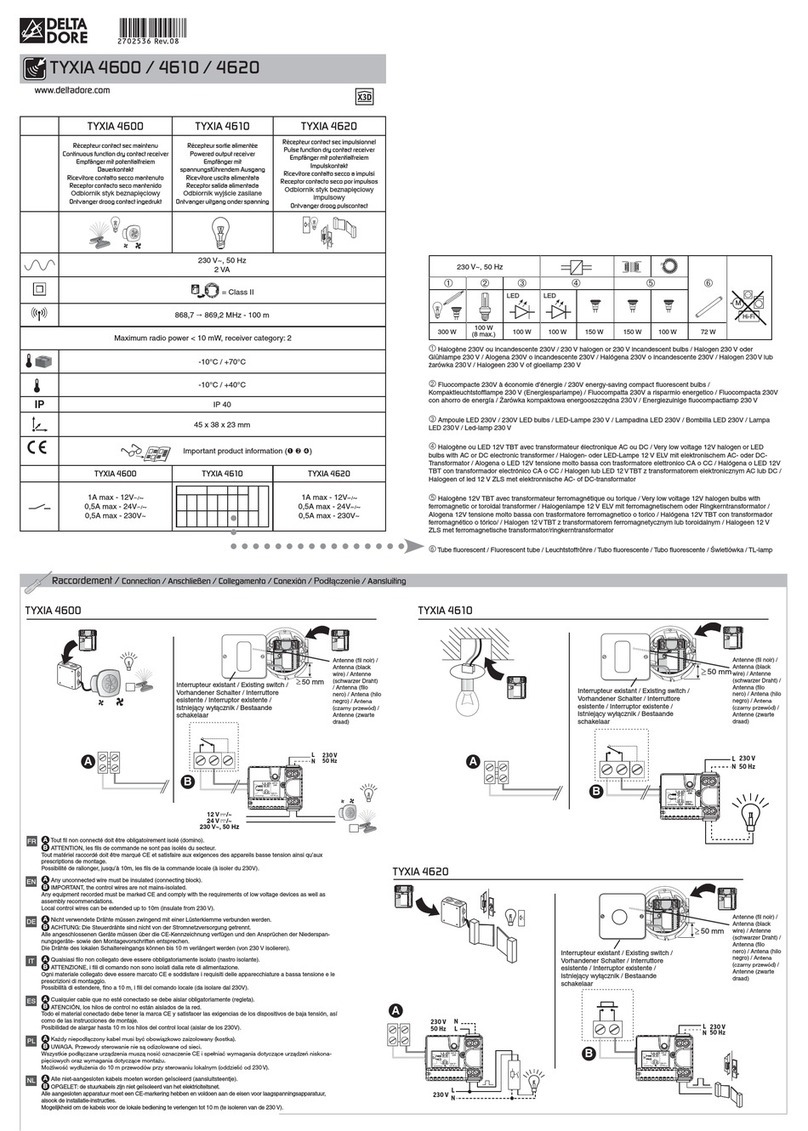

DELTA DORE DELTA 8000 BT User manual

EN Technical unit for Delta 8000 system

DELTA 8000 BT

Installation instructions

22 23

EN

CONTENTS

1/ Overview of the technical unit 24

2/ Mounting and connecting the

technical unit 25

3/ Connecting the technical unit's

inputs/outputs 27

4/ Application examples 28

4.1 Hard-wired 28

4.2 Wireless (option) 30

4.3 Hybrid hard-wired and wireless 31

4.4 Extension (option) 31

5/ Switch conguration 32

6/ Associating a room thermostat with

a technical unit 33

6.1 With a Room Thermostat (RT) 33

6.2 With a Programmable Room Thermostat (PRT) 34

7/ Conguring the technical unit 35

7.1 With a room thermostat (RT) 35

7.2 With a programmable room thermostat (PRT)

or programmer (PROG) 36

8/ Restoring the technical unit to

factory settings 37

8.1 With a room thermostat (RT) 37

8.2 With a programmable room thermostat (PRT)

or programmer (PROG) 38

9/ Water temperature monitoring 39

10/ Troubleshooting 40

11/ Technical characteristics 41

24 25

EN

❶Remove the cover

❷Mount the unit with a set of screws/sprigs

compatible with the substrate

(not included).

❸Connect the elements

(refer to the 'connection' §).

Fasten the cables using the nylon screws

provided.

❹Remove the temporary partitions to run

the cables to the required locations,

then close the unit.

2/ MOUNTING AND CONNECTING THE

TECHNICAL UNIT

Green Status

LED (ST)

Red circulator and burner

LEDs (P and G)

Red valve

LEDs (1 to 8)

On Normal

operation

Relay closed

Output on On

Off Initial heating

of the slab

Relay open

Output off Off

Slow fl ashing

... ... ...

.. .. .. .. ..

Association mode - -

Quick fl ashing

... ... ...

.. .. .. .. ..

Defect in progress - Defect in

progress

1

ON

6

5

4

32

DIP

88

7

Con guration

switches

Status LED

Water

monitoring input

Circulator LED

Burner LED

Change-over

input/output

Valve outputs

Valve supply

Master switch

Bus

Valve output LEDs

1/ OVERVIEW OF THE TECHNICAL UNIT

1

ON

6

5

4

32

DIP

88

7

DIP

1

ON

6

5

4

32

DIP

88

7

Ê

Ë

Ì

Í

Burner and

circulator outputs

26 27

EN

Switch off the mains power before handling the device.

❶Water monitoring input (option) by CTN sensor or dew point sensor

(according to SW8 conguration)

❷ Change-over input or output (according to SW6 conguration). If change-over output:

voltage off load < 28VDC, current < 50mA. Ensure the wires are correctly connected!

❸To connect the Bus, use the cable supplied (2x0.75², length 1 m) or twisted pair cable with

a minimum section of 6/10th, max. length. 30 m:

- 4 wires maximum per terminal

- Ensure the wires are correctly connected to the + and - poles.

- Room terminals can be connected to either one of the 2 Bus terminals.

❹Burner and circulator outputs, dry contact 2A Max, 230V~

❺Valve outputs. If you use 3 position actuators, you will only be able to connect 4 valves to

the technical unit (switch SW3 = ON).

If you need more outputs, use another technical unit in 'Extension' mode.

❻Valve power supply 24VAC/DC or 230 V~ / 240 V~.

❼Main power supply 230 V~ / 240 V~

Y1 Y2 Y3 Y4 Y5 Y6 Y7 Y8

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Y1

SW3 = OFF

SW3 = ON

N

NNNNNNNN

N N N N N N NY2 Y3 Y4 Y5 Y6 Y7 Y8

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

2 position actuators

3 position actuators

Z1 to Z8 max.

Z1 to Z4 max.

3/ CONNECTING THE TECHNICAL UNIT'S

INPUTS/OUTPUTS

1

ON

6

5

4

32

DIP

88

7

1 2 3 4 5 6 7

1 2 3 4 5 6 7

I0

Power supply

S

GENERAL

VALVE ACTUATORS

BUS

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 23 241 2 3 4

AUXILIARIES

Y1 Y2 Y3 Y4 Y5 Y6 Y7 Y8 L NN N N N N N N N

Power supply

21 22

LN

28 29

EN

Bus

30m max.

BT Master

SW1 = OFF

BT Extension

SW1 = ON

1 -> 8 sorties

1

ON

6

5

4

32

DIP

88

7

1

ON

6

5

4

32

DIP

88

7

BUS 1 BUS 2

BUS

Bus

30m max.

Bus

30m max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

BUS 1 BUS 2

BUS

Bus

30m max.

BUS 1 BUS 2

BUS

RT

zone 1

RT

zone 2 RT zone N

4/ APPLICATION EXAMPLES

If the system is without

programming, one of the

thermostats must be set to

'Master' mode (refer to the

thermostat manual).

If the system is without

centralized programming,

one of the thermostats must

be set to 'Master' mode (refer

to the thermostat manual).

PRT

zone 1

PRT zone 2 PRT zone N

Bus

30m max.

BT Master

SW1 = OFF

BT Extension

SW1 = ON

1 -> 8 sorties

1

ON

6

5

4

32

DIP

88

7

1

ON

6

5

4

32

DIP

88

7

BUS 1 BUS 2

BUS

Bus

30m max.

Bus

30m max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

BUS 1 BUS 2

BUS

Bus

30m max.

BUS 1 BUS 2

BUS

Example 3: Regulation with room by room programming

PRT: Programmable Room Thermostat

Programmer

RT

zone 1

RT

zone 2 RT

zone N

Bus

30m max.

BT Master

SW1 = OFF

BT Extension

SW1 = ON

1 -> 8 sorties

1

ON

6

5

4

32

DIP

88

7

1

ON

6

5

4

32

DIP

88

7

BUS 1 BUS 2

BUS

Bus

30m max.

Bus

30m max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

BUS 1 BUS 2

BUS

Bus

30m max.

BUS 1 BUS 2

BUS

Example 2: Room by room regulation with centralised programming

4.1 HARD-WIRED

Example 1: Room by room regulation without programming

RT: Room thermostat

30 31

EN

Bus

30m max.

BT Master

SW1 = OFF

BT Extension

SW1 = ON

1 -> 8 sorties

1

ON

6

5

4

32

DIP

88

7

1

ON

6

5

4

32

DIP

88

7

BUS 1 BUS 2

BUS

Bus

30m max.

Bus

30m max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

1-> 8 sorties max.

BUS 1 BUS 2

BUS

Bus

30m max.

BUS 1 BUS 2

BUS

Bus

30m max.

BUS 1 BUS 2

BUS

1-> 8 sorties max.

Wireless

programmer

Radio/bus

gateway

Technical

unit Wireless room

thermostats

Hard-wired

room

thermostats

4/ APPLICATION EXAMPLES

4.2 WIRELESS (OPTION)

Associating the radio/Bus gateway with the technical unit will enable access to the range's

wireless products and functions:

- Wireless room thermostats (room by room regulation),

- Wireless programmers (centralised programming),

- Wireless programmable thermostats (regulation + room by room programming),

- Window magnetic contacts: activates the Frost Protection mode when a window is

opened.

- Presence/absence detectors: lower the temperature setting when the premises are left

empty for a long period of time.

- Outdoor temperature sensor.

Bus

1-> 8 sorties max.

Wireless

programmer

Radio/bus

gateway

Technical unit

Room

thermostats

Wireless

4.3 HYBRID HARD-WIRED AND WIRELESS

Wireless and hard-wired solutions can be used concomitantly on the same installation :

- Room thermostats (room by room regulation),

- Programmers (centralised programming),

- Programmable thermostats (room by room regulation + programming),

Example:

4.4 EXTENSION (OPTION)

Another technical unit is added to control up to 16 outputs.

32 33

EN

SW1 Conguring the

technical unit

OFF Master

ON Extension (refer to the 'Extension option' §)

SW2 Production mode OFF Heat (boiler or non reversible heat pump)

ON Heat/Cool (reversible heat pump)

SW3 Valve actuator type

OFF Thermal 2 positions (number of outputs 8 max.)

ON Motorised 3 positions (number of outputs 4max.)

SW4 Valve control direction OFF Normally closed

ON Normally open

SW5 Override mode

(e.g: initial heating)

OFF No

ON Yes (valves and circulator active)

SW6

Heat pump change-over

communication

direction

OFF Heat pump to Technical Unit (Change-over input). The

heat pump delivers its production mode to the TU.

ON TU to heat pump (change-over output). The TU delivers

its production mode to the heat pump.

SW7 Heat pump change-over

conguration

OFF Contact closed= Heat mode

Contact open = Cool mode

ON Contact closed= Cool mode

Contact open = Heat mode

SW8

Type of 'water

monitoring'

measurement.

OFF

Absence of dew point measurement or sensor with

a Delta Dore condensation sensor (For cooling only,

shuts the system down if condensation is detected).

ON

Initial Cool or Heat temperature with CTN 10KW

sensor at 25°C (shuts the system down if the water is

too hot or too cool).

1

ON

6

5

4

32

DIP

88

7

SW5: Override mode

This mode overrides the 100% operation for initial heating. Set switch 5 to ON.

On the technical unit, the circulator LED and valve output LEDs are illuminat d. The 'Status'

LED is off.

On the room thermostat (RT) or the programmable thermostat (PRT) a

specic display indicates that initial heating is in progress.

All the switches are set to OFF by default.

HP: Heat pump TU: Technical unit

5/ SWITCH CONFIGURATION 6/ ASSOCIATING A ROOM THERMOSTAT WITH

A TECHNICAL UNIT

Example:

Associated outputs (CF20) Controlled outputs

Thermostat 1 1 Y1, Y2, Y3

Thermostat 2 4 Y4, Y5

Thermostat 3 6 Y6, Y7, Y8

Y1 N N N N N N N NY2 Y3 Y4 Y5 Y6 Y7 Y8

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Th 1 Th 2 Th 3

6.1 WITH A ROOM THERMOSTAT (RT)

❶Press and hold the 1st and 4th button for 3 seconds,

then release.

❷The screen displays CF20. Press OK to open the setting,

then press + and - to select the output with which the

thermostat will be associated.

Conrm with OK.

❸The screen displays CF21.

Select the transmitter and press OK.

❹The screen displays CF05.

Select the thermostat type and press OK.

3 s

1

2

(1) Output number 1 to 16 depending on the system.

Transmitter type

0Underoor heating

1 Heater

2 Ceiling or ductable

(2) Thermostat type 0 Zone thermostat

1 Master Thermostat

(2) CF05: the Master thermostat enables the centralised use of ON/OFF and HEAT/COOL

(at least one Master thermostat is required in an installation without a programmer).

34 35

EN

6/ ASSOCIATING A ROOM THERMOSTAT WITH

A TECHNICAL UNIT

(1) Output number 1 to 16 depending on the system.

Transmitter type 0Underoor heating

1 Heater

Heating percentage

limitation

From 10 to 100% in 10 increments (100%= No

limitation, by default).

6.2 WITH A PROGRAMMABLE ROOM

THERMOSTAT (PRT)

❶Turn the selector knob to .

❷Press and hold the 2nd button from the left for 3 seconds.

Release.

❸The screen displays Ln01. Press OK to open the

association mode.

❹The screen displays CF20. Press OK to open the setting,

then press + and - to select the output with which the

thermostat is to be associated.

Conrm with OK.

❺The screen displays CF21. Select the transmitter and

press OK.

❻The screen displays CF22.

Select the limitation value and press OK to conrm.

To exit the current mode, press or turn the dial.

3 s

(1) CF20: a product associated with an output also controls the following outputs in the same

manner, if these are not associated.

7/ CONFIGURING THE TECHNICAL UNIT

5 s

3 s

7.1 WITH A ROOM THERMOSTAT (RT)

❶From the OFF mode, press and hold the 2nd button

from the left for 5 seconds.

Release.

❷Press and hold OK for 3 seconds. Release.

❸The screen displays CL01.

• Press + or - to select the parameter to be set

(CL01 to CL08).

• Press OK to open the setting mode, then + and - to

perform the setting.

❹ Conrm with OK.

36 37

EN

Valve opening time 1 to 10 minutes in 30s increments (3 mn by default)

Not used

Frost Protection

(in system OFF mode)

0 Frost Protection mode authorised

1 No Frost Protection security

(1) Passive cooling 0 Not authorised

1 Allowed

(2) Max. ow water

temperature limit 45°C to 75°C in 5°C increments (50°C by default)

(2) Min. ow water

temperature limit 5°C to 30°C in 1°C increments (22°C by default)

Not used

7.2 WITH A PROGRAMMABLE ROOM THERMOSTAT (PRT)

OR PROGRAMMER (PROG)

❶Turn the selector knob to .

❷Press and hold OK for 3 seconds.

❸The screen displays CL01.

• Press + or - to select the parameter to be set (CL01 to CL08).

• Press OK to open the setting mode, then + and - to perform

the setting.

❹ Conrm with OK.

(1) CL04 only appears in Heat production mode (SW2=OFF), refer to the technical unit's

manual and for underoor heating (CF21 =0) or for ceiling/ductable (CF21 = 2).

Passive cooling: water ow for cooling (heating in OFF mode).

(2) CL06/CL07: if the limit is exceeded or reaches -> switch over to OFF mode. The defect

comes up on the thermostat screen (see 'Troubleshooting - Water monitoring input' §).

7/ CONFIGURING THE TECHNICAL UNIT

3 s

8/ RESTORING THE TECHNICAL UNIT TO

FACTORY SETTINGS

20 s

3 s

8.1 WITH A ROOM THERMOSTAT (RT)

❶From the OFF mode, Simultaneously press and hold the

1st and 3rd buttons from the left (i) for 20 seconds.

❷After 10 seconds, the screen displays rSt1.

Keep the button pressed until the screen displays rSt2.

Release.

❸Press and hold OK for 3 seconds until the rSt2

display ashes.

The system automatically returns to Shutdown

(or OFF mode).

38 39

EN

8.2 WITH A PROGRAMMABLE ROOM THERMOSTAT (PRT)

OR PROGRAMMER (PROG)

❶From the OFF mode, Simultaneously press and hold the

1st and 4th buttons from the left (i) for 20 seconds.

❷After 10 seconds, the screen displays rSt1.

Keep the button pressed until the screen displays rSt2.

Release.

❸Press and hold OK for 3 seconds until the rSt2 display

ashes.

The system automatically returns to Shutdown

(or OFF mode).

8/ RESTORING THE TECHNICAL UNIT TO

FACTORY SETTINGS

20 s

3 s

The multizone kit offers an optional water network temperature monitoring function

(hot and cold).

This function protects the system from overheating in the water network (protection of

the slab and pipes) or from abnormally low temperature, which will generally lead to the

formation of condensation on the ooring.

This information is immediately sent to the end user via a defect fed back to

the room thermostat.

Important: this feature still requires the connection of a safety device to the system

(bimetallic strip on the circulator or condensation sensor) aimed to monitor the system's

water temperature and to cut off the water ow if necessary.

Principle for the detection of excessively hot or cold water

Depending on the entered temperature limit value (to be set at the time of installation),

the system scans the water temperature and reconciles it with the set limit value. If the

water temperature is above (if the water is too hot) or below (if the water is too cold) the

limit value after 30 minutes of circulator operation, the defect is detected and sent to the

thermostat.

If a defect is found, the circulator is shut down immediately.

The system switches the thermostat to OFF mode.

The user must then contact the installer for a diagnosis or work on the heat pump or boiler

in order to reduce the hot water ow temperature setting or feed the cold water setting

back to the system.

The system can be restarted manually from a Master thermostat or a programmer.

The water network's temperature monitoring function is reactivated.

9/ WATER TEMPERATURE MONITORING

40 41

EN

When a defect is detected on the system, the symbol ashes on the room unit display.

Press 'i' to display the type of defect.

Error messages

After viewing, the symbol is displayed continuously until the problem is xed.

Downgraded mode

The technical unit operates in downgraded mode (30% in Heat, OFF and Cool mode),

for each channel, when:

- thermostat signal missing for over one hour (the red LED for the way blinks quickly),

- temperature sensor shorted.

- temperature sensor off.

Bus defect Check connection between the

room unit and the technical unit.

Green LED

ashing

RF defect -

Master TU missing defect

The technical unit must be cong-

ured as 'Master TU'.

Switch SW1 to OFF.

Green LED

ashing

TU address defect Green LED

ashing

Flow sensor shorted.

Check the sensor's connections. Green LED

ashing

Flow sensor cut off or missing

Feed water too hot Set the initial temperatures in the

technical unit conguration menu

('CL06, 07 or 08' menu).

Green LED

ashing

Inowing water too cool

Radio reception defect on

an associated door/window

magnetic contact

Check the radio association.

Check if the installation is not

affected by disturbances.

Move your products around to

check the radio range.

-

Radio reception defect on an

associated presence detector

Battery of an associated

window magnetic contact

defective Replace the batteries of the prod-

uct in question -

Battery of an associated

presence detector defective

10/ TROUBLESHOOTING

• Main power supply 230V~/240V~, +/-10%, 50/60 Hz,

• Valve power supply (24V~/= or 230V~/240V~): 4A Max for all valves

• Consumption: 2 to 15 VA depending on the number of elements connected to the bus and

the number and type of controlled valve actuator

• 8 outputs powered working contact for controlling the valves

Permanent current: 1A Max per output, 230V~/240V~ +/-10%

Accepted inrush current: 2A max. per channel, 6A max. for all channels

• 2 dry contact outputs controlling the burner and circulator (2A Max per output,

230V~/240V~ +/-10%)

• 1 change-over input or output (according to SW6 conguration).

• 2 communication buses for connecting the thermostats (star cabling)

• 1.C action (brownout)

• Class II insulation

• Surface-mounted

• Dimensions: 250 x 95 x 43 mm

• Degree of protection: IP 33

• Operating temperature: 0°C to +50°C

• Storage temperature: -10°C to +70°C

• Installation in an environment with normal pollution levels

• Anti-seize function (automatic start-up 1 to 10 minutes/week if the event that the valve

and circulator remain idle)

11/ TECHNICAL CHARACTERISTICS

www.deltadore.com

09/18

Table of contents

Other DELTA DORE Control Unit manuals

DELTA DORE

DELTA DORE Pack TYXIA 500 User manual

DELTA DORE

DELTA DORE TYXIA 4940 User manual

DELTA DORE

DELTA DORE PACK DELTA 8000 BUS CO 1.1 User manual

DELTA DORE

DELTA DORE DVR TYXAL+ User manual

DELTA DORE

DELTA DORE TYXIA 4940 User manual

DELTA DORE

DELTA DORE TYXIA 4910 User manual

DELTA DORE

DELTA DORE 6351034 User manual

DELTA DORE

DELTA DORE TYXIA 4600 User manual

DELTA DORE

DELTA DORE TYXIA 4910 User manual

DELTA DORE

DELTA DORE TYXIA 253 User manual