Norsjö Carrier User manual

Instruction manual version 6, 2008

Norsjö Carrier 4-Stroke

Short and Long version

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

CONTENTS

INTRODUCTION ................................................................................. 1

IDENTIFICATION of MOPED ................................................................. 2

SAFETY INSTRUCTIONS ...................................................................... 3

INSTRUMENT AND CONTROLS ............................................................. 4

DRIVING POSITION ............................................................................ 10

FUEL ................................................................................................. 11

MOTOR OIL ....................................................................................... 12

PRIOR TO START, DAILY CHECKS ......................................................... 12

STARTING AND STOPPING THE ENGINE ................................................. 13

DRIVING DURING THE WINTER ............................................................ 14

CHANGING GEAR ............................................................................... 15

BRAKES ............................................................................................ 16

LOADING PLATFORM ......................................................................... 18

SERVICE AND MAINTENANCE .............................................................. 20

TOWING THE MOPED .......................................................................... 25

LONG-TERM STORAGE OF MOPED ....................................................... 26

FAULT FINDING .................................................................................. 27

TECHNICAL DATA ............................................................................... 29

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

INTRODUCTION

We thank you for the trust you have shown us by buying a Norsjö Carrier 4-Stroke.

We hope that this manual will help you quickly get to know your new moped.

Read through this instruction manual from beginning to end before you start to use

your moped. Any queries will be answered by Norsjö Mekaniska AB.

About this instruction manual

This instruction manual describes how your carrier moped should be used, how service

and inspections should be carried out to make sure that the moped operates correctly

and safely. This instruction manual covers instructions for normal use and maintenance

which can be carried out by the driver. More in-depth fault fi nding and maintenance

should be carried out by qualifi ed service personnel. Remember that a well-maintained

moped will make your work more enjoyable and safer and will also lead to lower

maintenance costs and maintain a high second-hand value for your moped!

Guarantee

Even with a quality product, on the odd occasion, material or manufacturing faults

arise which are covered by the guarantee. Contact Norsjö Mekaniska AB if such a

fault occurs.

Do not modify the moped

The moped is designed and type-approved so that it complies with current legal

requirements. No modifi cations may be carried out on the moped to change the engine’s

power or increase its speed. In order to ensure correct working order and maintain a

roadworthy moped, it is important that you always use original spare parts. A modern

carrier moped is a technically advanced product. Always turn to a qualifi ed specialist if

the moped needs to be repaired or adjusted.

Running-in

Every engine needs a certain amount of time to wear in the moving parts against each

other. It is therefore important that during the fi rst 500 kms, the engine is not run too

hard. You should therefore change down when going uphill or if the conditions are poor

(uneven road surface for example). Do not use full acceleration except for short periods

during the run-in period. Furthermore, avoid using full throttle while the engine is cold

or when driving downhill. The moped requires service and inspection in connection

with the run-in period. For further information, see page 20. ”Service in connection with

run-in period”.

Page

1 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

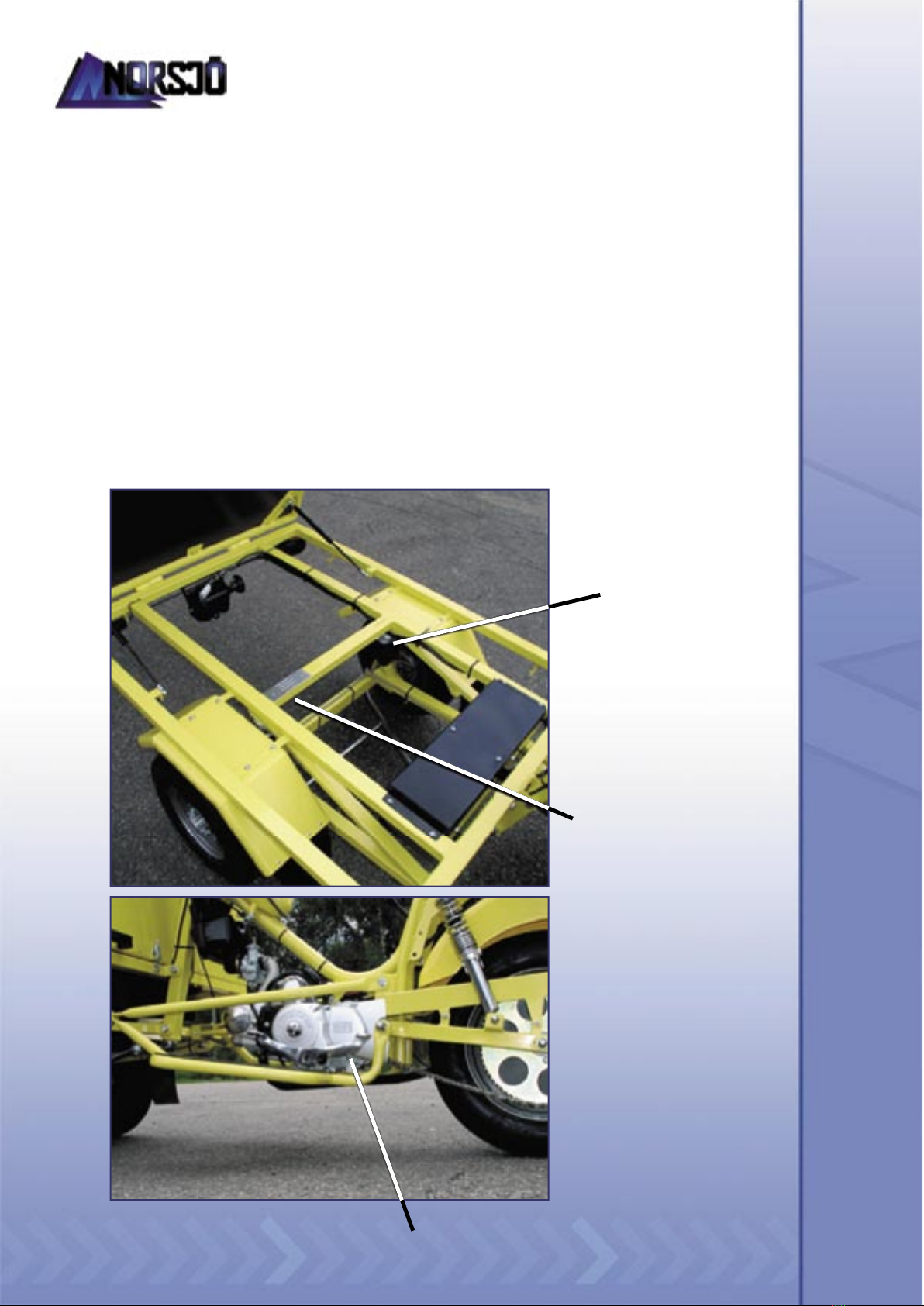

IDENTIFICATION of MOPED

Registration number

The moped’s primary identity is its registration number. When ordering spare parts,

the moped’s registration number should always be quoted. The registration number

can be found on the moped’s rear fender.

Type plate and frame number

The moped’s type plate and frame number are situated under the platform.

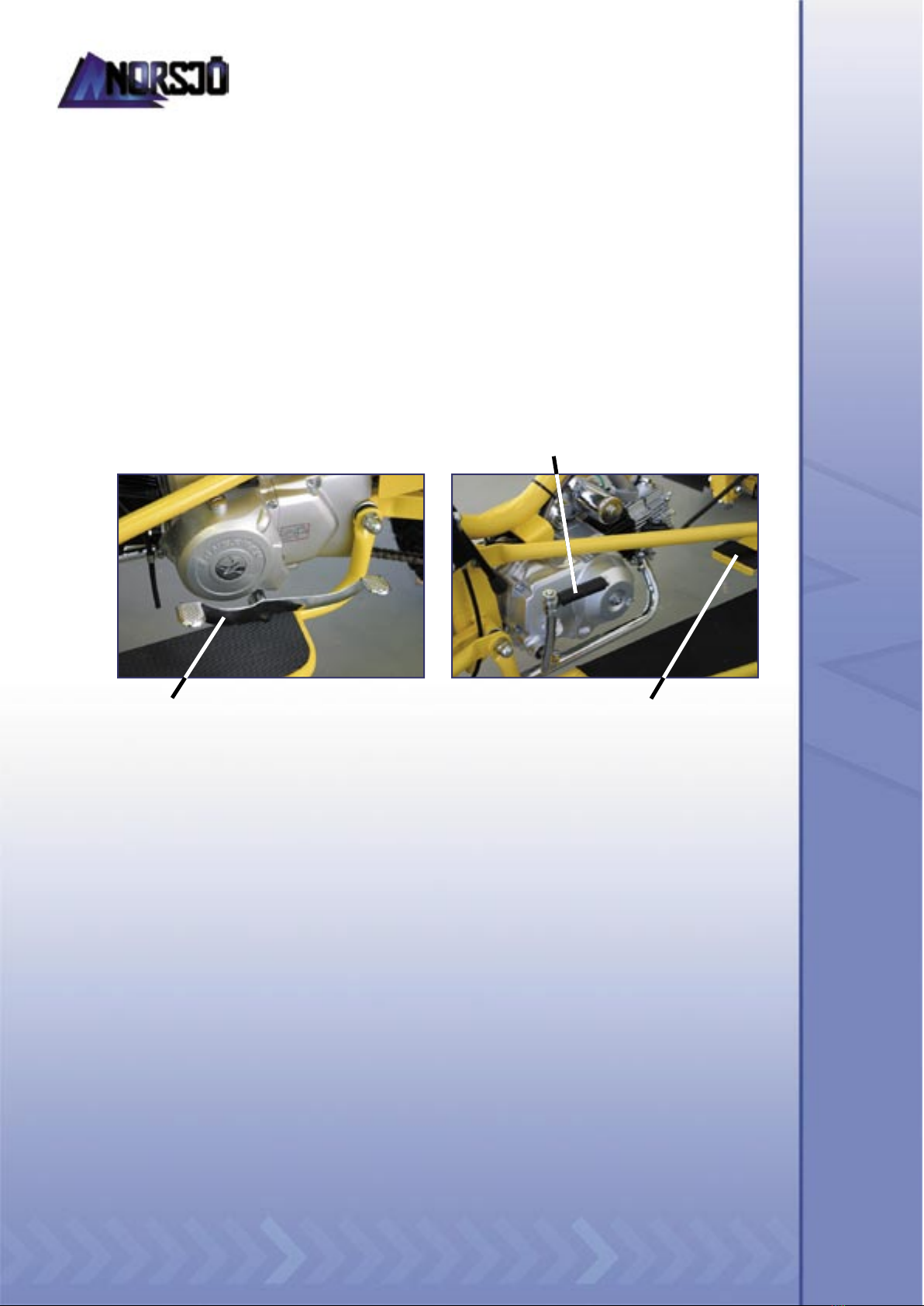

Engine number

The engine number can be found on the engine’s left side under the gear lever.

Page

2 of 30

Engine number

Type plate

Frame number

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

SAFETY INSTRUCTIONS

Risk of carbon monoxide poisoning

Exhaust fumes from internal combustion engines contain carbon monoxide.

Breathing in the exhaust fumes can be lethal!

You should therefore consider the following:

• Never start the moped in a closed area which lacks good ventilation.

• Never breathe in the exhaust fumes.

• Always ensure that the exhaust pipe is free of obstruction.

Handling and fi lling up with fuel - fi re risk

• Never fi ll the moped up with fuel when the engine is running.

• Never overfi ll the tank.

• If a spillage does arise when fi lling up with petrol, wipe away the petrol carefully

and then wait 5-10 minutes until any petrol that remains has evaporated.

• Do not fi ll up in the proximity of fi re.

• Never use a petrol-driven moped in an environment that is explosive or fl ammable.

• If there is a leakage in the fuel line, tank or any other part of the fuel system,

the engine should be stopped immediately and the fault should be rectifi ed

immediately.

• Avoid breathing in petrol fumes.

• Avoid skin contact with petrol.

Work with the moped’s battery

When working on the moped’s battery, special safety precautions must be taken.

See further, page 24, “The starter battery”.

Page

3 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

INSTRUMENT AND CONTROLS

Instrument

Ignition switch

The ignition switch has three positions, of which two of them are identical.

The three positions are:

• Position 1 = Locked

• Position 2 = Drive

• Position 3 = Drive

The ignition switch’s Locked position can be obtained by turning the key counter clockwise as

far as it will go. In this position, all electrical functions, except for the indicators are switched

off and the ignition key can be taken out.

The ignition switch’s Drive position can be obtained by turning the key to the middle position,

or as far clockwise as it will go. In this position, the engine’s ignition system and the moped’s

electrical system except for the lights are operating.

Power to the lights takes place via a generator which is completely separate from the battery

and the lights may therefore only be used when the engine is running.

Never leave the ignition switch in the Drive position when the engine is switched

off as this will discharge the battery. If left on for longer periods, the ignition sys-

tem may also be damaged.

Control lamps

On the instrument panel, there are control lamps:

• Green lamp - when lit, the gearbox is in neutral.

• Blue lamp - when lit, the main beam is switched on.

• Green lamp - when lit, the indicators are switched on.

Page

4 of 30

Speedometer

Control

lamps

Ignition

switch

• Green lamp - when lit, the indicators are switched on.

Speedometer

Control

lamps

Ignition

switch

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

Handlebar controls - left side

Functions which can be found on the handlebar’s left side are:

Full/half beam switch and full beam fl ash.

Full/half beam switch has two fi xed positions which switch on the full beam/half beam.

There is also a spring-back position which switches the full beam on (fl ash).

Half beam must be switched on when driving during daytime!

Horn

When the spring-cushioned switch is pressed in, the moped’s horn sounds.

Indicator switch

If the direction indicator control is pushed to the left, the left indicator light starts to

blink. If the direction indicator control is pushed to the right, the right indicator light

starts to blink. To reset the direction indicator control to its neutral position, press it in.

Brake handle

The control for the rear wheel brake is on the left-hand side of the handlebar.

Page

5 of 30

Horn

Brake handle

Full beam fl ash

Full/half beam switch

Indicators

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

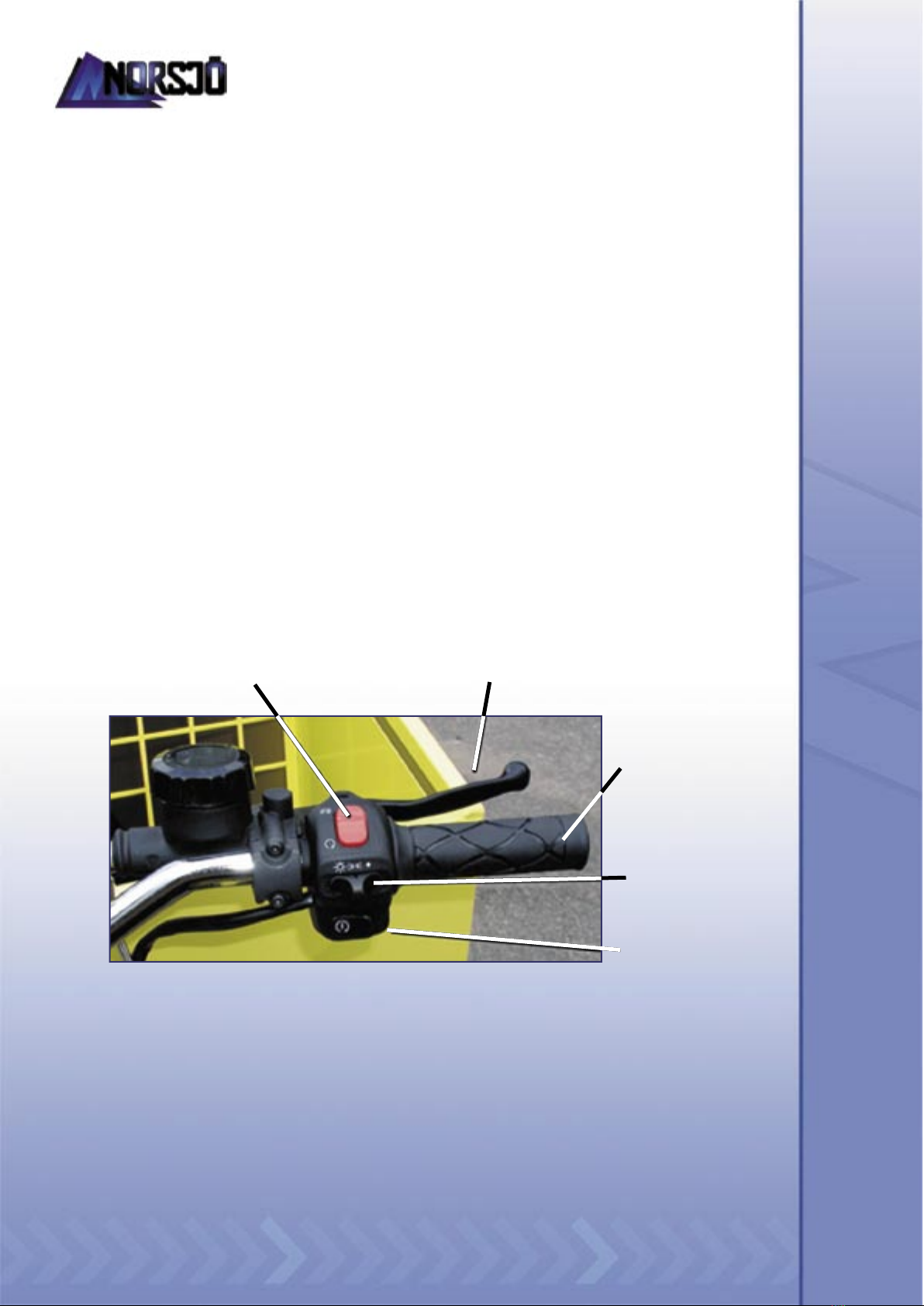

Handlebar controls – right-hand side

Emergency stop

The emergency stop may only be used in case of emergencies. If the emergency stop is

used on a daily basis to stop the engine, it may result in damage to the ignition system’s

electronics.

Brake handle

The control for the front wheel brakes is on the right-hand side of the handlebar.

Headlamp and parking lights

The sliding selector switch has 3 positions. The lights are fully switched off when

the selector switch is moved to the right. In the middle position, the parking light is

switched on, while full/half beam is activated when the selector switch is moved

to the left.

Start button

Starts the engine when the start button is pressed in at the same time as one of the

handbrakes is pressed in.

Page

6 of 30

Start button

Headlamp and

parking lights

Emergency

shutdown Brake handle

Gasreglage

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

Foot controls - left side

Gear lever

The gearbox has 4 gears and is manoeuvred with the left foot. The gears are placed with

fi rst gear, in the down position from neutral. The other gears are placed upwards.

Foot control – right-hand side

Kick-start

Is used as an alternative to the electrical start.

Accelerator pedal

This control is used to accelerate and is foot-manoeuvred with the right foot.

Page

7 of 30

Gear lever

Kick-start

Accelerator pedal

Kick-start

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

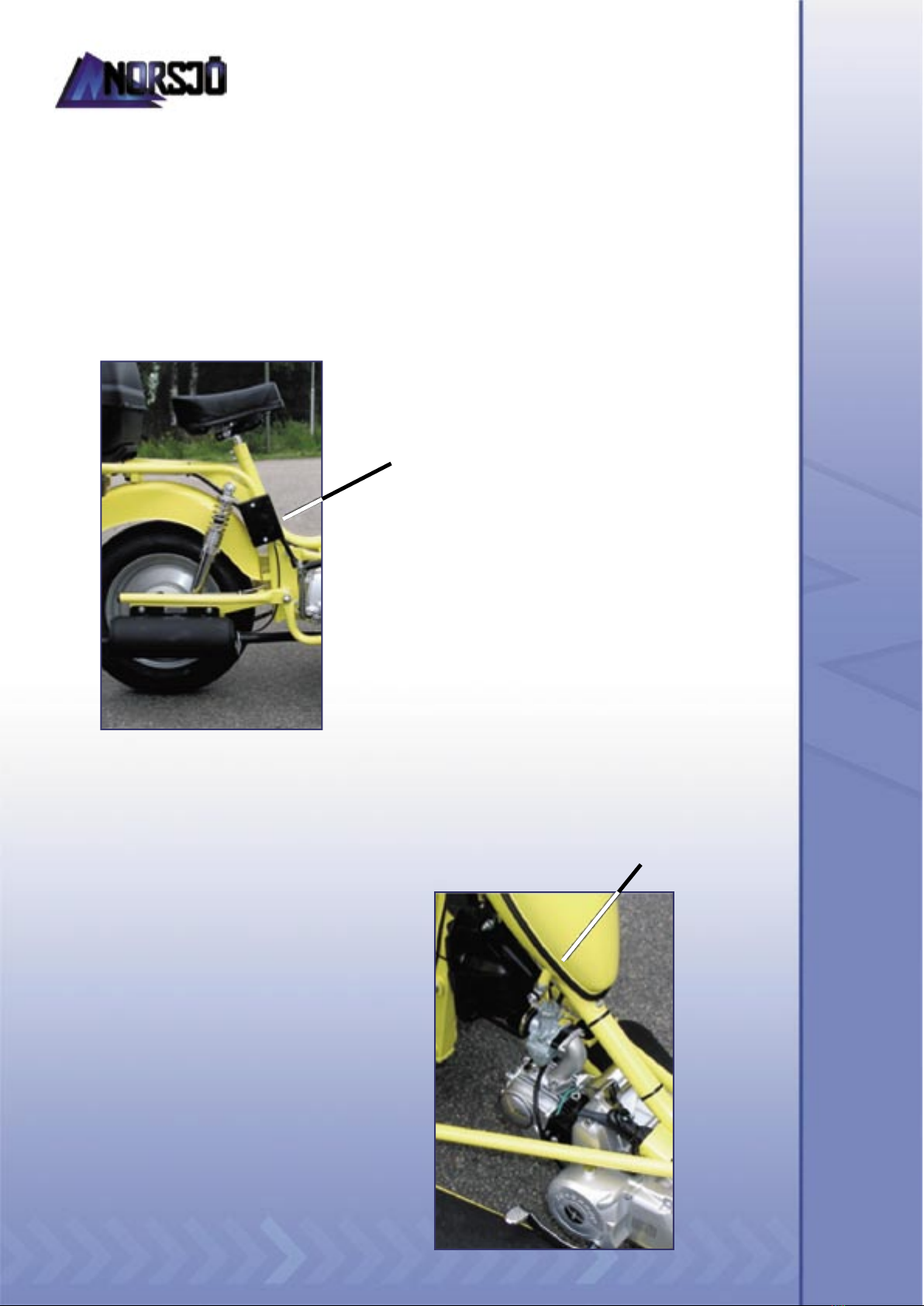

Parking brake

The moped is fi tted with a mechanically manoeuvred parking brake which operates on

the rear wheel. It is operated with a lever placed on the frame tube underneath the

saddle. The handbrake comes on when the lever is pulled upwards.

If the lever is pressed downwards, the handbrake is switched off/remains in

the off position.

Petrol shutoff valve

The petrol shutoff valve is situated on the tank’s left side. There are 3 positions:

• OFF -The petrol shutoff valve is

switched off.

• ON -normal position.

• RESERV - this position provides

a petrol reserve of approximately

0.5 litres. Only use this position on

your way to a petrol station after

you have run out of petrol.

Do not forget to change to the ”ON”

position after you have fi lled up

with petrol!

Page

8 of 30

Parking brake

Petrol shutoff valve

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

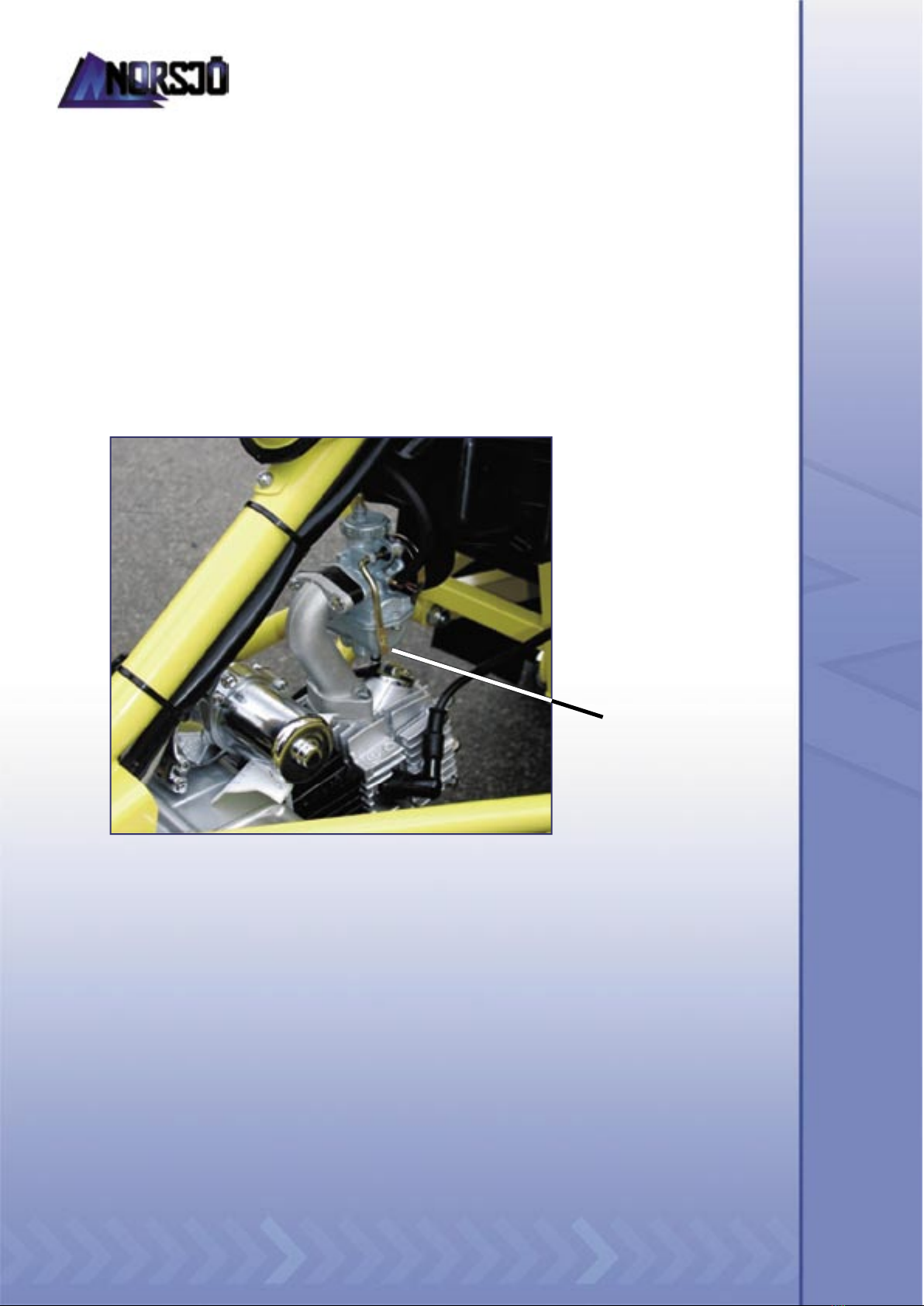

Choke

A cold engine needs a richer mixture of fuel and air in order to start. This can be

achieved by using the choke which is placed on the carburettor. Return the choke to its

original position when the engine has become warm.

Page

9 of 30

Choke

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version Page

10 of 30

DRIVING POSITION

Positioning the saddle

Height of saddle

Position required height of saddle by loosening both of the saddle seat screws.

Ensure that both of the saddle seat screws are tightly secured on the saddle post’s

fl at surface.

Saddle tilt

To change the saddle tilt, loosen the saddle bolt. Adjust the saddle to the required tilt

and tighten the saddle bolt so that the saddle sits securely in position.

Height adjustment of saddle

Loosen the saddle bolt and move the saddle backwards or forwards. After adjustment,

tighten the saddle bolt so that the saddle sits securely in position.

Saddle post

screws

Saddle bolt

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

Adjustment of rear shock absorbers (hardness)

Use universal pliers on the shock absorbers’ adjustment tube to adjust the rear shock

absorbers’ hardness. Turn in the required direction to adjust the suspension,

harder or softer.

When adjusting the shock absorbers, it is extremely important that both shock absorbers

have the same adjustment (hardness/softness) on both sides.

FUEL

The moped is equipped with a modern 4-stroke engine which is fi tted with a catalytic

converter which means that it should be run on lead-free petrol, at least 95 octane.

Normally, no additives are needed in the fuel - see Page 14, ”DRIVING DURING

THE WINTER”.

Always switch off the engine before fi lling up with petrol. Ensure that the area where

you are fi lling up with petrol is well-ventilated and avoid breathing in petrol fumes.

Also avoid skin contact with petrol. Do not smoke and ensure that there are no fl ames

or sparks in the vicinity of the moped when fi lling up.

Open the petrol cap by turning it counter clockwise. Close the petrol cap by turning it

clockwise. Both opening and closing the petrol cap is made easier if you press the petrol

cap lightly against the tank at the same time as it is turned.

To avoid leaks, the petrol tank must not be fi lled completely up to the top. This gives the

petrol the possibility of expanding a little after fi lling up. Fuel at petrol stations often

has a lower temperature than the moped’s ambient temperature so the volume of the fuel

will increase when it warms up in the tank.

When fi lling up, it is important to ensure that no water or other substances enter

the tank.

Page

11 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

MOTOR OIL

All motor oils have different types of additives to comply with requirements regarding

function and longevity. The quality requirements and range of application which the oil

is suitable for is specifi ed by indicating which norm the oil fulfi ls.

The moped is equipped with an air-cooled 4-stroke engine. The motor oil must also

lubricate the gearbox, the clutch as well as the engine. The standards which the oil must

meet in order to do this are designated JASO MA and API SG.

Only use oils which comply with both of the above norms. Only use oils from

known quality manufacturers. Incorrect oil or oil that is of low quality may lead

to the risk of incorrect functioning of the gearbox and clutch and may also

result in serious engine damage.

PRIOR TO START, DAILY CHECKS

Make it a habit to check the moped every day. Faults that are discovered and rectifi ed

early, keep maintenance costs low.

During the daily inspection, the following should be checked:

• Check the engine so that it is clean of dust and oil. If there is an oil leak,

the reason must be investigated and rectifi ed.

• Check the oil level in the engine and top up if required. When driving on

hot days and when driving hard, an increase in oil consumption is normal.

• Check that the moped’s lights, indicators, brake light and horn work as intended.

• Ensure that all of the moped’s brakes function as intended.

• Check the brake fl uid level in both containers.

• Check that the driving chain is correctly tightened and oiled.

• Check that the accelerator pedal moves easily and springs back to its

original position.

• Check that the tyres are not damaged and that the air pressure is correctly adjusted.

Page

12 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

STARTING AND STOPPING THE ENGINE

Ensure that the gearbox is in its neutral position before the engine is started.

This is indicated when the red lamp on the instrument panel is lit.

Using the electric starter motor

The moped is equipped with a push-button operated starter motor. So that the starter

motor is not activated unintentionally, the moped’s rear brake (left brake handle) or

front brake (right brake handle) should be pressed in.

Release the starter button immediately after the engine has started. The starter motor

must not be initiated when the engine is running, this can cause damage.

In order not to overload the starter motor, it is important that it is not used for more than

three seconds at a time. On repeated start attempts, the starter motor must be allowed

to rest for at least 10 seconds between every start attempt. This will provide the starter

motor with the possibility of cooling down at the same time as the starter battery can

recover for the next start attempt.

Normally, the engine will start after 1 - 2 seconds of running the starter motor.

If the engine does not start immediately, Check:

• that the emergency stop is not activated.

• that there is petrol and the petrol shutoff valve is open.

Use of kick-start

The moped is equipped with a foot-operated kick-start. Fold out the top part of the

kick-start lever and press the kick-start down until the connecting mechanism moves

into it operating position. Kick down calmly and resolutely with requisite force.

When the kick-start has reached its lowest position, it must be returned immediately to

its original position. Carry out this procedure with your foot still on the kick-start lever.

Holding down the kick-start in its lowest position after the engine has

started or releasing the kick-start in an uncontrolled manner leads to

an abnormal amount of wear.

Starting a cold engine

Activate the choke by pulling the choke upwards. Turn the ignition key clockwise to

position 2 or 3. Start the engine by pressing in the start button at the same time as the

brake handle is press the end. Use little or no throttle during the starter. After the engine

has started, open the throttle up a little.

Run the engine until it is warm and then activate the choke by pressing downwards.

Page

13 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

Starting the engine when the engine is warm

A warm engine is started in the same way as a cold engine, with the exception that the

choke is not used.

Stopping the engine

The engine is stopped by turning the ignition switch counter clockwise to position 1.

Make it a habit to always switch off the petrol shutoff valve when driving has been

completed.

Running the engine warm/hot

All parts of the engine expand when they are heated up. They are therefore

manufactured so that they fi t together optimally when the engine has reached its

correct working temperature.

In order to ensure long working life, do not overload or rev up the engine before it has

reached its correct working temperature.

The engine will reach its optimal working temperature when it is run with a light

load 1-3 minutes dependent upon ambient temperature. The engine has reached its

correct working temperature when it responds to the throttle without the choke

having to be used.

DRIVING DURING THE WINTER

Risk of ice forming in the fuel system

When driving during the winter, considerable condensation may build up in the petrol tank.

This is particularly so for vehicles which are exposed to great variations in temperature due to

changes in the weather or if the vehicle is moved in and out of heated premises.

Condensation water can then freeze to ice and produce operating disturbances in the form of

uneven running of the engine; in worst cases the engine will stop completely. Avoid this:

• Keep the petrol tank well-fi lled to avoid condensation.

• Add suitable amounts of carburettor spirits.

Check wires and the chain more often when it is cold.

Both the wires and the chain need extra attention during the winter period. This is particularly

important when driving through areas where road salt has been used. You should therefore make

it a habit to clean the chain and lubricate both the chain and wires more and at more regular

intervals during the winter.

Use the right oil type to make it easier to start when the engine is cold.

Ordinary mineral oil is more viscous when the temperature drops which leads to the engine

being more diffi cult to start during the winter. Half or fully synthetic oils have however

excellent cold-start characteristics and are a more suitable choice of oil for the winter period.

Page

14 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

CHANGING GEAR

The moped is equipped with a semi-automatic 4-speed gearbox. The gearbox is

semi-automatic which means that it is equipped with a centrifugal clutch which

is controlled by the engine speed. The engine is engaged when the accelerator pedal

is pressed; this takes place at an engine speed which is a little greater than the

engine’s idle speed.

All gear changing must take place when the engine is idling.

Gear changing with the throttle open may cause serious damage to the gearbox!

Starting from rest

When starting from rest, engage fi rst gear when the engine is idling. The moped will

move forwards by calmly and slowly engaging the throttle.

If the moped is used on a fl at and hard surface such as asphalt, use second gear to start.

This can still be an advantage when driving short distances between mailboxes,

as there will be no need to change up and down between each stop.

Changing gear up and down

Changing up to a higher gear is done by reducing the throttle so that the engine speed

drops down to the idle speed. Engage the next gear by pressing with your heel on the

gear lever’s rear part.

When changing down, this should be done in a similar manner. Ensure however that

the moped’s speed has dropped to a suitable level for the gear you are going to engage

before the gear-change is carried out.

Temporary stops

For short stops, for example when stopping at traffi c lights, fi rst gear may be engaged.

For longer stops, the gearbox should be placed in neutral; for environmental reasons,

you should also consider switching off the engine.

Never leave the moped with the engine running and in gear.

Page

15 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

BRAKES

The moped is equipped with:

• a hydraulic brake which operates on both of the front wheels.

• a hydraulic brake which operates on the rear wheel.

• a mechanically operated parking brake.

Use both the front brake and the rear brake at the same time to ensure safe and effi cient

braking. Get to know how the brakes work by ”test driving” in a secluded area away

from normal traffi c.

Use of the hydraulic brakes should produce an ”immediate” effect. If the brake handle

however feels as though there is too much or too little play, the brakes must be inspected

immediately by a specialist.

Please note!

It is extremely important that the brakes work properly and effi ciently.

In order to ensure that they work properly,

all service and repairs must be carried out by an expert.

Page

16 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

Checking the brake fl uid

If the brake fl uid level is too low, air can enter the system which will either reduce the

brakes’ effi ciency or cause them to stop functioning. Before you drive, always check the

brake fl uid level on both hand-operated brakes.

Important:

• There must be no impurities in the brake fl uid. Before you fi ll up with brake fl uid,

ensure that the area around the fi ller cap is clean. Filling up with brake fl uid

must also take place in an area where the air is free from airborne pollutants.

• Used only recommended brake fl uid. Incorrect brake fl uid can damage rubber

seals and hoses which will cause leakages and ineffi cient braking.

• Ensure that no water is mixed in with the brake fl uid,

as this will lower its boiling point.

Vaporisation which occurs when brake fl uid boils leads to ineffi cient braking

or no braking effect at all.

• Brake fl uid is highly corrosive on paint and plastic and spilled brake fl uid

must therefore be wiped away immediately.

Changing the brake fl uid

Brake fl uid is a hygroscopic fl uid which means that it absorbs water from the ambient

air. As already mentioned, this will cause a reduction in the boiling point for the brake

fl uid. Furthermore, water mixed in with brake fl uid leads to corrosion in the

braking system. For these reasons, brake fl uid must be changed every two years.

This should be carried out by an expert.

Page

17 of 30

Norsjö Carrier 4-Stroke

Model Post Petrol Short and Long version

PLATFORM LOADS

Loading

Ensure that the load is as evenly distributed over the loading area as possible.

Also ensure that the centre of gravity is low by placing heavy objects as low-down as

possible. If possible, position the load so that it cannot move when you are driving.

Always adjust your speed based on the load you are carrying, this is of particular

importance when you’re driving round curves and on uneven ground.

Page

18 of 30

The lockable hatch

door is kept in the

open position by

two gas springs.

Lockable box

for helmet

Placing of the lock

The weather protection in the up position

functions as a windbreak for the driver.

Weather protection in down position.

Table of contents