NOVAKON CD-100 User manual

Novakon Systems Ltd

CD-100

COMPUTER DRIVER

OPERATOR’S MANUAL

CHAPTER 1

INTRODUCTION

1.1 Thank you for your order

Congratulations on your purchase of CD-100 Computer Driver. With proper set-up and maintenance,

your computer driver should provide many years of quality work and enjoyment. This manual covers

general instructions regarding machine set-up, operation, maintenance and troubleshooting for the CD-

100 Computer Driver.

1.2 Important

Before opening your CD-100 Computer Driver, this instruction and any accompanying manual should be

read carefully. Instruction manuals should be kept in a safe place where they are always easily accessible

for reference during the operation of the machine.

While this manual has been compiled to give the general description and usage of the CD-100 Computer

driver, changes are possible due to continuous design and development efforts.

Remember, safety comes above all else. Carefully read, follow, and understand the safety information

outline in Chapter 3 of this manual and always let common sense be your guide.

1.3 Suggestions or Comments

We are interested in any suggestions you might have to improve our products and services. Feel free to

contact us with your suggestions by phone or in writing.

If you have any comments about this operator’s manual, or if you’d like to share with us, contact:

NOVAKON SYSTEMS LTD.

160 Gibson Drive, Unit 11

Markham, Ontario

L3R 3K1

Canada

If you have questions regarding our products, we are available from Monday to Friday from 10:00 a.m.

to 6:00 p.m. Eastern Time; or you may also e-mail your questions 24 hours a day to [email protected].

If you are calling outside Canada, please dial 1-905-258-0366 or 1-905-258-0566. You may also fax your

questions to 1-905-258-0633.

1.4 Customer Information

Please record your information below about your CD-100 Computer Driver. Having this information

readily available will save time if you will need to contact Novakon Systems Ltd for questions, service,

accessories, or replacement parts.

Model Number: ________________________________________

Serial Number: ________________________________________

Purchase Date: _________________________________________

Delivery Date: _________________________________________

We look forward to a long working relationship with you, and thank you for putting your trust in

Novakon Systems Ltd.

CHAPTER 2

WARRANTY

Novakon Systems Ltd warrants its CD-100 Computer Driver and machines for a period of one (1) year to

the original purchaser from the date of purchase. If within (1) year from the date of purchase, the CD-

100 Computer Driver and machines fails due to a defect in material or workmanship, Novakon system

Ltd will at their choice repair and/ or replace components with new or remanufactured parts free of

charge.

Most warranty repairs and/or replacements are handled routinely, but sometimes request for warranty

service may not be appropriate. This warranty does not apply to defects due to either directly or

indirectly misuse, abuse, negligence, accidents, repair or lack of routine maintenance.

An investigation will be made by Novakon Systems Ltd to determine whether the warranty applies or

not. To qualify, listed below are some of the causes of machine failure that this warranty does not cover.

1. Normal Wear –All mechanical devices need periodic parts service and replacement. This

warranty does not cover repair when normal use has exhausted the life of the parts or

components.

2. Improper Maintenance –The life of the machine and computer driver depends upon the

conditions under which it operates, and the care it receives. Application of this machine may be

in dusty and dirty environment, which can cause what appears to be premature wear. Such

wear when caused by dirt, dust, cleaning grit, or any abrasive material is not covered under

warranty.

3. Machine Installations –Improper installation of the machine or computer driver can prevent

starting, causes unsatisfactory performance and can shorten machine life.

4. Parts damaged by excessive speed or overheating. Refer to the instruction manual for the

recommended working environment and maintenance schedule.

5. Parts broken by excessive vibration caused by improper mounting of the machine or tools,

installation, unbalances set-up, improper attachment of work pieces or other abuse in

operation.

6. Parts which are determined to have failed due to improper use or excessive wear caused by

continuous use in a production environment. In cases such as this, Novakon systems Ltd will

inspect the machine or part and will be the sole judge of the merit of the claim.

7. Mishandling, improper operation or using the machine for operations other than what they

were intended for.

Transportation charges of parts and/or components submitted for repair and/or replacement under this

warranty are the responsibility of the purchaser. Before returning the machine or component, a Return

Merchandise Authorization (RMA) number must be assigned in order for us to accept the return

shipment.

No warranty registration is necessary. Please provide your invoice as proof of purchase. In the event that

it is not provided, the date at the time of warranty will be determined by the purchase date and will be

used to determine the warranty period.

In no event shall Novakon Systems Ltd be liable for indirect, incidental or consequential damages from

the sale or use of the product. This disclaimer applies to both during and after the terms of this

warranty.

CHAPTER 3

GENERAL SAFETY GUIDELINES

3.1 Safety is # 1

CD-100 Computer Driver has been proven to be safe and reliable. However, if abused or operated

improperly, it can cause injury to you or others. Please read the safety guidelines properly before

starting up with your computer driver. Proper use will create a safe working environment and prolong

the life of your computer driver.

All wires should be treated as HOT and suitably protected. Care must be taken that the user cannot

come in contact with these volts above ground.

3.2 Basic Points of Safety

•There are high voltages terminals on the electrical control panel, when you switch it off make

sure to wait for 3-5 minutes to allow the capacitor to discharge fully before touching any

components of the driver.

•Make sure all cables are fitted before the power is switched ON.

•If any components are to be removed, first power down and turn off the computer switch and

unplug the controller.

•Check all electrical cables for damage to prevent electrical shock.

•When you disconnect a cable, pull on the connector or its strain-relief loop, not on the cable

itself. Some cables have a connector with locking tabs; if you are disconnecting this type of

cable, press in the locking tabs before you disconnect the cable. As you pull the connector

apart, keep them evenly aligned to avoid bending any connector pins.

•Do not remove the motor cable if the high voltage power supply is still on, this may damage the

motor drivers.

•Before you connect a cable, ensure that all connectors are correctly oriented.

CHAPTER 4

INSTALLATION & SET-UP

4.1 Set-up Clearances

When considering the permanent location for your CD-100 Computer Driver, the following should be

taken into consideration.

•The computer driver should be installed on a flat surface so that it will not rock or slide during

the operation.

•This location should be the machine’s permanent location. For best results, use our professional

work station to mount your computer driver system (see figure1).

•Improper installation and unleveled machine can cause both numerical error and loss of

precision in your operation.

4.2 Power Requirements

The power cord/plug that is supplied with your CD-100 Computer Driver has a capability for both 110

voltages and 220 voltages. Refer to Table 4.1 for the power requirement of your Computer Driver.

Voltage

HV Power

Computer Power

110

10 amps

5 amps

220

5 amps

2.5 amps

Table 4.1 Power Requirement

4.3 Stand Requirements

Your work station should be located in a vibration free area with a floor that is designed to support the

full weight of the machine, accessories and materials.

If you purchased the optional Professional Work Station, it includes 4 power strip screws and 2

controller screws that are mountable to your workstation. (See figure 1)

Figure 1: Work Station

4.4 Start-up Connection

Our computer driver is easy to use; just follow the steps below to start up the connection of your CD-

100 computer Driver.

Step1: Connect the monitor, mouse and keyboard to your computer. Use the supplied adaptor to

connect the monitor to the video card digital output.

Step 2: Plug in the power cord to monitor.

Step3: Plug in the two (2) power cords to the back of the computer driver. One power cord is used for

the computer operation and the other power cord is used for the high voltage stepper motor.

Step 4: Connect the parallel jumper cable between the computer parallel port and the driver card input.

Secure the screws to hold the connectors in place.

Step 5: Connect the stepper motor cable between the driver card (stepper motor power) and the CNC

machine.

Step 6: Connect the Limit Switch Spindle Control cable between the driver card (Limit Switch & Spindle

Control) and the CNC Machine.

Step 7: Plug in the CNC machine power cord. (If you have the NM200 model, you will need to make

special two- pole switch to your power)

Step 8: You may now begin to power up the system in the following order:

•Turn the computer switch to ON. The computer may auto start, or it may also need to be

initiated by pressing the Computer Start (green) button.

•The computer will perform its windows XP start up procedure and will bring you to the

windows desk top screen.

•From the desk top, you may select the appropriate icon to start your Bob CAD/CAM software

or you can start the MACH3 Mill Program.

•Refer to the applicable operation manual for the operation of the software.

4.5 Installations

Now that your CD-100 has been set-up, you are ready to install your control system. If you purchased a

Mach 3 system or PC Ready System, please refer to the documentation sent with your controller. If you

have purchased the base machine, we have supplied you with a set of plugs that match the sockets on

the junction box of the bed mill. You will be able to use these to wire your control system of choice to

your bed mill. Please refer to the installation diagram below for easy guide.

Figure 4.5 Installation Diagram

4.6 Computer Connections

Figure 4.6 Controller Connections

1. Limit switch & spindle control

2. Video card output

3. Computer reset

4. Parallel port

5. Computer switch

6. Computer plug

7. High voltage plug

8. High voltage switch

9. Computer start

10. Driver card input

11. Stepper motor power

12. Model & Serial Numbers

1

2

3

4

5

6

7

8

9

10

11

12

CHAPTER 5

COMPUTER COMPONENTS, IDENTIFICATION &

FUNCTION

5.1 OVERVIEW

This chapter will help you familiarize yourself with the major components and function of your CD-100

Computer Controller also known as SMART DRIVE (see figure 5.1)

Figure 5.1 CD-100 Computer Controller

The CD-100 is a software controlled system which was comprehensively designed from the ground up to

host a variety of CNC machines. It contains a powerful computer and driver for sophisticated software

stepper motor operation. It comes complete with four (4) fully functional axes control drivers utilizing

the power of the popular Mach3 software. Add one of our high performances Bob CAD-CAM software

packages and you will have all the capability you need in one complete and compact unit. You can now

plug our professional controller into any of our mills, your home projects or any other stepper motor

controlled machine without making tedious adjustments. It also features special circuitry that identifies

the attaching machine requirements and automatically selects the proper voltage and current settings

for your CNC machine. With the 1050 VA transformer, the controller drives each stepper motor up to 7

Amperes @ 75 volts. Our controller has become a true Plug & Play device for your shop. Refer to the

specifications below for more detailed features of our CD-100 computer driver.

5.2 Specifications

Physical:

Size 6-3/4” W x 14 ½” L x 15” L

Weight 42 pounds

Chassis 16 gage cold roll sheet, zinc plated

Finish blue base/ yellow cover powder coated

Shipping weight 102 pounds

Electrical:

Voltage 110/220 Volts AC 50/60 cycles

Input Power 1500 Watts Maximum

Output Voltage 38/75 Volts Selectable

Output Stepper Drive 4 axes @ 7 Amps, 75 Volts Maximum

Output Spindle Control 0-10 Volts DC Variable

4th Axis Control User Definable

Computer (Full System)

Intel Core 2 Dual Processor 2 GHz 2MB Cache 800 MHz & MB

1 GB RAM

450 Watt Power Supply

512 MB Graphics Card

80 GB SATA-II Hard Drive

Windows XP Operating System

Mach3 Control Software http://www.machsupport.com

19”LCD Monitor

Keyboard, mouse and Interface cables

5.3 Components

The CD-100 Computer Driver has several components which includes the following:

Description

Product Photo

Power Cords

-There are two power cords, one power cord is

used for the computer operations and the other one

is used for the high voltage stepper motor power.

Parallel jumper Cable

-To be connected in the computer parallel port

to driver card input.

Motor Driver Cable

To be connected in the driver card and the CNC

machine

Spindle / Limit Switch Control cable

To be connected in the driver card and the CNC

machine

Mach3 Control Software

Version 3 of the PC based CNC control software

which is preloaded in your computer.

Drivers and Manuals for your motherboard, video

card, RAM, and hard drive.

Microsoft XP Operating System

It is preloaded in your computer driver

Optical Mouse, keyboard and 19” Samsung

mountable LCD monitor

These are to be connected together to your

computer.

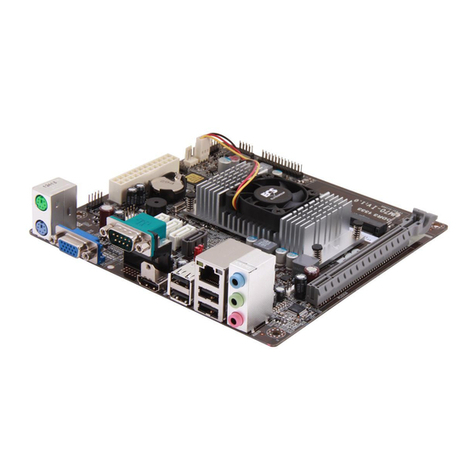

CHAPTER 6

PARTS & DIAGRAMS

6.1 Manual Parts & Diagrams

This chapter will help you familiarize yourself with various parts and diagrams of CD-100 Computer

Driver. The photograph in this section shows the interior part the computer controller driver.

Figure 5: Interior View of Controller

1. Computer Interface

2. Controller Driver Card Assembly

3. Mother Board

4. Transformer

5. Power Supply Regulator

1

2

4

5

3

6.2 Controller Driver

Figure 6.2: Controller Driver

1. C11G Break out Board

2. Gecko Drivers

3. Fuses

Figure 6.3A: X & Y Axis

Figure 6.3B: Z-Axis & 4th Axis

1

2

3

X Axis

Y Axis

4th Axis

Z Axis

6.3 UNI-Mate Connectors

Figure 6.3: Rear View of UNI-Mate Connectors

1. DB15 Connectors

2. UNI-Mate J3

3. DB15 Connector

1

2

3

6.3 Controller Driver Wiring Connection

Wire color

Start Location

Pin Number (End location)

Function

Black

DB25, J1-1

Driver X, pin 3

X axis, stepper motor A+

Black

DB25, J1-2

Driver X, pin 4

X axis Stepper motor A-

Black

DB25, J1-3

Driver x, pin 5

X axis stepper motor B+

Black

DB25, J1-4

Driver X, pin 5

X-axis, stepper motor B-

Black

DB25, J1-5

Driver Y, pin 3

Y axis, stepper motor A+

Black

DB25, J1-6

Driver Y, pin 4

Y axis, stepper motor A-

Black

DB25, J1-7

Driver Y, pin 5

Y axis, stepper motor B+

Black

DB25, J1-8

Driver Y, pin 6

Y axis, stepper motor B-

Black

DB25, J1-9

Driver Z, pin 3

Z axis, stepper motor A+

Black

DB25, J1-10

Driver Z, pin 4

Z axis, stepper motor A-

Black

DB25, J1-11

Driver Z, pin 5

Z axis, stepper motor B+

Black

DB25, J1-12

Driver Z, pin6

Z axis, stepper motor B-

Open

Open

Open

Open

Black

DB25, J1-14

Driver A, pin 3

A axis, stepper motor A+

Black

DB25, J1-15

Driver A, pin 4

A axis, stepper motor A-

Black

DB25, J1-16

Driver A, pin 5

A axis, stepper motor B+

Black

DB25, J1-17

Driver A, pin 6

A axis, stepper motor B-

Yellow

DB25, J1-18

Driver X, pin 11

Driver X, current set

Yellow

DB25, J1-19

Driver X, pin 12

Driver X, current set

Yellow

DB25, J1-20

Driver Y, pin 11

Driver Y, current set

Yellow

DB25, J1-21

Driver Y, pin 12

Driver Y, current set

Yellow

DB25, J1-22

Driver Z, Pin 11

Driver Z, current set

Yellow

DB25, J1-23

Driver Z, pin 12

Driver Z, current set

Yellow

DB25, J1-24

Driver A, pin 11

Driver A, current set

Yellow

DB25, J1-25

Driver A, pin 12

Driver A, current set

Table 6.1: DB25 Connectors

Wire Color

Start Location

End Location

Function

Blue

DB15, J2-1

Board Ac relay

AC relay

Blue

DB15, J2-2

Board AC relay

AC relay

Orange

DB15, j2-3

Board DC relay NO

Mech. relay N.O

Yellow

DB15, J2-4

Board Analog 0-10

V

Spindle sheet

White

DB15, J2-5

Board 10

Emergency stop

White

DB15, J2-6

Board 11

X,Y,Z axis limit switches

White

DB15, J2-7

Board 12

AUX 1 input

White

DB15, J2-8

Board 13

Aux 2 input

White

DB15, J2-9

Molex, J5 -4

Group 2 Select

Orange

DB15, J2-10

Board DC relay

COM

Mech. Relay Com

Green

DB15, J2-11

Board Analog GND

Analog GND

Blue

DB15, J2-12

Board IN 12 VDC

Group 2 select (12VDC)

Blue

DB15, J2-13

Molex, J5-5

Neg. 12 VDC

Green

DB15, J2-14

Board In GND

Limit Switches COM

Blue

DB15, J2-15

Board IN +12 VDC

12 VDC

Table 6.2: Electrical Connection

Wire Color

Start Location

End Location

Function

Blue

Molex J3-1

Board AC relay

Coolant Pump

Blue

Molex J3-2

Board AC relay

Coolant Pump

Green

Molex J4-1

Terminal Board

Driver ground

Green

Terminal Board

Driver X, pin 1

Driver Ground

Green

Terminal Board

Driver Y, pin 1

Driver ground

Green

Terminal Board

Driver Z, pin 1

Driver ground

Green

Terminal Board

Driver A, pin1

Driver ground

Blue

Fuse holder 1

Driver X, pin 2

X Axis power

Blue

Fuse holder 2

Driver Y, pin 2

Y Axis power

Blue

Fuse Holder 3

Driver Z, pin 2

Z Axis power

Blue

Fuse Holder 4

Driver A, pin 2

A Axis power

Blue

Molex J4-2

Fuse holder 1

X axis high power

Blue

Molex J4-3

Fuse holder 2

Y axis high power

Blue

Molex J4-4

Fuse Holder 3

Z axis high power

Blue

Molex J4-5

Fuse Holder 4

A axis high power

Green

Molex J5-1

Board power ground

Low voltage ground

Blue

Molex J5-2

Board power 12V

12 volts DC

Red

Molex J5-3

Board power 5 V

5 volts DC

Blue

Molex J5-4

DB 15, J2-9

Group 2 select

Blue

Molex J5-5

DB15, J2-13

Neg. 12VDC

Table 6.3: J4 & J5 Electrical Connection

6.4 Break out Board

Overview

This card has been designed to provide a flexible interface and functions to your computer numerical

control projects by using parallel port control software. This board comes as a response to many users

that have been asking for a faster way to connect devices and reduce the possibility of wiring errors.

(See Figure 10)

Figure6.5: C11G Breakout Board

Wire color

Start Location

End Location

Function

White

Breakout Board 2

Driver X, pin 9

X step clock

White

Breakout Board 3

Driver X, pin 8

X direction clock

White

Breakout board 4

Driver Y, pin 9

Y step clock

White

Breakout board 5

Driver Y, pin 8

Y direction clock

White

Breakout board 6

Driver Z, pin 9

Z step clock

White

Breakout board 7

Driver Z, pin 8

Z direction clock

White

Breakout Board 8

Driver A, pin 9

A step clock

White

Breakout Board 14

Driver A, pin 8

A Direction clock

Breakout Board 10

Breakout Board +5VDC

Pull up Resistor 1KOhm

Breakout board 11

Breakout Board +5VDC

Pull up Resistor 1KOhm

Breakout board 12

Breakout Board +5VDC

Pull up Resistor 1KOhm

Breakout board 13

Breakout Board +5VDC

Pull up Resistor 1KOhm

Green

Board Power GND

DC/DCV-in-

Blue

Board power +12V

DC/DC V-in+

Green

Analog GND

DC/DC V –out-

Blue

Analog +12V

DC/DC V-out-

Table 6.4 Break-out Board Wiring Table

6.5 Breakout Board Adjustment

C11G breakout board has an analog 0-10 VDC output that will convert a step signal into an analog signal

that can be used to command a commercial VFD (Variable Frequency drive). But with the use of

Table of contents