NovaFlex Z-Flex DVK-HR User manual

1

Installation and Maintenance Instructions

All models are intended for use on natural or propane gas fired direct vent appliances (stoves, heaters,

fireplaces and inserts) tested and third party listed (CSA, ETL, OMNI, PFS, UL or Warnock Hersey) to

appropriate ANSI Z21 standard(s) for use with coaxial (concentric) flexible aluminum vent.

MODEL DVK-HR Coaxial

Flexible Direct Vent Kit with

Coaxial Horizontal Round

Termination

Kit Includes:

•Coaxial Horizontal

Round Termination

•Coaxial Flexible Vent

•Coaxial Flexible Spacers

•Coaxial Flexible Supports

•High Temperature Mill-

Pac Black Sealant

•Self-drilling Screws

MODEL DVK-HT Coaxial

Flexible Direct Vent Kit with

Coaxial Horizontal Square

Termination

Kit Includes:

•Coaxial Horizontal

Square Termination

•Coaxial Flexible Vent

•Coaxial Flexible Spacers

•Coaxial Flexible Supports

•High Temperature Mill-

Pac Black Sealant

•Self-drilling Screws

MODEL DVK-VX Coaxial

Flexible Direct Vent Kit with

Coaxial Vertical Extreme

Weather Termination

Kit Includes:

•Coaxial Vertical Extreme

Weather Termination

•Rigid Pipe

•Storm Collar/Support

•Roof Flashing 0 - 30 Degree

•Roof Termination Support

•Coaxial Flexible Vent

•Coaxial Flexible Spacers

•Coaxial Flexible Supports

•Fire Stop/Insulation Shield

•Insulation Collar

•High Temperature Mill-Pac

Black Sealant

•Self-drilling Screws

Tools Required: Safety glasses, gloves, tape measure, plumb line, level, cordless drill, drill

bits, #2 Phillips bit or #2 Phillips screwdriver, snips or utility knife, reciprocating saw,

hammer and framing materials.

MH60654 Direct Vent Venting System

Listed to UL 2112, ANSI Z21.88/CSA 2.33

Manufacture's address:

U.S.A.:

20 Commerce Park North

Bedford, NH 03110-6911

CANADA:

452 Attwell Drive

Etobicoke, ON M9W 5C3

2

Installation Guide

Z-FLEX

DEFINITIONS

BEST PRACTICE

Indicates recommendations made by Z-Flex for installers which will help ensure optimum

operation and longevity of the venting system.

GENERAL INSTRUCTIONS

WARNINGS Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

A Qualified professional must INSTALL and MAINTAIN venting system in accordance with

these instructions, appliance manufacturer's installation instructions, local building codes

or in absence of local codes latest edition of National Fuel Gas Code; ANSI Z223.1/NFPA

54 in USA or CSA-B149.1 or .2 in Canada. A qualified professional would be certified in

USA by National Fireplace Institute (NFI) as NFI Woodburning Specialists or Chimney

Safety Institute of America (CSIA) or in Canada by Wood Energy Technical Training

(WETT) or other appropriate certifying body. These instructions are to be used as a

guideline, if there is any conflict refer to appliance manufacturer's installation

instructions.

A by-product of any fuel burning appliance is carbon monoxide, which is an invisible and

odorless gas. Read, understand and follow all instructions and appropriate local codes

when installing, using or maintaining any fuel burning appliance and vent system. Install

carbon monoxide detector and alarms in accordance with local codes.

DO NOT install or attempt to repair damaged (torn, crushed or punctured) flexible vent.

To ensure proper operation of venting system do not make any alterations/modifications

or use any substitute materials or joining methods other than those specified in these or

appliance manufacturer's installation instructions. Z-Flex accepts no liability for any

damage, injury or loss of life resulting from incorrect installation, alteration or substitute

materials. Contact Z-Flex or appliance manufacturer if there is any installation questions.

Do not combine flexible and rigid venting systems or systems from different vent

manufacturers unless stated in these or appliance manufactures installation instructions.

Do not common vent multiple appliances in same vent or chimney.

Do not clamp flexible pipes.

WARNING

Indicates a potentially hazardous situation which, if ignored, can result in death, serious

injury or substantial property damage.

CAUTION

Indicates a potentially hazardous situation which, if ignored, can result in minor property

damage or injury.

3

Installation Guide

Z-FLEX

CAUTION Risk of Burns! Risk of Shock!

Before servicing appliance or vent system turn off gas and power and allow to cool.

CAUTION Risk of Cuts! Risk of Abrasions!

Wear gloves and safety glasses to protect against cuts from sharp edges or flying debris.

1. Read these instructions and appliance manufacturers' installation instructions

carefully prior to installing coaxial flexible direct vent kit. If any doubts or questions

exist, contact your local distributor or Z-Flex at 1-800-654-5600 (in NH 603-669-5136).

2. Contact your local building and fire officials about any necessary permits, restrictions

and installation inspections required in your area to ensure installation meets with all

local code requirements including fire stopping.

APPLIANCE LIST

This list details the intended use of the coaxial flexible aluminum direct vent kits. If your

appliance does not meet the following requirements or if you are not sure it is

appropriate to use a coaxial flexible aluminum direct vent kit, contact your appliance

manufacturer prior to installation.

•All models are intended for use on natural or propane gas fired direct vent

appliances (stoves, heaters, fireplaces and inserts) tested and third party listed

(CSA, ETL, OMNI, PFS, UL or Warnock Hersey) to appropriate ANSI Z21

standard(s) for use with coaxial (concentric) flexible aluminum vent.

WARNINGS

Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

Do not allow flexible pipes to bunch up; keep flexible pipes pulled tight.

Do not bend coaxial flexible vent more than 90 degrees.

Coaxial

flexible vent kits contain spacers, attach spacers to inner flexible pipe

to maintain

an air gap to outer

flexible pipe. Maintain gap for safe operation of appliance. A spacer

is required a maximum of every

foot to maintain air gap. DO NOT REMOVE SPACERS.

Coaxial flexible vent kits contain

supports. Install supports to maintain minimum

clearance to combustibles from vent system as outlined in

appliance

manufacturer's

installation instructions.

Do not place insulation or other materials in any required

clearances to combustibles or

air

space around vent system or fire stop(s) to prevent a fire hazard.

Venting system should be inspected before first use and at

least annually thereafter by

qualified

professional. Ensure area around appliance and venting system do not contain

combustible

materials, gasoline or other flammable vapors or liquids and meet

appliance

manufacturer's clearances to combustibles. Venting systems must be

unobstructed, undamaged, properly assembled, supported and sealed.

4

Installation Procedure

Z-FLEX

1. Read all instructions and warnings carefully prior to installing and using appliance.

2. Refer to appliance manufacturers' installation instructions for appropriate use,

minimum and maximum vent lengths, number of elbows or bends, minimum

vertical vent rise between appliance and first elbow or bend, relationship between

length of vent run to vent rise, joining methods, spacers, supports, clearances to

combustibles, clearances to termination and wall or combustible ceiling

penetrations, etc.

BEST PRACTICE

Minimize vent length and number of bends and use 45 degree bends instead of 90

degree bends whenever possible for optimum performance.

3. Determine placement of coaxial termination (vertical or horizontal) ensuring location

meets all clearance requirements in appliance manufacturer's installation

instructions, local codes and national codes, is not easily blocked or obstructed

and meets appliance manufacturer's allowable vent configuration.

WARNING

Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

Check coaxial termination after each snow fall and corresponding clean up to ensure

termination and surrounding area are clear and unblocked.

Do not direct any snow

towards termination especially when using a snow blower.

Termination must be

above grade and expected snow level or snow accumulation/drift.

5

Installation Procedure

Z-FLEX

COAXIAL FLEXIBLE DIRECT VENT KITS

a. Coaxial flexible direct vent kits may be purchased in 3"/5", 3"/6", 4"/6", 4"/7", 4.5"/7.5",

5"/7", 5"/8", 6"/8", 7"/10" and 8"/11" coaxial diameters and are available in 5', 10', 20' or

40' lengths. Additional kit lengths are available upon request.

b. Inner flexible pipe is 4' longer in coaxial flexible direct vent vertical kits; 2DVK-VX

to extend inner flexible pipe through rigid pipe at roof.

c. Read and follow appropriate sections within these instructions before installing kit.

COAXIAL FLEXIBLE VENT EXTENSION KITS

BEST PRACTICE

Order Coaxial Flexible Direct Vent Kit in required length to avoid additional

joints associated with Coaxial Flexible Vent Extension Kit.

a. Coaxial flexible vent extension kits may be purchased in 3"/5", 3"/6", 4"/6", 4"/7",

4.5"/7.5", 5"/7", 5"/8", 6"/8", 7"/10" and 8"/11 coaxial diameters, kit includes 20

feet of coaxial flexible vent, coaxial flexible coupling, coaxial flexible spacers,

coaxial flexible supports, Mill-Pac Black sealant and screws.

b. ONLY IF NECESSARY a single coaxial flexible vent extension kit with coaxial flexible

coupling is allowed to extend the length of coaxial flexible vent.

BEST PRACTICE

Attach flexible extension kit to APPLIANCE COAXIAL COLLAR or DV TO COAXIAL

FLEXIBLE ADAPTOR if required when used to extend coaxial flexible direct vent

vertical kits; 2DVK-VX to avoid cutting extra 4' of inner flexible pipe provided in

these kits; 2DVK-VX necessary to extend inner flexible pipe through rigid pipe

at roof.

c. Coaxial flexible vent extension kits; part numbers:

2DVK(305,306,406,407,4.507.5,507,508,608,710,811)20X are sold separately.

d. Read and follow appropriate sections within these instructions before installing kit.

WARNING

Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

Total length of coaxial flexible vent must not exceed maximum length specified

in the appliance manufacturer's installation instructions.

6

Installation Procedure

Z-FLEX

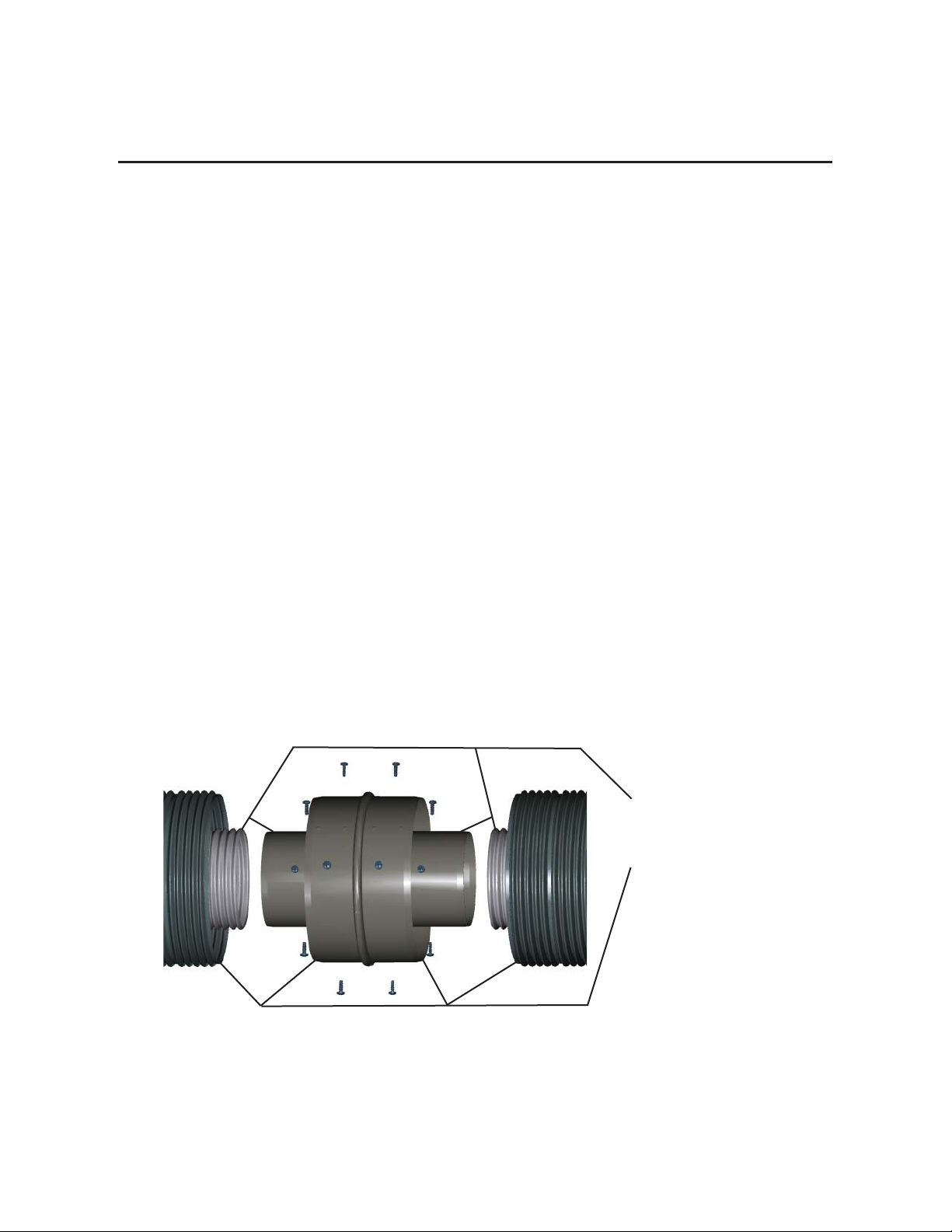

COAXIAL FLEXIBLE COUPLING

a. ONLY IF NECESSARY a single Z-Flex coaxial flexible coupling is allowed to join 2

coaxial flexible vents.

b. Join inner flexible pipes to each end of coaxial flexible coupling inner collars with

a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black sealant

applied approximately 3/4" from end of each flexible coupling inner collar outside

edge and evenly slip inner flexible pipes over flexible coupling inner collars with as

much overlap as possible. Secure inner flexible pipes to flexible coupling inner

collars with four self-drilling screws evenly spaced 90 degrees apart for each

flexible pipe.

c. Join outer flexible pipes to each end of coaxial flexible coupling outer collars with

a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black sealant

applied approximately 3/4" from end of each flexible coupling outer collar outside

edge and evenly slip outer flexible pipes over flexible coupling outer collars with

as much overlap as possible. Secure outer flexible pipes to flexible coupling outer

collars with four self-drilling screws evenly spaced 90 degrees apart for each

flexible pipe.

d. Add coaxial flexible support directly below coaxial flexible coupling.

e. Z-Flex coaxial flexible couplings; part numbers: 2DVK(305,306,406,407,4.507.5,507,

508,608,710,811)C are sold separately.

Apply Mill-Pac Black Sealant

& Secure with Screws:

Appliance Inner Male Collars

to Inner Flexible Pipes

& then

Appliance Outlet Male Collars

to Outer Flexible Pipes

Fig. 1 Installation of Z-Flex Coaxial Flexible Coupling

7

Installation Procedure

Z-FLEX

COAXIAL FLEXIBLE VENT

a. Coaxial flexible vent diameters must not be sized less than that specified in the

appliance manufacturer's installation instructions.

b. Prior to installing any flexible pipes extend pipes to their maximum length (see

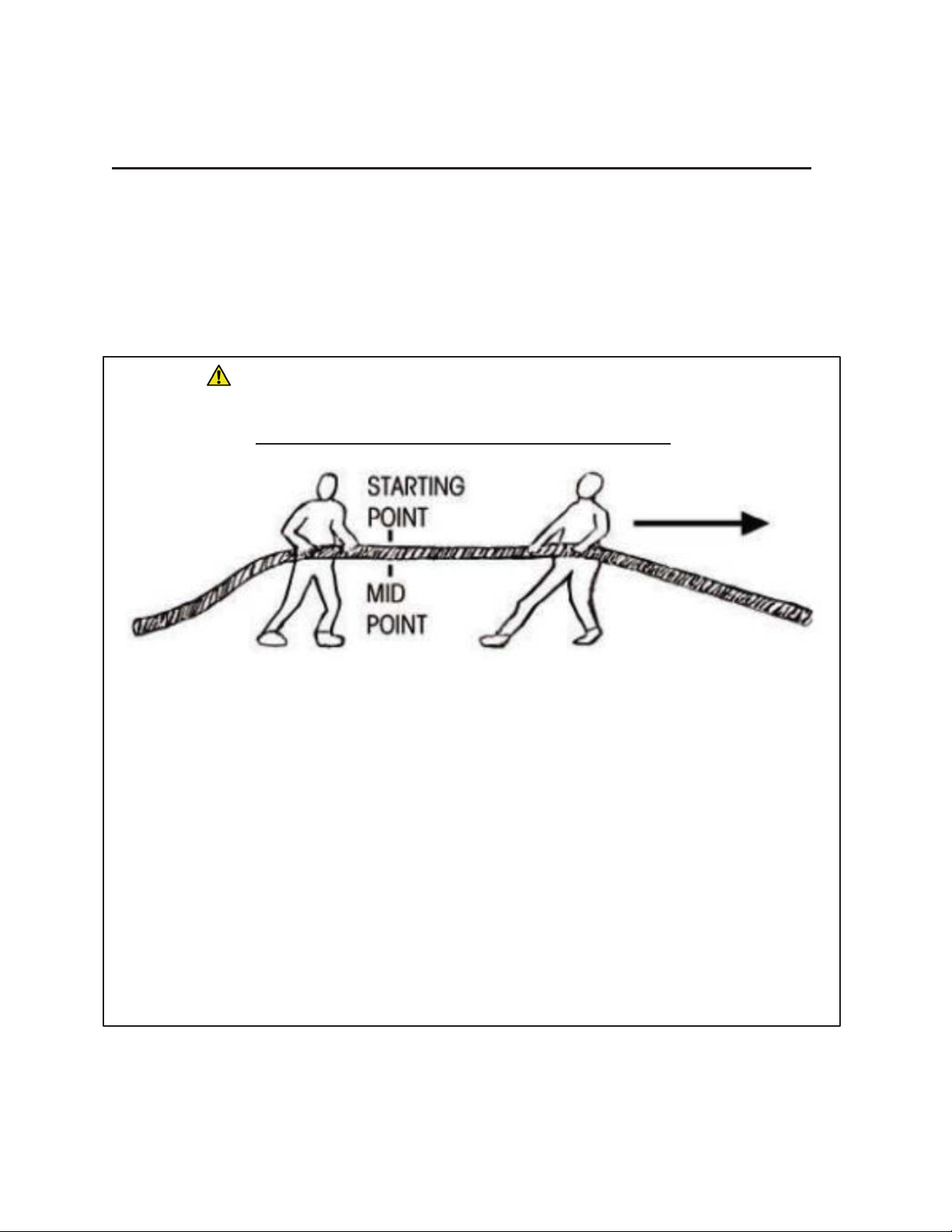

figure 2 for proper stretching techniques).

Fig. 2 Proper Stretching Technique for Flexible Pipes

CAUTION

Risk of Injury! Risk of Damage!

Follow these instructions carefully to prevent personal injury and damage to flexible pipes.

PROPER STRETCHING TECHNIQUE FOR FLEXIBLE PIPES

The enclosed flexible pipes are in a fully compressed form.

The stretching of the flexible pipes requires two people

wearing gloves.

A flexible pipe should be stretched working half the length at a time.

Start by facing each other at the appropriate mid-point in the flexible pipe.

Holding the flexible pipe firmly in your hands one person

should walk backwards,

stretching portions of the pipe as they backup.

As you stretch the flexible pipe, watch the corrugations to make

sure you are expanding

the pipe fully as well as not over

-stretching it.

Follow the same procedure for the other half of the flexible pipe.

The flexible pipe should now be at full length.

Repeat above for other flexible pipe.

If you have any questions contact Z-Flex or appliance manufacturer.

8

Installation Procedure

Z-FLEX

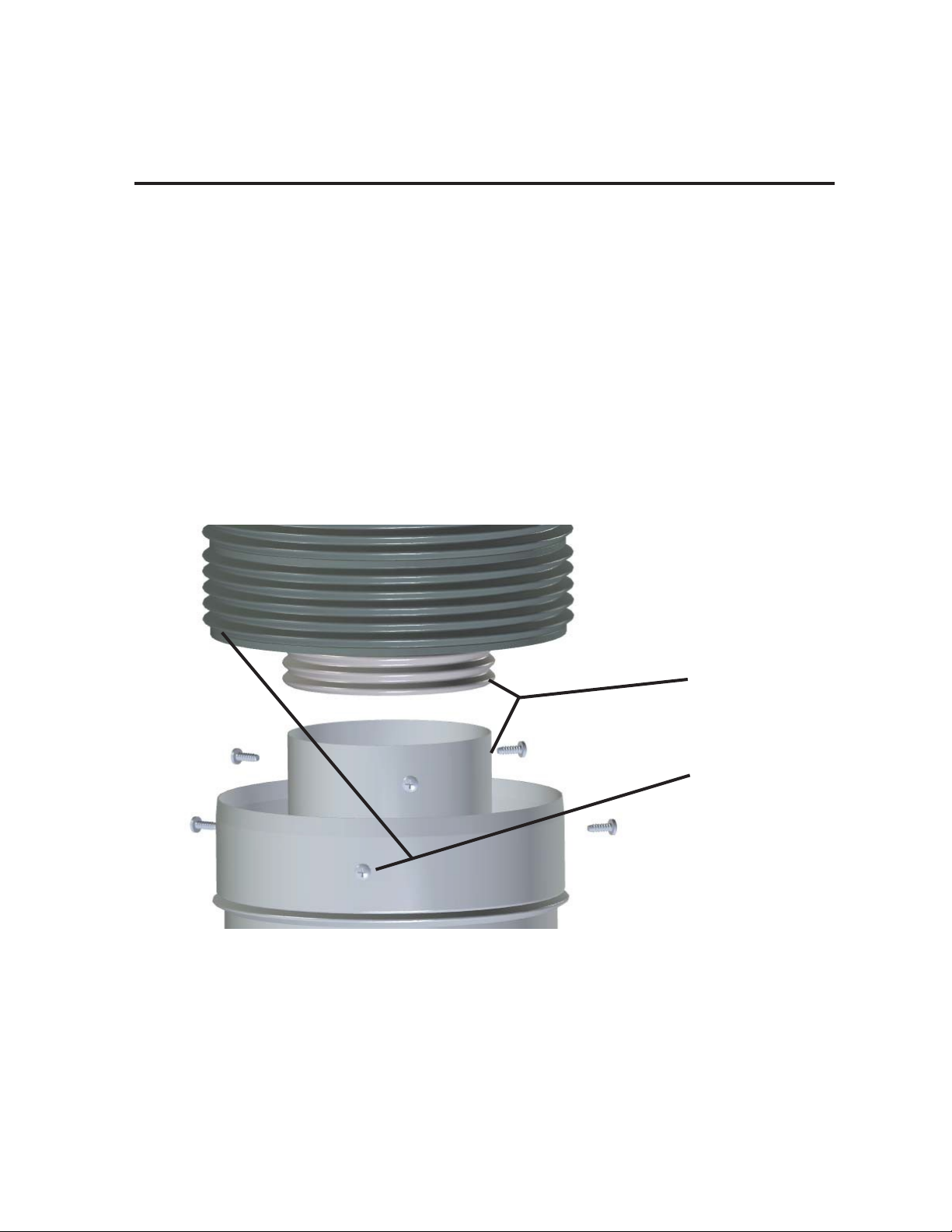

COAXIAL FLEXIBLE SPACERS

a. Install coaxial flexible spacers included in kit(s) around extended/stretched

inner (smaller diameter) flexible pipe at every foot maximum, rotate each

WIRE spacer 1/4 turn from previous installed spacer (if supplied intertwine

ends of alternate SPRING spacer).

b. Slide outer extended/stretched flexible pipe over inner flexible pipe with

spacers exercising care not to dislodge any spacers.

c. Additional coaxial flexible spacers; part numbers: 2DVK(35,36,46,47,

57,58,68,710,811)S are sold separately in kits of 10. Use 2DVK58S for

4.5"/7.5" coaxial diameters.

Install Coaxial Flexible

Spacers Around Inner

Flexible Pipe, Rotate Each

WIRE Spacer ¼ Turn From

Previous Installed Spacer

Slide Outer Flexible Pipe

Over Inner Flexible Pipe

With Coaxial Flexible

Spacers

1’ Max.

Between

Coaxial

Flexible

Spacers

Fig. 3 Coaxial Flexible Spacer Installation

9

Installation Procedure

Z-FLEX

APPLIANCE COAXIAL COLLAR

4. Apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from male end of appliance inner collar outside edge

and slip inner flexible pipe over appliance inner collar with as much overlap as

possible. Secure inner flexible pipe to appliance inner collar with four self-drilling

screws evenly spaced 90 degrees apart.

5. Apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from male end of appliance outer collar outside edge

and slip outer flexible pipe over appliance outer collar with as much overlap as

possible. Secure outer flexible pipe to appliance outer collar with four self-drilling

screws evenly spaced 90 degrees apart.

Apply Mill-Pac

Black Sealant &

Secure with

Screws

:

Appliance Inner

Male Collar to

Inner Flexible Pipe

& then

Appliance Outer

Male Collar to

Outer Flexible Pipe

Fig. 4 Appliance Coaxial Collar Installation

10

Installation Procedure

Z-FLEX

DV TO COAXIAL FLEXIBLE ADAPTOR - OPTIONAL

a. This adaptor is used to adapt an appliance with Duravent coaxial rigid twist lock

vent connection to coaxial flexible vent. The adaptor's appliance connection has

an inner male collar and outer female collar. The adaptor's flexible vent

connection has an inner male collar and outer male collar. The adaptor part

numbers are 2DVK407A or 2DVK508A & are sold separately.

b. On adaptor's appliance connection with inner male collar and outer female collar,

apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from inner male collar outside edge.

c. On adaptor's appliance connection with inner male collar and outer female collar,

apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from outer female collar inside edge.

d. Slip adaptor's appliance connection into/over appliance inner and outer collars

with as much overlap as possible. Secure outer collars with four self-drilling

screws evenly spaced 90 degrees apart.

e. On adaptor's flexible vent connection with inner and outer male collars, apply a

heavy bead approximately 1/4" wide of high temperature Mill-Pac Black sealant

to approximately 3/4" from male inner collar outside edge and slip inner flexible

pipe over inner collar with as much overlap as possible. Secure inner flexible pipe

to inner collar with four self-drilling screws evenly spaced 90 degrees apart.

f. On adaptor's flexible vent connection with inner and outer male collars, apply a

heavy bead approximately 1/4" wide of high temperature Mill-Pac Black sealant

to approximately 3/4" from male outer collar outside edge and slip outer flexible

pipe over outer collar with as much overlap as possible. Secure outer flexible

pipe to outer collar with four self-drilling screws evenly spaced 90 degrees apart.

Apply Mill-Pac Black Sealant

& Secure with Screws:

Inner Male Collar to Inner

Flexible Pipe

& then

Outer Male Collar to Outer

Flexible Pipe

Apply Mill-Pac Black Sealant:

Inner Male Collar Outside Edge &

Outer Female Collar Inside Edge

Secure with Screws

through

Outer Collars

Flexible Vent

Connection

DV to Coaxial

Flexible Adaptor

Appliance Connection

Appliance Twist

Lock Connection

Fig. 5 DV to Coaxial Flexible Adaptor Installation

11

Installation Procedure

Z-FLEX

6. Slope all horizontal runs up and away from appliance with no sags or dips; a minimum

of 1/4" vertical rise per 1 foot of horizontal run.

BEST PRACTICE

For optimum performance; slope all horizontal runs up and away from appliance

with no sags or dips; 1" vertical rise per 1 foot of horizontal run.

COAXIAL FLEXIBLE SUPPORTS

a. Install coaxial flexible supports included in kit every 2 feet maximum for horizontal

runs and every 3 feet maximum for vertical runs and top of each elbow/bend or

according to appliance manufacturer's installation instructions to maintain

appliance manufacturer's clearance to combustibles.

b. Additional coaxial flexible supports; part numbers: 2DVK(05,06,07,07.5,08,10,11)SUP

are sold separately in kits of 5.

Secure Coaxial

Flexible Support to

Building Using

Field Supplied

Hardware

Coaxial Flexible Support:

Every 2 Feet Maximum for

Horizontal Runs

Every 3 Feet Maximum for

Vertical Runs

Top of Each Elbow/Bend

Secure Coaxial

Flexible Support

to Coaxial Flexible

Vent with Bolt &

Nut

Fig. 6 Coaxial Flexible Support Installation

WARNING

Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

Do not slope horizontal runs downward which can lead to poor draft and excessive

temperatures.

12

Installation Procedure

Z-FLEX

7. Using snips or utility knife trim the flexible pipes to the required length.

HORIZONTAL INSTALLATION

8. Use wall thimble(s) when coaxial flexible vent passes through any combustible walls

according to appliance manufacturer's installation instructions.

WALL THIMBLE for Horizontal Combustible Wall

a. Locate center of coaxial flexible vent on wall and mark Inside Opening around

center mark - see Table 1.

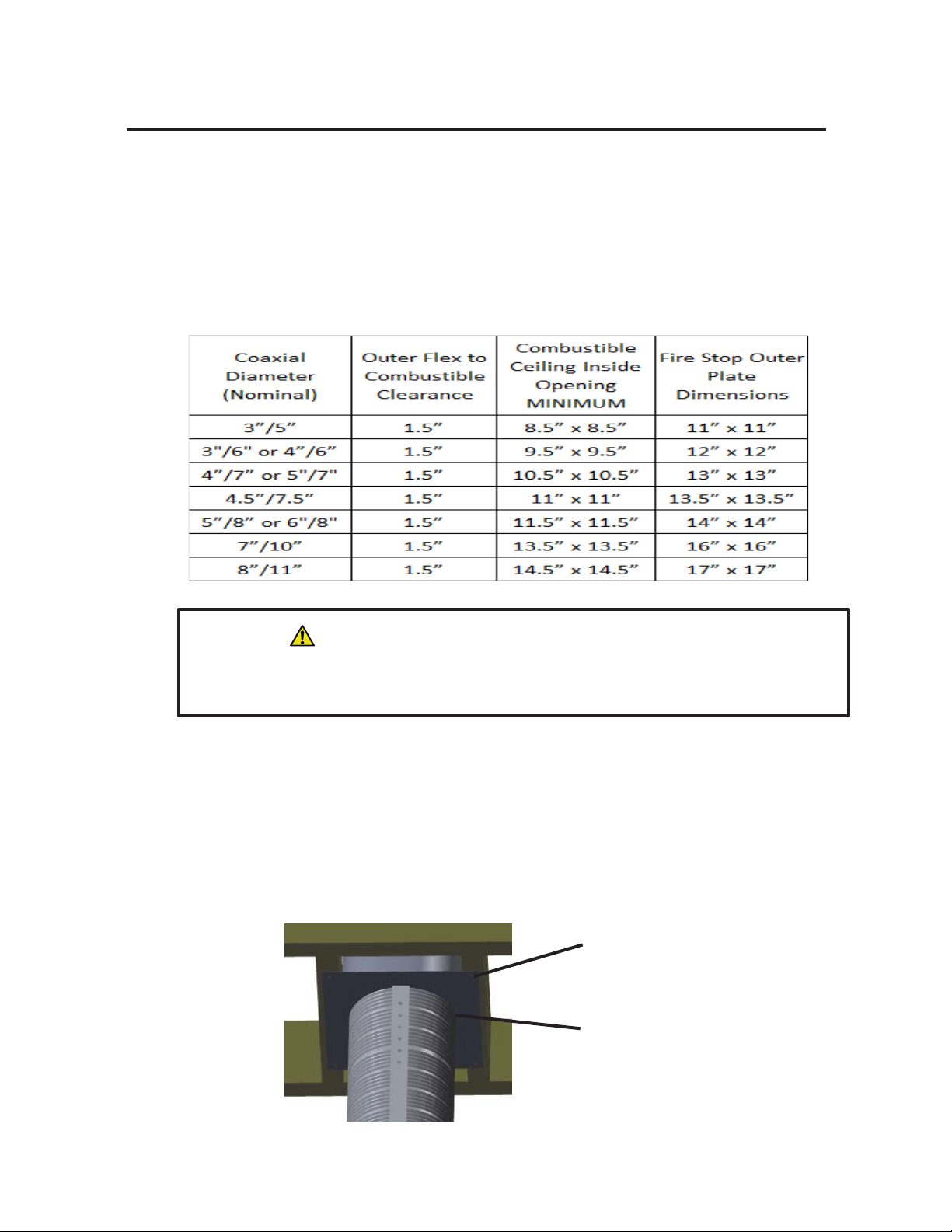

Table 1. Combustible Wall Inside Opening MINIMUM for Wall Thimble

b. Cut opening, frame wall & sheet rock to accept wall thimble.

c. Wall thimble is adjustable/telescopic and accommodates wall thickness of 4" to 7".

d. Wall thimble extended is adjustable/telescopic and accommodates

wall thickness of 6" to 11".

e. Separate two halves of thimble and secure to wall with screws from both sides

ensuring each end of thimble overlaps in middle (telescopic).

f. Seal around outer flexible pipe/thimble and wall/thimble with field supplied

sealant. If horizontal fire stop is necessary, discuss sealant and assembly with

fire stop professional and local building and fire officials to ensure assembly

meets with local fire stopping code requirements.

g. Wall thimble; part numbers: 2DVK(05,06,07,07.5,08,10,11)WT, Wall thimble extended;

part numbers: 2DVK(05,06,07,07.5,08,10,11)WTE and Mill-Pac Black sealant; part

number: 2DVKS are sold separately.

WARNING

Risk of Fire!

Review appliance manufacturer's instructions and verify above clearances in

Table 1 are appropriate as it may be necessary to increase

Combustible

Wall Inside Opening MINIMUM for additional clearance.

13

Installation Procedure

Z-FLEX

Secure Wall Thimble to

Building Using Field

Supplied Hardware

Wall Thimble:

Seal Around All Openings

& Wall Thimble with

Field Supplied Sealant

Fig. 7 Wall Thimble Installation - Sold Separately

9. Use siding standoff when flexible pipes pass through and terminate on exterior side

wall with vinyl or wood siding.

SIDING STANDOFF for Horizontal Termination

a. Install siding standoff between exterior wall and coaxial horizontal termination.

b. Secure and seal siding standoff to wall with field supplied screws and sealant.

c. Siding standoffs; part numbers: 2DVK(05,06,07,07.5,08,10,11)SS are sold separately.

10.

11.

12.

13.

Properly orient Horizontal Termination with "UP" stamp on termination.

Apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from male end of Horizontal Termination inner collar

outside edge and slip inner flexible pipe over horizontal termination inner collar with

as much overlap as possible. Secure inner flexible pipe to inner collar with four self-

drilling screws evenly spaced 90 degrees apart.

Apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from male end of Horizontal Termination outer collar

outside edge and slip outer flexible pipe over horizontal termination outer collar

with as much overlap as possible. Secure outer flexible pipe to outer collar with four

self-drilling screws evenly spaced 90 degrees apart.

Secure Horizontal Termination to the wall or standoff, ensure "UP" stamp on

termination is properly oriented. Seal around termination where it comes in contact

with wall or standoff with field supplied sealant and paint if required.

WARNING

Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

Coaxial vent/air termination must not be installed recessed into a wall or siding.

14

Installation Procedure

Z-FLEX

Horizontal

Round

Termination

Included in

2DVK-HR

Kits

Wall Thimble -

Sold Separately

Consult

Appliance

Manufacturer’s

Instructions

OR

Siding Standoff -

Sold Separately

Consult

Appliance

Manufacturer’s

Instructions

Horizontal

Square

Termination

Included in

2DVK-HT

Kits

Fig. 8 Wall Thimble, Siding Standoff & Horizontal Terminations

15

Installation Procedure

Z-FLEX

VERTICAL INSTALLATION

14.

15.

Use firestop(s) when coaxial flexible vent passes through any combustible floors or

ceilings without insulation.

Use fire stop/insulation shield kit(s) with insulation collar when coaxial flexible vent

passes through any combustible floors or ceilings with insulation.

FIRE STOP - Vertical

a. Locate center of coaxial flexible vent on floor or ceiling and mark Inside Opening

around center mark - see Table 2.

Table 2. Combustible Ceiling Inside Opening MINIMUM for Fire Stop

b. Cut opening, frame floor joists or ceiling & sheet rock to accept fire stop. AVOID

cutting joists by offsetting coaxial flexible vent.

c. Install fire stop on ceiling (bottom side of ceiling or floor joists) and secure with

screws.

d. Seal around outer flexible pipe/fire stop and fire stop/ceiling/joists with field supplied

fire stop sealant. Discuss sealant and assembly with fire stop professional and local

building and fire officials to ensure fire stop meets with local code requirements.

e. Fire stops; part numbers: 2DVK(05,06,07,07.5,08,10,11)FS are sold separately.

Secure Fire Stop to

Building Using Field

Supplied Hardware

Fire Stop:

Seal Around All Openings

& Fire Stop with Field

Supplied Fire Stop Sealant

Fig. 9 Fire Stop Installation

WARNING

Risk of Fire!

Review appliance manufacturer's instructions and verify above clearance in Table 2

is appropriate as it may be necessary to increase Combustible

Ceiling Inside

Opening MINIMUM for additional clearance.

16

Installation Procedure

Z-FLEX

FIRE STOP/INSULATION SHIELD KIT with INSULATION COLLAR

a. Fire stop/insulation shield kit with insulation collar prevents insulation from

coming in contact with flexible pipes when passing through any combustible

floor or ceiling.

b. Fire stop/insulation shield is 18" tall and the height of its insulation shield

(pipe) can be cut down provided installed height of shield is above insulation.

c. Locate center of coaxial pipe on floor or ceiling and mark appropriate opening

(inside dimensions) around center mark - see Table 2.

d. Cut opening and frame floor joists or ceiling to accept fire stop. AVOID cutting

joists by offsetting coaxial flexible pipe.

e. Install fire stop on ceiling (bottom side of ceiling or floor joists) and secure with

screws.

f. Seal around outer flexible pipe/fire stop/insulation shield and fire stop/

insulation shield/ceiling/joists with field supplied fire stop sealant. Discuss

sealant and assembly with fire stop professional and local building and fire

officials to ensure fire stop meets with local code requirements.

g. Cover top of fire stop/insulation shield (pipe) with insulation collar included in

kit; slide insulation collar with flared end down, over and down coaxial pipes

until it is just above top of fire stop/insulation shield (pipe).

h. Secure insulation collar to coaxial flexible pipe with gear clamp.

i. A fire stop/insulation shield kit: part number: 2DVK(05,06,07,07.5,08,10,11)FSIS

is included in the vertical kit additional kits are sold separately.

Insulation

Collar

Insulation

Shield:

Installed

Height

Must Be

Above

Insulation

Cover Top of Insulation

Shield with Insulation Collar

& Secure to Coaxial Flexible

Vent with Gear Clamp

Secure Fire Stop to

Building Using Field

Supplied Hardware

Coaxial

Flexible

Vent

Fire Stop:

Seal Around All Openings

& Fire Stop with Field

Supplied Fire Stop Sealant

Fig. 10 Fire Stop/Insulation Shield Kit Installation

17

Installation Procedure

Z-FLEX

16. Enclose coaxial vertical pipes in any occupied areas above first floor, including closets

and storage spaces. The enclosure needs to support and maintain minimum

clearances to coaxial pipes/vent and may be framed and sheet rocked.

17. Locate and mark center of coaxial pipe on roof.

18. Review appliance manufacturer's installation instructions for clearances of vent to

combustible surfaces and cut appropriate sized hole in roof incorporating necessary

clearances.

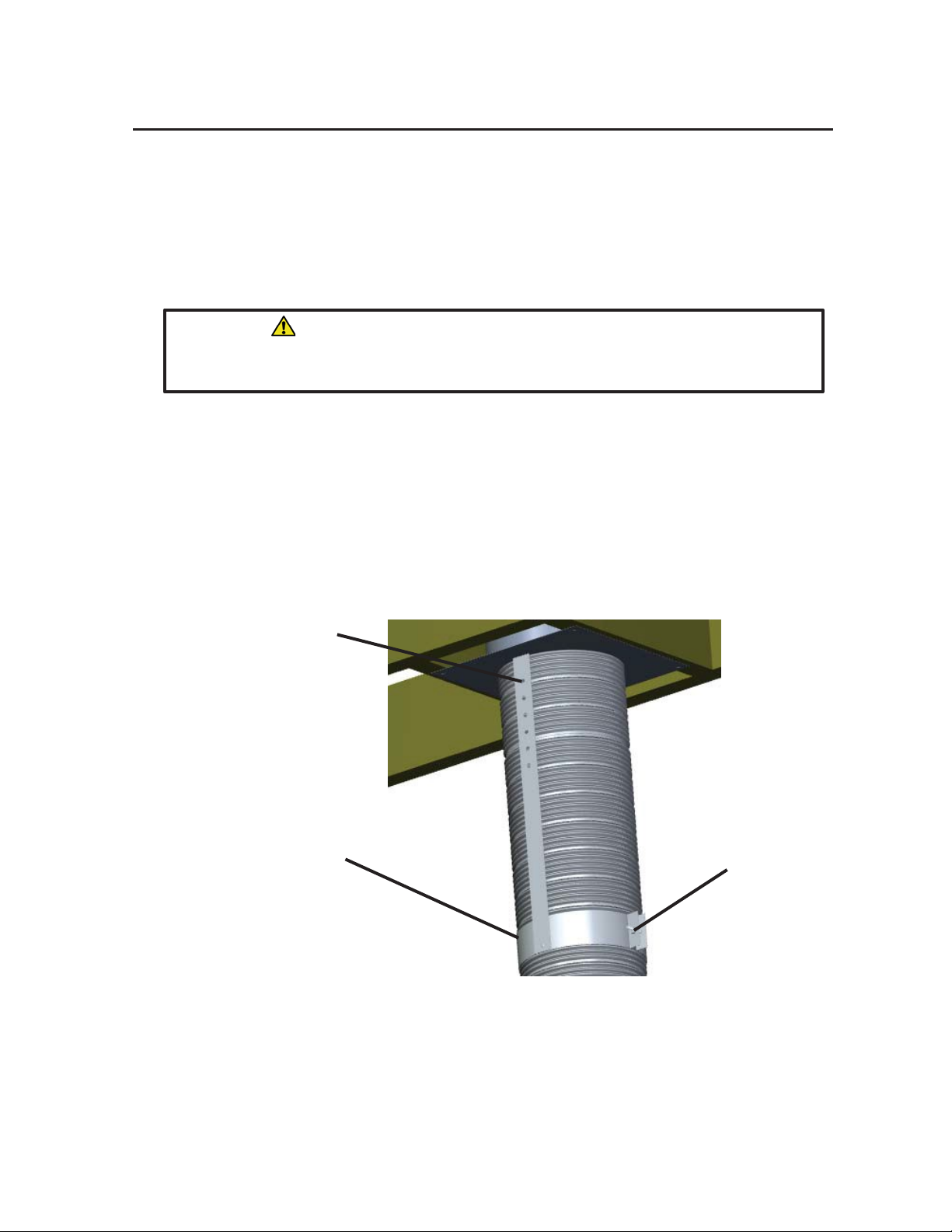

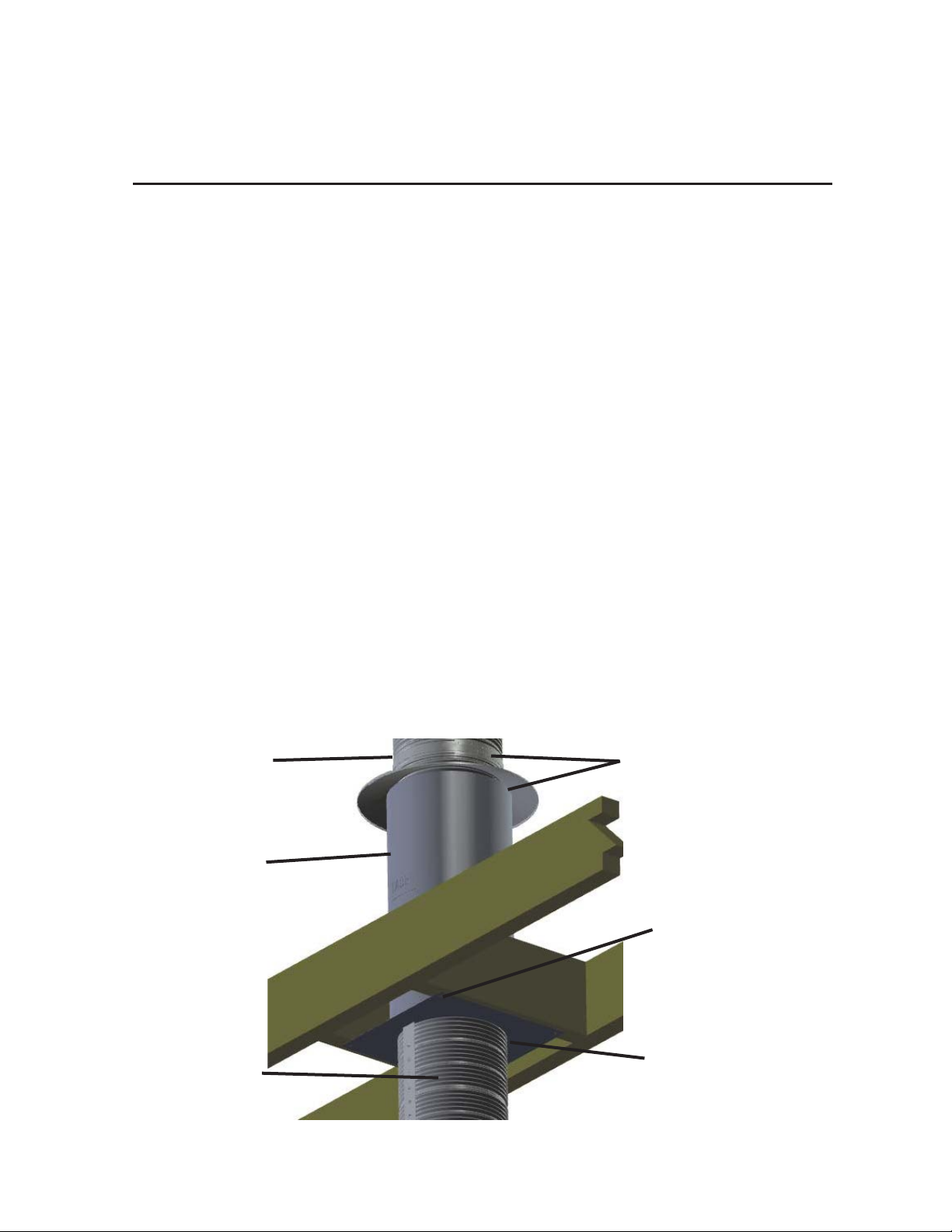

ROOF TERMINATION SUPPORT

a. Center roof support over hole in roof and secure to top of roof.

b. Install 42" long rigid pipe included in vertical kit through roof support and tighten

roof support around outer rigid pipe and with provided 1/2" long screws ensuring

pipe is vertically plumb and extends below roofline approximately 1 foot below

lowest opening in roof or enough to facilitate connection to outer flexible pipe.

c. Inner flue pipe provided in 2DVK-VX kits are 48" longer than outer pipe and

include 4 additional coaxial flexible spacers.

d. Install spacers every foot on inner flue pipe and route inner flue pipe through 42"

long rigid pipe yielding a coaxial assembly.

Rigid

Pipe

Secure Roof

Termination

Support to

Rigid Pipe

with Bolts/

Nuts & 3

Self-drilling

Screws

Secure Roof

Termination

Support to Top

of Roof Using

Field Supplied

Hardware

Route Inner

Flexible Pipe

with Coaxial

Flexible

Spacers

Through

Rigid Pipe

Apply Mill-Pac Black Sealant &

Secure with Screws:

Outer Rigid Pipe to Outer Flexible Pipe

Fig. 11 Roof Termination Support Installation

18

Installation Procedure

Z-FLEX

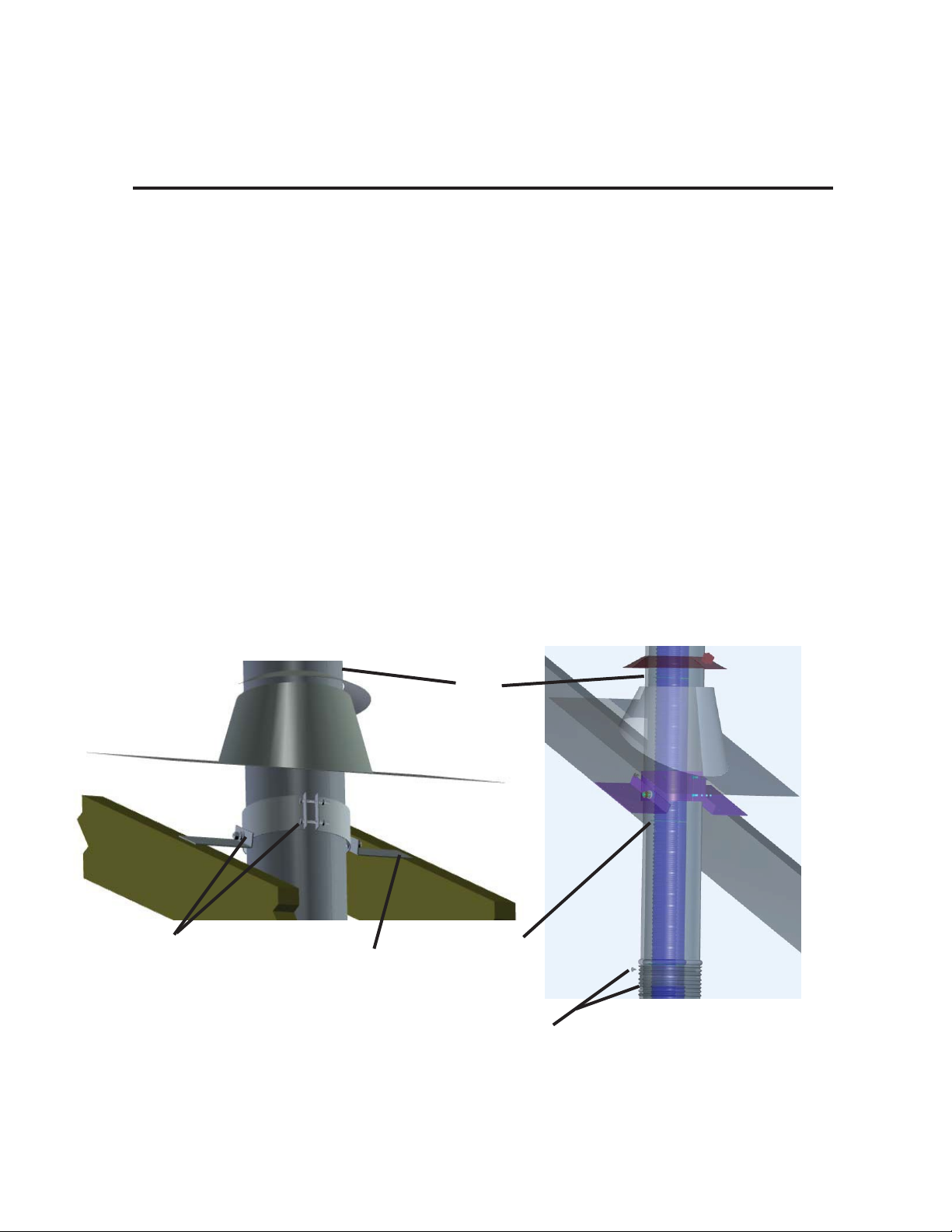

ROOF FLASHING

a. The roof flashing provided in vertical kit is for roofs with pitch of 0 to 30

degrees (0/12 to 7/12 pitch).

b. Optional flashings; part numbers: 2DVK(05,06,07,0.75,08,10,11)F are available

for roofs with larger pitch of 30 to 45 degrees (7/12 to 12/12 pitch) and are

sold separately.

c. Check roof pitch and ensure proper flashing is installed.

d. On top of roof, slide flashing with appropriate pitch over rigid pipe.

e. Slip upper half of roof flashing plate under roof shingles while lower half of

flashing plate rests on top of roof shingles.

f. Seal roof flashing to roof with a suitable field supplied waterproof mastic.

g. Secure roof flashing to roof using field supplied roofing nails and neoprene

washers or suitable waterproof mastic to cover nail heads.

Fig. 12 Roof Flashing Installation

19.

20.

Review appliance manufacturer's installation instructions and local codes to

determine required installation height of termination above highest point of roof.

Add rigid extension pipe to top of rigid pipe protruding through roof as necessary

to meet required installation height of termination above roof.

Rigid Pipe

Roof Flashing Plate:

Slip Upper Half

Under Roof Shingles

Seal & Secure Roof

Flashing to Roof

Using Field Supplied

Hardware & Sealant

19

Installation Procedure

Z-FLEX

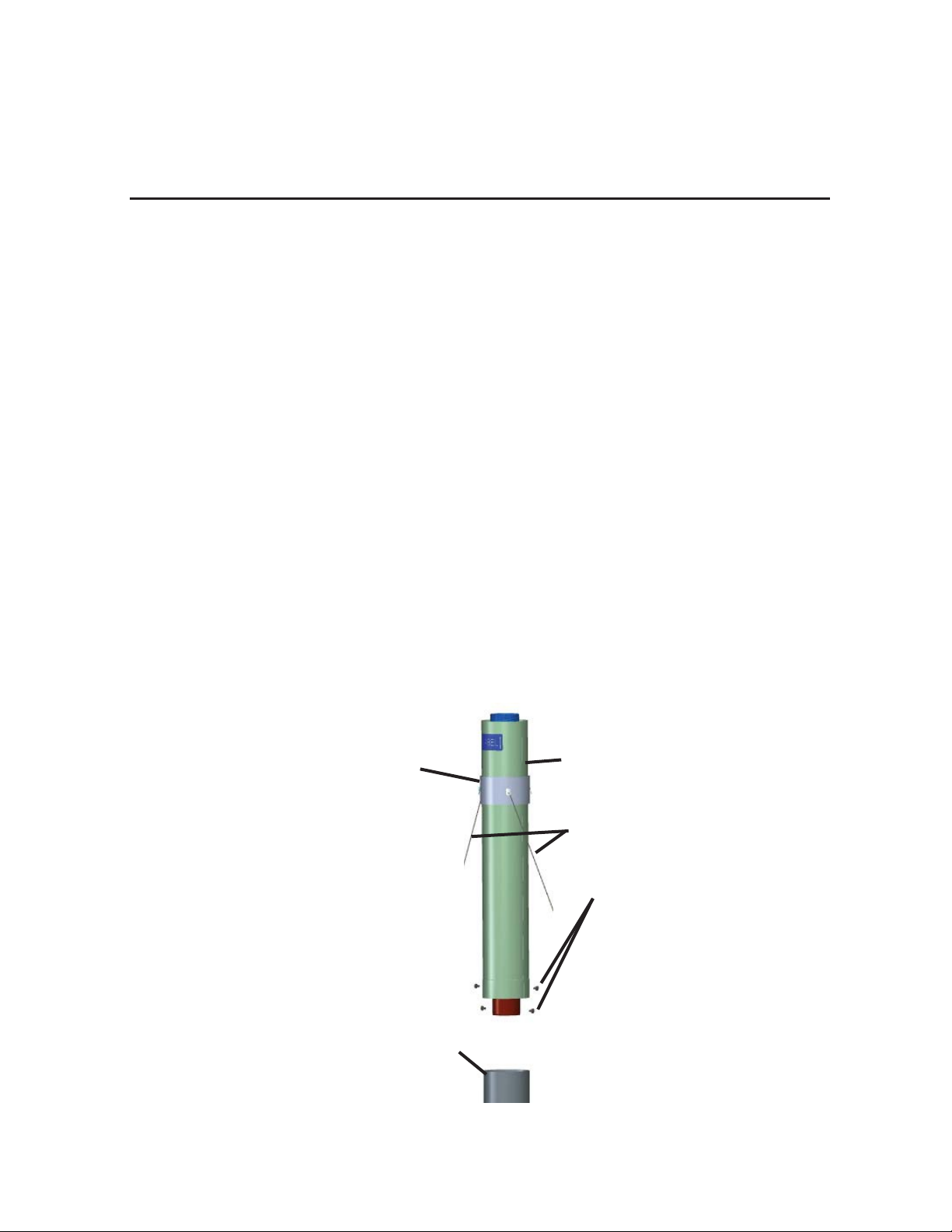

RIGID EXTENSION PIPE - For Extending Height of Vertical Termination

a. A 30 Inch long rigid extension pipe with flexible inner pipe, flexible spacers, male

connector and guy band support; part numbers:

2DVKRE(35,36,46,47,4.57.5,57,58,68,710,811) are sold separately.

b. Cut top of flexible inner pipe just above 42" long rigid pipe as necessary to facilitate

the joint.

c. Apply a heavy bead approximately 1/4" wide of high temperature Mill-Pac Black

sealant to approximately 3/4" from bottom male connector end of rigid extension

pipe inner collar outside edge and slip flexible pipe over collar with as much overlap

as possible. Secure inner pipe to collar with four self-drilling screws evenly spaced 90

degrees apart.

d. Slip rigid extension pipe over rigid pipe with as much overlap as possible. Secure rigid

extension pipe to rigid pipe with four self-drilling screws evenly spaced 90 degrees

apart.

e. Slide guy band support down rigid extension pipe to within 1 foot of vent

termination and secure with #10-24 bolt and nut provided with guy band support.

f. Attached field supplied stainless steel or galvanized cable with a minimum rated

capacity of 500lbs. to each of the four anchor holes.

g. Anchor cables to a rigid building member using an appropriate field supplied

fastening method.

Guy

Band

Support

Rigid Extension Pipe:

30” Long

Field Supplied Cables:

500lbs Rating

Rig

id Pi

pe:

42” Long

Apply Mill-Pac Black

Sealant & Secure with

Screws:

Inner Male Collar to Inner

Flexible Pipe

& then

Outer Rigid Pipes

Fig. 13 Rigid Extension Pipe Installation

20

Installation Procedure

Z-FLEX

STORM COLLAR/SUPPORT

a. Slide storm collar/support with flared end down, over and down rigid pipe(s)

until it is just above top of roof flashing.

b. Seal/waterproof between inside diameter of storm collar/support and outside

diameter of rigid pipe with high temperature Mill-Pac Black sealant.

c. Secure storm collar/support to rigid pipe with bolt and nut.

Secure Storm

Collar/Support to

Rigid Pipe Just

Above Roof

Flashing & Seal

Between Both

with Sealant

Rigid

Pipe

Storm

Collar/

Support

Roof

Flashing

Fig. 14 Storm Collar/Support Installation

WARNING

Risk of Fire! Risk of Explosion! Risk of Asphyxiation!

High wind conditions, nearby big trees, adjoining roof lines, steep pitched roofs may

cause poor draft or down drafting.

In these cases increasing the installation height of

termination above highest point of roof may solve drafting

problem. Review

appliance manufac

turer's instructions to ensure maximum installed lengths (vertical

and horizontal) are not exceeded.

This manual suits for next models

2

Table of contents

Popular Fireplace Accessories manuals by other brands

Dimplex

Dimplex SMP-175-PE install guide

Lennox Hearth Products

Lennox Hearth Products LSO-43 installation instructions

Outdoor Lifestyles

Outdoor Lifestyles ODCOUG-36SSL installation instructions

FireplaceXtrordinair

FireplaceXtrordinair 564 25K Installation

Valor

Valor L2 SERIES installation manual

Empire Comfort Systems

Empire Comfort Systems EMBC-1S-C-1 Assembly instructions

Town & Country Fireplaces

Town & Country Fireplaces TC42 installation instructions

pleasant hearth

pleasant hearth LS932B manual

O-TL

O-TL System 4 LP Installation and operation guide

CMC

CMC DV ReFace Screen Installation & operation manual

SBI

SBI AC02082 Installation

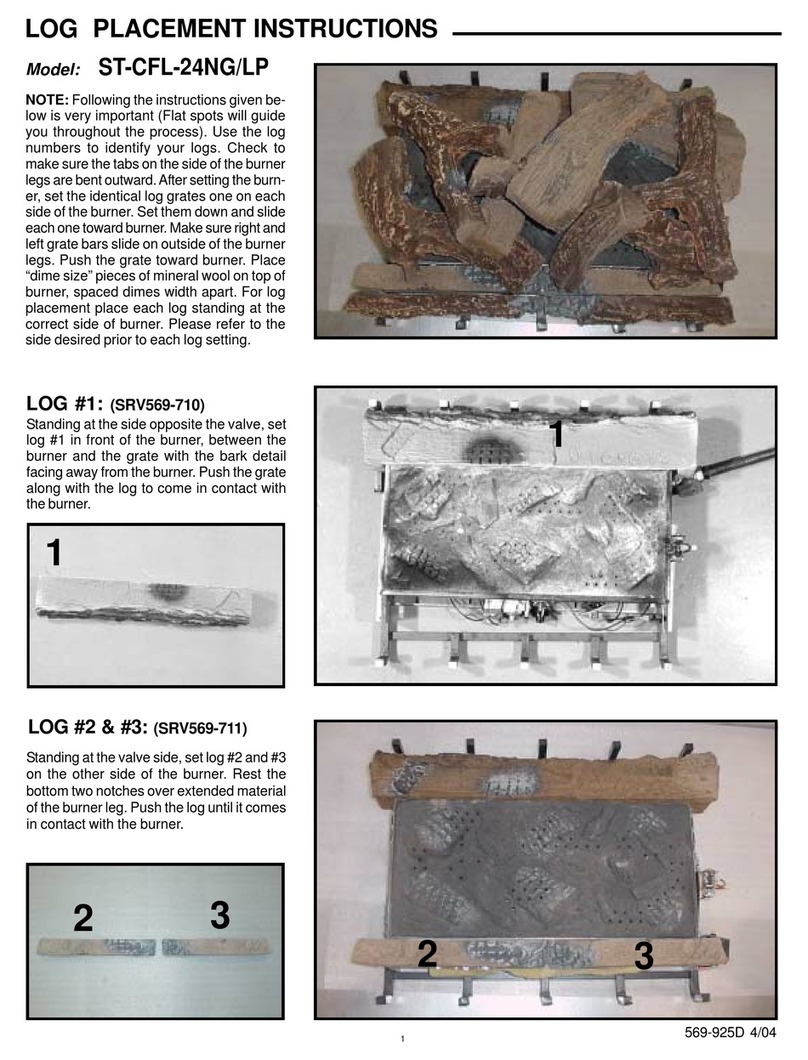

Heatilator

Heatilator ST-CFL-24NG Log Placement Instructions