5

ADDITIONAL SAFETY RULES FOR TOOL

1. Wear eye protection.

2. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still cause

severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before each

use. Do not operate saw if blade guard does not

move freely and close instantly. Never clamp or tie

the blade guard into the open position.

4. Do not perform any operation freehand. The

work piece must be secured firmly against the

turn base and guide fence with the vise during

all operations. Never use your hand to secure the

work piece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving work piece or changing settings.

7. Unplug tool before changing blade or servicing.

8. Always secure all moving portions before

carrying the tool.

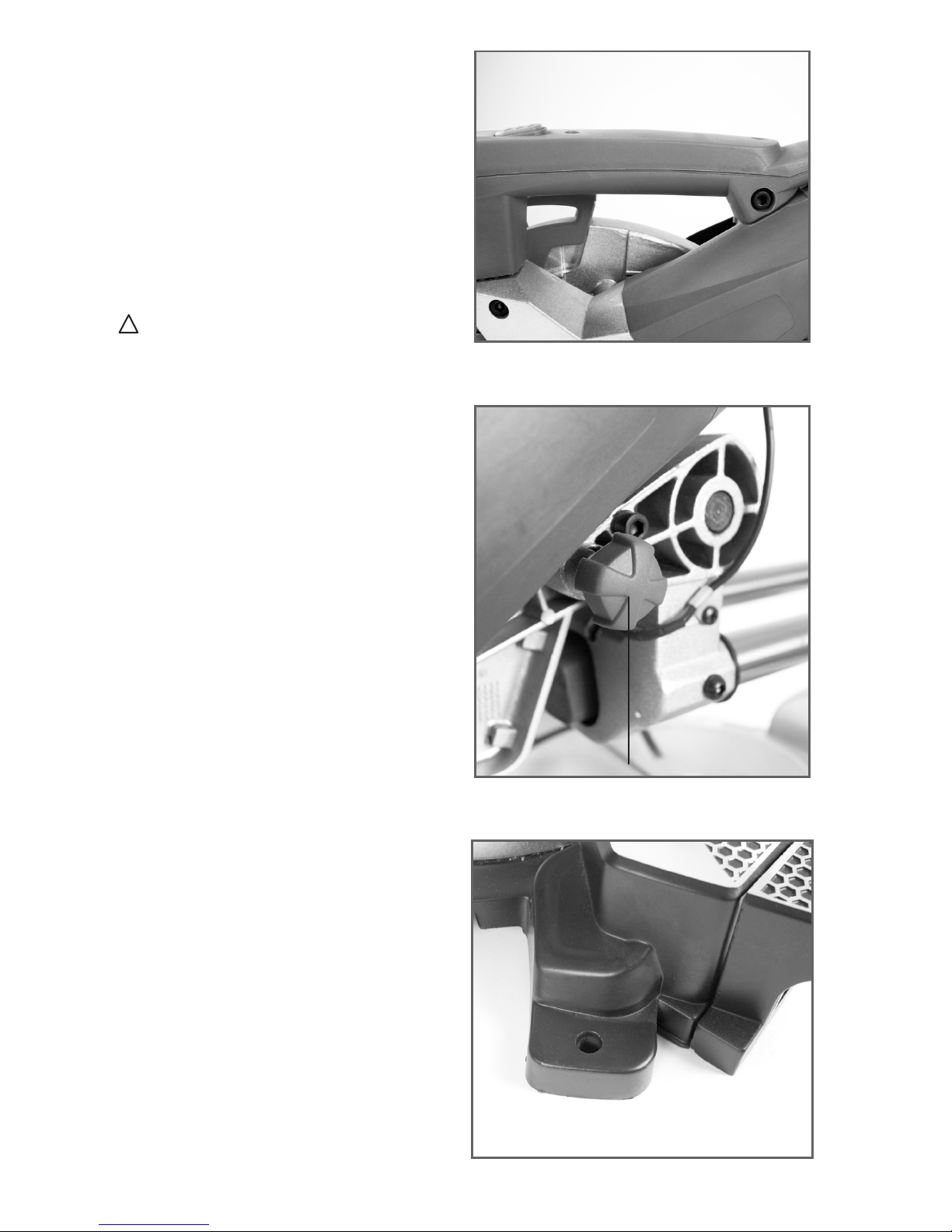

9. Stopper pin which locks the cutter head down

is for carrying and storage purposes only and not

for any cutting operations.

10. Do not use the tool in the presence of

flammable liquids or gases.

11. Check the blade carefully for cracks or

damage before operation. Replace cracked or

damaged blade immediately.

12. Use only flanges specified for this tool.

13. Be careful not to damage the arbor, flanges

(especially the installing surface) or bolt. Damage

to these parts could result in blade breakage.

14. Make sure that the turn base is properly

secured so it will not move during operation.

15. For your safety, remove the chips, small

pieces, etc. from the table top before operation.

16. Avoid cutting nails. Inspect for and remove all

nails from the work piece before operation.

17. Make sure the shaft lock is released before the

switch is turned on.

18. Be sure that the blade does not contact the

turn base in the lowest position.

19. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

20. Make sure the blade is not contacting the

work piece before the switch is turned on.

21. Before using the tool on an actual work

piece, let it run for a while. Watch for vibration or

wobbling that could indicate poor installation or a

poorly balanced blade.

18. Use outdoor extension leads. When tool

is used outdoors, use only extension cords

intended for outdoor use.

19. Stay alert. Watch what you are doing. Use

common sense. Do not operate tool when you

are tired.

20. Check damaged parts. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

free running of moving parts, breakage of

parts, mounting and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired

or replaced by an authorized service center

unless otherwise indicated in this instruction

manual. Have defective switches replaced by an

authorized service facility. Do not use the tool if

the switch does not turn it on and off.

21. Do not use other accessories. The use of

any accessory or attachment, other than those

recommended in this instruction manual may

present a risk of personal injury.

22. Have your tool repaired by a qualified

technician. This electric tool is in accordance

with the relevant safety requirements. Repairs

should only be carried out by qualified persons

using original spare parts, otherwise this may

result in considerable danger to the user.

23. This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they

have been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety

24. Children should be supervised to ensure

that they don’t play with the tool.

25. If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similar qualified person in order to avoid a

hazard.