North Coast Synthesis MSK 009 User manual

MSK 009 Coiler Multi-Mode

Filter and Rectifier

North Coast Synthesis Ltd.

Matthew Skala

November 24, 2020

Documentation for the MSK 009

Copyright ©2018, 2019, 2020 Matthew Skala

This documentation is free: you can redistribute it and/or modify it under the terms of the GNU General

Public License as published by the Free Software Foundation, version 3.

This documentation is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY;

without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PUR-

POSE. See the GNU General Public License for more details.

You should have received a copy of the GNU General Public License along with this documentation. If not,

see http://www.gnu.org/licenses/.

2

Contents

General notes 5

Controls and connections ......................................... 5

TUNE knob ............................................... 5

res knob ................................................. 5

att knob ................................................. 5

IN inputs ................................................ 6

CV inputs ................................................ 6

HP, BP, and LP outputs ........................................ 6

Specifications ................................................ 6

Voltage modification ............................................ 7

Source package ............................................... 7

PCBs and physical design ......................................... 7

Use and contact information ........................................ 7

Safety and other warnings 9

Bill of materials 10

Building Board 2 12

Preliminaries ................................................ 12

Decoupling capacitors ........................................... 12

Fixed resistors ............................................... 12

Semiconductors ............................................... 14

Electrolytic and film capacitors ...................................... 15

Trimmer potentiometers .......................................... 15

Inductors .................................................. 15

Eurorack power connector ......................................... 16

Building Board 1 17

Preliminaries ................................................ 17

Some notes on knobs ............................................ 17

Decoupling capacitors ........................................... 19

Fixed resistors ............................................... 19

Semiconductors ............................................... 20

Compensation capacitors ......................................... 21

Exponential converter cluster ....................................... 21

Board to board connectors ......................................... 22

Panel components ............................................. 22

Final assembly ............................................... 23

Adjustment and testing 25

Short-circuit test .............................................. 25

Output offset adjustment ......................................... 25

Troubleshooting .............................................. 26

3

Patch ideas 28

Circuit explanation 30

Two-pole state-variable intuition ..................................... 30

Integrators ................................................. 31

Input mixer and rectifier .......................................... 34

Exponential converter ........................................... 35

Mechanical drawings 37

4

General notes

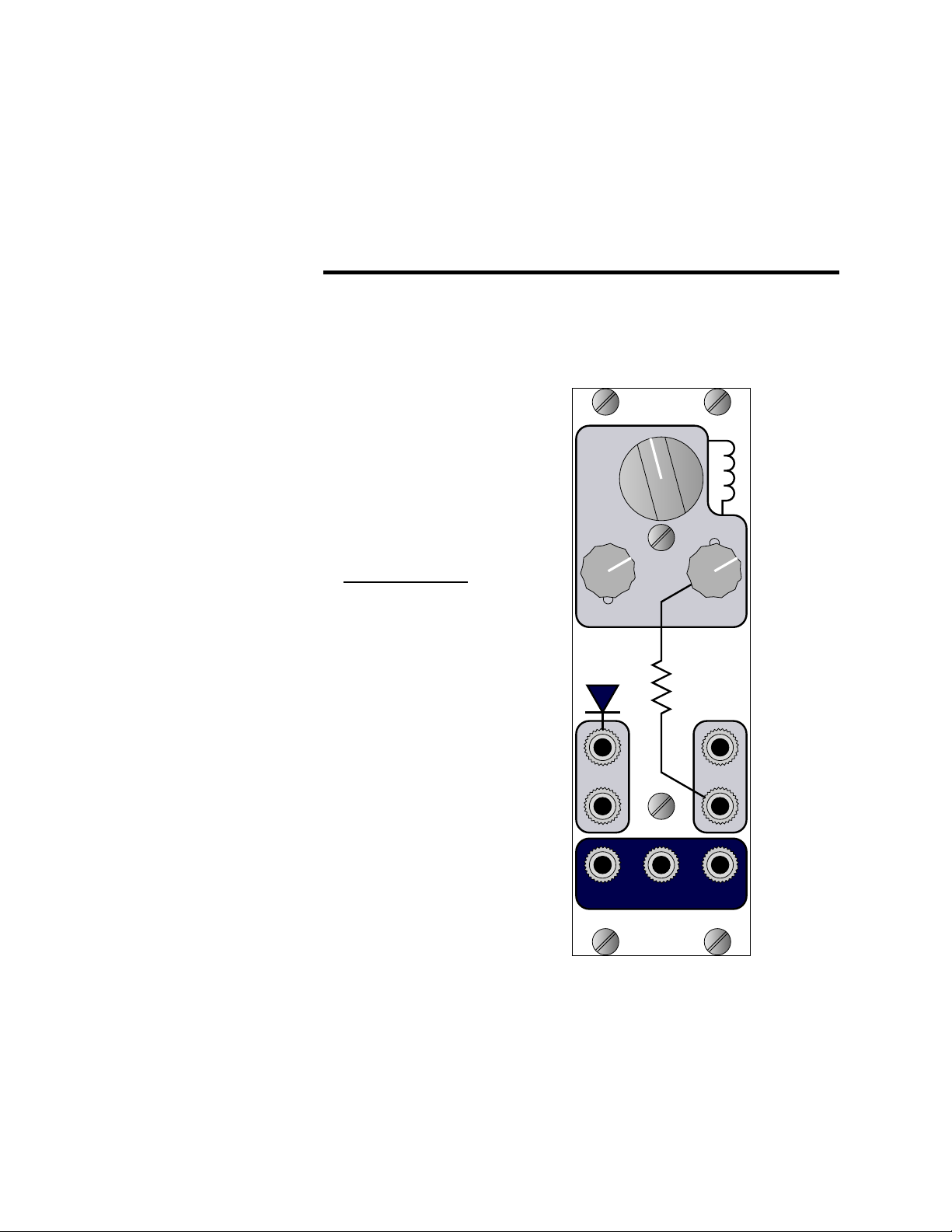

This manual documents the MSK 009 Coiler Multi-

Mode Filter and Rectifier, which is a module for

use in a Eurorack modular synthesizer. The mod-

ule contains a voltage-controlled two-pole state vari-

able filter implemented using inductors (coils, hence

the name) as the main energy-storing components in

the integrators. It also uses capacitors, which have

their main effect at bass frequencies, with the filter’s

behaviour shading from capacitor-based to inductor-

based between about 500Hz to 2kHz. There are sep-

arate outputs for high-pass, band-pass, and low-pass

transfer functions, and two audio inputs, one of which

goes through a full-wave rectifier before being fed into

the filter.

Controls and connections

The front panel of the module is shown in Figure 1.

TUNE knob This knob adjusts the overall frequency

of the filter, for all three outputs. Its setting is added

to the control voltage inputs. It should cover the

entire usable range of the filter, with a little bit of

excess at the low end to allow for “closing” the filter

more completely when using voltage control in a low-

pass gate patch.

res knob This sets the “resonance” of the filter by

attenuating one of the feedback paths. Counter-

clockwise for a flatter response curve, clockwise for

a sharper peak. Near the clockwise maximum res-

onance, the filter will oscillate. Because of the way

the inductors respond differently to phase at different

points on the audio spectrum, this knob’s effect inter-

acts with the current frequency setting; the height of

the resonance peak and the point at which oscillation

begins will change with the cutoff frequency, creating

a wide range of varying-timbre effects.

att knob This is an attenuator for the CV2 input—

the lower of the two CV inputs, to which this knob

is joined by the zigzag resistor line in the panel art,

symbolizing attenuation. With the knob fully clock-

wise the sensitivity of this input is approximately

T

U

N

E

res att

fw rect

coiler

multi

mode

filter

IN CV

HP BP LP

MSK 009

NORTH

COAST

Figure 1: Module front panel.

5

1V/octave, the same as the unattenuated input. At

lower settings, the CV2 input is less sensitive.

IN inputs Audio inputs to the filter. The upper in-

put, marked with a diode symbol and the notation fw

rect, is subjected to full-wave rectification (positive

and negative voltages translated into their absolute

values) before being applied to the filter. The lower

input is a direct connection. Both inputs may be used

at once; their effects are summed.

The rectified input includes a phase inverter (both

positive and negative voltages are translated into neg-

ative) to cancel out the naturally-occuring phase in-

version between the input and LP output in this filter

topology. As a result, if you feed an audio signal into

the rectified input with the filter cutoff significantly

below the frequency of the audio, it will be rectified

and filtered into a positive voltage tracking the overall

amplitude of the input signal. This way the module

can be used as an envelope follower.

The inputs can accept any voltages between the

module’s power rails (−12V to +12V) without dam-

age. The module my be overdriven, creating signifi-

cant distortion, with inputs beyond about ±5V.

CV inputs Exponential control voltages for filter

cutoff frequency. The upper socket (CV1) has a

nominal sensitivity of 1V/octave; but the tracking

of this filter is not meant to be very accurate, and

it cannot be made highly accurate because of the

somewhat unpredictable properties of the inductors.

Tracking will differ in different parts of the audio

spectrum. The CV-processing circuit is partially

temperature-compensated, with zeroth-order “offset”

compensation but not first-order “tracking” compen-

sation. The lower socket’s (CV2) sensitivity is ad-

justable with the att knob, to a maximum of the same

sensitivity as CV1. The CV1 input, attenuated CV2

input, and TUNE knob setting are all summed to

produce the control value for the filter core.

Both CV inputs can accept voltages anywhere be-

tween the module’s power rails (−12V to +12V) with-

out damage. Which voltages are useful depends on

the patch and the setting of the TUNE knob, but a

typical user might aim for 0V to 5V.

HP, BP, and LP outputs These are the three out-

puts of the filter core: high-pass, band-pass, and low-

pass. Because this is a two-pole filter, the asymptotic

slopes of the response curves are 12dB/octave for the

high-pass and low-pass, and 6dB/octave on each of

two slopes for the band-pass.

All three outputs are active simultaneously,

driven by the combined input from the two IN jack

sockets. The phase relationships among the three

outputs will change with frequency as the filter shifts

between using its capacitors and its inductors; that

means mixing outputs to produce other filter func-

tions (such as notch filtering) may produce results

that sound good, but they are unlikely to be strong

on measures like stopband attenuation.

Voltage levels on the audio outputs will normally

be similar to the voltage levels on the inputs, with the

maximum possible voltage limited by possible clip-

ping in the op amp chips at around ±10V. Output

level at maximum oscillation will be about ±5V. At

the lowest resonance setting, the BP output will be

a little quieter than the other two, an effect which

tends to disappear at higher resonance.

Specifications

The nominal input impedance is 100kΩfor all inputs

except the rectifier input, which varies between 50kΩ

and 100kΩ. Nominal output impedance is 1kΩfor all

outputs.

Any voltage between the power supply rails (nom-

inally ±12V) is safe for the module, on any input;

output voltages are limited by the capabilities of the

op amps to about ±10V and will clip if the inputs

are driven sufficiently hard. Distortion resulting from

limiting in internal feedback paths may show up be-

fore the outputs actually clip.

The circuit is DC-coupled throughout; as a result,

it can operate at very low frequencies, but small DC

offsets may appear on the outputs. Trimmers are

provided for minimizing offset effects.

Briefly shorting any input or output to any fixed

voltage at or between the power rails, or shorting

two to each other, should be harmless to the module.

Patching the MSK 009’s output into some other mod-

ule’s output should be harmless to the MSK 009, but

doing that is not recommended because it is possible

the non-MSK 009 module may be harmed.

This module (assuming a correct build using the

recommended components) is protected against re-

verse power connection. It will not function with the

power reversed, but will not cause or suffer any dam-

age. Some other kinds of power misconnection may

possibly be dangerous to the module or the power

supply.

In normal operation the maximum current de-

mand of this module is 25mA from the +12V supply

6

and 25mA from the -12V supply. Placing an unusu-

ally heavy load on the outputs (for instance, with so-

called passive modules) can increase the power supply

current beyond those levels.

Voltage modification

This circuit is designed for ±12V power. It should

work acceptably on ±15V power without modifica-

tion, assuming all components are rated for the in-

creased voltage, but some current levels and adjust-

ment ranges are related to the power supplies and so

just applying ±15V power with no changes may not

give optimal results. In particular, I would expect

doing that to create “dead zones” at the ends of the

tuning control range. My suggestion if using ±15V

power would be to increase all four 220kΩresistors

(R5, R8, R19, and R29) to 270kΩ; that should restore

the intended current levels and adjustment ranges.

I have calculated but not tested these resistor

changes.

Source package

A ZIP archive containing source code for this doc-

ument and for the module itself, including things

like machine-readable CAD files, is available from the

Web site at https://northcoastsynthesis.com/.

Be aware that actually building from source requires

some manual steps; Makefiles for GNU Make are pro-

vided, but you may need to manually generate PDFs

from the CAD files for inclusion in the document,

make Gerbers from the PCB design, manually edit

the .csv bill of materials files if you change the bill of

materials, and so on.

Recommended software for use with the source

code includes:

•GNU Make;

•L

A

T

E

X for document compilation;

•LaTeX.mk (Danjean and Legrand, not to be

confused with other similarly-named L

A

T

EX-

automation tools);

•Circuit_macros (for in-document schematic di-

agrams);

•Kicad (electronic design automation);

•Qcad (2D drafting); and

•Perl (for the BOM-generating script).

The kicad-symbols/ subdirectory contains my

customised schematic symbol and PCB footprint li-

braries for Kicad. Kicad doesn’t normally keep de-

pendencies like symbols inside a project directory, so

on my system, these files actually live in a central di-

rectory shared by many projects. As a result, upon

unpacking the ZIP file you may need to do some re-

configuration of the library paths stored inside the

project files, in order to allow the symbols and foot-

prints to be found. Also, this directory will probably

contain some extra bonus symbols and footprints not

actually used by this project, because it’s a copy of

the directory shared with other projects.

The package is covered by the GNU GPL, version

3, a copy of which is included in the file COPYING.

PCBs and physical design

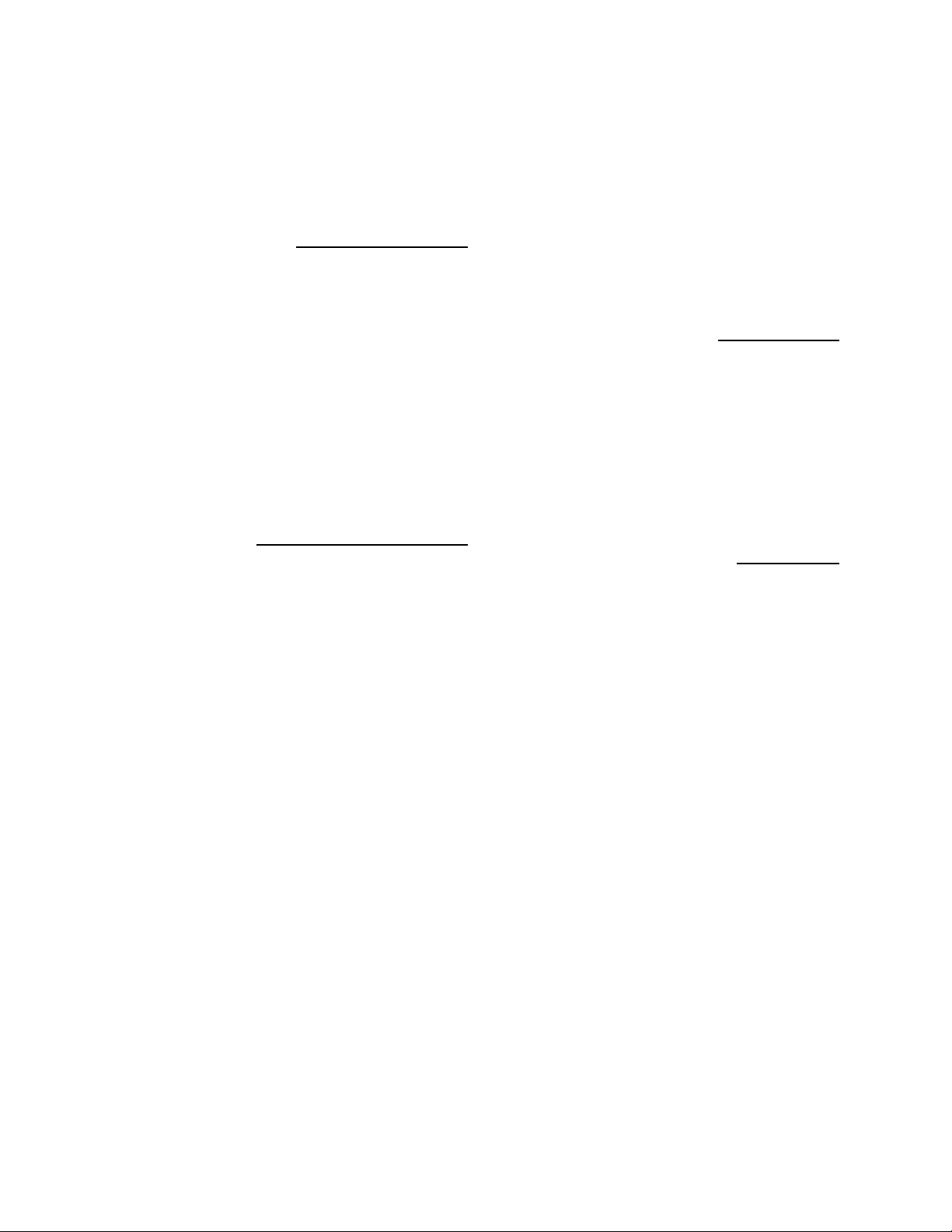

The enclosed PCB design is for two boards. Board

1 is 3.90′′ ×1.50′′ or 99.06mm×38.10mm. Board 2 is

a little shorter, 3.40′′ ×1.50′′ or 86.36mm×38.10mm.

The two boards are intended to mount in a stack par-

allel to the Eurorack panel, held together with M3

machine screws and male-female hex standoff hard-

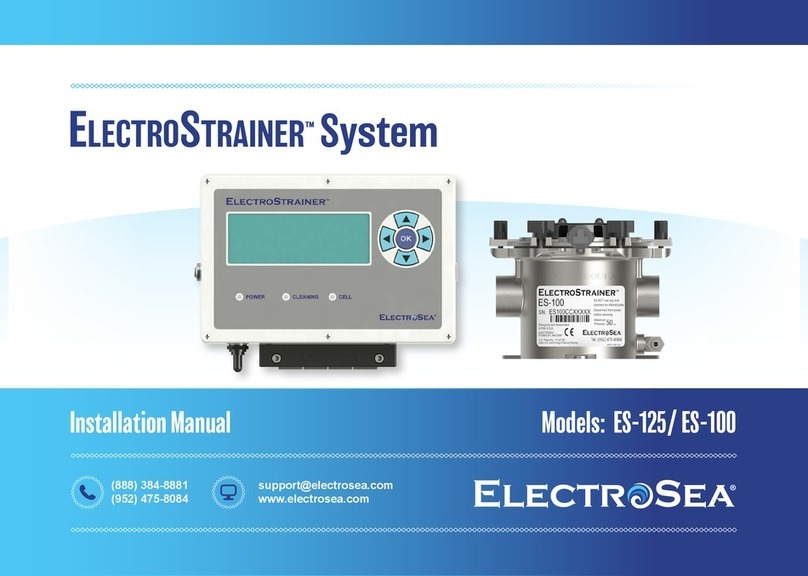

ware. See Figure 2. Including 18mm of clearance for

the mated power connector, the module should fit in

46mm of depth measured from the back of the front

panel.

Use and contact information

This module design is released under the GNU GPL,

version 3, a copy of which is in the source code pack-

age in the file named COPYING. One important con-

sequence of the license is that if you distribute the

design to others—for instance, as a built hardware

device—then you are obligated to make the source

code available to them at no additional charge, in-

cluding any modifications you may have made to the

original design. Source code for a hardware device in-

cludes without limitation such things as the machine-

readable, human-editable CAD files for the circuit

boards and panels. You also are not permitted to

limit others’ freedoms to redistribute the design and

make further modifications of their own.

I sell this and other modules, both as fully assem-

bled products and do-it-yourself kits, from my Web

storefront at http://northcoastsynthesis.com/.

Your support of my business is what makes it pos-

sible for me to continue releasing module designs for

free. The latest version of this document and the

associated source files can be found at that Web site.

Email should be sent to

7

13mm

stand-

off

11mm

stand-

off

2mm front panel

2×1.6mm PCBs

18mm

clearance

for mated

power

connector

≈46mm depth

Figure 2: Assembled module, side view.

8

Safety and other warnings

Ask an adult to help you.

North Coast Synthesis Ltd. does not offer war-

ranties or technical support on anything we did not

build and sell. That applies both to modules built

by you or others from the kits we sell, and to fully-

assembled modules that might be built by others us-

ing our plans. Especially note that because we pub-

lish detailed plans and we permit third parties to

build and sell modules using our plans subject to the

relevant license terms, it is reasonable to expect that

there will be modules on the new and used markets

closely resembling ours but not built and sold by us.

We may be able to help in authenticating a module

of unknown provenance; contact us if you have ques-

tions of this nature.

For new modules purchased through a reseller,

warranty and technical support issues should be

taken to the reseller first. Resellers buy modules from

North Coast at a significant discount, allowing them

to resell the modules at a profit, and part of the way

they earn that is by taking responsibility for support-

ing their own customers.

We also sell our products to hobbyists who enjoy

tinkering with and customizing electronic equipment.

Modules like ours, even if originally built by us, may

be quite likely to contain third-party “mods,” added

or deleted features, or otherwise differ from the stan-

dard specifications of our assembled modules when

new. Be aware of this possibility when you buy a

used module.

Soldering irons are very hot.

Solder splashes and cut-off bits of component

leads can fly a greater distance and are harder to

clean up than you might expect. Spread out some

newspapers or similar to catch them, and wear eye

protection.

Lead solder is toxic, as are some fluxes used with

lead-free solder. Do not eat, drink, smoke, pick your

nose, or engage in sexual activity while using solder,

and wash your hands when you are done using it.

Solder flux fumes are toxic, especially from lead-

free solder because of its higher working temperature.

Use appropriate ventilation.

Some lead-free solder alloys produce joints that

look “cold” (i.e. defective) even when they are cor-

rectly made. This effect can be especially distressing

to those of us who learned soldering with lead solder

and then switched to lead-free. Learn the behaviour

of whatever alloy you are using, and then trust your

skills.

Water-soluble solder flux must be washed off

promptly (within less than an hour of application)

because if left in place it will corrode the metal. Sol-

der with water-soluble flux should not be used with

stranded wire because it is nearly impossible to re-

move from between the strands.

Residue from traditional rosin-based solder flux

can result in undesired leakage currents that may af-

fect high-impedance circuits. This module does not

use any extremely high impedances, but small leakage

currents could possibly reduce its accuracy. If your

soldering leaves a lot of such residue then it might be

advisable to clean that off.

Voltage and current levels in some synthesizer cir-

cuits may be dangerous.

Do not attempt to make solder flow through the

board and form fillets on both sides of every joint.

Some soldering tutorials claim that that is desirable

or even mandatory, it does look nicer, and it may

happen naturally when the conditions are good and

the leads happen to be small in relation to the holes.

But with large wire leads that just fit in the holes,

when the holes are connected to the ground plane

(even through thermal reliefs), on some harder-to-

wet lead finishes, with lead-free solder, and so on,

you may only end up dumping excessive heat into

the joint and damaging the components while you

fuss over perfect fillets. A well-made solder joint that

just covers the pad and makes good contact to the

lead on one side of the board, is good enough.

Building your own electronic equipment is seldom

cheaper than buying equivalent commercial products,

due to commercial economies of scale from which you

as small-scale home builder cannot benefit. If you

think getting into DIY construction is a way to save

money, you will probably be disappointed.

9

Bill of materials

Qty Ref Value/Part No.

1 C12 33pF radial ceramic, 0.2′′ lead spacing

1 C1 100pF radial ceramic, 0.2′′ lead spacing

2 C2, C3 6800pF film, 0.2′′ lead spacing

6 C6–C11 0.1µF axial ceramic

2 C4, C5 10µF radial aluminum electrolytic, 0.1′′ lead spacing

1 D1 1N4148 or 1N914; switching diode

2 D4, D5 1N5230B 4.7V Zener

2 D2, D3 1N5818 or SB130; Schottky rectifier

2 H1, H2 nut for M3 machine screw

2 H3, H4 M3x11 M3 male-female standoff, 11mm body length

2 H7, H8 M3x13 M3 male-female standoff, 13mm body length

6 H15–H20 M3x6 M3 machine screw, 6mm body length

4 H11–H14 nylon washer for M3 machine screw

7 J1–J7 1502 03 switched mono 3.5mm panel jack, Lumberg

1 J8 female single-row socket, 10 pins at 0.1′′

2 L1, L2 22mH EPCOS 5% axial ferrite choke, B82144A2226J

1 P1 male single-row header, 10 pins at 0.1′′

1 P2 male Eurorack power header, 2×5pins at 0.1′′

2 Q1, Q2 PN200A PNP general purpose amplifier, TO-92 EBC

4 R22, R23, R32,

R33

510Ω

3 R15, R27, R37 1kΩ

1 R6 1.8kΩ

1 R7 2.7kΩ

2 R24, R34 9.1kΩ

2 R25, R35 10kΩ

1 R10 18kΩ

1 R38 22kΩ

4 R21, R26, R31,

R36

27kΩ

1 R11 36kΩ

2 R9, R17 51kΩ

2 R20, R30 100kΩhorizontal single turn, Vishay T73YP or similar

3 R2, R4, R16 100kΩvertical conductive plastic panel pot, BI Technolo-

gies P260T series, linear taper

7 R1, R3,

R12–R14, R18,

R28

100kΩ

4 R5, R8, R19,

R29

220kΩ

10

Qty Ref Value/Part No.

1 U3 LM13700 dual operational transconductance amp

2 U1, U2 TL074 quad JFET-input op amp

Fixed resistors should be 1% metal film throughout. RoHS-certified zinc-plated steel hardware is recom-

mended, not stainless steel because of galvanic-corrosion incompatibility with aluminum parts.

Newer kits may include TL074B op amps instead of TL074, to make offset nulling easier.

Also needed: solder and related supplies, PCB, panel, knobs, a cable tie, Eurorack power cable, etc.

11

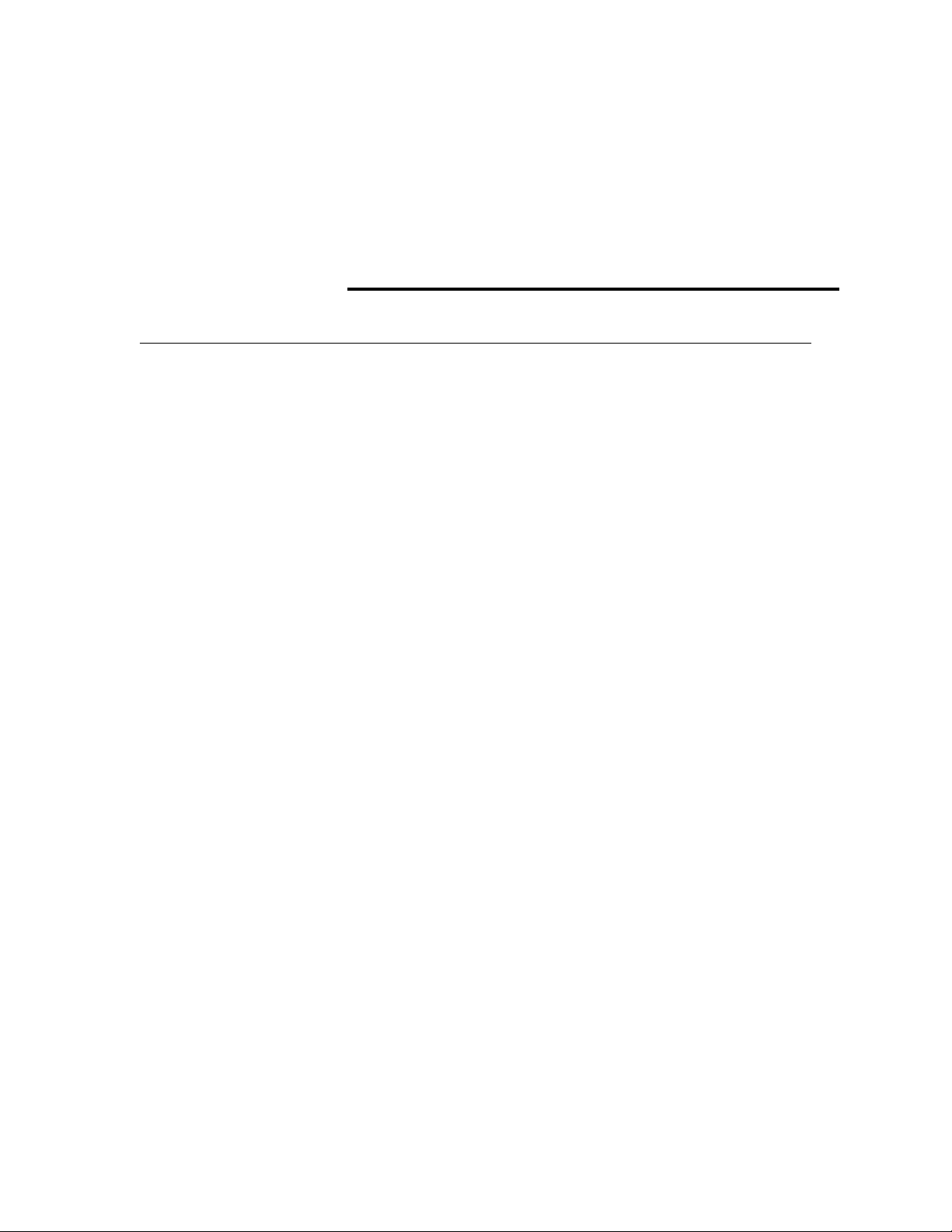

Building Board 2

The recommended order for building this module is

to assemble Board 2, the one further from the front

panel, first. That will make it easier to get all the

physical positioning right for the components that

bridge between the boards or pass through the panel.

Note that although I’m describing a separate step

for each component value, and that’s how I built my

prototype so as to have plenty of photo opportunities,

if you are reasonably confident about your skills you

may find it easier to populate all or most of the board

(i.e. put the components in place) and then solder

them in a single step. Except where noted, the order

in which you add components does not matter much.

Preliminaries

Count out the right number of everything according

to the bill of materials. There is an abbreviated BOM

for Board 2, excluding a few items that will be added

when combining this board with Board 1, in Table 2.

There are two trimmers to be installed on this

board. Before installing them, use an ohmmeter to

adjust each one to 50% of its range. Measure the re-

sistance along the track, then measure the resistance

from the wiper to one end and adjust to make the

wiper half the total track resistance. This need not

be exact, but having them start near their midpoints

will help with adjustment later, by reducing issues

with interaction among the different settings. With

both trimmers pre-set to 50%, the module should ba-

sically work even if it is not at its best, whereas if

they are installed at extreme values instead, then you

may have trouble getting it up and running enough

to adjust it more accurately.

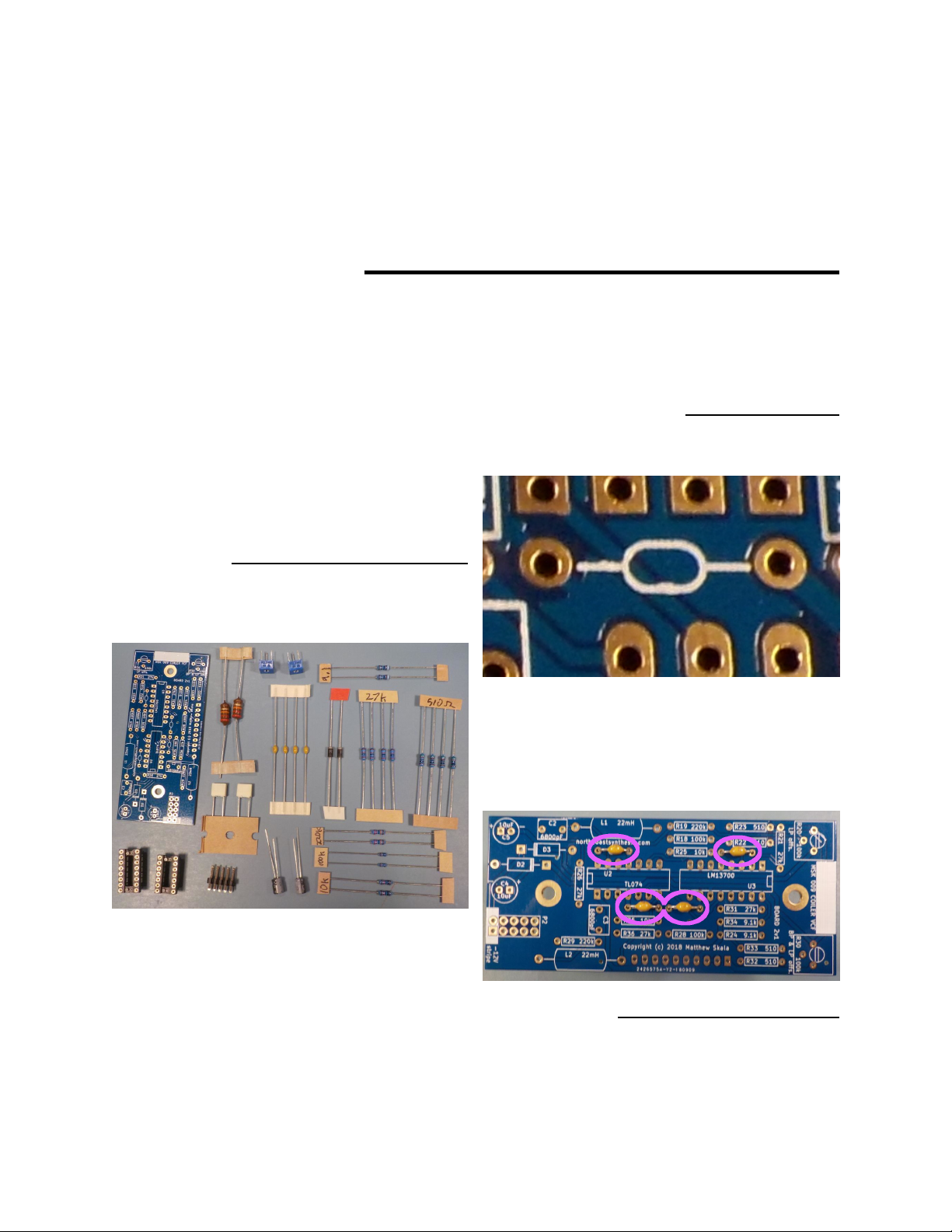

Decoupling capacitors

The four axial ceramic 0.1µF decoupling capacitors,

C8 to C11, are shown on the board by a special sym-

bol without their reference designators.

Install these four capacitors where the symbol ap-

pears. They are not polarized and may be installed

in either orientation. These capacitors act as filters

for the power supplies to the op amp and OTA chips.

An MSK 009 kit should include six of these capaci-

tors, and only four are used on this board; save the

remaining two for use on Board 1.

Fixed resistors

Resistors are never polarized. I like to install mine in

a consistent direction for cosmetic reasons, but this

is electrically unnecessary. In this module, the fixed

12

Qty Ref Value/Part No.

2 C2, C3 6800pF film, 0.2′′ lead spacing

4 C8–C11 0.1µF axial ceramic

2 C4, C5 10µF radial aluminum electrolytic, 0.1′′ lead spacing

2 D2, D3 1N5818 or SB130; Schottky rectifier

2 L1, L2 22mH EPCOS 5% axial ferrite choke, B82144A2226J

1 P2 male Eurorack power header, 2×5pins at 0.1′′

4 R22, R23, R32, R33 510Ω

2 R24, R34 9.1kΩ

2 R25, R35 10kΩ

4 R21, R26, R31, R36 27kΩ

2 R20, R30 100kΩhorizontal single turn, Vishay T73YP or similar

2 R18, R28 100kΩ

2 R19, R29 220kΩ

1 U2 14-pin DIP socket

1 U3 16-pin DIP socket

Table 2: Bill of Materials for assembling Board 2. Also needed is the PCB itself.

resistors are metal film 1% type. They usually have

blue bodies and four colour bands designating the

value, plus a fifth band for the tolerance. The tol-

erance band is brown for 1%, but note that we may

occasionally ship better-tolerance resistors in the kits

than the specifications require, if we are able to source

them at a good price. Accordingly, I mention only the

four value band colours for this type of resistor; if you

are using resistors with other codes, you are respon-

sible for knowing them. Note that colour codes on

metal film 1% resistors are often ambiguous (reading

from one end or the other end may give two different

values, both plausible) and some of the colours are

hard to distinguish anyway. If in doubt, always mea-

sure with an ohmmeter before soldering the resistor

in place.

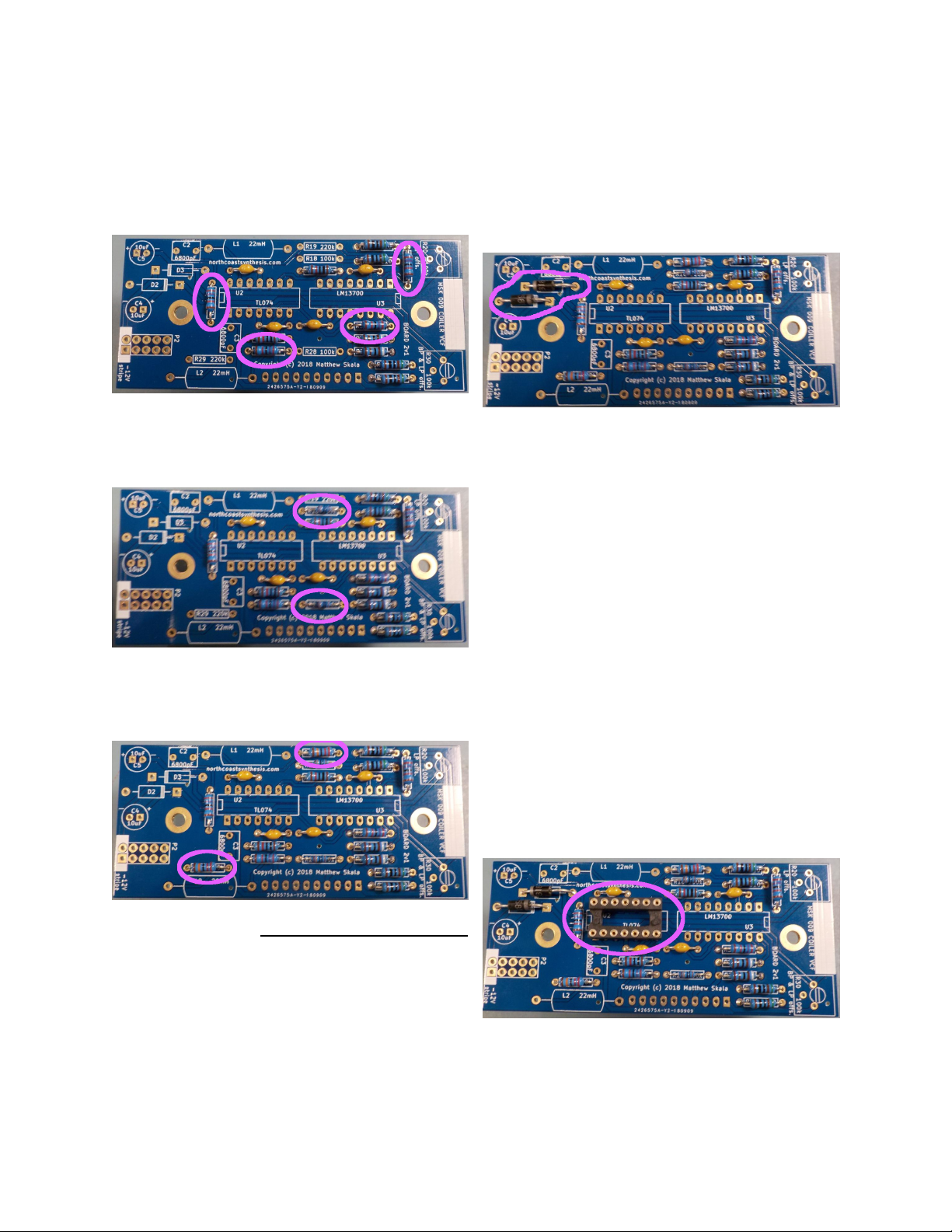

Install the four 510Ω(green-brown-black-black)

resistors R22, R23, R32, and R33. These resistors,

with the 100kΩones added later, set the signal levels

at the inputs of the OTA chips.

Install the two 9.1kΩ(white-brown-black-brown)

resistors R24 and R34. These limit the maximum

control current for the OTAs.

Install the two 10kΩ(brown-black-black-red) re-

sistors R25 and R35. These are feedback resistors for

the current-to-voltage converters in the filter core.

13

Install the four 27kΩ(red-violet-black-red) resis-

tors R21, R26, R31, and R36. These are feedback

resistors for the integrators (R26 and R36), and set

the current for the linearizing diodes in the LM13700

chips (R1 and R31).

Install the two 100kΩ(brown-black-black-orange)

resistors R18 and R28. These resistors participate in

setting the input levels for the OTA chips. A full

kit contains seven resistors of this value; five should

remain for use on Board 1.

Install the two 220kΩ(red-red-black-orange) re-

sistors R19 and R29. These resistors set the adjust-

ment ranges for the DC offset trimmers. A full kit

contains four resistors of this value; save two for use

on Board 1.

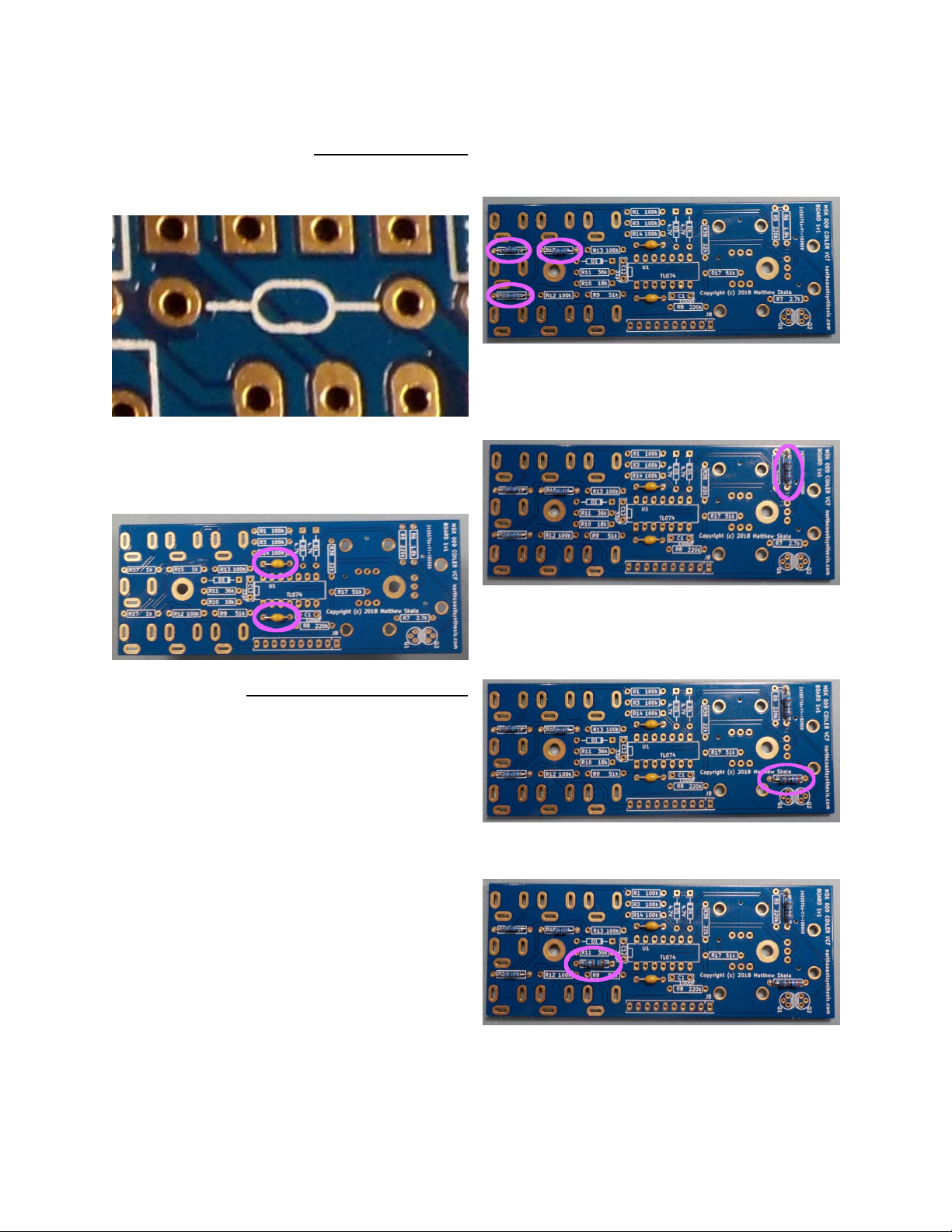

Semiconductors

Install the two 1N5818 or SBA130 Schottky rectifier

diodes D2 and D3. These are for reverse-voltage pro-

tection; they cut off power to the module when the

power plug is backwards. They are polarized and it is

important to install them in the right direction. Each

diode is packaged inside a black or dark grey plastic

slug with a white or light grey stripe at one end;

that end is the cathode. The silkscreen markings on

the board have a corresponding stripe and the diodes

should be installed with their stripes matching the

markings on the board. The solder pads for the cath-

odes are also square instead of round. Installing these

backwards means they will have the opposite of the

intended protective effect.

Install the 14-pin DIP socket for the operational

amplifier chip U2. This chip does most of the am-

plification in the filter core. DIP sockets themselves

do not care which direction you install them, but it

is critically important that the chips installed in the

sockets should be installed in the right direction. To

help with that, the sockets will probably be marked

with notches at one end (indicating the end where

Pin 1 and Pin 14 are located) and you should in-

stall the sockets so that the notched ends match the

notches shown on the PCB silkscreen. The solder pad

for Pin 1 is also distinguished by being rectangular

instead of rounded.

Installing DIP sockets without having them tilted

at a funny angle can be tricky. I recommend inserting

the socket in the board, taping it in place on the

component side with vinyl electrical tape or sticking

it there with a small blob of putty at each end, then

soldering one pin on one corner and checking that

the socket is snug against the board before soldering

the other pins. That way, if you accidentally solder

the first pin with the socket tilted, it will be easier

to correct (only one pin to desolder instead of all of

them).

If you somehow manage to solder an entire socket

in backwards, don’t try to desolder it to turn it

around. Just leave it as it is and remember that when

14

you insert the chip, you must insert it so the chip

matches the markings on the board, not the turned-

around socket.

Install the 16-pin DIP socket for the OTA (opera-

tional transconductance amplifier) chip U3. This chip

contains two current-controlled amplifiers, which, by

means of a frequency-dependent control current, tune

the filter core to the desired frequency. See the gen-

eral instructions regarding DIP sockets above.

Electrolytic and film capacitors

Install the two 6800pF film capacitors C2 and C3.

These are timing components used in the integrators

at low frequencies to complement the inductors used

at medium to high frequencies. They are unpolarized

components and may be installed in either orienta-

tion.

The markings on film capacitors may vary de-

pending on the manufacturer and model. These ones

might be marked “682” (for 68 followed by two 0s

number of picofarads), “6n8” (for 6.8nF), or even

“0.0068” (value in µF). However, these are the only

film capacitors in the module, so confusion is unlikely.

Install the two 10µF electrolytic capacitors C4

and C5, which filter the power supply for the mod-

ule as a whole. These are polarized components and

they may explode if installed backwards. Each one

will be marked on its casing with a stripe and minus

signs to indicate the negative lead; the positive lead

will probably also be longer. These clues should be

matched with the markings on the PCB: plus and

minus symbols in the silkscreen and a square solder

pad for the positive (long) lead.

Trimmer potentiometers

If you have not already set the trimmers to 50% of

their full scale value as described under “Preliminar-

ies” above, then do it now.

Trimmers usually are not washable, so if you plan

to clean your boards by full immersion in water or

other solvent, your last chance is now; future clean-

ing will have to be done with a brush and some care

to avoid letting liquid seep into the trimmers. Even

now you should take some care with the DIP sockets,

because solvent can carry flux residue into them and

form a varnish-like layer if not carefully rinsed away.

Trimmers are not exactly polarized, but the three

legs of each trimmer serve different functions and

need to be connected to the right holes. The physi-

cal arrangement of the legs and corresponding holes

should make it impossible to install the trimmers

wrong way round.

Install the two 100kΩtrimmers R20 and R30.

These trimmers are for compensating DC offsets in

the filter core.

Inductors

The two 22mH ferrite-bobbin inductors, that is, coils,

L1 and L2 give this module its name. Install them

now. They are the main timing components in the

filter core, serving at medium to high frequencies.

Single inductors like these have no polarity and may

be installed in either direction; the situation is more

complicated with transformers made of two or more

interacting inductors.

15

The inductors are delicate, especially in the area

where the leads attach to the bodies, because the

windings that connect to the leads are made of very

fine wire. The ferrite core material is also somewhat

brittile. It is important not to bend the leads too

close to the bodies. There is some extra space for the

inductors on the circuit board to allow for a gentle

bend radius.

Eurorack power connector

Install the 2×5-pin Eurorack power connector J2.

This connector is not polarized in itself, although

the connection it makes is polarized. As with the

DIP sockets, you should be careful to get it installed

snugly against the board, not tilted at an angle. Use

tape or putty to hold it in place, solder one pin, then

check that it is straight before you solder the other

pins.

The six pins in the centre of the connector, that is

all except the four corner pins, are for grounding and

they are all connected together on the board. Thus, if

you accidentally form solder bridges among these six

pins while installing the connector, don’t waste effort

trying to remove them; they will have no electrical

effect.

In between completed boards is a good time to

take a break.

16

Building Board 1

Board 1 has components on both sides, and for best

results, it is important to install them in the right

order. Build Board 2 first, and see the general com-

ments in the Board 2 chapters about how to approach

the task.

Preliminaries

Count out the right number of everything according

to the bill of materials. There is an abbreviated BOM

for the items needed in this chapter (including the

connection to Board 2 and final assembly of the mod-

ule) in Table 3.

Some notes on knobs

The first batch of knobs I ordered for North Coast

products turned out to have serious quality problems,

specifically with the setscrews that hold the knobs

onto the potentiometer shafts. Some of the screws

had marginal threads that would strip when the screw

was tightened, and I ended up having to do a bunch of

extra testing and ship extra knobs to some customers

to replace any that might fail. Later batches have

also had issues, although they’re under better control

now because the bad first batch served as a warning

to step up the testing procedures. Starting with kits

prepared in August 2019, I switched to blue knobs

with 100% testing; in September 2020, I switched to

a new manufacturer, and knobs that are a slightly

darker shade of blue. Although all the knobs I ship

in kits now have been tested and passed at least twice,

and should be fine to use, I am also shipping spare

setscrews in any kits with knobs from batches where

a signficant number of knobs failed testing.

Here are some things to be aware of as a kit

builder.

•Some photos in these instructions were taken

with the older grey knobs, and some dealers

will still have kits containing grey knobs in their

stock, but newer kits will have blue knobs.

•Do not overtighten the setscrews when attach-

ing the knobs! The screw should be tight

enough to hold the knob onto the shaft, but

there’s no advantage to making it tighter than

that, and overtightening may risk destroying

the screw thread or damaging the drive slot.

•If, despite my efforts to make sure no bad screws

get sent to customers, you still get a bad screw

that cannot be tightened and no spare for it,

then please contact me.

•If you want to source an exact replacement for

the setscrew, it should be an M3×3mm flat-tip

slotted setscrew, which is also sometimes called

a “grub screw,” made of RoHS-compliant brass

(possibly by exemption). Stainless steel is fine

too, and I may sometimes ship stainless steel

screws instead of brass if I can find a reliable

source for them; plain steel should not be used

here for galvanic corrosion reasons. Hex-socket

screws are fine if you have the driver for them,

but I don’t ship those because I’m not sure all

DIY builders do have the right driver.

•Because it’s a standard M3 thread, in a pinch

it’s possible to substitute a plain M3 machine

screw such as are commonly used with Eurorack

cases, although one of those would obviously

look less nice.

17

Qty Ref Value/Part No.

1 C12 33pF radial ceramic, 0.2′′ lead spacing

1 C1 100pF radial ceramic, 0.2′′ lead spacing

2 C6, C7 0.1µF axial ceramic

1 D1 1N4148 or 1N914; switching diode

2 D4, D5 1N5230B 4.7V Zener

2 H1, H2 nut for M3 machine screw

2 H3, H4 M3x11 M3 male-female standoff, 11mm body length

2 H7, H8 M3x13 M3 male-female standoff, 13mm body length

2 H15, H16 M3x6 M3 machine screw, 6mm body length

7 J1–J7 1502 03 switched mono 3.5mm panel jack, Lumberg

1 J8 female single-row socket, 10 pins at 0.1′′

1 P1 male single-row header, 10 pins at 0.1′′

2 Q1, Q2 PN200A PNP general purpose amplifier, TO-92 EBC

3 R15, R27, R37 1kΩ

1 R6 1.8kΩ

1 R7 2.7kΩ

1 R10 18kΩ

1 R38 22kΩ

1 R11 36kΩ

2 R9, R17 51kΩ

3 R2, R4, R16 100kΩvertical conductive plastic panel pot, BI Technolo-

gies P260T series, linear taper

5 R1, R3, R12–R14 100kΩ

2 R5, R8 220kΩ

1 U3 LM13700 dual operational transconductance amp

2 U1, U2 TL074 quad JFET-input op amp

1 U1 14-pin DIP socket

Table 3: Bill of Materials for Board 1. Newer kits may include TL074B op amps instead of TL074, to

make offset nulling easier. Also needed: the PCB itself, the aluminum front panel, knobs, a cable tie, the

assembled Board 2, and panel-to-rack mounting hardware.

18

Decoupling capacitors

The two axial ceramic 0.1µF decoupling capacitors

C6 and C7 are shown on the board by a special sym-

bol without their reference designators.

Install these two capacitors where the symbol ap-

pears. They are not polarized and may be installed

in either orientation. These capacitors act as filters

for the power supplies to the op amp chip, protecting

them from high-frequency crosstalk.

Fixed resistors

Resistors are never polarized. I like to install mine in

a consistent direction for cosmetic reasons, but this

is electrically unnecessary. In this module, the fixed

resistors are metal film 1% type. They usually have

blue bodies and four colour bands designating the

value, plus a fifth band for the tolerance. The tol-

erance band is brown for 1%, but note that we may

occasionally ship better-tolerance resistors in the kits

than the specifications require, if we are able to source

them at a good price. Accordingly, I mention only the

four value band colours for this type of resistor; if you

are using resistors with other codes, you are respon-

sible for knowing them. Note that colour codes on

metal film 1% resistors are often ambiguous (reading

from one end or the other end may give two different

values, both plausible) and some of the colours are

hard to distinguish anyway. If in doubt, always mea-

sure with an ohmmeter before soldering the resistor

in place.

Install the three 1kΩ(brown-black-black-brown)

resistors R15, R27, and R37. These are current-

limiting resistors to protect the audio outputs, and

other modules, in case of short circuits or bad patch-

ing.

Install the 1.8kΩ(brown-grey-black-brown) resis-

tor R6. This is the feedback resistor for the CV-

processing op amp, setting the CV sensitivity to ap-

proximately 1V/octave. Do not confuse this with the

18kΩresistor, which has a similar colour code.

Install the 2.7kΩ(red-violet-black-brown) resistor

R7. This is a ballast resistor for the temperature-

servo op amp, preventing the voltage gain of the tran-

sistor in the feedback loop from rendering the ampli-

fier unstable.

Install the 18kΩ(brown-grey-black-red) resistor

R10. This resistor is used to control the gain in the

full-wave rectifier circuit.

Install the 22kΩ(red-red-black-red) resistor R38.

This resistor controls the amount of clipping applied

on an internal feedback path, to set the amplitude

19

level during oscillation. Do not confuse this resistor

with the 220kΩresistors, which have a similar colour

code.

Install the 36kΩ(orange-blue-black-red) resistor

R11. This controls the level of the full-wave rectified

input signal applied to the input mixer.

Install the two 51kΩ(green-brown-black-red) re-

sistors R9 and R17. These are used for level and

impedance control: R9 on the rectifier input, and

R17 on the internal BP feedback path.

Install the five 100kΩ(brown-black-black-orance)

resistors R1, R3, R12, R13, and R14. The first three

of these are used to set input impedances for the un-

rectified audio input and both CV inputs. The re-

maining two, R13 and R14, set gain levels in the in-

put mixer.

Install the two 220kΩ(red-red-black-orange) re-

sistors R5 and R8. The first, R5, controls the scale

of the main tuning knob; the second, R8, contols the

reference current for the exponential converter.

Semiconductors

There are two different kinds of diodes to install on

this board and they look almost exactly alike: one

1N4148 or 1N914 switching diode named D1, and two

1N5230B or equivalent 4.7V Zener diodes named D4

and D5. All three diodes will be packaged in little

pink glass beads with near-microscopic etched num-

bers indicating their type. Be careful not to confuse

them; swapping the switching diode with a Zener will

result in incorrect behaviour of the full-wave rectifier

at high input voltages, and incorrect feedback levels

probably causing either very strong oscillation at all

resonance settings, or preventing oscillation entirely.

If you are unsure which diode is which and you

cannot confidently read the etched markings, hook up

a diode in series with a 10kΩresistor reverse-biased

across a 12V power supply and measure the voltage

drop across the diode. If it is near 12V, then you are

testing the switching diode; if it is near 4.7V, you are

testing one of the Zener diodes; if it is near 0.6V, you

probably have the diode connected forward-biased

and should reverse the polarity of it or the power

supply.

Both kinds of diodes are polarized and must be

installed in the correct direction to function properly.

One end of the glass body of the diode package will

be labelled with a black band or stripe; that end is

the cathode. The direction for the cathode is marked

on the PCB silkscreen by a matching stripe in the

printed symbol; and the solder pad for the cathode is

square rather than round. The note “4.7V” is also on

the PCB silkscreen next to the locations of the two

Zener diodes as an added reminder of which diode

goes where.

20

Table of contents