Novanta IMS Liberty MDrive Motion Control User manual

Hardware Manual

Liberty MDrive Motion Control

NEMA 23 (57 mm) & NEMA 34 (85 mm) with M12 Circular Connectors

Publication IMS-MN-LMDM57-85C.pdf

04/2022

REACH IP/20IP65

LISTED

2IMS-MN-LMDM57-85C.pdf

LMD Motion Control

For information on the availability of products, go to https://novantaims.com/

The information contained in the present document is subject to change without notice. The

technical characteristics of the devices described in the present document also appear online.

The characteristics that are presented in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may

revise content over time to improve clarity and accuracy. If there is a difference between the

document and online information, use the online information as reference. All details provided

are technical data which do not constitute warranted qualities.

Some of the product designations are registered trademarks of their respective owners, even if

this is not explicitly indicated.

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is

not intended as a substitute for and is not to be used for determining suitability or reliability

of these products for specific user applications. It is the duty of any such user or integrator to

perform the appropriate and complete risk analysis, evaluation and testing of the products with

respect to the relevant specific application or use thereof.

Neither Novanta IMS nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or

amendments or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Novanta IMS, given in writing.

You also agree not to establish any hypertext links to this document or its content.

Novanta IMS does not grant any right or license for the personal and noncommercial use of the

document or its content, except for a non-exclusive license to consult it on an “as is” basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing

and using this product. For reasons of safety and to help ensure compliance with documented

system data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed. Failure to use Novanta IMS software or approved software with

our hardware products may result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

3

IMS-MN-LMDM57-85C.pdf

Table of Contents

Safety Information 5

Important Information...............................................................................................................5

Qualification of Personnel........................................................................................................5

Intended Use.................................................................................................................................5

Product Related...........................................................................................................................6

About this Manual 8

Introduction...................................................................................................................................8

Terminology Derived from Standards .................................................................................8

Source Documents and Software .........................................................................................9

Writing Conventions and Symbols.......................................................................................9

Documentation and Literature References ......................................................................10

Website Directory ......................................................................................................................10

Documentation Feedback ......................................................................................................10

Chapter 1:Introduction 11

About this Product ....................................................................................................................12

Unit Overview ..............................................................................................................................12

Components and Interfaces...................................................................................................13

Conditions for UL 508C........................................................................................................... 15

Name Plate....................................................................................................................................16

Part Number Identification.....................................................................................................17

Chapter 2: Technical Data 20

Certifications................................................................................................................................ 21

Environmental Conditions ......................................................................................................21

Mounting Data.............................................................................................................................22

Mechanical Data ........................................................................................................................ 25

Electrical Data ............................................................................................................................ 30

Rotary Motor Data .................................................................................................................... 33

External Linear Actuator Data ............................................................................................. 35

Electric Cylinder Data.............................................................................................................. 36

Chapter 3: Engineering 37

External Power Supply Units ................................................................................................ 38

Auxiliary Power Supply............................................................................................................41

Wiring and Shielding.................................................................................................................41

Ground (Earth) Design............................................................................................................ 42

Monitoring Functions............................................................................................................... 43

4IMS-MN-LMDM57-85C.pdf

Table of Contents

Liberty MDrive Motion Control

Chapter 4: Installation 44

Electromagnetic Compatibility, EMC................................................................................. 46

Mechanical Installation............................................................................................................ 47

Electrical Installation................................................................................................................ 49

Supply Voltage VDC Connection........................................................................................ 49

Multifunction Interface Connection.....................................................................................51

Signal Input Circuits ..................................................................................................................52

Power Output Circuits............................................................................................................. 54

Signal Output Circuit ............................................................................................................... 56

Analog Input ............................................................................................................................... 56

Communications Interface Connection .............................................................................57

Checking Wiring ........................................................................................................................ 59

Chapter 5: Configuration 60

Preparing for Configuration ...................................................................................................61

Chapter 6: Operation 62

Basics............................................................................................................................................. 63

Software Operation Modes ................................................................................................... 65

Operation by hMT Modes....................................................................................................... 67

I/O Operation.............................................................................................................................. 69

Appendix A: Diagnostics and Troubleshooting 70

Operation State and Error Indication ................................................................................ 70

Error codes ...................................................................................................................................71

Appendix B: Accessories and Spare Parts 72

Accessories...................................................................................................................................72

Appendix C: Service, Maintenance, and Disposal 74

Service Address ..........................................................................................................................75

Maintenance .................................................................................................................................75

Replacing Units ...........................................................................................................................75

Shipping, Storage, and Disposal.......................................................................................... 76

Appendix D: LMD with Absolute Encoder 77

Overview........................................................................................................................................77

Unboxing Procedure .................................................................................................................77

Connection of the Multifunction Interface .......................................................................77

ICP0531 Encoder Back-up Battery Pack .......................................................................... 78

Glossary 82

5

IMS-MN-LMDM57-85C.pdf

ABOUT THIS MANUAL

Introduction

Read and understand the material contained in this manual before working on Liberty MDrive

(LMD) products for the first time. Take particular note of the safety information (see “Safety

Information” on page 5). Only qualified persons are allowed to work with the LMD product

(see “Qualification of Personnel” on page 5).

A copy of this manual must be available for personnel who work with LMD products.

The purpose of this manual is to show the capabilities of the LMD and how to use it safely and

properly. Follow the instructions within this manual to help:

• reduce risks,

• reduce repair costs and downtime of the LMD product,

• increase the service life of the LMD product, and

• increase reliability of the LMD product.

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual,

or that appear in or on the products themselves, are generally derived from the terms or

definitions of international standards.

In the area of functional safety systems, drives and general automation, this may include, but

is not limited to, terms such as safety, safety function, safe state, fault, fault reset, malfunction,

failure, error, error message, dangerous, etc.

Among others, these standards include:

IEC/EN 61131-2:2007 Programmable controllers, Part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety-related parts of control systems. General principles for

design.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment. Part 1: General requirements

and tests.

ISO 12100:2010 Safety of machinery: General principles for design - Risk assessment and risk reduction.

IEC/EN 60204-1:2006 Safety of machinery: Electrical equipment of machines - Part 1: General requirements.

ISO 14119:2013 Safety of machinery: Interlocking devices associated with guards - Principles for design

and selection.

ISO 13850:2015 Safety of machinery: Emergency stop - Principles for design.

IEC/EN 62061:2015 Safety of machinery: Functional safety of safety-related electrical, electronic, and

electronic programmable control systems.

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-related systems:

General requirements.

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-related systems:

Requirements for electrical/electronic/programmable electronic safety-related systems.

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-related systems:

Software requirements.

IEC 61784-3:2016 Digital data communication for measurement and control: Functional safety field buses.

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

6IMS-MN-LMDM57-85C.pdf

Source Documents and Software

LMD Motion Control

In addition, terms used in the present document may tangentially be used as they are derived

from other standards such as:

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in industrial

control systems

Finally, the term, “zone of operation” may be used in conjunction with the description of

specific hazards, and is defined as it is for a hazard zone or danger zone in the Machinery

Directive (2006/42/EC) and ISO 12100:2010.

NOTE: The aforementioned standards may or may not apply to the specific products cited

in the present documentation. For more information concerning the individual standards

applicable to the products described herein, see the characteristics tables for those product

references.

Source Documents and Software

The latest versions of the manuals are available online from:

https://novantaims.com/dloads/product-literature/manuals-3/

Writing Conventions and Symbols

Work Steps

Work steps must be performed consecutively. Work steps will be numbered in order of

expected operation.

A response to a work step may be indicated. This allows verification that the work step has

been performed correctly.

Unless otherwise stated, the individual steps must be performed in the specified sequence.

Bulleted Lists

The items in bulleted lists are sorted alphanumerically or by priority. Bulleted lists are

structured as follows:

• Item 1 of bulleted list

• Item 2 of bulleted list

–Subitem for 2

–Subitem for 2

• Item 3 of bulleted list

Parameters

Parameters are shown as follows

RC Motor Run Current

Units of Measure

Measurements are given in both imperial and metric values. Metric values are given in

parenthesis unless otherwise indicated.

Examples:

1.00 in (25.4 mm)

100 oz-in (70.6 N-cm)

7

Documentation and Literature References

IMS-MN-LMDM57-85C.pdf

LMD Motion Control

Documentation and Literature References

This document should be used in conjunction with the following document:

• LMD MCode Programming and Reference Manual

The latest version of this manual can be downloaded from: https://novantaims.com/dloads/

Website Directory

NOTE: Direct links are subject to change as website and search engine updates occur. Each of

the websites below can also be accessed through menu options on the Novanta IMS Main Page:

https://novantaims.com/

Downloads:

https://novantaims.com/dloads/

Resources:

https://novantaims.com/resources/

Warranty:

https://novantaims.com/warranty-and-disclaimer/

Certifications and Listing Information:

https://novantaims.com/dloads/certificationssustainability/

Contact and Support:

https://novantaims.com/contacts/

CyberSecurity Information:

https://novantaims.com/all-products/cybersecurity/

Knowledge Based Solutions:

https://novantaims.com/resources/troubleshooting/

Documentation Feedback

To provide feedback on this or any Novanta IMS documentation, submit all feedback,

corrections, or concerns to the following e-mail address.

documentati[email protected]om

Please include the following information:

• Document number and revision/print date

• Detailed description of the issue or concern

• Contact information

9

About this Product

IMS-MN-LMDM57-85C.pdf

Liberty MDrive Motion Control

About this Product

This manual is valid for all Liberty MDrive Programmable Motion Control NEMA 23 and NEMA

34 rotary and linear products. This chapter lists the type code for this product. The type code

can be used to identify whether your product is a standard product or a customized model.

This document is applicable to the following products:

Rotary

• NEMA 23: LMDxM57C

• NEMA 34: LMDxM85C

External Linear

•NEMA 23: LMDxM571C-Lxxxxxxxx

If using the NEMA 17 (42 mm) Liberty MDrive Programmable Motion Control product, refer to

the hardware manual specific to that product

Unit Overview

The “LMD MDrive Motion Control” consists of a stepper motor and integrated electronics. The

product integrates interfaces, drive and control electronics and the power stage. There are

three basic control variants:

Closed Loop with hMT: loop is closed by a 1000-line (4000 edge) magnetic encoder. May be

operated as:

•hMT off: standard encoder functions for position and stall monitoring

•hMT on: enhanced closed loop functions such as anti-stall and position maintenance.

Absolute with hMT: Closed loop with multi-turn absolute encoder, which will retain position

information upon loss/removal of power. standard encoder and hMT features will function as on

a closed loop model. See Appendix D on page 74 for details.

Open Loop: standard open loop stepper control.

Operating modes

The “LMD Motion Control” is a fully programmable motion control system allowing for complex

program and I/O interaction. Operating modes may be used interchangeably:

•Immediate mode: In immediate mode, also known as streaming commands, the device

will respond to 1 and 2 character ASCII commands sent via the RS-422/485 fieldbus

interface

•Program mode: In program mode the device may be programmed with multiple

functions, subroutines and process interactions using the MCode programming

language, which is made up of 1 and 2 character ASCII mnemonics. Stored programs

may be executed using an input, by labeling a program SU to run it on start up, or via an

immediate mode command.

All setup parameters are set via the service interface.

10 IMS-MN-LMDM57-85C.pdf

Components and Interfaces

Liberty MDrive Motion Control

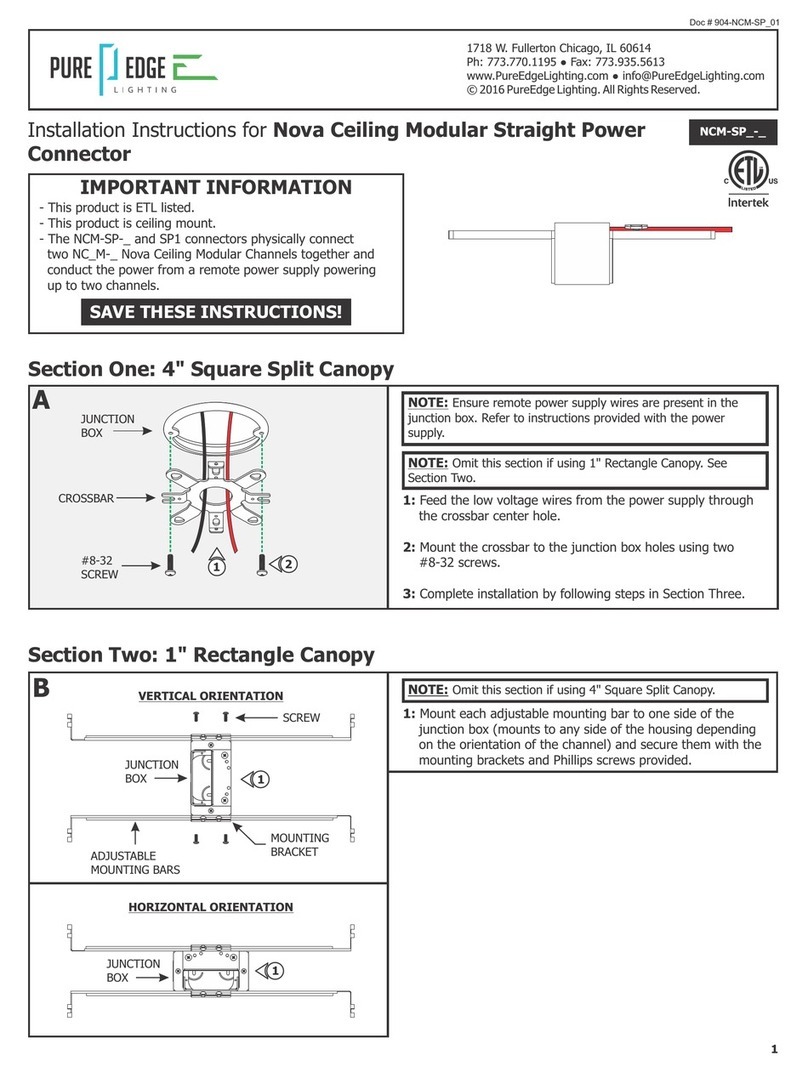

Components and Interfaces

NEMA 23 (57 mm) product shown below, the NEMA 34 (85 mm) has identical components and

interfaces

A

B

C

F

G

D

E

(A) Electronics housing

(B) Two phase stepper motor

(C) DC power interface

(D) Multifunction interface

(E) Service interface

(F) Protective earth

(G) LED indicators

Components

Motor

The motor is a two phase brushless stepper motor. The motor has a high torque density due to

the use of the latest magnetic materials and enhanced design. The step angle of the motor is

1.8°.

Electronics housing

The electronics system is comprised of control electronics and power stage.

The drive system is controlled by streaming commands via the service interface, embedded

programming, or by pulse and direction input signals.

11

Components and Interfaces

IMS-MN-LMDM57-85C.pdf

Liberty MDrive Motion Control

Interfaces

Standard available interfaces connect using standard M12 circular connectors.

DC power supply voltage

The DC Power Interface connection supplies VDC and AUX power connections for the drive via

a 4-position M12 (male, B-coded) connector (P1). The VDC connection provides power to the

control electronics and power stage. The 12 to 24V Aux-Power input supplies power to logic

circuits in the event of main supply loss.

The ground connections of all interfaces are galvanically connected. For more information see

“Ground (Earth) Design” on page 39. This chapter also provides information on protection

against reverse polarity.

Multifunction Interface

The multifunction interface operates at the following signal levels:

• 24V input signals are opto-isolated

• 24V output signals are opto-isolated and current limited

• 0 to 10V analog signal is not isolated

The 24V input signals are programmable as general purpose or to predefined functions. One of

the inputs has the alternate high speed function and may be used as a capture input.

Two 100mA/24 VDC power outputs are programmable as general purpose or to a set of

predefined functions. One output is a 5.5 mA signal output which can be defined as high speed

trip.

The reference voltage or current is applied to the analog input can be used for a number of

programmatically defined operations.

Service Interface

The service interface provides a connection to the RS-422/485 bus.

A PC may be connected to the interface via a USB to RS-422/485 converter via a 5-position

M12-F connector. The commissioning software may then be used for tasks such as

parameterization and monitoring the status of the device.

The service interface is also used for firmware upgrades.

Protective Earth (PE)

Protective earth provides a means of grounding to the device chassis.

12 IMS-MN-LMDM57-85C.pdf

Conditions for UL 508C

Liberty MDrive Motion Control

Conditions for UL 508C

The following conditions must be met if the product is used to comply with UL 508C.

Ambient temperature during operation:

• Surrounding air temperature [°C] 0 ... +50.

Pollution degree:

• Use in an environment with pollution degree 2.

Power supply:

• Use only power supply units that are approved for over-voltage category III.

• Wiring - Use only 60/75°C copper conductors.

Safety Integrity Level (SIL) Probability of Failure/Hour (PFH)

at high or continuous demand

4≥10-9 ... <10-8

3≥10-8 ... <10-7

2≥10-7 ... <10-6

1≥10-6 ... <10-5

Hardware Fault Tolerance (HFT) and Safe Fail Fraction (SFF):

Depending on the SIL for the safety system, the IEC 61508 standard requires a specific

hardware fault tolerance HFT in connection with a specific proportion of safe failures SFF (safe

failure fraction). The hardware fault tolerance is the ability of a system to execute the required

safety function in spite of the presence of one or more hardware faults. The SFF of a system is

defined as the ratio of the rate of safe failures to the total failure rate of the system. According

to IEC 61508, the maximum achievable SIL of a system is partly determined by the hardware

fault tolerance HFT and the safe failure fraction SFF of the system.

SFF HFT Type A Subsystem HFT Type B Subsystem

0 1 2 0 1 2

< 60% SIL1 SIL2 SIL3 — SIL1 SIL2

60% ...<90% SIL2 SIL3 SIL4 SIL1 SIL2 SIL3

90% ...<99% SIL3 SIL4 SIL4 SIL2 SIL3 SIL4

≥99% SIL3 SIL4 SIL4 SIL3 SIL4 SIL4

Fault Avoidance Measures

Systematic errors in the specifications, in the hardware and the software, usage faults and

maintenance faults of the safety system must be avoided to the maximum degree possible.

To meet these requirements, IEC 61508 specifies a number of measures for fault avoidance

that must be implemented depending on the required SIL. These measures for fault avoidance

must cover the entire life cycle of the safety system, i.e. from design to decommissioning of the

system.

13

Name Plate

IMS-MN-LMDM57-85C.pdf

Liberty MDrive Motion Control

Name Plate

The name plate has the following information

(1) Part number

(2) Nominal voltage

(3) Max. Holding torque

(4) Max required input current

(5) Serial number

(6) Date of manufacture

(7) Communication interface

(8) Data matrix

(9) Ingress Protection Rating

14 IMS-MN-LMDM57-85C.pdf

Part Number Identification

Liberty MDrive Motion Control

Part Number Identification

LMD Rotary Motor

The following graphic displays a breakdown of the LMD rotary motor part number

identification.

LMD O M 57 1 C

Product

LMD = standard torque motor

LMH1 = high torque motor

Communication interface

M = Programmable Motion Control

Length

1 = 1 stack

2 = 2 stacks

3 = 3 stacks

Variation

C = M12 Circular Connectors, IP20/IP652

Control type

O = Open loop (no encoder)

C = Closed loop (with encoder)

A = Absolute encoder

1 NEMA 23 (57 mm) rotary motors only

2 Motor shaft is not sealed. For IP65 applications, the NEMA flange

must be properly sealed.

Size

57 = 57 mm / NEMA 23

85 = 85 mm / NEMA 34

15

Part Number Identification

IMS-MN-LMDM57-85C.pdf

Liberty MDrive Motion Control

LMD External Linear Actuators

The following graphic displays a breakdown of the LMD external linear actuator part number

identification.

Linear actuator

-C = Electric cylinder

Connector Style

C = M12 Circular Connectors, IP20

Nut

S = PEEK Blend

Lead / Pitch (travel/rev)

A = 0.100” / 2.54mm

B = 0.250” / 6.35mm

C = 0.500” / 12.70mm

D = 1.000” / 25.40mm

Stroke length

available in 0.1” increments

020 = Minimum 2.0" / 50.8mm

180 = Maximum 18.0" / 457.2mm

Mounts

M = Flange mounts

F = Foot mounts

Options

NN = Reserved

LMD O M 57 1 C -C S A 020 M NN

Product

LMD = standard torque motor

Control Type

M = Motion Control

Feedback

O = Open loop (no encoder)

C = Closed loop (with encoder)

A = Absolute encoder

Size

57 = NEMA 23 (57 mm)1

Length

1 = 1 stack

1 NEMA 34 (85 mm) not available as an Electric Cylinder.

16 IMS-MN-LMDM57-85C.pdf

Part Number Identification

Liberty MDrive Motion Control

LMD Electric Cylinders (eCylinders)

The following graphic displays a breakdown of the LMD eCylinder part number identification.

Linear actuator

-C = Electric cylinder

Connector Style

C = M12 Circular Connectors, IP20

Nut

S = PEEK Blend

Lead / Pitch (travel/rev)

A = 0.100” / 2.54mm

B = 0.250” / 6.35mm

C = 0.500” / 12.70mm

D = 1.000” / 25.40mm

Stroke length

available in 0.1” increments

020 = Minimum 2.0" / 50.8mm

180 = Maximum 18.0" / 457.2mm

Mounts

M = Flange mounts

F = Foot mounts

Options

NN = Reserved

LMD O M 57 1 C -C S A 020 M NN

Product

LMD = standard torque motor

Control Type

M = Motion Control

Feedback

O = Open loop (no encoder)

C = Closed loop (with encoder)

A = Absolute encoder

Size

57 = NEMA 23 (57 mm)1

Length

1 = 1 stack

1 NEMA 34 (85 mm) not available as an Electric Cylinder.

17

IMS-MN-LMDM57-85C.pdf

Chapter 2:

Technical Data

What’s in this Chapter?

This chapter contains information on the ambient conditions and on the mechanical and

electrical properties of the device family and the accessories.

This chapter includes the following topics:

Topic Page

Certifications 18

Environmental Conditions 18

Mounting Data 19

Mechanical Data 22

Electrical Data 27

Rotary Motor Data 30

External Linear Actuator Data 32

Electric Cylinder Data 33

18 IMS-MN-LMDM57-85C.pdf

Certifications

Liberty MDrive Motion Control

Certifications

Certification Regulation #

RoHS 2011/65/EU, 2015/863

EMC 2004/108/EC

REACH EC 1907/2006

UL UL 1004-1, UL 1004-3

CSA C22.2 No. 100

CSA C22.2 No. 77

A current list of certifications and compliance information can be viewed at:

https://novantaims.com/dloads/certificationssustainability/

Environmental Conditions

Ambient Operating Conditions

The maximum permissible ambient temperature during operation depends on the distance

between the devices and the required power. Observe the pertinent instructions referenced in

“Installation” on page 41.

The following relative humidity is permissible during operation.

Operating temperature1[°C (°F)] -20 ... 50 (-4 ... 122) (no icing)

Temperature variation [°C (°F) min] 0.5 (32.9)

Humidity [%] 5 ... 95 (non-condensing)

1 If the product is to be used in compliance with UL 508C, note the information provided in “Conditions for UL 508C” on page 12.

Storage and Transport

The environment during transport and storage must be dry and free from dust. The maximum

vibration and shock load must be within the specified limits.

Temperature [°C (°F)] -25 ... 70 (-13 ... 158)

Temperature variation [°C (°F) min] -25 ... 30 (-13 ... 86)

Humidity [%] 5 ... 95 (non-condensing)

Temperature Maximums

Power stage1[°C (°F)] 85 (185)

Motor2[°C (°F)] 100 (212)

1 May be read via parameter.

2 Measured on the surface of the motor laminations.

Installation Altitude

The installation altitude is defined as height above sea level

Installation altitude 1 [ft (m)] 3280 (1000)

1 Installation above 3280 (1000) may require derating output current and maximum ambient temperature.

Vibration and Shock

Vibration, sinusoidal m/s210 IEC 60721-3-2

Shock, non-sinusoidal m/s2100 IEC 60721-3-2

19

Mounting Data

IMS-MN-LMDM57-85C.pdf

Liberty MDrive Motion Control

EMC

Emission IEC61800-3 (Category C2)

Noise immunity IEC61000-6-2

IP Degree of Protection

These products have the following degree of ingress protection (IP) as per EN 60529.

Degree of protection IP20

The total degree of protection is determined by the component with the lowest degree of

protection.

Mounting Data

Mounting Positions

NOTE: Unless otherwise stated, all drawing measurements are in inches (mm) ±0.005”

(0.13mm).

Drawings are not to scale.

The following mounting positions are defined and approved as per EN 60034-7:

• IM B5 drive shaft horizontal

• IM V1 drive shaft vertical, shaft end down

• IM V3 drive shaft vertical, shaft end up

IM V1 IM V3IM B5

20 IMS-MN-LMDM57-85C.pdf

Mounting Data

Liberty MDrive Motion Control

Mounting (Rotary and External Linear Actuators)

NEMA 23 (57 mm) Mounting Holes

Mounting the LMDXA57XC uses four (4) M5 x 0.5 screws on a bolt circle diameter (BCD)

of 2.625” (66.67 mm). The length of the screws will be determined by the thickness of the

mounting material plus a maximum of 0.186” (4.72 mm) into the motor housing.

The maximum tightening torque of the screws is 7.8 lb-in (9 kg-cm). The following graphic

shows rotary and actuator mounting hole pattern.

�1.856

(�47.14)

Pilot diameter

Ø 1.500 (38.1)

Ø 2.625 ±0.008

(Ø 66.67 ±0.02)

0.197 (5.0) Thru 4 Places on a

2.625 ±0.008 (66.67 ±0.02) Circle

NEMA 34 (85 mm) Mounting Holes

Mounting the LMDXX85XC uses four (4) #12 (M6) screws on a bolt circle diameter (BCD)

of 3.873” (98.37 mm). The length of the screws will be determined by the thickness of the

mounting material plus 0.390” (9.9 mm) motor mounting flange thickness.

The maximum tightening torque of the screws is 7.8 lb-in (9 kg-cm). The following graphic

shows rotary mounting hole pattern.

�2.739

(�69.57)

Pilot diameter

Ø 2.874 (73.0)

Ø 3.873 (98.37)

0.256 (6.5) Thru 4 Places

on a 3.873 (98.37) Circle

Table of contents

Popular Cables And Connectors manuals by other brands

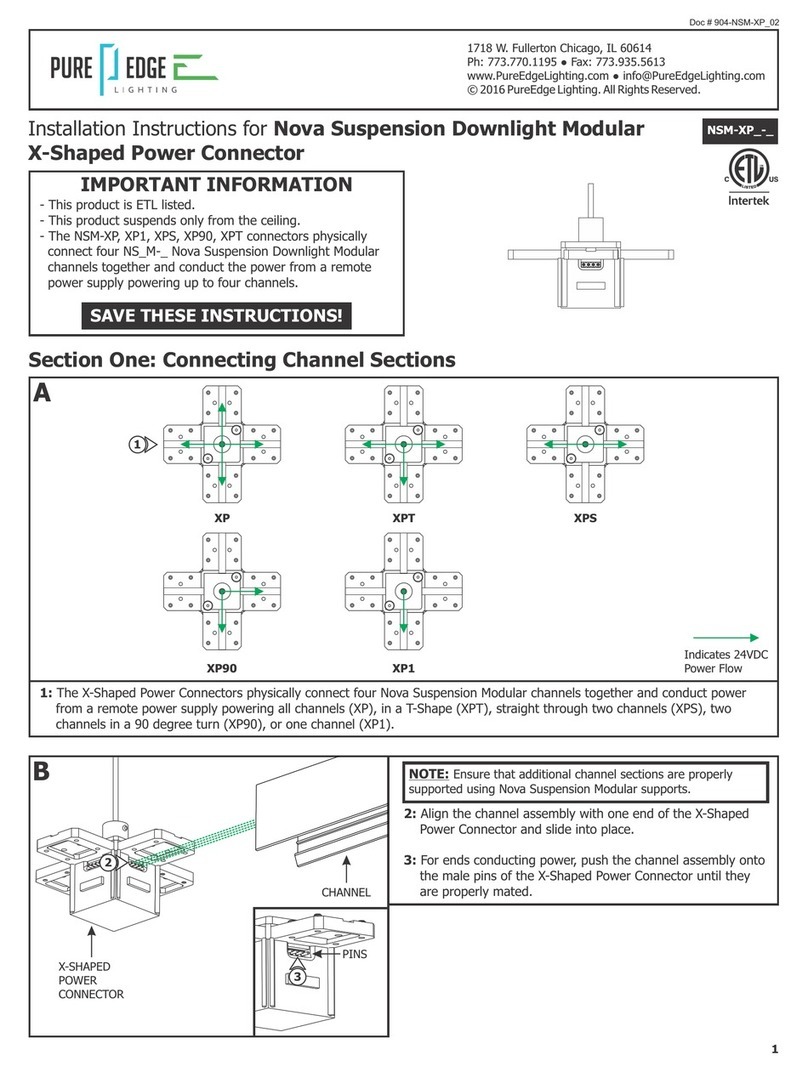

PureEdge Lighting

PureEdge Lighting NSM-XP Series installation instructions

PCB Piezotronics

PCB Piezotronics 010G50 Installation and operating manual

Extron electronics

Extron electronics MHRVGA Specification sheet

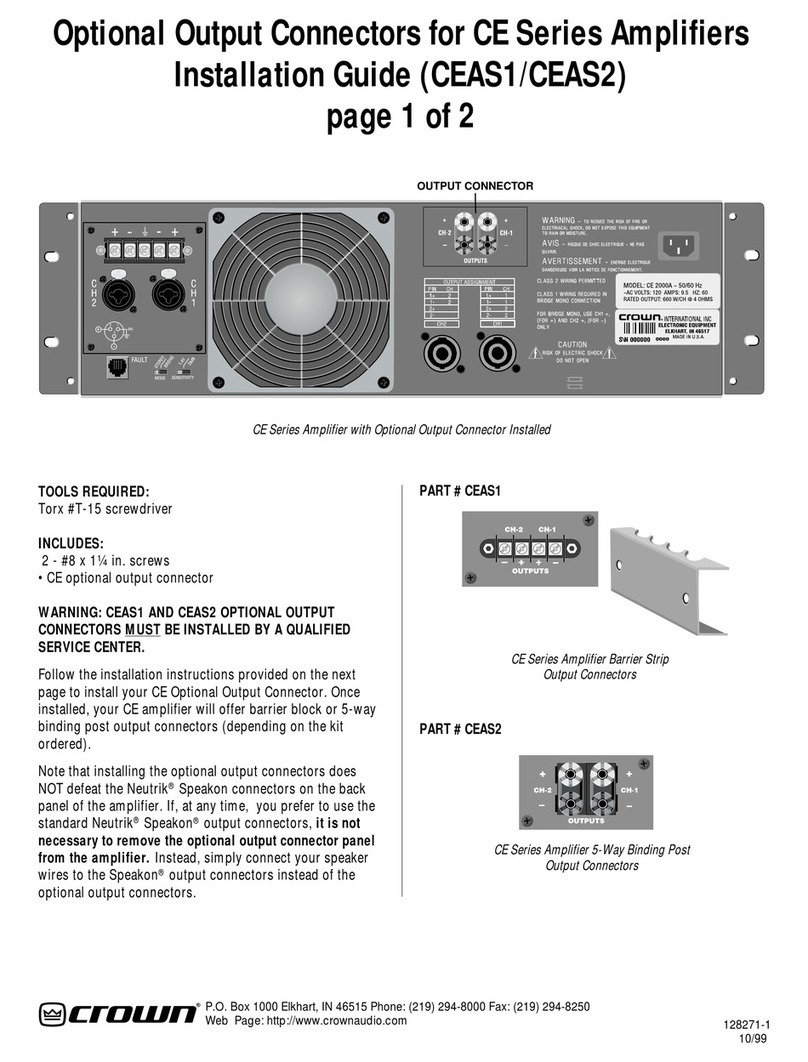

Crown

Crown CEAS1 installation guide

Philips

Philips SWA2797W Specifications

CommScope

CommScope FIST-RSKG-16 installation instructions