8

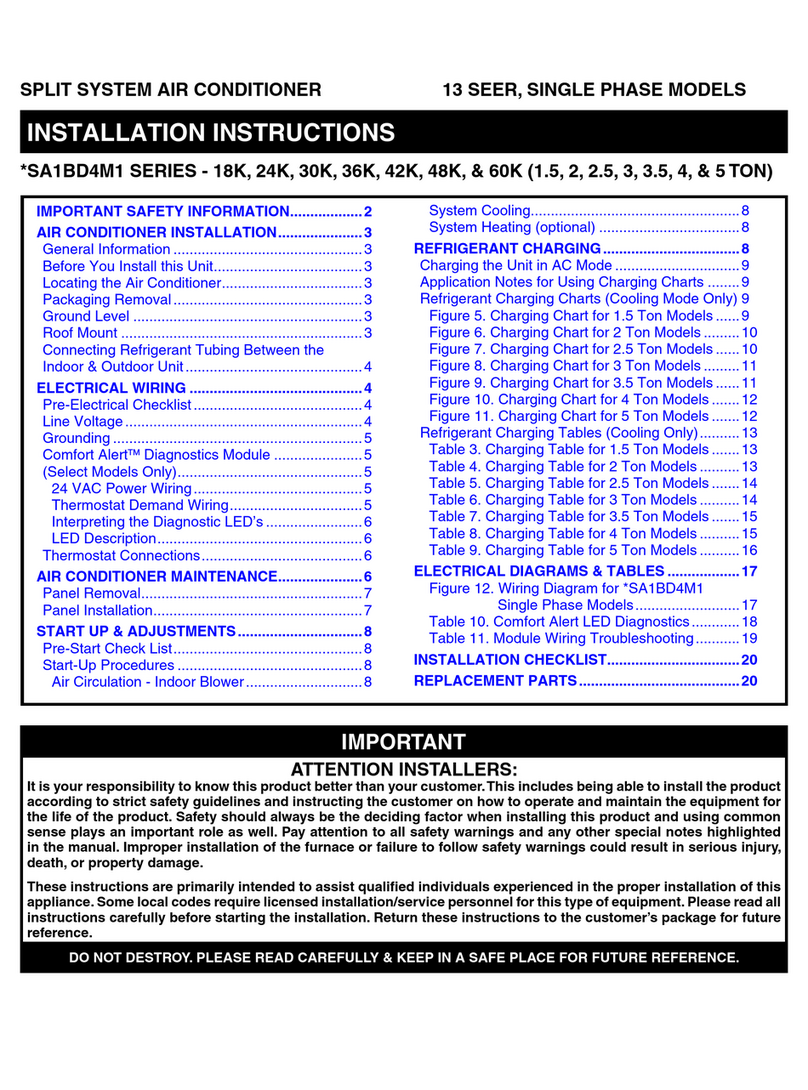

AIR CONDITIONER MAINTENANCE

WARNING:

To prevent electrical shock, personal injury, or

death,disconnectallelectricalpowertotheunit

before performing any maintenance or service.

The unit may have more than one electrical

supply.

Proper maintenance is important to achieve optimum

performancefromtheairconditioner.Theabilitytoproperly

perform maintenance on this equipment requires certain

mechanical skills and tools. If you do not possess these

skills, contact your dealer for maintenance.Consult your

localdealerabouttheavailabilityofmaintenancecontracts.

Routine maintenance should include the following:

• Inspectandcleanorreplaceairltersatthebeginning

ofeachheatingandcoolingseason,ormorefrequently

if required.

• Inspectthecondensatedrainandoutdoorcoilatthe

beginningofeachcoolingseason.Removeanydebris.

(pages 10 -12) and Figures 3 - 9 (pages 12 - 15) for

correct system charging.

• S4BDoutdoorunitswithnon-AHRIlistedindoorcoils

arenotrecommended.Deviationsfromratedairflowsor

non-listedcombinationsmayrequiremodificationtothe

expansiondeviceandrefrigerantchargingprocedures

for proper and efficient system operation.

• Therefrigerantchargecanbecheckedandadjusted

through the service ports provided external to the

outdoor unit. Use only gage line sets which have a

“Schrader” depression device present to actuate the

valve.

Charging the Unit in AC mode at outdoor temperatures

above55°Fforoptimizedsub-coolingof10°F-12°F.

1.Withthesystemoperatingatsteady-state,measurethe

liquid refrigerant pressure (in psig) at the outdoor unit

service valve.

2.Measure the liquid refrigerant temperature (in

Fahrenheit) at the service valve.

3.Determinetherequiredliquidrefrigerantpressurefrom

the appropriate charging chart (Figures 3 - 9).

•IfthepressuremeasuredinStep1isgreaterthan

therequiredliquidrefrigerantpressuredeterminedin

Step3,thenthereistoomuchchargeinthesystem.

Remove refrigerant and repeat Steps 1 through 3

until the system is correctly charged.

•IfthepressuremeasuredinStep1islessthanthe

required liquid refrigerant pressure determined in

Step 3, there is too little charge in the system. Add

refrigerant and repeat Steps 1 through 3 until the

system is correctly charged.

COMPONENT FUNCTIONS

Comfort AlertTM Diagnostics (Select Models Only)

The Comfort Alert diagnostics module troubleshoots

heat pump and air conditioning system failures and

accurately detects the cause of electrical and system

related failures without any sensors. A flashing LED

indicatorcommunicatestheALERTcodetoquicklydirect

the technician to the root cause of a problem.

High Pressure Switch (HPS) - A high-pressure switch

is factory-installed and located in the liquid line internal

to the outdoor unit.The switch is designed to protect the

systemwhen very highpressures occur during abnormal

conditions.Undernormalconditions,theswitchisclosed.

Iftheliquidpressurerisesabove575psig,thentheswitch

willopenandde-energizetheoutdoorunit.Theswitchwill

close again once the liquid pressure decreases to 460

psig.Pleasenotethattheswitchinterruptsthethermostat

inputs to the unit.Thus, when the switch opens and then

closes,theremaybea5minuteshortcyclingdelaybefore

theoutdoorunitwillenergize.

Low-Pressure Switch - (Select Models) A low-pressure

switch is factory-installed and located in the suction line

internal to the outdoor unit. The switch is designed to

protectthecompressorfromalossofcharge.Undernormal

conditions,theswitchisclosed.Ifthesuctionpressurefalls

below5psig,thentheswitchwillopenandde-energizethe

outdoor unit.The switch will close again once the suction

pressure increases above 20 psig. Please note that the

switch interrupts the thermostat inputs to the unit.When

theswitchopensandthen closes,therewillbea 5 minute

shortcyclingdelaybeforetheoutdoorunitwillenergize.

Cleantheoutdoorcoil andlouversasnecessary using

amilddetergentandwater.Rinsethoroughlywithwater.

• Inspecttheelectricalconnectionsfortightnessatthe

beginningofeachheatingandcoolingseason.Service

as necessary.

CAUTION:

The unit should never be operated without a

filterinthereturnairsystem.Replacedisposable

filters with the same type and size.

• Do not attempt to add additional oil to motors un-

equippedwithoiltubes.Thecompressorishermetically

sealed at the factory and does not require lubrication.