Northline Express DuraVent DuraLiner SDL User manual

1

THESE INSTALLATION AND OPERATION INSTRUCTIONS

COVER DURALINER MASONRYRELININGSYSTEM

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS

FAILURE TO MAINTAIN REQUIRED CLEARANCES (AIR

SPACES) TO MASONRY MATERIALS. IT IS OF THE

UTMOST IMPORTANCE THAT THIS DURALINER

CHIMNEY SYSTEM BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

Readthroughalltheseinstructionsbefore beginning your installation. Failure

to install this DuraLiner product as described in these instructions will void

the manufacturer’s warranty and may have an effect on your homeowner’s

insurance and UL/ULC listing status. Keep these instructions for the future

reference.

APPLICATIONAND LISTING

DuraLiner is a double-wall, insulated all-fuel reliner for masonry chimneys.

DuraLiner is listed and approved for installation with zero clearance between

the liner and masonry, plus zero clearance between the masonry and

combustibles. The DuraLiner lining system is intended for field installation

into new or existing masonry chimney used for natural draft venting of gas,

liquid and solid-fuel fired residential type appliances in which the maximum

continuous flue gas outlet temperatures do not exceed 1000OF/538OC (UL

1777) or 1200OF/650OC (ULC S635, ULC S640). DuraLiner is listed to the

UL 1777 standard for Chimney Liners, under the listing file number

MH14420. DuraLiner is also listed to the Canadian Standards ULC S635

and ULC S640 for lining new and existing masonry chimneys, under the

listing file number CMH1329. DuraLiner meets all the thermal, mechanical

andmaterial requirements ofthe UL1777,ULCS635, &ULC S640 standards.

DURALINER (SDL)

6"-8" DIAMETER

(ROUND & OVAL)

INSTALLATION INSTRUCTIONS MH14420 CMH1329

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

2

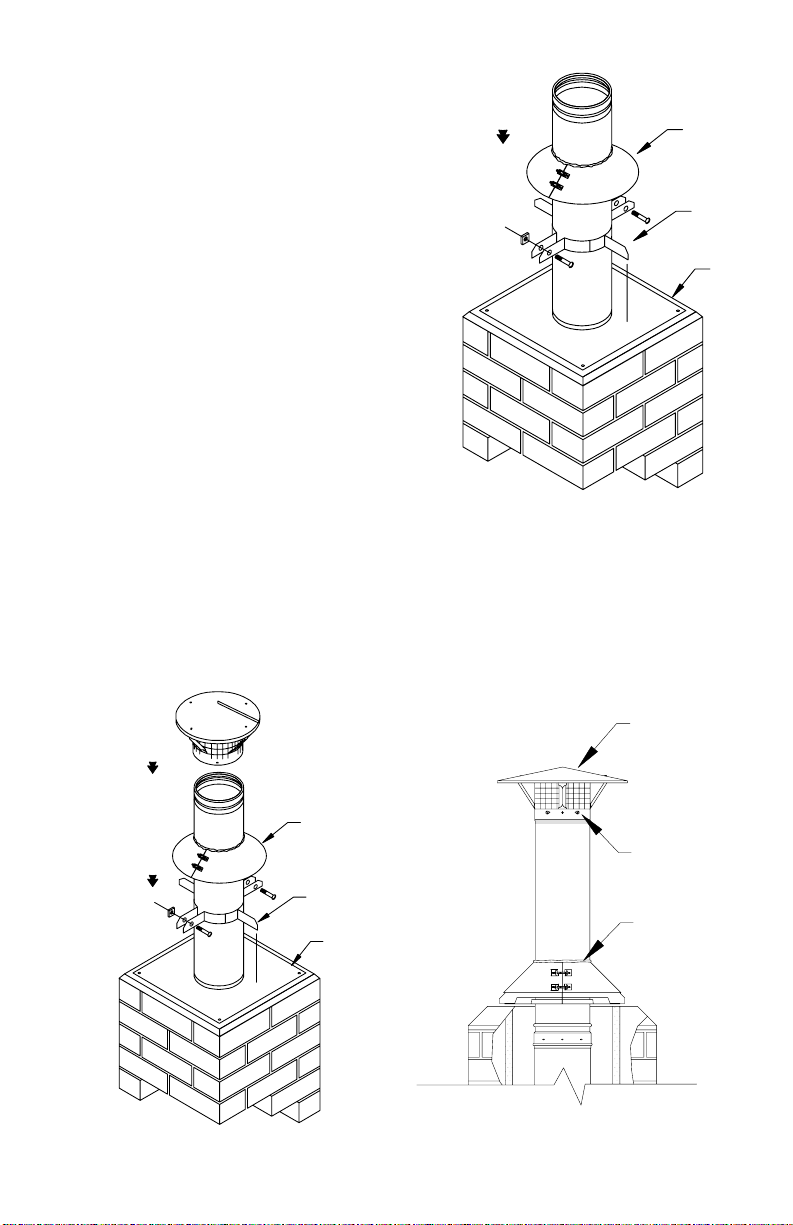

Fig. 2a Chart 2a Fig. 2

Fig. 1

IMPORTANT MEASUREMENTS

1. Flue Size I.D.

a.______________

2. Opening of Fireplace

a. Height_________

b. Width _________

c. Depth _________

3. Damper Opening

a.Length_________

b.Width_________

4. Total Chimey and

Fireplace Height

a.______________

5. Total Chimney Height

to Tee Opening

a._______________

6. Height to First Tile

a._______________

7. Height of Stove or Insert

a. _______________

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

3

TABLE OF CONTENTS

APPLICATIONAND LISTING..............................................................1

GENERALINSTALLATION INSTRUCTIONS ..................................5

MASONRYTHIMBLEAND WALL PENETRATIONS ....................11

EXTEND-A-CAPINSTALLATION .....................................................13

INSTALLING INSULATION SLEEVES .............................................16

DURALINER MAINTENANCE INSTRUCTIONS ...........................18

WARRANTY ...........................................................................................20

AN IMPORTANT MESSAGEABOUTRELININGYOUR CHIMNEY

1. Have a professional installer thoroughly clean, and install your new

appliance and relining system.

2. Determine condition of creosote buildup in masonry flue, always clean

before relining. Any tar glaze creosote buildup must be removed prior to

relining the chimney.

3. Determine condition of masonry fireplace and chimney. See that they

meet code requirements. The chimney should be checked for cracked, loose

or missing bricks, mortar, or other materials that could inhibit a correct

installation of the liner system. Make necessary repairs before relining.

4. The air space clearances between the masonry chimney exterior and

combustible materials should be checked to verify that the chimney is in

accordance with the clearance specifications of 1) the NFPA; 2) other

applicable building codes; or 3) these instructions (DuraLiner is approved

for 0” clearance if installed in accordance with these instructions).

5. Determine if your setup is an open hearth (Figure 1) or tee installation

(Figure 2). Also determine the available size of your chimney (Figure 2a)

and the corresponding allowable DuraLiner size. (Chart 2a)

6. If you have an open hearth setup, verify your flue size, and the fireplace

opening and depth before you purchase your appliance and reliner. (See

Figure 1)

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

4

7. If you have a tee installation setup, verify your flue size and chimney

height from tee, before you purchase your appliance and reliner. (Figure 2)

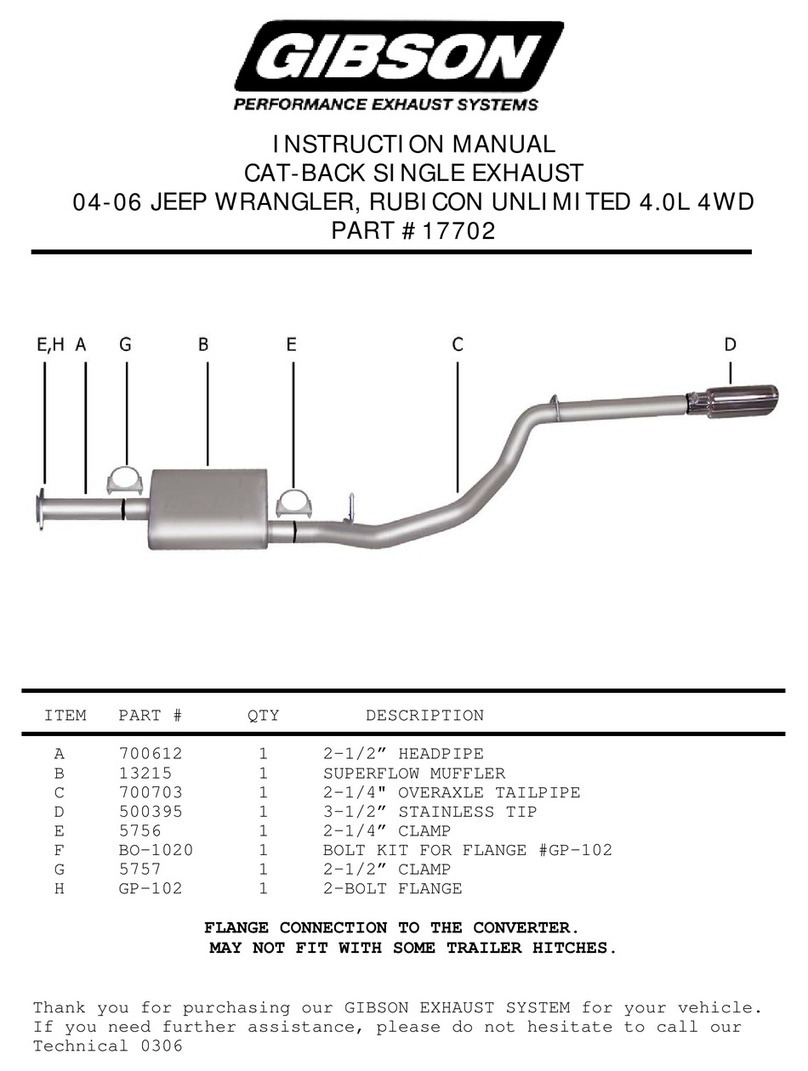

8. After selection of proper size appliance, determine the correct size of

DuraLiner and Stove Connector to the appliance. (Follow stove

manufacturer’s recommendations). There are three different types of

connections: (See Figure 3).

a. Round, for top flue exit.

b. Round, for rear flue exit.

c. Rectangular, for top flue exit

9. Chimney flue size (Figure 1) determines the size top you select. (See

catalog for details).

10. Necessary tools and equipment you may need:

Ladder Vicegrips

Safety Glasses Light Rope

Gloves Snips

Tape Measure Drill & 5/32" Twist Drill Bit

Hammer Metal Saw

Screwdriver Pop Rivet Gun

High Temperature Waterproof Sealant

Make sure all equipment is in good condition.

11. Safety Tips:

Do not go on roof when wet or icy.

Sheet metal parts have sharp edges, wear gloves.

Safety Glasses.

Safety Hat.

Practice good workmanship. Sloppy work could jeopardize your installation.

Fig. 3

CBA

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

5

12. Clearances: Simpson Dura-Vent’s DuraLiner is

listed by Underwriters Laboratories (UL & ULC) as

a liner for listed all-fuel burning appliances.

DuraLiner is designed and listed for installation in

masonry chimneys only. The minimum clearance

from pipe to masonry construction is “0”. Never

fill any required clearance (air space) with

combustible or noncombustible materials.

DuraLiner shall be sized not less than that specified

in the appliance manufacturer’s instructions.

13. Permits: Contact your local building official or

fire department regarding permits, restrictions, and

installation inspection in your area.

GENERALINSTALLATION INSTRUCTIONS

Choose an appliance that is listed by a recognized

testing laboratory.

a. Follow the appliance manufacturer’s

instructions.

b. Connect only one flue liner per appliance.

c. DO NOT mix or match with other products

or improvise solutions. (You may void

warranties.) DO NOT modify parts.

d. Follow the appliance manufacturer’s

instructions and manual for maximum

efficiency and safety. Over firing can

damage the appliance and lining system.

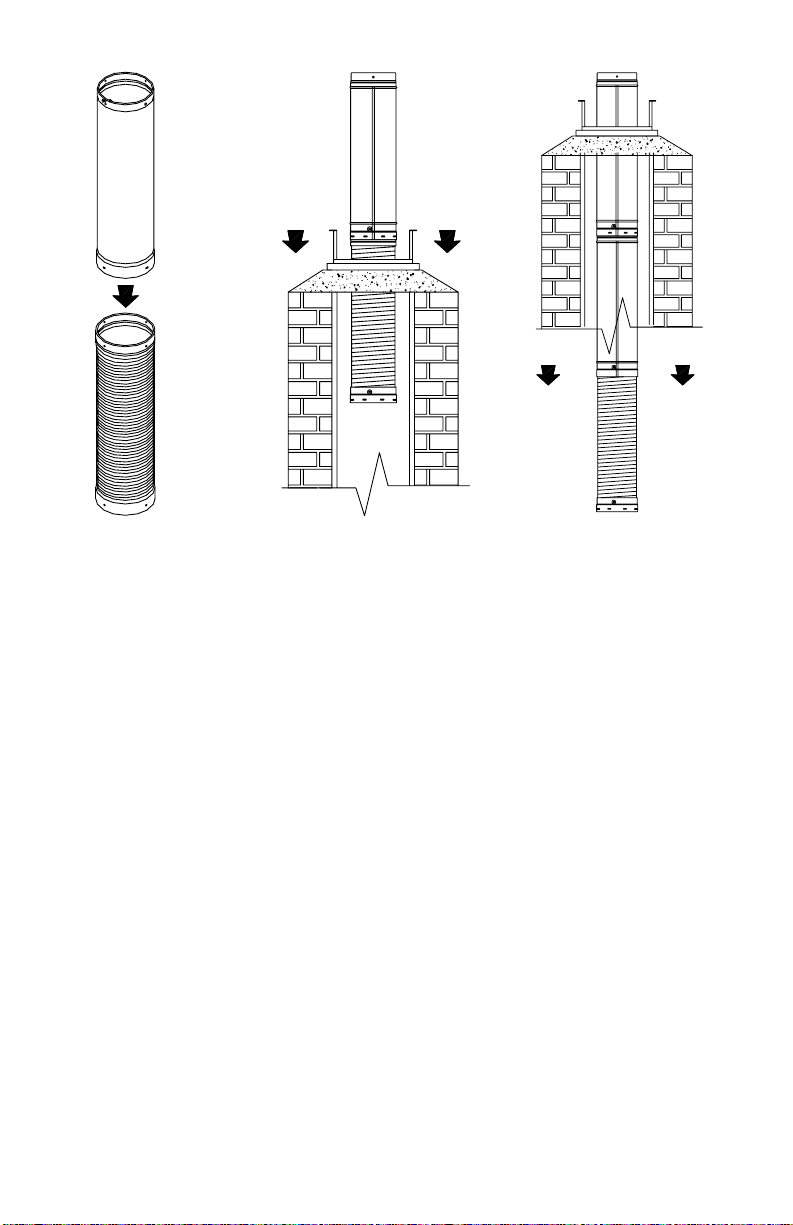

Follow these basic assembly instructions when

installing DuraLiner in the open hearth installation

(Figure 1). For tee installations, refer to the Tee

Installation section of these instructions. The oval

liner fits together in the same manner as the round

liner.

STEPONE: If needed, remove theexisting damper

from your fireplace to allow liner to fit.

Fig. 4

TOP

SLIP

CONNECTOR

SECONDARY

TOP

SCREEN

FRAME

HANGER

DAMPER

SMOKE

SHELF

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

6

Your fireplace insert or stove and DuraLiner are designed to work without

your existing damper. In order to install the DuraLiner, you must remove the

damper and in some cases part of the smoke shelf, to allow DuraLiner to pass

through this area freely. Note: DuraLiner flex pipe is available in both round

and oval shapes to ease installation.

Now that the old damper assembly and part of the smoke shelf has been

removed, the chimney and fireplace should be free from obstructions.

STEPTWO: The DuraLiner system is held in place by the framework at the

top of the chimney is designed to support the weight of a relining system up

to 50 feet. The minimum height of system must be at least 10-feet to insure

proper drafting performance.

The top comes assembled. You must take the top apart to get the bottom

frame in place. The top has six major components: Top, Screen, Secondary

Top, Frame, Slip Connector and Hanger. (See Figure 4) Place frame on top

of masonry chimney, the weight of the DuraLiner will hold the top in place.

We also provide screws that may be attached to bottom of frame and attached

tile. (See Figure 5).

STEP THREE: All DuraLiner pipe (flex and rigid) has male and female

connectorswith (4) pre-punched holesandslots that lineupand are connected

with stainless steel pop rivets. Do not use screws. When connecting sections

of flex pipe, it is necessary to first align the holes with the slots, and then drill

through the flex pipe with a 5/32” (4 mm) diameter twist drill bit. Next,

install the pop rivets. Drilling is not needed to connect sections of rigid pipe.

Connectfirst rigid sectionof DuraLinerontop offlex section with(4) stainless

steel pop rivets.

Note: The DuraLiner flex sections

can be easily insulated with the

Two-Ply Insulation Sleeve. This

blanket insulating sleeve permits

complete flexibility. It is held in

place by simple strap clamps that

aresecured withboltand nutat each

Fig. 5

FRAME

SCREWS SEALANT

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

7

end of DuraLiner flexible pipe lengths. Refer to the Insulation Sleeve

Instruction section.

Fromthe stove,up throughthe damperto thefirstflue tile,it isNOT mandatory

touse anInsulation Sleeve.Abovethe firstflue tile,flex pipemust beinsulated.

(NOTE: For improved draft and fire safety, we recommend the use of an

insulation sleeve on all flex pipes.)

After pipe is riveted together, lower through the Frame of DuraLiner Top and

hold in position. Each DuraLiner pipe section is then riveted and lowered

down the chimney. This procedure is repeated until the flex section reaches

the smoke shelf area. As the pipe is being lowered further down, bend the

flex pipe to fit through the damper. (See Figure 7a and 7b)

STEP FOUR: Before you rivet the last section of pipe in place, attach the

hanger to the last section of pipe just below the bead. (See Figure 8)

Attach the hanger strap holder to the last hole on the strap. (See Figure 8)

Lower DuraLiner to final position. (See Figure 9) If appliance has top flue

exit, hold approximately ½” above connector. (See Figure 13) If appliance

has rear flue exit, line up branch of tee with connector. (See Figure 16)

Fig. 7aFig. 6 Fig. 7b

6” OR 8”

ROUND

RIGID PIPE

(VARIOUS

LENGTHS)

6” OR 8”

FLEX PIPE

(VARIOUS

LENGTHS)

RIGID PIPE

FLEX PIPE

RIGID PIPE

FLEX PIPE

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

8

Attach hanger strap to holes in chimney top

frame. Secure with nut and bolt. (See Figure

10)

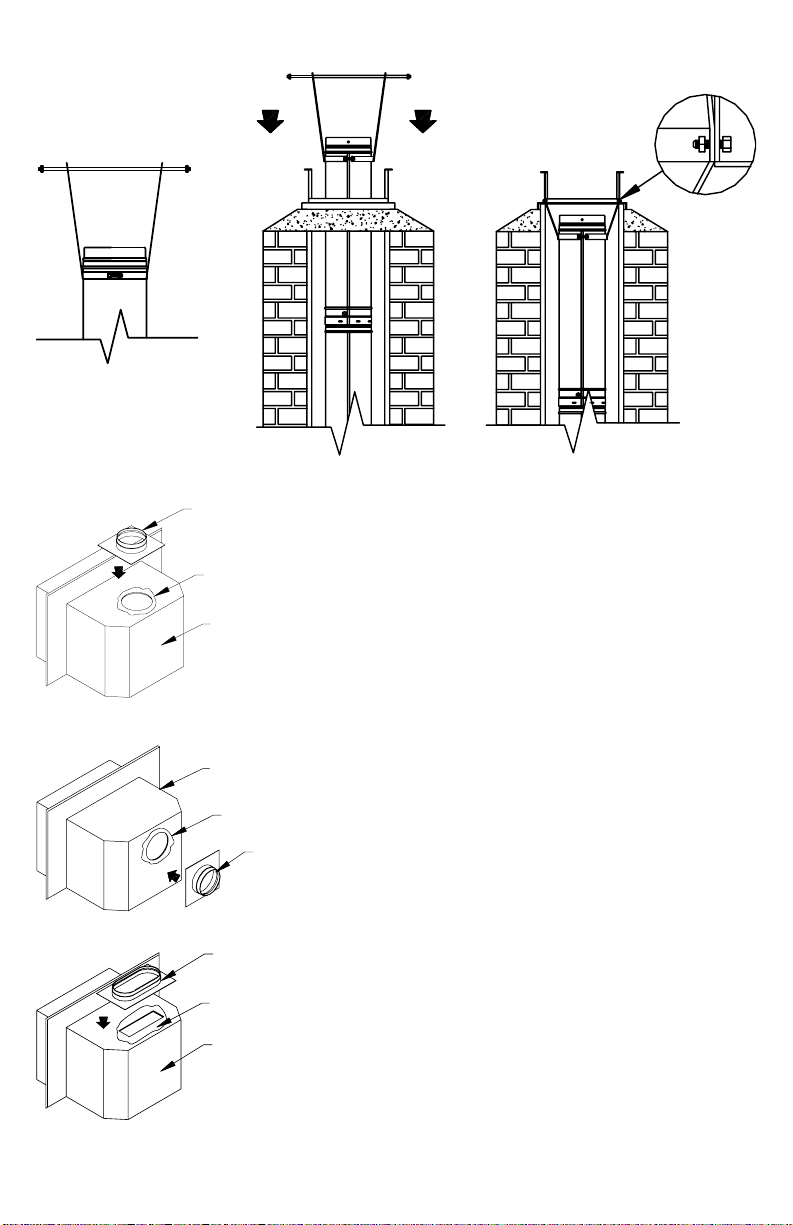

STEP FIVE: Stove top connector - round

and oval. Attach the proper Stove Connector

to your insert or stove. (See Figure 3) The

DuraLiner round Stove Connector fits either

a top vented found flue appliance or a rear

ventedroundflue appliance. Place the proper

sized connector over the flue exit and mark

onthe insert orstovethe locations ofthe holes

where the connector will be attached. (See

Figure 11a or 11b) Drill and tap hole in top

orrear of applianceor use selftapping screws.

Before attaching permanently, put a bead of

high temperature sealant between stove

connector and insert. (See Figure 11a and

11b)

The DuraLiner oval Stove Connector fits on

top vented appliances or inserts with oval or

rectangularopenings. (See Figure 12) Attach

same as in round openings. (See Figure 11a)

Fig. 8

Fig. 9 Fig. 10

Fig. 11a

Fig. 11b

Fig. 12

HANGER STRAP HOLDER

HANGER

BEAD ON

RIGID

HANGER STRAP

HOLDER

HANGER

FRAME

NUT/BOLT

BEND

ROUND STOVE

CONNECTOR

HIGH

TEMPERATURE

SEALANT

STOVE

INSERT

ROUND

STOVE

CONNECTOR

HIGH

TEMPERATURE

SEALANT

STOVE

INSERT

OVAL STOVE

CONNECTOR

HIGH

TEMPERATURE

SEALANT

STOVE

INSERT

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

9

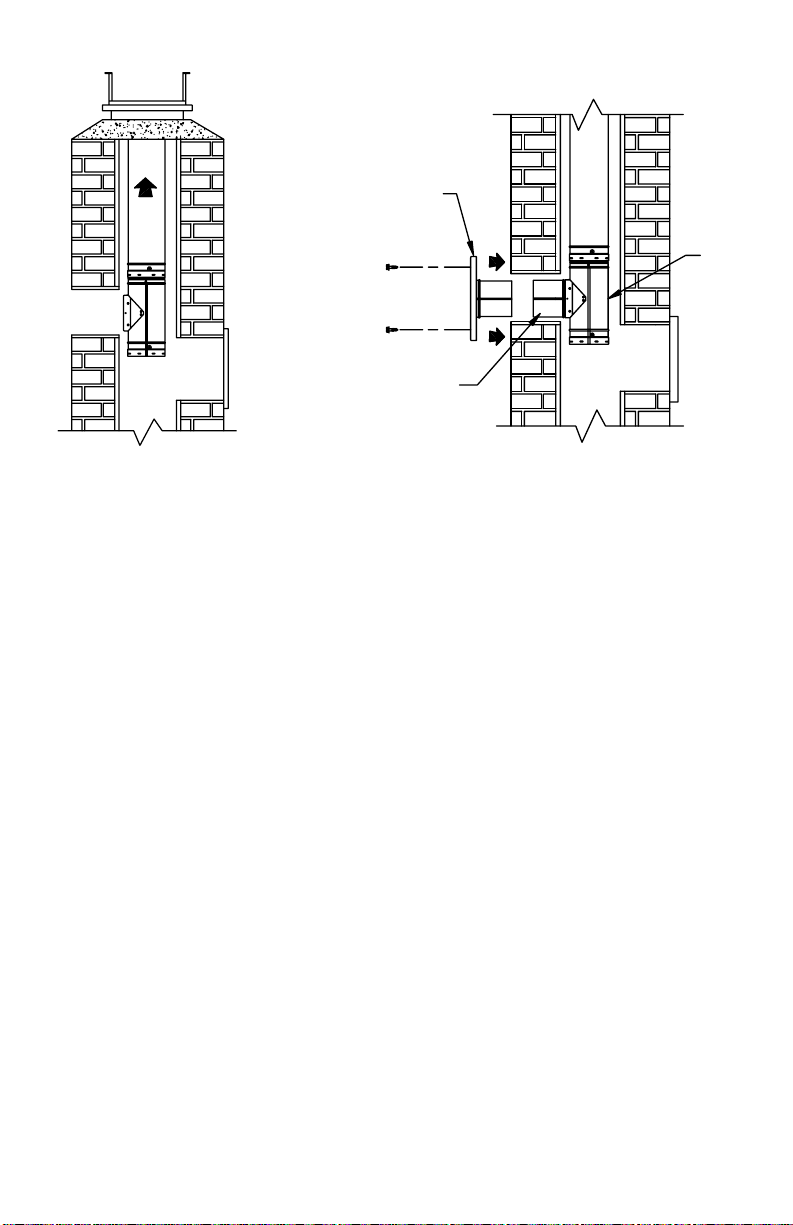

STEP SIX: Connect stove or insert to DuraLiner. When connecting

DuraLiner to top-exiting appliance outlets, follow this procedure. After stove

or insert has been set in proper location, pull flex pipe down over Stove

Connector and pop rivet or screw together. (See Figure 1) If the flex pipe

does not provide sufficient height adjustment, further adjustment may be

made by selecting a different set of holes on the DuraLiner Hanger at the top

of the system. The Slip Connector will accommodate up to 10" adjustment.

Note: If you have a round flue outlet on your stove, and you have used Oval

Flex or Oval-To-Round flex through the damper area, a 14" Round-To-Oval

flexible pipe adapter will be required for the stove connection. (See Catalog)

If stove or insert has a round rear exit, attach round or oval Tee to bottom of

flex pipe. (See Figure 14) Line up branch of Tee with stove outlet.

Fig. 13

Fig. 14 Fig. 15

FLEX PIPE

1/2”

STOVE

CONNECTOR

POP RIVET OR

SCREW FLEX

PIPE TO STOVE

CONNECTOR

FLEX PIPE

OVAL OR

ROUND

RIGID TEE

OVAL OR

ROUND

BRANCH

OF TEE REMOVABLE

TEE CAP

ADJUSTMENT

FLEX PIPE

OVAL OR

ROUND

RIGID TEE

OVAL OR

ROUND

ADJUSTABLE SLEEVE

(MIN. OVERLAP 2”)

TEE CAP

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

10

When branch of tee is alligned with rear exit of

appliance, attach DuraLiner Adjustable Sleeve to

branch. The Adjustable Sleeve has pre-formed

buttons. (See Figure 15) The buttons snap into

branch ring. Slide stove or insert into proper

position. Adjust pipe and snap into back of stove.

SecureAdjustableSleeve in final position withsheet

metal screws. Rear flue exit should look like Figure

16.

STEP SEVEN: Now you are ready to do the final

top assembly. Take the slip connector and attach to

Secondary Top. This is held in place by pre-formed

buttons. (NOTE: with oval pipe the Slip Connector

pipe must be attached to the Secondary Top with

pop rivets in four pre-punched holes.) (See Figure

17) When this is done, slide Slip Connector into

DuraLiner and over chimney top Frame. Attach

Secondary Top to frame using eight screws. (See

Figure 18)

After Secondary Top is attached to Frame, slide

Screen into position between legs of Frame

(optional). Put Top on (4) legs, line up prepunched

holes and bolt firmly into position. (See Figure 19)

Fig. 17

Fig. 18

Fig. 19

SECONDARYTOP

PRE-FORMED

BUTTONS

SLIP

CONNECTOR

SECONDARY

TOP

FRAME

SLIP

CONNECTOR

TOP

SCREEN

LEGS

SCREWS

SEALANT

Fig. 16

FLEX PIPE

OVAL OR

ROUND

ADJUSTABLE

SLEEVE (MIN.

OVERLAP 2”)

STOVE

CONNECTOR

RIGID TEE

OVALOR

ROUND

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

11

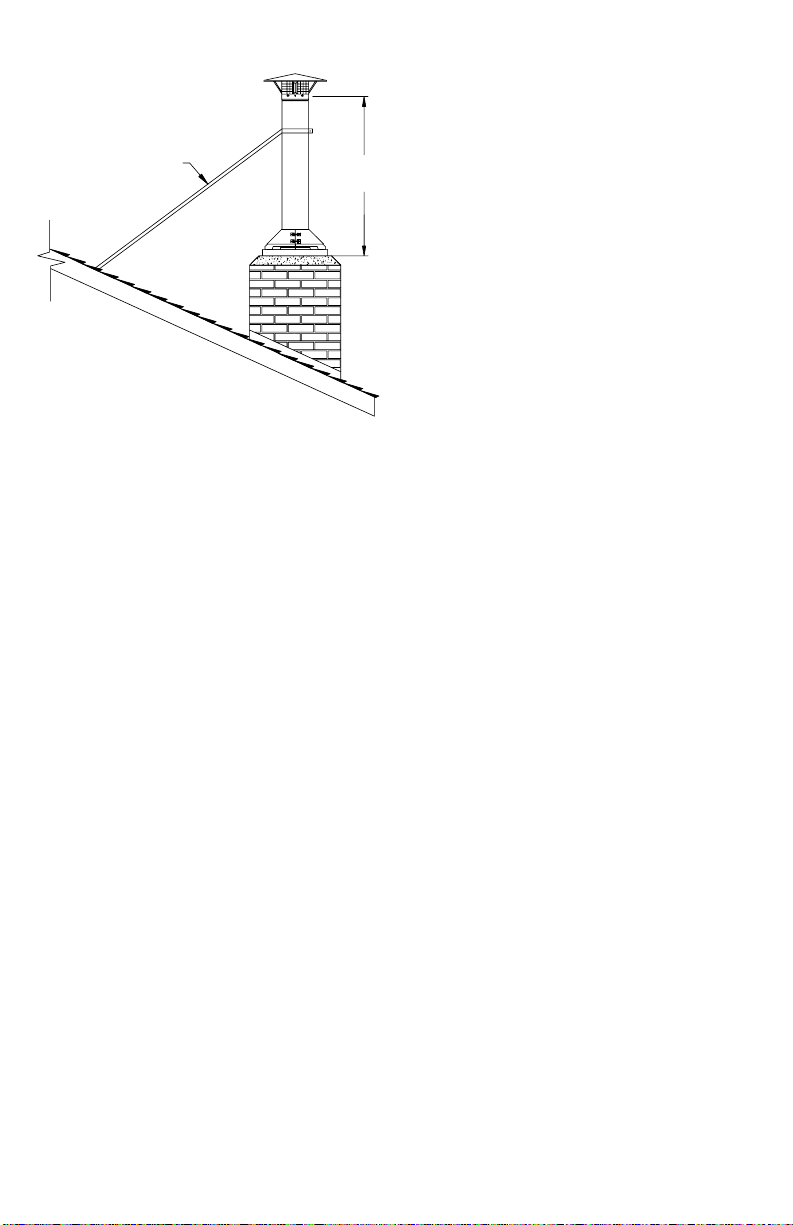

Note: National Fire Protection

Association standard #211 states;

“Chimneys shall extend at least three

feet above the highest point where

they pass through roof of a building

and at least two feet higher than any

portion of a building within ten feet.”

(See NFPA 211 Example)

MASONRYTHIMBLEAND WALLPENETRATIONS

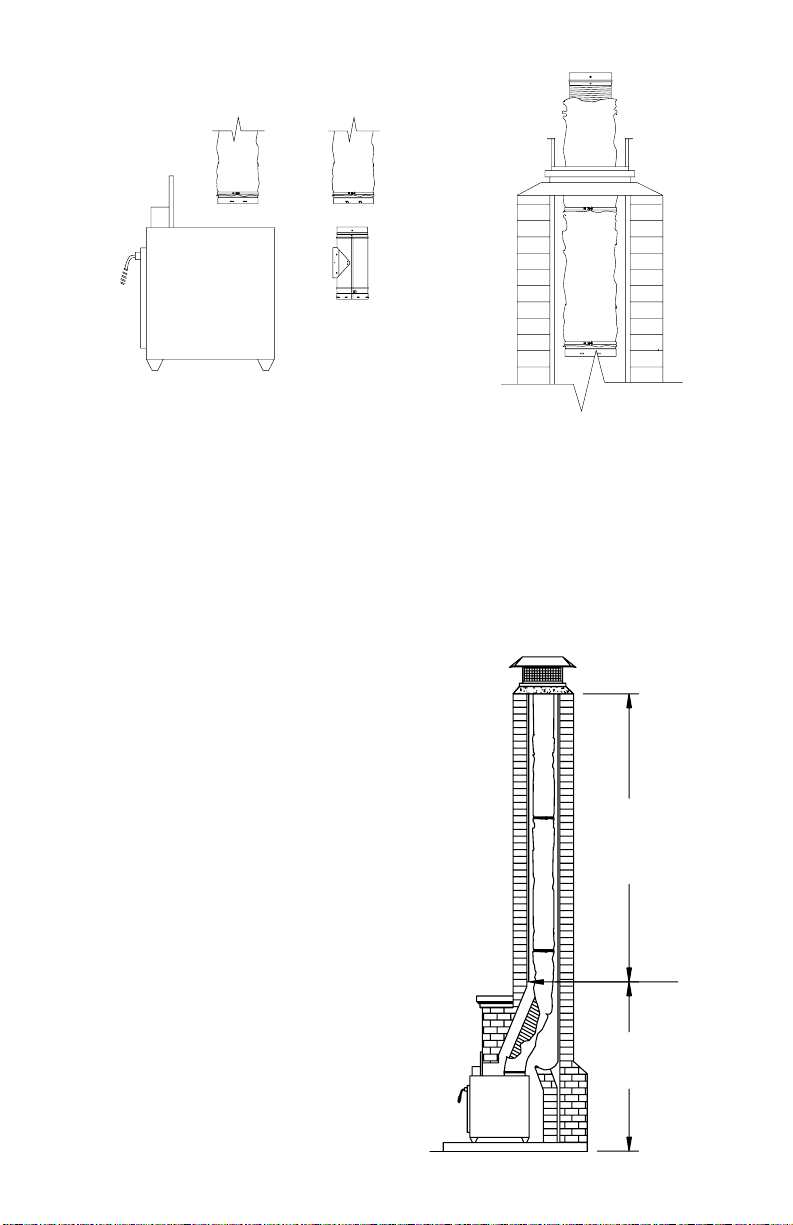

Follow these basic assembly instructions when installing DuraLiner in a Tee

installation, as shown in Figure 2. (Note: Wall penetration assemblies shall

not be located directly behind a heating appliance.)

STEPONE: If a Masonry Thimble is used as a wall pass through for a Tee

installation, you must maintain proper clearances to combustibles from the

connector pipe. (See Figure 20)

STEP TWO: All DuraLiner pipe, flex or rigid, has male and female

connectors with prepunched holes and slots that line up and are connected

with stainless steel pop rivets. Do not use screws. When connecting sections

of flex pipe, it is necessary to first align the holes with the slots, and then drill

through the flex pipe with a 5/32” (4 mm) diameter drill. Next, install the

pop rivets. Drilling is not needed to connect sections of rigid pipe. Connect

COMBUSTIBLE

*18”

*18” MINIMUM

CLEARANCE SINGLE-WALL

PIPE TO COMBUSTIBLE

MATERIALS (NFPA 211)

3 FEET MIN.

FROM ROOF

PENETRATION

2 FEET MIN.ABOVE

POINT OF ROOF

WITHIN 10 FEET

10 FEET

NFPA 211 EXAMPLE

Fig. 21

6” OR 8”

ROUND

RIGID PIPE

6” OR 8”

ROUND

RIGID TEE

REMOVABLE

TEE CAP

Fig. 20

ACCESS

DOOR FOR

CLEANOUT

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

12

first rigid section of DuraLiner on top of Tee with four stainless steel rivets.

(See Figure 21) After pipe and Tee are riveted together, lower them down

through the Frame of DuraLiner Top and hold in position. Each DuraLiner

pipe section is then riveted and lowered down the chimney. This procedure is

repeated until the Tee reaches the masonry opening.

STEPTHREE: Before you rivet the last section of pipe in place, attach the

Hanger to the pipe just below the top on the last of the rigid DuraLiner pipe.

(SeeFigure 8)As the DuraLinerrigid pipe is beinglowered into final position,

line up the branch of the Tee with hole in the masonry chimney wall. (See

Figure 22).

When branch of tee is in line with hole in wall of masonry chimney, attach

slipconnector fromthe MasonryThimble. The SlipConnectorhas pre-formed

buttons. The buttons snap into branch ring. Slide Thimble section into slip

connector and attach black finishing ring to wall of chimney using screws.

(See Figure 23).

Fig. 22

FRAME

Fig. 23

SEALANT

ANCHOR

SCREWS

SLIPCONNECTOR

FROM MASONRY

THIMBLE

TEE

TEE

MASONRY

THIMBLE

ACCESS

DOOR FOR

CLEANOUT

ACCESS

DOOR FOR

CLEANOUT

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

13

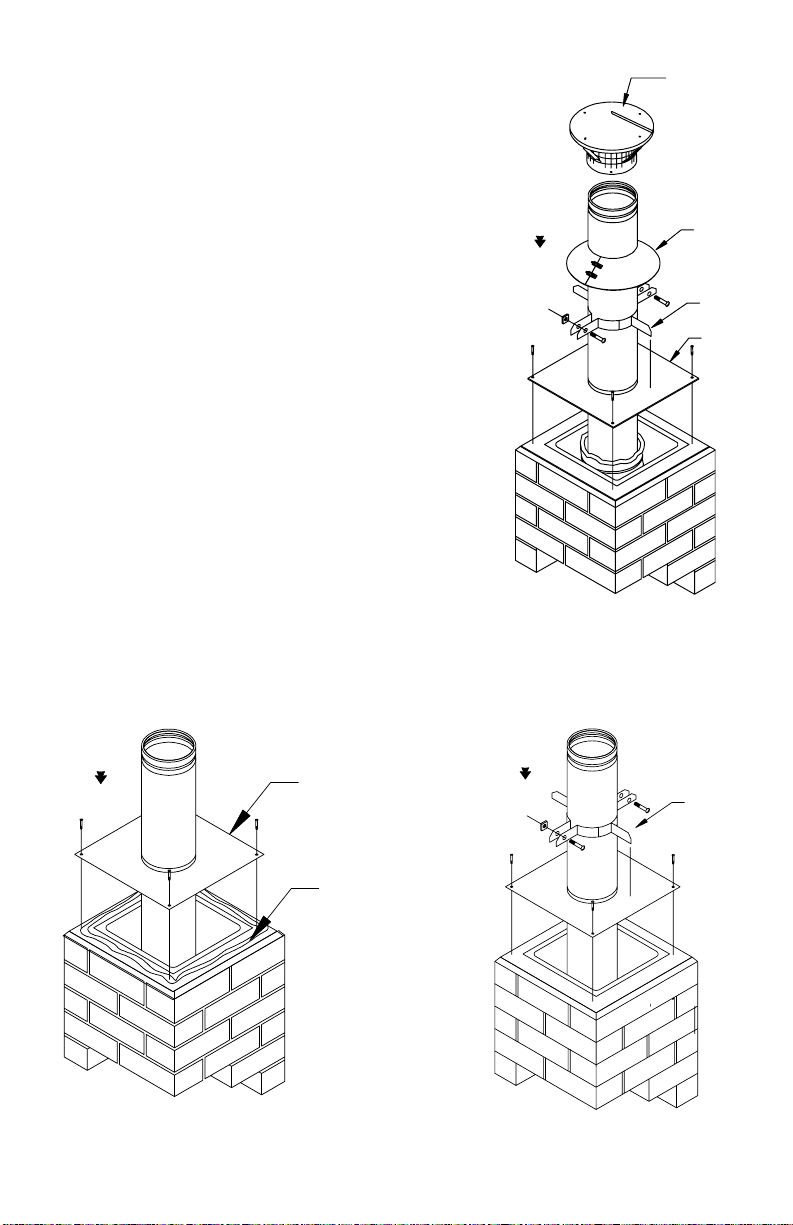

EXTEND-A-CAP INSTALLATION

The Extended-A-Cap is used with a DuraLiner

system when it is desired to extend the length

above the level of the existing masonry for the

purpose of improving draft, to accommodate

remodeling, to comply with safety requirements

for height of chimney above the roof, or as an

alternative to the Standard Termination.

Refer to the General Installation Instructions for

the majority of the installation. Extend-A-Cap

installationonly refers tothe top ofthe DuraLiner

installation, and is used instead of the Standard

Termination. All notes, warnings, maintenance

procedures, clearance, and basic instructions

containedinthe General Installation Instructions

are applicable to the Extend-A-Cap.

An exploded diagram of the Extend-A-Cap is

shown in Fig. 24. The cap may be installed on both round and oval rigid

systems.

BASE

CLAMP

STORM

COLLAR

CAPAND

SPARK

ARRESTOR

Fig. 24

Fig. 25

SEALANT

BASE

Fig. 26

CLAMP

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

14

STEP ONE: Center the base plate on the

top of the masonry chimney as shown in

Fig.25. Trimtofitthe chimneyasrequired.

Use non-hardening sealant to seal the base

plate to the masonry chimney, but this can

be done after the liner has been lowered

into place. Anchors or screws are

recommended but not required, as the base

plate will ultimately be supporting the

entire weight of the installation.

STEPTWO: Position the clamp assembly

on top of the base as shown in Figure 26.

Adjust the bolts on the clamp assembly so

that pipe sections will just pass through the

clamp.

STEPTHREE: If needed, remove the existing damper from the fireplace,

as stated in STEP ONE on page 5 of the General Installation Instructions. It

Fig. 27

BASE

CLAMP

STORM

COLLAR

BASE

CLAMP

STORM

COLLAR

Fig. 28

CAP WITH

SPARKARRESTOR

#8 SHEET

METALSCREWS

EXPLODED VIEW COMPLETED EXTEND-A-CAP

BEAD OF SEALANT

AROUND TOP OF

STORM COLLAR

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

15

may be necessary to remove part of

the smoke shelf to allow the liner

sections to pass through the throat.

STEP FOUR: After the basic

measurements have been taken, and

the correct parts are on hand, begin

assembling the pipe sections as

described in STEPTHREE on page 6

of the General Installation

Instructions. Alternately tighten and

loosenthe clampassembly tohold and

lower the pipe sections as they are

assembled with pop rivets.

STEPFIVE: Once the desired length of liner has been achieved, tighten the

clampassembly bolts, until thesystemis firmly supported bythe base. Attach

the storm collar, and seal with non-hardening sealant as shown in Figure 28.

STEPSIX: Install the cap, using #8 sheet metal screws, as shown in Fig. 28.

If the cap is 4-feet or more above the top of the masonry chimney, use an

extended roof bracket as shown in Fig. 29.

STEPSEVEN: Completethe connection of your stove orinsertas described

in STEP FIVE on pages 8, 9, and 10 of the General Installation Instructions.

The Maintenance Instructions contained on page 18 of these Installation

Instructions are all applicable to the Extend-A-Cap installation, other than

cap removal, which is accomplished by removing the four sheet metal screws

holding the band to the pipe section.

DuraLiner systems are designed solely for relining masonry chimneys,

therefore no clearances to combustibles have been established for these

systemsoutside of masonry chimneys. Inview of this,do not construct chases

or other enclosures around DuraLiner pipe sections which extend above the

masonry.

Fig. 29

MORETHAN

4-FEET

EXTENDED

ROOF

BRACKET

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

16

INSTALLING INSULATION SLEEVES

In a situation where the chimney liner consists of rigid

sections,except forthefirst sectionof flexpipe, as shown

in Figure 6 on page 7, and it is desired to insulate the

flex pipe, follow the steps listed below:

STEP ONE: Slip the proper size of the Two-Ply

Insulation Sleeve over the flex pipe, and position it

approximately 1" up from the bottom. (See Figure 30)

Install the bottom insulation sleeve clamp, and push the

top of the sleeve down 4" to 6". Position clamps so that

the nut and bolt connections are pointing towards the

corner of a rectangular chimney.

STEPTWO: Connect the first rigid section of pipe to

the top of the flex pipe using stainless steel pop rivets,

asdescribed intheGeneral InstallationInstructions. (See

Figure 6)

STEPTHREE: Push the insulation sleeve back to its

full length and secure it with an insulation sleeve clamp.

(See Figure 31)

STEP FOUR: From this point on, follow the general

instructions as written. Refer to Figure 6, 7a, 7b, 8, 9

and 10. The liner should now be ready to be attached to

the appliance. (Figure 32).

STEP FIVE: Secure the flex pipe to the insert or tee as

shown in Figure 13 or Figure 14 of the General

Installation Instructions.

STEPSIX: After attaching the insert or the tee, proceed

with the remainder of the General Installation

Instructions.

Fig. 30

Fig. 31

1-INCH

CLAMP

4-6 INCHES

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

17

In situations where the chimney liner will consist totally of flex-pipe, insulate

the entire length and follow the steps listed below:

STEPONE: Slip the appropriate sized insulationsleeve over the firstsection

of flex-pipe and position as shown in Figure 30. Lower the first section

down the chimney approximately ¾ of its length, and hold in place.

STEPTWO: Connect the second section

of flex-pipe to the first section by means

of stainless steel pop rivets as described

in the general installation instructions.

STEP THREE: Slip another length of

insulation sleeve over the second section

of flex-pipe. Pull up the top of the lower

section of insulation shield so it overlaps

the top section by 1" to 2" and attach an

insulationsleeve clampas shownin Figure

33.

STEPFOUR: Lower the assembly down

the chimney. Repeat steps and three until

the desired length is achieved.

Fig. 32 Fig. 33

- OR -

TEE

INSERT

Fig. 34

ZERO CLEARANCE TO

MASONRYIN THIS

AREA IF INSULATION

SLEEVE IS USED.

FLUE TILE

STARTSAT

THIS POINT

ZERO CLEARANCE

TO MASONRY IN

THISAREA

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

18

STEPFIVE: Complete theinstallation asdescribed inthe GeneralInstallation

Instructions. Complete insulated system shown in Figure 34.

DURALINER MAINTENANCE INSTRUCTIONS

Creosote and Soot-Formation and Need for Removal:

When wood is burned slowly, it produces tar and other organic vapors, which

combine with expelled moisture to form creosote. The creosote vapors may

condenseon theinside ofthe chimneylinerduring slow-burningfiring periods.

Asaresult, creosote residue accumulatesonthe chimney liner. When ignited,

this creosote makes an extremely hot fire.

1. Access – Chimney liners must be installed so that access is provided for

inspection and cleaning.

2. When to Clean – The chimney liner should be inspected at least once

every two months during the heating season to determine if creosote or soot

buildup has occurred. Check spark arrestor screens every 2-4 weeks. If

creosote or soot has accumulated, it should be removed to reduce the risk of

chimney fire. At a minimum, the liner must be cleaned at least once a year.

3.How to Clean –Have your chimney linercleaned by aprofessionalcertified

chimneysweepif you have doubtsabout your ability to cleanit. Use a plastic,

wood, or flexible steel or wire brush. Do not use a brush that will mar the

stainless steel liner surface. Scrub the spark arrestor with a wire brush.

To remove the chimney cap for cleaning, unscrew the four screws that attach

the cap’s support legs to the cap base.

4. Coal – To reduce corrosion in chimneys where coal is burned, clean the

chimneythoroughly within 48hours of shuttingdownthe stoveforthe season.

Check the chimney’s lining for acid corrosion regularly.

5. No Chemical Cleaners – Do not use chemical chimney cleaners. Their use

does not eliminate the need for mechanical cleaning and they may be highly

corrosive.

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

19

6. In case of Fire – If a flue fire occurs, close all appliance draft openings and

call your Fire Department. Do not use the chimney again until it is inspected

for possible damage.

7.Flues – Connect onlyone solid fuel applianceperchimney liner. DuraLiner

shall be sized not less than that specified in the appliance manufacturer’s

instructions.

8.Appliance – Choose an appliance that is listed by a recognized testing and

listing agency and is not larger than you need.

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

20

SIMPSON DURA-VENT, INC.

ENGINEERED EXCELLENCE

45 YEARS OF LEADERSHIP IN CHIMNEY DESIGN.

SIMPSON DURA-VENT, P.O. BOX 1510,

VACAVILLE, CA 95696-1510

VICKSBURG, MS

(800) 835-4429 (707) 446-4740 FAX

www.duravent.com June 2005

L402

WARRANTY

Simpson Dura-Vent warrants DuraLiner for a period of 25 years from date of

installation. The warranty includes all components and fittings except

chimney caps. Chimney caps carry a five-year warranty. All warranties,

whether expressed or implied, shall be limited to replacement (exclusive of

installation costs) of the product found to be defective under this warranty

providing all recommended installation and maintenance instructions are

followed.

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454

Table of contents