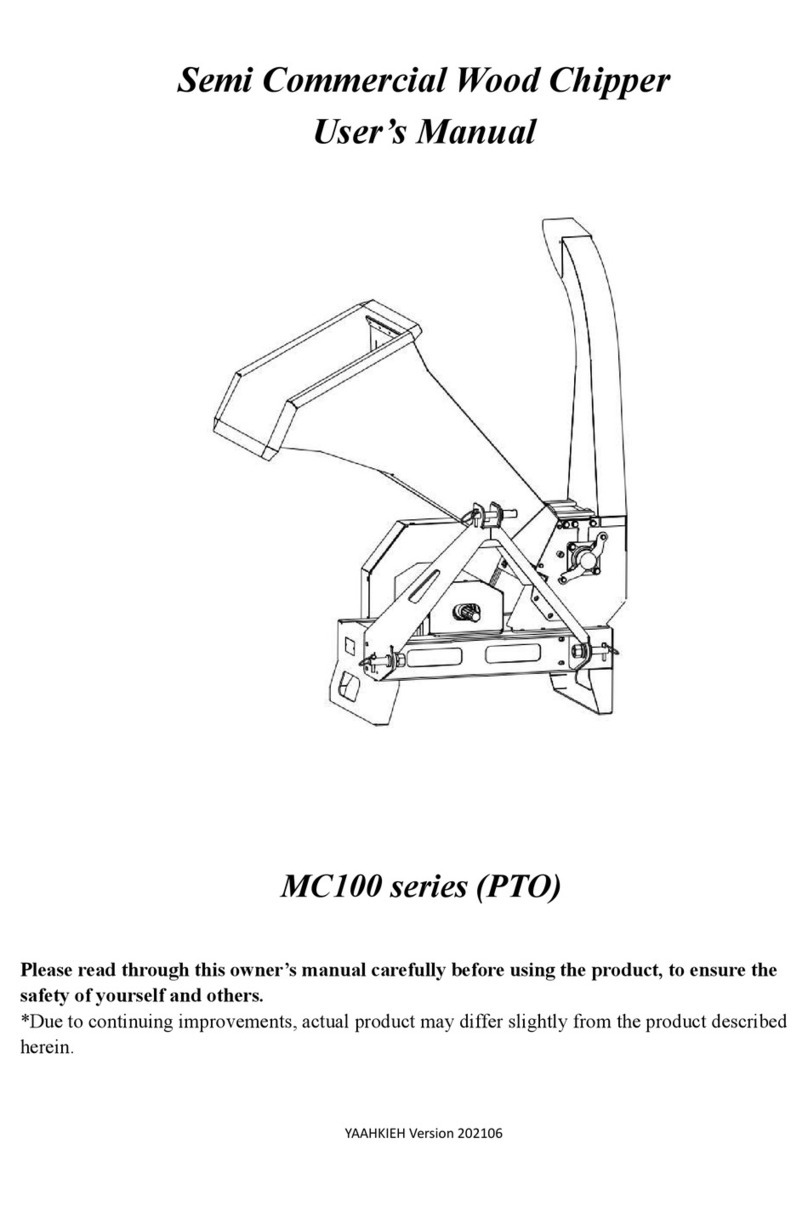

Northern Industrial Tools PTO-Driven 6" User manual

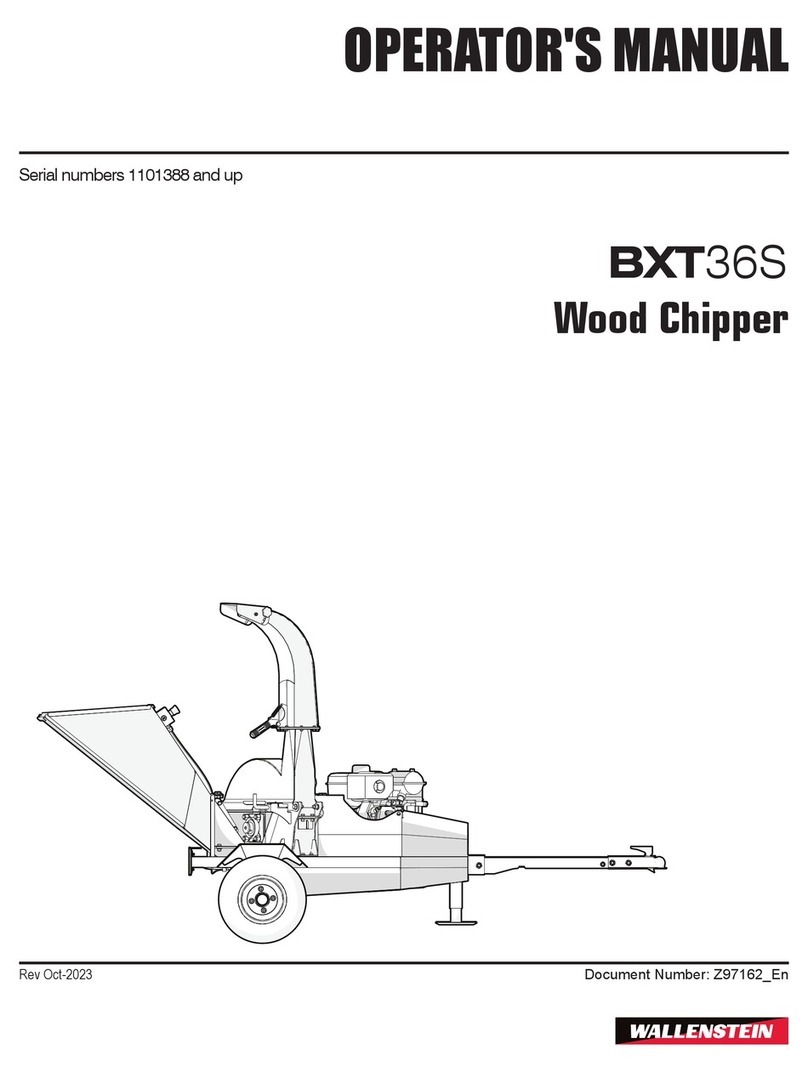

PTO-Driven 6" Wood Chipper

OWNER’S MANUAL

Read carefully and understand RULES FOR SAFE OPERATION and instructions

before operating. Failure to follow the safety rules and other basic safety precautions

may result in serious personal injury.

Ite m # 1 80 10 0

Thank you very much for choosing a NORTHERN TOOL + EQUIPMENT CO., INC.,

Product! For future reference, please complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire

manual to become familiar with this product before you begin using it.

This machine is designed for certain applications only. Northern Tool + Equipment

strongly recommends this machine is not modified and/or used for any application other

than that for which it was designed. If you have any questions relative to a particular

application, DO NOT use the machine until you have first contacted Northern Tool +

Equipment to determine if it can or should be performed on the product.

For technical questions and replacement parts, please call 1-800-222-5381.

DESCRIPTION & INTENDED USE

The PTO-DRIVEN 6" wood chipper features an advanced design with a compact structure,

superior technology and substantial attack strength. This model is safe and easy to

operate.

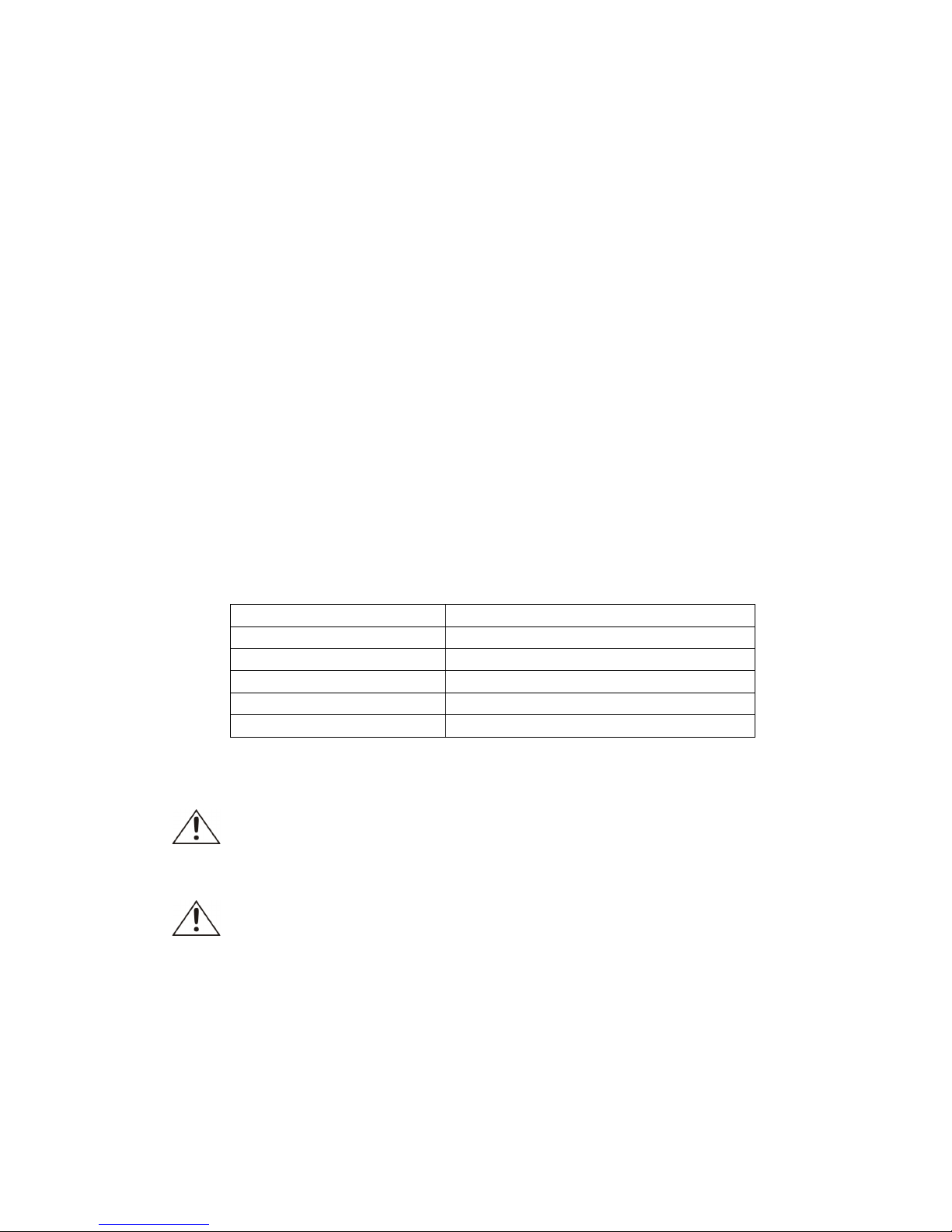

Technical Specifications

Item

Description

PTO

540 RPM

Flywheel Dia.

2 Feet (605mm)

Flywheel RPM

1220

Max Chipping Dia.

6"

Net Weight

772 Lbs. (350 kg)

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury.

WARNING: The warnings, cautions, and instructions discussed in this

instruction manual cannot cover all possible conditions or situations that could

occur. It must be understood by the operator that common sense and caution are

factors which cannot be built into this product, but must be supplied by the

operator.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep everyone — especially children — away from the area of operation.

Anyone who has not read this manual and received instructions from a

qualified person should not be in the area.

Provided labels on the unit advise the user of proper hitch dimensions and

maximum safe operating speed. Check that proper danger labels are supplied with

the drive-line (replacements are available from your drive-line supplier). Provide

easy-to-understand instructions for proper drive-line operation, maintenance and

repair in the operator’s manual.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common sense when operating a

chipper. Do not use a chipper while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating a chipper

may result in serious personal injury.

Do not attempt to operate the chipper until you have read and understood the

owner’s manual.

Always keep the guards and chip deflector installed properly while operating

the chipper.

Keep the decals in place and in good repair. The factory or your dealer will furnish

new decals upon request.

Keep hair, hands, feet and other extremities out of and away from the hopper.

Make sure there are no loose ends or strings to be caught by the machine.

Point the discharge chute away from doorways, sidewalks, or any areas where

your view is obstructed. The chute should be pointed downwind when possible or the

fines will blow into your eyes and down your neck.

WEAR PROTECTIVE GEAR:

EYES — Wraparound ANSI-approved safety glasses.

EARS — Ear plugs

HANDS — Leather gloves

FEET — Steel-toed boots

LEGS — Heavy pants

ARMS — Long-sleeved shirt

Always use the appropriate eye and ear protection and other safety equipment.

Safety equipment such as dust mask, non-skid safety shoes and a hardhat used for

appropriate conditions will reduce personal injuries.

Avoid accidental starting. Disconnect chipper from PTO when not in use, and when

moving chipper to another work area.

Never leave the chipper running unattended.

Do not attempt alterations, repairs, or adjustments while the chipper head is

turning. Always disconnect the PTO and stop the motor.

ALWAYS make sure the feed roll drive-shaft and pivots are properly lubricated.

ALWAYS make sure the feed roll clutch is properly lubricated and the clutch

releases when the handle is pushed toward the chute.

ALWAYS make sure the PTO shaft does not come apart or bottom out during

the normal lifting range.

Check the chip pile to see if the blades need to be serviced. Long slivers in the

chip pile are a good indication that the blades are dull and need sharpening.

CAUTION: Turn the chipper head over by hand before applying power to

make sure that the head is clear, all the bolts are clear and the knives clear the

case and cutter bar.

DRIVE-LINE SAFETY CHECKLIST

DRIVE-LINE SPECIFICATIONS The first step toward a safe application is

to specify and test the drive-line to make sure it operates properly

under expected field conditions.

Specify and test the proper size joints and telescoping members based upon the

power required by the implement, speed of rotation, joint angles, shock loads, and

expected life. More information may be found in all drive-line manufacturers’ catalogs.

Design and test the hitch angle to prevent the drive-line from:

Extending beyond the recommended maximum length.

Bottoming out.

Reaching a position that allows joints to lock.

Exceeding the maximum allowable angle for constant velocity (CV) joints.

Specify and test telescoping members to allow the lowest possible thrust loads,

considering the expected working conditions.

Specify and test torque limiters to control excessive shock loads. Where necessary,

specify and test overrunning clutches to prevent inertial loads from overpowering the

tractor.

Specify and test torque limiters to control excessive shock loads.

Where necessary, specify and test overrunning clutches to prevent inertial loads from

overpowering the tractor.

HAZARD REDUCTION The second step in specifying a safe drive-line

application is to eliminate as many hazards as possible.

On drive-lines with torque limiting or overrunning devices, specify that the device be

positioned on the end of the drive-line by the implement.

For implement connections which require bolts or set screws, select and/or supply

hardware which minimizes protrusions.

For tractor PTO shaft connections, specify a safety type yoke (twist or slide collar) to

minimize protrusions.

Provide a proper clearance zone for the operation of the drive-line to avoid damaging

the shielding components.

Some common areas of interference are:

Three point linkage.

Extended or eye loop hitch pins.

Hydraulic hoses.

GUARDING Hazards which cannot be eliminated effectively must be

guarded against at all times.

The PTO master shield, integral drive-line shield and implement input connection

shield should provide an interactive guarding system.

Provide instructions by labels or manuals. The implement should be used only with

the tractor’s PTO master shield in place.

Specify and test an integral drive-line shield with end cones which will overlap, but not

interfere with the PTO master shield or implement input connection shield.

Provide an implement input connection shield to interact with the integral drive-line

shield to provide guarding of the shaft coupling and any torque limiting device installed

on the drive-line.

Check that all routine maintenance of the drive-line can be done without removal of

the shields.

MACHINE OPERATION

CAUTION! Turn the chipper head over by hand before applying power to make

sure that the head is clear, all the bolts are clear and the knives clear the case and cutter

bar.

CAUTION: Do not move the unit while the flywheel is turning. Block the wheels and

set the brake while running the head.

This manual suits for next models

1

Table of contents

Other Northern Industrial Tools Chipper manuals