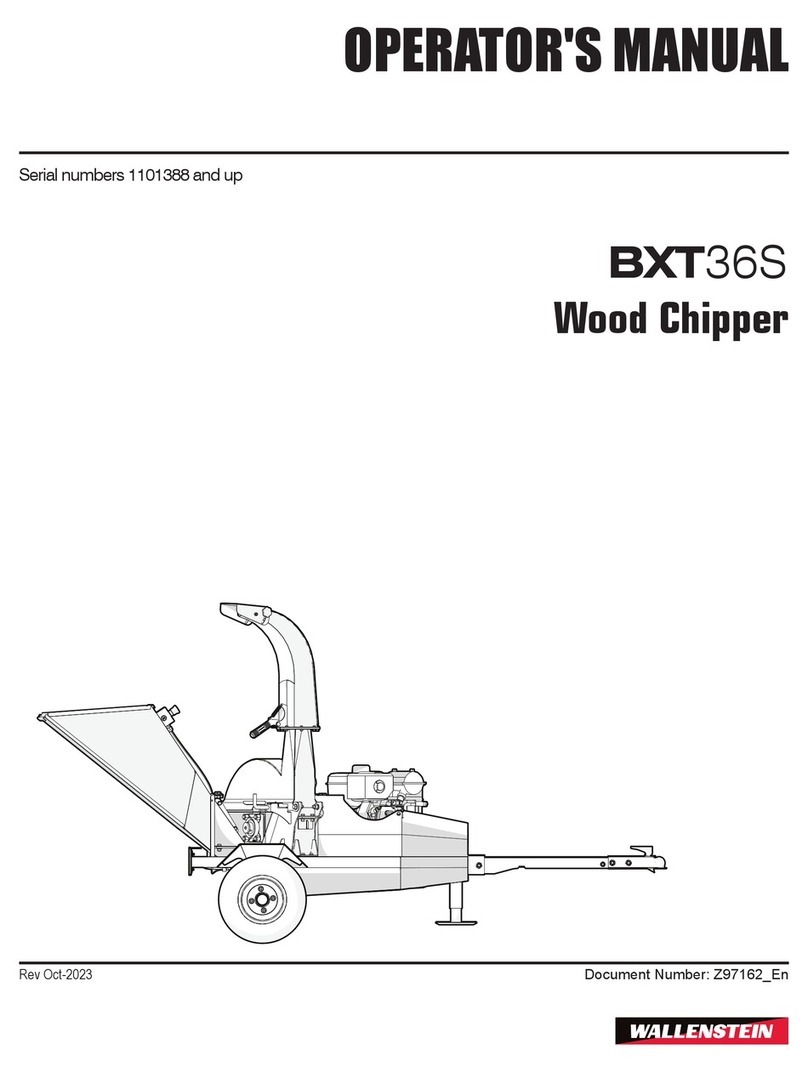

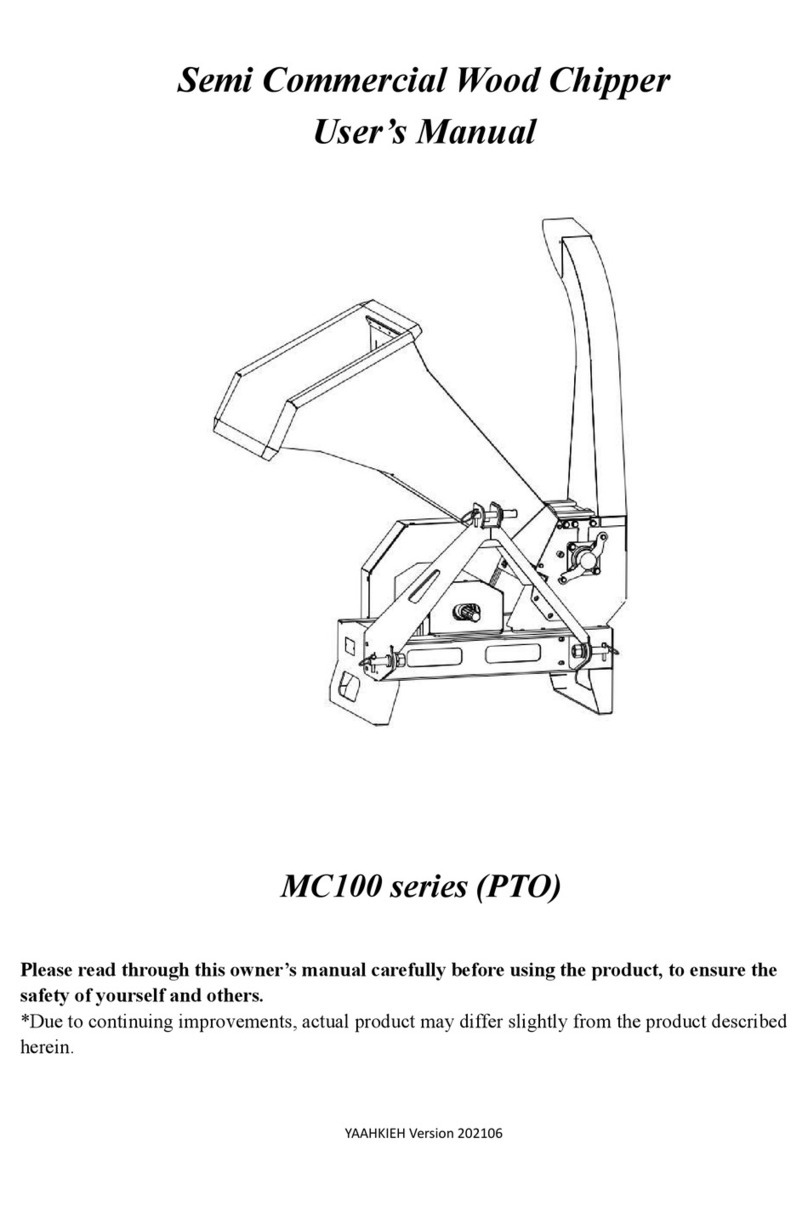

Northern Industrial Tools PTO 540 RPM User manual

Thank you verymuch for choosinga NORTHERNTOOL+ EQUIPMENTCO., INC., Product!

For future reference,please complete theowner's record below:

Model: _______________ PurchaseDate: _______________

Save the receipt,warranty and theseinstructions. It isimportant that youread the entire

manual to becomefamiliar with thisproduct before youbegin using it.

This machine isdesigned for certainapplications only. NorthernTool+ Equipment strongly

recommends that youdo not modifyor use thismachine for anyapplication other thanthat

for which itwas designed. Ifyou have anyquestions relative toa particular application,DO

NOT usethe machine untilyou have firstcontacted NorthernTool+ Equipment todetermine

if it canor should beperformed on orwith this product.

For technical questionsand replacement parts,please call 1-800-222-5381.

DESCRIPTION & INTENDEDUSE

The PTO-Driven4.5" WoodChipper features anadvanced design witha compact structure,

superior technology andsubstantial attack strength.This modelis safe andeasy to operate.

TECHNICAL SPECIFICATIONS

SAVETHESE INSTRUCTIONS.

GENERAL SAFETYRULES

WARNING:Points out importantsafety precautions.This symbol meansATTENTION!

BE ALERT!It indicates ahazardous situation, ifnot avoided,COULD RESULT IN DEATH

OR SERIOUS INJURY.

CAUTION: This symbol indicatesa hazardous situation,which, if notavoided,COULD

RESULTIN MINOR ORMODERATEINJURY.

CAUTION: Read this safetyand operating manualand your tractorowner's manual

before you usethe PTO-Driven4.5" WoodChipper. Becomefamiliar with theoperation and

service recommendations toensure the bestperformance from yourmachine.

WARNING:This is ahigh-powered machine, withmoving parts operatingwith high

energy at highspeeds. You must useproper clothing andsafety gear whenoperating this

machine to preventor minimize therisk of severeinjury.This machinecan crush, grind,cut,

and sever partsof your bodyif they enterthe inlet ordischarge area ofyour chipper.

DANGER: The warnings, cautions,and instructions inthis manual cannotcover all

possible conditions orsituations that couldoccur. Itmust be understoodby the operatorthat

common sense andcaution are factorsthat cannot bebuilt into thisproduct, but mustbe

supplied by theoperator. Operatingthis chipper safelyis necessary toprevent or minimize

the risk ofDEATHOR SERIOUS INJURY. Unsafe operationcan create anumber of hazards

for you.

OPERATINGPRECAUTIONS

· Do not attemptto operate thechipper until youhave read andunderstood the owner's

Manual.

· THIS MACHINE ISDESIGNED TOOPERATEAT540 RPM ONLY! Never operate the

machine at afaster speed; doingso can causeserious injury tothe operator orbystanders

And couldcause damage tothe machine thatis not coveredunder warranty.

1 OF 13

Item

PTO

Flywheel Diameter

Flywheel RPM

Max Chipping Diameter

Specification

540 RPM

2 Feet (605mm)

1220

4.5in.

Knife to WearPlate Gap

Net Weight

Item

Knife & WearPlate

Bolt Torque

772 Lbs. (350kg)

Specification

1/8in. -3/16in. (3-5mm)

52ft.lb. (70Nm)

· Make sure thatthe guards andchip deflectors areinstalled properly beforeoperating the

Chipper.

· Avoid accidentalstarting. Disconnect thechipper from thePTO whennot in useand

when moving thechipper to anotherwork area.

· Never leave thechipper unattended whenit is running.

· Check the chippile to seeif the bladesneed to beserviced. Long sliversin the chippile

are a goodindication that theblades are dulland need sharpening.

· Never use themachine without firstensuring that allthe guards andshields are inplace,

including the chipperhopper, dischargechute, and blowbackshield.

· Never transport thechipper with thePTO engagedand the flywheelturning.

· The chipper mustbe operated withthe weight ofthe machine onthe ground. Operatingthe

machine while itis offthe ground canresult in injuryto yourself orothers, or candamage to

the machine, whichis not coveredunder warranty.

· Keep in mindthat the operatoris responsible foraccidents to otherpeople, their property,

and themselves.

· YourPTO-Driven 4.5"Wood Chipperis a tool,not a toy. Exercise extremecaution at all

Times.

This machineis designed tochip wood. Donot use itfor any otherpurpose.

· Know how tostop the chipperquickly by disengagingthe PTOand shutting downthe

Tractor.

· Operate this machineon a levelsurface only. Never operatethe unit ona slippery, wet,

muddy,or icy surface. Exercise caution toavoid slipping orfalling.

· Keep a safedistance from thechipper hopper toavoid accidental bounceback of any\

Material.

· When feeding materialinto the chipperhopper, beextremely careful thatpieces of metal,

rocks, or otherforeign objects arenot included.This could resultin personal injuryor

damage to themachine.

· Whenever you leavethe operating positionor if youhave to removeprocessed material,

leaves, or debrisfrom the machine,always disengage thePTO, shutdown theTractor

engine, remove thekey,and wait forall moving partsto come toa complete stop.Then

disconnect the PTO shaft fromthe Tractor. Waitan additional 5minutes before removing

processed material, leaves,or debris fromthe machine.

· If the machineshould start makingan unusual noiseor vibration, disengagethe PTO

immediately,shut down theTractor engine,remove the key, and waitfor all movingparts to

come to acomplete stop.Then disconnect thePTO shaftfrom theTractor.Wait an

additional 5 minutesbefore inspecting theunit for cloggingor damage. Vibration is

generally a warningthat something iswrong with themachine. Clean andrepair and/or

replace damaged parts.

· Never tamper withsafety devices. Checkthat they areoperating properly ona regular

Basis.

· Stay alert forpotential hazards.

· Never carry passengerson the machine.

· Never overload orattempt to chipmaterial beyond themanufacturer's specifications.This

could result inpersonal injury ordamage to themachine.

· While using thePTO-Driven 4.5"Wood Chipper, don't rush.When in doubt,stop the

machine and takethe time tocheck your surroundings.

· Never operate themachine when underthe influence ofalcohol or drugs,including

Medication.

· Use the machineduring daylight hours.

· Keep all nutsand bolts tightand the equipmentin good operatingcondition.

· YourPTO-driven 4.5"Wood Chipperis driven bya PTOshaft that transferspower from

your Tractor. APTO shaftis extremely dangerousand can causeserious injury ordeath.

Read and understandall of thesafety and operatinginstructions that camewith your PTO

Shaft.

· No list ofwarnings and cautionscan be all-inclusive.If situations occurthat are not

covered by thismanual, the operatormust apply commonsense. Alwaysoperate the

chipper in asafe manner.

2 OF 13

PERSONAL SAFETY

DANGER: THIS ISAHIGH-POWERED MACHINE WITHMOVING PARTS. Operate the

machine safely. Unsafe operationcan create anumber of hazardsfor you, aswell as

anyone else inthe nearby area.

SAFETY PRECAUTIONS

· Stay alert, watchwhat you aredoing and usecommon sense whenoperating a chipper. Do

not use thechipper while youare tired orunder the influenceof drugs, alcohol,or

medication. Amoment of inattentivenessmay result inserious personal injury.

· Keep the decalsin place andin good repair. Thefactory or yourdealer will furnishnew

decals upon request.

· Keep hair,hands, feet, andother extremities awayfrom the hopper.

· Point the dischargechute away fromdoorways, sidewalks, orany areas whereyour view is

obstructed. Thechute should bepointed downwind whenpossible to avoidgetting dust in

your eyes, nose,and mouth.

· Safety equipment suchas a dustmask, non-skid safetyshoes, and ahardhat should be

used to reducethe chance ofpersonal injuries.

· Always wear protectivegoggles or safetyglasses with sideshields while chipping

to protect youreyes from debris.

· Avoid wearingloose-fitting clothing orjewelry,which can catchon moving partsor

the material fedinto the chipperhopper.

· We recommendwearing gloves whilechipping. Make surethe gloves fitproperly and

do not haveloose cuffs ordrawstrings.

· Wear shoeswith non-slip treadswhen using yourchipper. Ifyou have safetyshoes,

we recommend wearingthem. Do notuse the machinewhile barefoot orwearing

Sandals.

· Wear longpants while operating.

· Use ear protectorsor earplugs ratedfor at least20 db toprotect your hearing.

· Do not attemptalterations, repairs, oradjustments while thechipper head isturning.

Always disconnectthe PTOand stop themotor.

· Never allow peoplewho are unfamiliarwith the instructionsto use thechipper. Only

individuals who arefamiliar with theserules should usethe machine.

· Never place yourhands, feet, orany part ofyour body inthe chipper hopper, discharge

opening, or nearor under anymoving part whilethe machine isrunning. Keep areaof

discharge clear ofpeople, animals, buildings,glass, or anythingelse that willobstruct

clear discharge and/orcause injury ordamage. Wind canchange the dischargedirection,

so be aware.

· If it becomesnecessary to pushmaterial into thechipper hopper,use a smalldiameter

stick, not yourhands.

· Keep bystanders back100 feet fromthe work areaat all times.Wood chipsexit the chipper

at great speeds.To be safe,do not operatethe machine nearsmall children orpets, and

never allow childrento operate thechipper. Disengagethe PTOand stop theTractor

engine when achild or apet is present.

· Never pass orstand on thedischarge side ofthe machine whenthe Tractorengine is

running or theflywheel is turning.

RECOMMENDED PROTECTIVE GEAR

· EyesWraparoundANSI-Approved Safety Glasses

· EarsEar-Plugs

· HandsLeather Gloves

· FeetSteel-ToedBoots

· LegsHeavy Pants

· ArmsLong-Sleeved Shirt

3 OF 13

WORK AREA

· Keep everyone, especiallychildren, away fromthe area ofoperation. Anyonewho has not

read this manualand received instructionsfrom a qualifiedperson should notbe in the

area.

· Thoroughly inspect thearea in whichyou will beworking and removeall foreign objects.

Look for rope,wire, etc., andremove these objectsbefore chipping. Insertingthese

objects into thechipper hopper coulddamage the machineand/or cause injury.

· Never, underany conditions, remove,bend, cut, fit,weld, or otherwisealter standard parts

on the PTO-driven 4.5" woodchipper.This includes allshields and guards.Modifications

to the machinecould cause personalinjuries and propertydamage and willvoid your

Warranty.

STARTINGTHE CHIPPER

· The chipper isa flywheel-and-knife typeof chipper,not a shredder. Theblades actually

chip the limbsas they arefed into thehead. Theblades must besharp to operateproperly.

Dirt, rocks, nails,or other foreignmaterial will shortenblade life.

· Before operating thechipper, reviewthe machine checklist.After turningthe chipper by

hand and makingsure there areno obstructions inthe head, startthe Tractorand raise the

chipper until thePTO shaftis within 15degrees of straight.

· Start the chipperslowly with thePTO engaged,and release thePTO

clutch slowly. Gradually increasespeed until theTractor PTO speed is

540 RPM.

OPERATIONNOTES

· Only operate thePTO-Driven 4.5"Wood Chipperfrom the OperatorZones (on the

Opposite side ofthe discharge chute)shown in theFigure below.

· The material willfeed into thehead more easilyif you startthe pieces largeend first.The

feed roll willfold branches asthey are pulledinto the hopper. Occasionally, a limbfork may

have to becut to feedproperly.

· If the materialstops feeding, sometimesa little pushon the longend of thelimb will help.

· If the materialstops the feedroll, release thefeed roll clutchby stepping onthe bar

beneath the hopper(See below picture).Hold the clutchin the disengagedmode, and pull

the material outof the hopper. Release thefeed roll clutchand the feedroll will turnagain.

· Watch thedischarge chute whileoperating the unit.If the chipsstop flowing, stopfeeding

material into theunit by steppingon the barbeneath the hopperand pulling thematerial

from the hopper. Most ofthe time thiswill be enoughto clear thechips out ofthe unit. Ifthe

unit slows downnoticeably,first shut off the PTO power,then theTractor,and remove the

Key.

Stepping on thebar to release theclutch

4 OF 13

· With the PTO and thetractor turned off, unplug thehead by turningit backwards byhand

with the dischargechute and topsection of thewrapper off.

· Remove the chipsfrom the topof the head.If this fails,remove the clean-outdoor, located

on the lowerpart of thefront side-plate ofthe chipper belowthe main shaft,then work the

chips out ofthe case.

· Replace the clean-outdoor after allthe chips areremoved, being sureto use boththe lock

washers and flatwashers.

· Do not operatethe unit withoutthe guards inplace.

Before stopping thechipper, besure the allof the materialis out ofthe head andout of the

feed roll.

· All of thematerial in thechute must begone or theunit could jamon a smallpiece of

material. Thiscan usually becleared by turningthe unit backwardsby hand.

· ALWAYS disengage thePTO whenleaving the OperatingZones or whenmoving the

Machine.

· Never move theChipper while thePTO isturning.

· Always operate theTractor PTO at 540RPM when chipping.

PROCESSING MATERIAL

CAUTION: The Chipperis designed toaccept wood only.

· The Chipper Knifemounted on arevolving flywheel turnsbranches fed intothe Chipper

Hopper into "chips".

· YourPTO-Driven 4.5Wood Chippercan process dryor green woodup to 4.5"in diameter.

· The Chipper willself-feed the woodonce it contactsthe knife edgeso forcing thebranches

into the Hopperis not necessaryif the knifeis sharp.

· Green wood willprocess quicker andeasier than drywood.

· Softwood processes easierthan hardwood.

· Experience will teachyou how different types ofwood will chipand how fastyou can

process them.

· When chipping branches,sometimes a tailwill develop atthe end ofa branch.Toavoid

this, rotate thebranch while feedingit into theChipper Hopper.

· Rotating the branchas you feedit into themachine will improvechipping performance.

· Use caution withsmall diameter greensaplings and branchesless than 2"in diameter.

Chip these groupedor bundled togetherto provide support.If the materialis 2" orlarger,

feed one ata time intothe Chipper Hopper.

· Make sure thePTO-Drive 4.5"Wood Chipperfinishes processing materialin the Hopper

before disengaging thePTO andshutting theTractor engineoff.

· Do not forcematerial into theChipper. Ifthe machine doesnot chip well,the Chipper Knife

may need sharpeningor replacement, orthe gap betweenthe Knife andthe WearPlate

needs adjusting.

· NEVER THROWREMAINING STUBS ORKNOTS INTOTHE CHIPPERHOPPER;

DAMAGE WILLRESULT.

· Extremely hard knotswill not processvery well. Feedthem in slowlyto reduce clogging.

Push any shortstubs that havenot self-fed throughthe chipper withthe next branchto be

chipped.

· Cut the materialto be chippedinto manageable lengthsof no morethan five orsix feet

before chipping.

· Overloading the chipperhopper will causethe rotor speedto decrease. Ifyou hear the

engine RPM decreasing,stop feeding materialinto the chipperhopper until theengine has

returned to fullspeed.

TO FREEAJAMMED FLYWHEEL

CAUTION: Before performing anymaintenance procedure orinspection on thechipper,

disengage the PTO, shut downthe Tractorengine, remove thekey,and wait forall moving

parts to cometo a completestop. Thendisconnect the PTO shaft fromthe Tractor. Waitan

additional 5 minutes.

5 OF 13

CAUTION: Never pry againstthe scroll weldmentwhen removing thedeflector or

discharge chute, orat any othertime. Thiswill cause damageto the machine.

CAUTION: Be certain theflywheel turns freelybefore trying toprocess more material

into the chipperhopper.

TO DISASSEMBLE

1.Disconnect thePTO Shaft.

2.Remove anymaterial in theChipper

Hopper.

3.Remove thetwo bolts andlocknuts with

Wrench andthen remove theaccess cover.

4.Check tosee if theFlywheel and theKnife are clogged.If it is,clear it witha branch.

5.With awooden stick, loosenand remove anymaterial left inthe Chipping Chamberand

make sure theFlywheel turns freelywith the stick.

TO REASSEMBLE

1.Position theaccess cover ontothe Chipper andsecure with twobolts and locknutsusing

Wrench.

2.Reconnect thePTO Shaft,start theTractor engineand engage thePTO; allowingthe

remaining material inthe Chipping Chamberto discharge.

3.If theChipping Chamber doesn'tclear and theflywheel is stilljammed, repeat theprocess.

TRANSPORTATION SAFETY

· Before transporting, becertain the chipperis correctly andsecurely attached toyour

Tractor andthe PTOsafety chains arein place.

· Make sure thechipper is raisedhigh enough toclear all obstaclesduring transportation.

· Never transport themachine long distances.

· Never allow anyoneto ride onthe chipper.

· Never transport anythingon the machine.

· Never transport thechipper with thePTO engaged.

· Obey local, state,and federal regulationswhen transporting themachine on publicroads

and highways.

· Factor in theadded length ofthe chipper indriving situations, e.g.,when turning, parking,

and crossing intersections.

· Adjust your speedfor terrain andconditions.

· Use caution whenbacking or turning.Be aware ofthe large turningradius required with

The PTO-driven4.5" wood chipperattached to yourTractor.

MACHINE ASSEMBLY

1. Set upthe chipper standplates and tighten 2. Put thebody onto thestand and

the bolts; fixthe lift arms(Part#13);

Part#8 Front Plate

Part#14

Left Plate Part#102

Right Plate

Part#103 Rear Plate

6 OF 13

3. Attachthe hopper assemblyto the chipper;

4. Fix thechute stand andattach the dischargechute;

5. Attachthe clutch barsto the chipper;

6. Attachthe PTOshaft to thetractor and thechipper;

STEP1 Insert the Keyinto the 3-PointHitch Drive Shaftof

the Chipper Align the KeySlot of thePTO Shaftwith the Key

in the Shaftand slide itonto the Shaft.

NOTE: Do notallow the 3-PointHitch Shaft toextend more

than 1/4" intothe U-Joint.This will allowproper clearance to

Prevent hitting theGrease Fitting.

STEP 2 Push in thePTO ShaftSpring Pin andslide the PTO

Shaft onto theTractor Spline;Release the SpringPin and

continue sliding thePTO Shafton until theSpring Pin Popsout

and locks intothe detent inthe TractorPTO Spline;

NOTE: Secure thePTO ShaftSafety Chains tostationary

parts of theChipper Frame andTractor tostop the Guardfrom

Turning;

Part#86

Chute Stand Part#83

Discharge Chute

7 OF 13

Part#20 Part#63

Hopper

Part#110

Clutch arm

Part#60

Rod

MACHINE MAINTENANCE

CAUTION: Before performing anymaintenance procedure orinspection on thechipper,

disengage the PTO, shut downthe Tractorengine, remove thekey,and wait forall moving

parts to cometo a completestop. Thendisconnect the PTO shaft fromthe Tractor. Waitan

additional 5 minutes.

CAUTION: The service intervalsshown are themaximum under normaloperating

conditions. Increase maintenancefrequency under extremelydirty or dustyconditions. See

the owner's manualthat came withthe Tractorand with thePTO shaftfor specificTractor

and PTOshaft maintenance.

BEFORE EACH USE

· Check General EquipmentCondition.

· Check that theFlywheel turns freely(with a longstick only).

· Visually inspectKnife for damage.

EVERY 8-10HOURS

· Check Knife andWear Platefor Sharpness.

· Check Knife andWear PlateAttachment Screws.

· Check Flywheel BearingCollar Set Screws. · Check Knife toWear PlateGap.

· Lubricate Flywheel Bearings. · Lubricate PTOShaft Grease Fittings.

· Lubricate PTOSheave Bearings. · Check BeltTensionand Condition.

EVERY 18-20HOURS

· Lubricate PTOShaft Spline endsand center overlap.

EVERY 40HOURS

· Inspect or replaceDrive Belt.

GREASE FITTINGS

CAUTION:Over lubrication candamage the bearings.

1.Remove theBelt Cover

2. Wipe alldirt, etc., fromthe grease fittingswith a cleancloth.

3. Grease witha flexible hosegrease gun toeach Bearing GreaseFitting.

8 OF 13

4.Replace theBelt Guard.

REMOVING, REPLACINGAND ADJUSTINGTHE CHIPPER KNIFEAND WEARPLATE

CAUTION: Excessive vibration thatwill cause damageto the PTO-driven 4.5" wood

chipper.

Routinely check thewear plate fora sharp squareedge. Using arounded or chippedwear

plate will decreaseperformance and causeexcessive vibration thatwill cause damageto

the PTO-Driven4.5" WoodChipper.

CAUTION: Before performing anymaintenance procedure orinspection on thechipper,

disengage the PTO, shut downthe Tractorengine, remove thekey,and wait forall moving

parts to cometo a completestop. Thendisconnect the PTO shaft fromthe Tractor. Waitan

additional 5 minutes.

1.Remove thetwo screws thatsecure the

Front AccessCover with awrench and

remove theAccess Cover.

2.Rotate theFlywheel with along stick until

the Knife isvisible.

3.If theKnife has visiblenicks or damageit must besharpened or replaced.Remove the dull

or damaged Knifeand visually inspectthe Flywheel Slotand Knife mountingarea and be

sure they areclean and thatthe replacement Knifewill be ableto mount flushagainst the

Flywheel. Install anew or sharpenedKnife as shownwith the Knifeedge facing upand

towards you. Fingertighten the screwsand lock nutsto hold theKnife to theFlywheel.

4.If theKnife does notappear to haveany damage, replacethe FrontAccess Cover and

secure with twoscrews using awrench.

" "

Adjusting the Knifeto WearPlate Gap

The knife towear plate gapis pre setat 1/8 - 3/16 (3-5mm) before leavingthe factory. After

use for aperiod of time,the wear plateand knife willget wearing andso the gapwill be

widened. To adjust thewear plate gap,loosen the nutson the boltsof wear plate,so the

wear plate willmove but stillhave a slightresistance. Now youcan slide thewear plate upor

down (in orout) to achievethe correct gapsetting. Adjustthe wear plateto desired position

and then tightenthe nuts.After that, reinstallthe hopper assembly.

9 OF 13

TROUBLESHOOTING

SYMPTOM

Flywheel won't turn.

The Belt fraysor rolls overthe Drive Pulley.

Chipping action seemstoo slow orflywheel

stalls.

The Belt burns.

The Flywheel won'tturn.

The machine hasexcessive vibration.

When chipping, the logseems to

vibrate excessively and "hammers"

my hands.

PTO turns butthe flywheel doesn'trotate. ·Loose Drive Belt; ReplaceBelt.

·Remove any built-updebris from theChipper Hopper Inletand

Discharge Chute.

POSSIBLE CAUSE/FIX

·The Flywheel maybe jammed. Immediatelydisengage the PTOand

stop the Tractor engine. Removeany built-up debrisfrom the Chipper

Hopper Inlet andDischarge Chute.

·Check the Drive Pulleyalignment and adjust ifnecessary.

·Replace the Drive Beltor reinstall if theBelt has come off the pulleys.

·Turn the Flywheelwith a woodenstick to besure it turnsfreely. Ifthe

Flywheel still won'tturn, call usfor assistance.

·The Drive Pulleygroove may havea nick init. File offany nicks onthe

Pulley.

·Check the Drive Beltfor wear and hardspots.

·The Drive Belt maybe stretched; replace it.

·The Pulleys maybe misaligned.

·If the DriveBelt still rollsoff the DrivePulley, callus for assistance.

·The PTO speedis too slowcausing the beltto slip. Runthe PTO at

540 RPM.

·Check for looseor damaged DriveBelt; replace asneeded.

·Check for adull or damagedKnife; sharpen orreplace the Knife.

·Immediately disengage thePTO and shutoff the Tractor.

·Turn the Flywheelwith a woodenstick to besure it turnsfreely.

·Check for a looseDrive Belt.

·Remove any built-updebris from theChipper Hopper Inletand

Discharge Chute.

·Check for adull or damagedKnife; sharpen orreplace the Knife.

·The Knife is notproperly seated on theflywheel. Loosen the Knife

mounting screws, reset theKnife and tighten thescrews.

·If the DriveBelt still rollsoff the DrivePulley, callus for assistance.

·The Knife is dull;sharpen or replace it.

·The gap betweenthe Knife andWear Plate istoo great; adjustthe Gap.

·Check PTO RPMs;run PTO at540 RPM whenchipping.

10 OF 13

DIAGRAM

11 OF 13

PARTSLIST

12 OF 13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

180100-01

180100-02

180100-03

180100-04

180100-05

180100-06

180100-07

180100-08

180100-09

180100-10

180100-11

180100-12

180100-13

180100-14

180100-15

180100-16

180100-17

180100-18

180100-19

180100-20

180100-21

180100-22

180100-23

180100-24

180100-25

180100-26

180100-27

180100-28

180100-29

180100-30

180100-31

180100-32

180100-33

180100-34

180100-35

180100-36

180100-37

180100-38

180100-39

180100-40

180100-41

180100-42

180100-43

180100-44

Protective Cover for Pulley

Nut M10

Washer 10

Bolt M10x25

Spring Washer 35

Big Belt Pulley

Belt

Front Plate

Drive Shaft

Feed Roll Bearing 207

Nut 22

Spring Washer 22

Front Connecting Plate

Side Plate(2)

Connecting Pin

Nut M14

Spring Washer 14

Big Washer 14

Bearing Seat AdjustScrew

Bolt 10x35

Bolt M12x35

Wash 12

Nut M12

Front Supporting Plate

Outer Cover Assy

Stickler Assy

Bolt M14x140

Bolt 8x40

Nut 8

Main Shaft Assy

Bolt12x50

Key C10*60

Tension Spring

Knife

Bolt M10x45

Spring for Drive Knob

Circlip 25

Outer Drive Shaft

Oil Cup M6

Spring for Drive Shaft

Inner Drive Shaft

Clutch Outer Claw

Clutch Inner Claw

Key 5x20

1

28

26

4

1

1

5

1

1

2

2

2

2

1

2

26

16

22

4

20

8

14

22

1

1

1

14

2

2

1

4

1

2

4

8

2

2

1

1

1

1

1

1

1

58

59

60

61

62

63

64

180100-58

180100-59

180100-60

180100-61

180100-62

180100-63

180100-64

Release Handle

Tension Spring

Rod

Hair Pin 2.5/25

Rob Bracket

Hopper

Rob Bracket

1

1

1

4

1

1

1

Ser. No. NTE Part# Description Q'ty Ser. No. NTE Part# Description Q'ty

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

180100-65

180100-66

180100-67

180100-68

180100-69

180100-70

180100-71

180100-72

180100-73

180100-74

180100-75

180100-76

180100-77

180100-78

180100-79

180100-80

180100-81

180100-82

180100-83

180100-84

180100-85

180100-86

180100-87

180100-88

180100-89

180100-90

180100-91

180100-92

180100-93

180100-94

180100-95

180100-96

180100-97

180100-98

180100-99

180100-100

180100-101

Feed Roll Bearing204

Feed Roll

Bolt M10x35

Wear Plate

Flywheel

Spring Washer 10

Upper Small pulley

B-Pin 8/24

Upper Pulley Bracket

Lower Small Pulley

Steel String 2/820

Tension Spring

Nut4

Spring Washer 4

Clamp

Clutch Guard-2

Clutch Guard-1

Discharge Pipe

Protective Cover

Tightening Handle

Discharge Pipe

Rear Cover

Washer 6

Spring Washer 6

Bolt 6x12

Bolt M14x50

Bolt 6x20

Bearing Cover

Bearing 22209

Lower Cover

Feed Roll Bearing 209

Lock Washer 45

Screw M45/1.5

Small Belt Pulley

Screw M30*1.5

Lock Washer 30

Side Plate(1)

2

1

3

1

1

7

3

3

1

1

1

1

4

4

2

1

1

1

1

1

1

1

2

9

6

1

3

1

1

2

1

1

1

1

2

1

1

13 OF 13

45 180100-45 Bolt 8x25 18

46

47

48

49

50

51

52

53

54

55

56

57

180100-46

180100-47

180100-48

180100-49

180100-50

180100-51

180100-52

180100-53

180100-54

180100-55

180100-56

180100-57

Release Hand Seat

Gearbox Mounting Plate

Spacer 8

Nut8

Spring Washer 12

Spring Washer 8

Bolt 8x20

Key 4x20

Worm reduction gear

WPR40 30 1II

Bolt 6x90

Bolt 6x25

Nut6

1

1

20

24

8

8

8

1

1

1

2

3

Ser. No. NTE Part# Description Q'ty Ser. No. NTE Part# Description Q'ty

102

103

104

105

106

107

108

109

110

111

112

113

114

180100-102

180100-103

180100-104

180100-105

180100-106

180100-107

180100-108

180100-109

180100-110

180100-111

180100-112

180100-113

180100-114

Rear Plate

Bearing Seat Shim

Key C10*50

Screw M6x12

Driving pulley of W.R.G

Driving pulley of W.R.G

Key C6*20

Clutch Step Arm

Nut M10

Belt

Little around plate

Guide Plate

Flywheel Bearing Seat

1

2

1

2

1

1

1

1

1

1

1

1

1

For replacement partsand technical questions,please call1-800-222-5381.

WARRANTY

One-YearLimited Warranty

WARNING

Some dust createdby power sanding,sawing, grinding, drilling,and other construction

activities contains chemicalsknown to theState of Californiato cause cancer, birth defects

or other reproductiveharm. Some examplesof these chemicalsare:

Lead from lead-basedpaints

Crystalline silica frombricks and cementand other masonryproducts, and arsenicand

chromium from chemically-treatedlumber.

Yourrisk from theseexposures varies, dependingon how oftenyou do thistype of work.To

reduce your exposureto these chemicals:work in awell ventilated area,and work with

approved safety equipment,such as thosedust masks thatare specially designedto filter

out microscopic particles.

·

·

This manual suits for next models

1

Table of contents

Other Northern Industrial Tools Chipper manuals