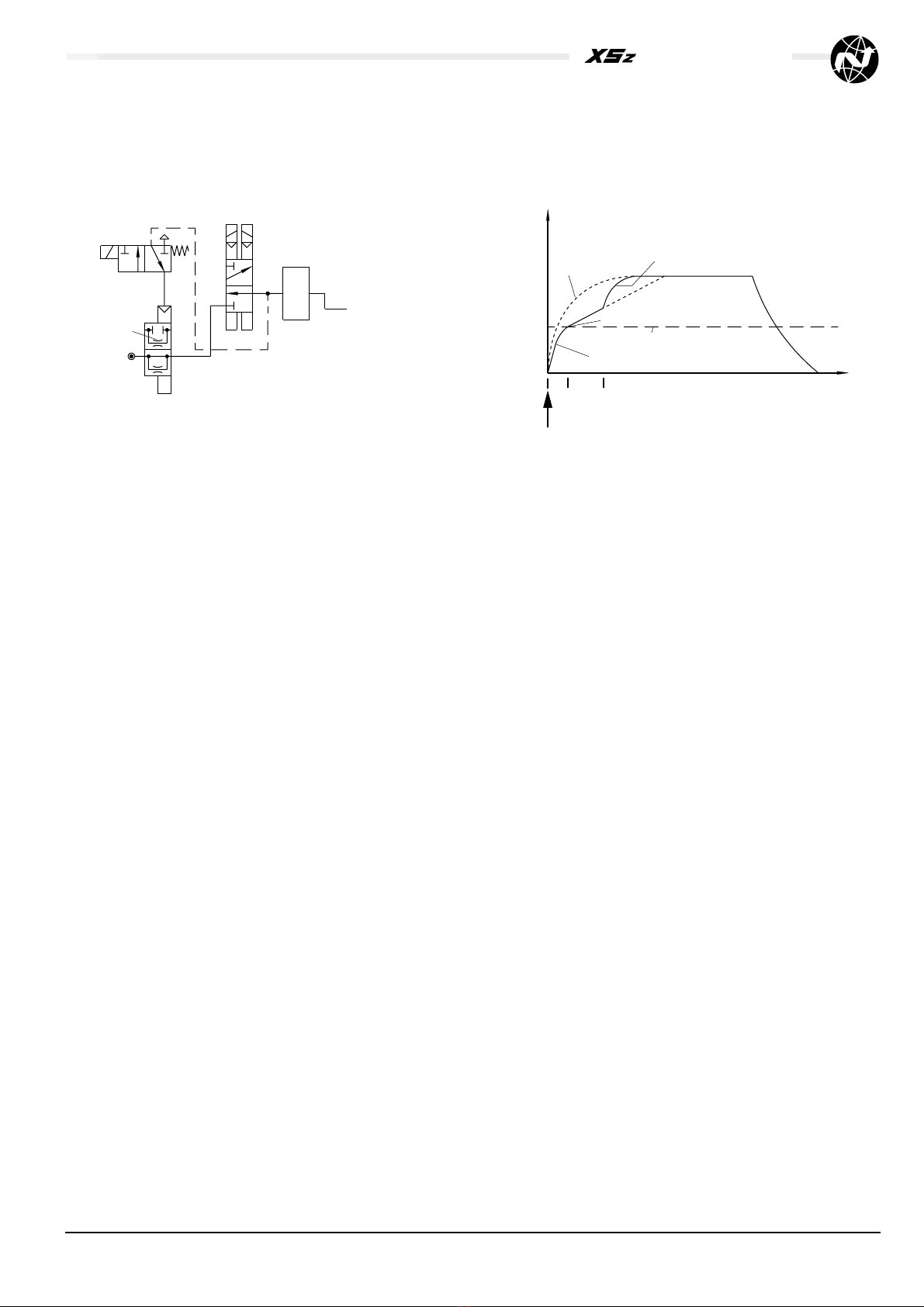

Threshold pressure of clutch from 0 to 2 bar

Damping modules

M1

2

D

1 (P)

3 (R)

XS / XSz

2 (A)

12 (Z)

24

1

C

1 (P)

Threshold pressure of clutch from 2 bar up

Switching diagram and characteristic curve for pressure build-up

1

Menergized

Sequence valve closed (orifice D

2

)

Sequence valve open

t

Threshold pressure of clutch

Stages abc

Pressure

in the

clutch

pe

1

I

Menergized

E = Safety valve solenoids (1) are energized

Fig. 2

As shown in Fig. 2 the clutch (C) is vented via safety

valve (1). Pressure supply via filter, lubricator and the

2/2 directional control valve (2). However, the clutch is

shut off by press safety valve (1).

As soon as the solenoids of the safety valve (1) are

energized, the clutch is pressurized in three stages:

a) Fully open, the 2/2 directional control valve (2)

causes a quick pressure build-up to a level where

engagement pressure of the clutch is reached. From

this pressure level, the 2/2 directional control valve (2)

is closed through line 4.

b) Further pressure build-up via orifice D2can be

controlled as the orifice diameter determines the

acceleration period between flywheel and driving shaft.

c) After acceleration phase, M1 is energized, and the

2/2 directional control valve (2) opens. Pressure in the

clutch quickly raises to a pre-set value. Torque

transmission from the flywheel to the crank shaft of the

press is assured.

By de-energizing the solenoid of the safety valve (1),

the clutch is vented; the 2/2 directional control valve (2)

remains in open position.

The 3/2 solenoid valve (M1) allows a setup operation of the

press: after switching the solenoid valve (M1) and the

safety valve (1), pressure will build-up in the clutch. This

operation will cancel the soft engagement function of the

soft start valve.

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specifications given in this document. N/** 5.11.041•0303/01

Damping modules

G 1/4

G 1/4 Solenoid valve Type 9602340.0700 (DC) / 9602340.3703 (AC)

Silencer at Z1 and 3 (R)

(included in type 1020113.0700)

Solenoid valve Type 2401103.0800(DC) / 2401103.3803 (AC)

Silencer at Z and 3 (R)

(enclosed in type 1020141.0800)

approx. 260

165

12 (Z) 3 (R)

G 1/8

52

80

1 (P)

40

78

235

12 (Z) 3 (R)

q 50

2

G 1

M8

1 (P)

105

M10

Adapter plate

type 0557164

for XS / XSZ 50

13 25

96

159

(Z1)

1

12

changeable bypass

orifice D2

(Z1)

1

12

A suitable air treatment unit (dehydration, filtration, lubrication) must be connected upstream of pressure port P. Lubrication can be omitted if the connected consuming device and all additional

equipment is suited for oil-free operation (see page 1). Degree of filtration: 5 µm.

It is the responsibility of the purchaser and/or installer of the Norgren-Herion safety valves to make sure that the valve and all other components comply with all relevant national regulations and the

specifications of the local safety associations.

The valve should be checked at intervals depending on the loads to which it is subjected, at least, however, once a year. The relevant tests must be carried out according to the corresponding operation

and maintenance instructions of the unit and the local safety regulations. In case of malfunctions the unit has to be tested and/or replaced immediately.

For information on installation, operation and maintenance of the damping modules please see maintenance manual no. 5.4.3 6.

All liability is denied for unauthorised modification of the units, installation or usage not in accordance with the manual, the local safety re uirements or the principles

of EN 692 and EN 954-1.

Our policy is one of continued research and development. We therefore reserve the right

to amend, without notice, the specifications given in this document.

N/** 5.11.041•04 03/01

Table of contents

Popular Control Unit manuals by other brands

Grundfos

Grundfos LC 108 Installation and operating instructions

Viessmann

Viessmann EM-P1 Installation and service instructions

Val-Matic

Val-Matic 100S Operation, maintenance and installation manual

EFI

EFI EB-32 Installation and service guide

Emerson

Emerson Fisher N551 instruction manual

Siemens

Siemens SIMATIC ET 200SP TM ECC 2xPWM ST product manual

Weinzierl

Weinzierl KNX RF/TP Coupler 673 secure Operation and installation manual

Tyco

Tyco DV-5A manual

Johnson Controls

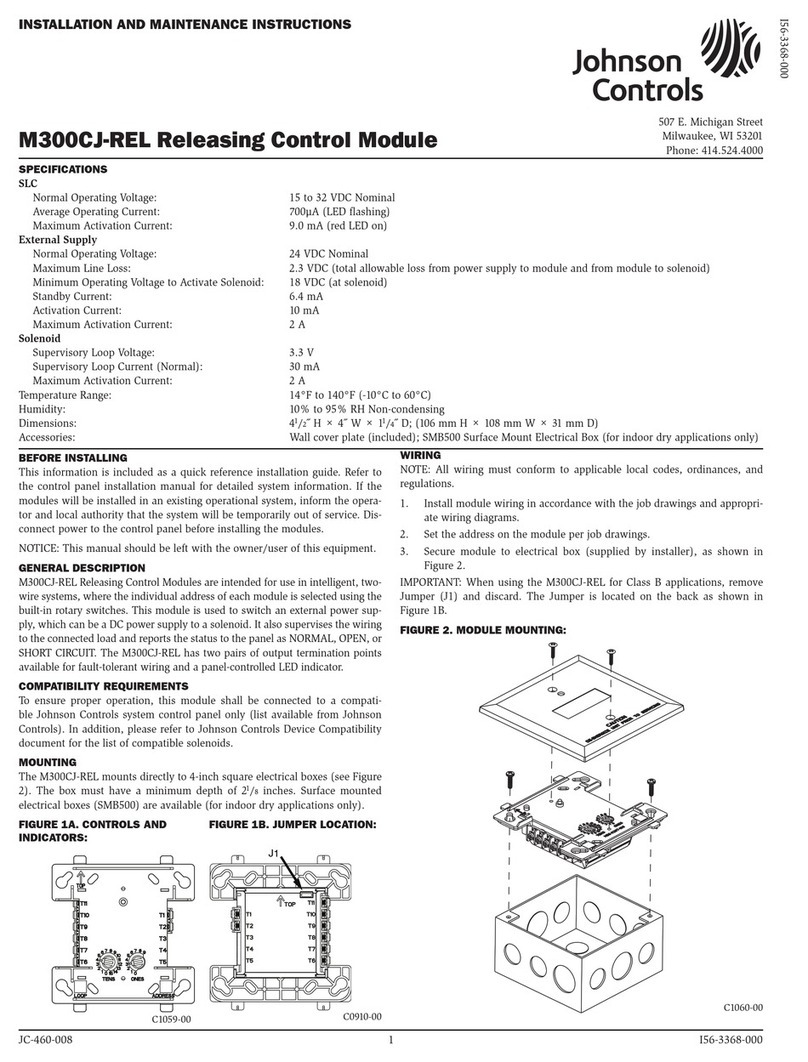

Johnson Controls M300CJ-R Installation and maintenance instructions

Dwyer Instruments

Dwyer Instruments DP3 Series Installation and operating instructions

Definox

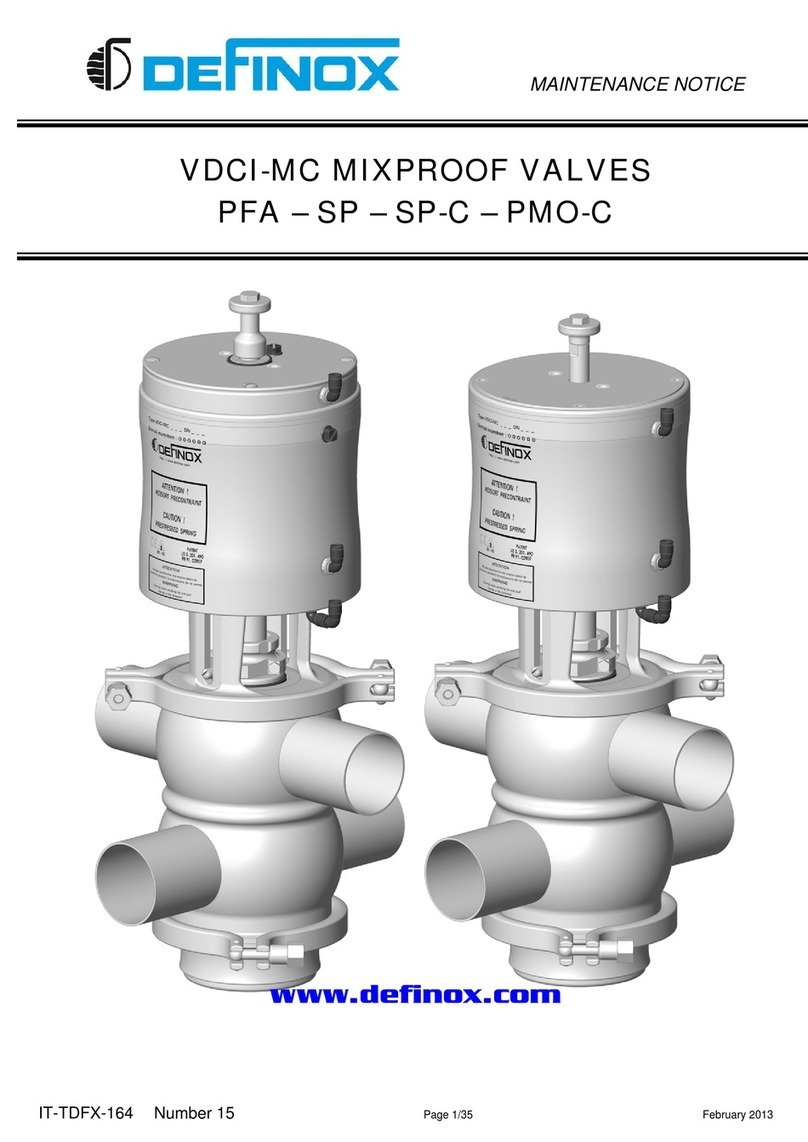

Definox VDCI-MC PFA manual

Beijing

Beijing DAM-E3311 user manual