NovaTec VL Series User manual

© 2012 Novatec, Inc. All Rights Reserved Page 2 VL-VLP IM 10-24-2012

Models: VL-5, VL-12, VL-19, VL-38

VLP-5, VLP-12, VLP-19, VLP-38

VACUUM LOADERS

VL and VLP Series

DOCUMENT: VL-VLP IM 4-12-2013

VL-12 Model Pellet

and Regrind

Loader

VLP-38 Model

Powder Loader

VL-5-MM

Machine Mount

Pellet Loader

Mini PLC

Self - Contained

Loader Control

© NOVATEC, Inc. 2013 All Rights Reserved

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

2

NOTES:

Please record the following

information, which is specific to

this piece of equipment, in the

space provided. Our Parts/Service

Department will need these

numbers to properly respond to

any of your requests.

Instruction Manual: VL-VLP IM 4-12-2013

Model #:___________________________

Serial #____________________________

DISCLAIMER: NOVATEC, Inc. shall not be liable for

errors contained in this Instruction Manual nor for

misinterpretation of information contained herein.

NOVATEC shall not, in any event, be held liable for any

special, indirect or consequential damages in

connection with performance or use of this information.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

3

Table of Contents

1-PRINCIPLE OF OPERATION......................................................................................................4

2-UNPACKING AND INSPECTION ................................................................................................4

3-VL SPECIFICATIONS..................................................................................................................5

4-VLP SPECIFICATIONS ...............................................................................................................6

5-LOADER INSTALLATION...........................................................................................................7

5.1 CONTROL INSTALLATION .............................................................................................................. 7

6-OPERATION OVERVIEW ...........................................................................................................8

7-NO-LOAD ALARM FEATURE......................................................................................................8

8-ADJUSTING the LOADER CONTROL ........................................................................................9

8.1 TO CHANGE LOADING PARAMETERS........................................................................................ 9

8.2 PARAMETERS EXPLANATION....................................................................................................... 9

9-INITIAL START UP....................................................................................................................11

9.1 CONVEYING NOTES....................................................................................................................... 11

10-MAINTENANCE.......................................................................................................................12

10.1- VL Series - FLAT FILTER CLEANING:...................................................................................... 12

10.2- VLP Series - CARTRIDGE FILTER CLEANING: ..................................................................... 13

10.3- VACUUM MOTOR BRUSH REPLACEMENT........................................................................... 14

10.4- VL-12 through VL-38 and VLP-12 through VLP-38 MOTOR BRUSH REPLACEMENT.. 15

10.5- VL-5, VLP-5 MOTOR BRUSH REPLACEMENT...................................................................... 15

10.6- MOTOR REPLACEMENT............................................................................................................ 16

11-TROUBLESHOOTING.............................................................................................................17

12-WARRANTY –NOVATEC, INC. - Effective Date 6-12-2012...................................................18

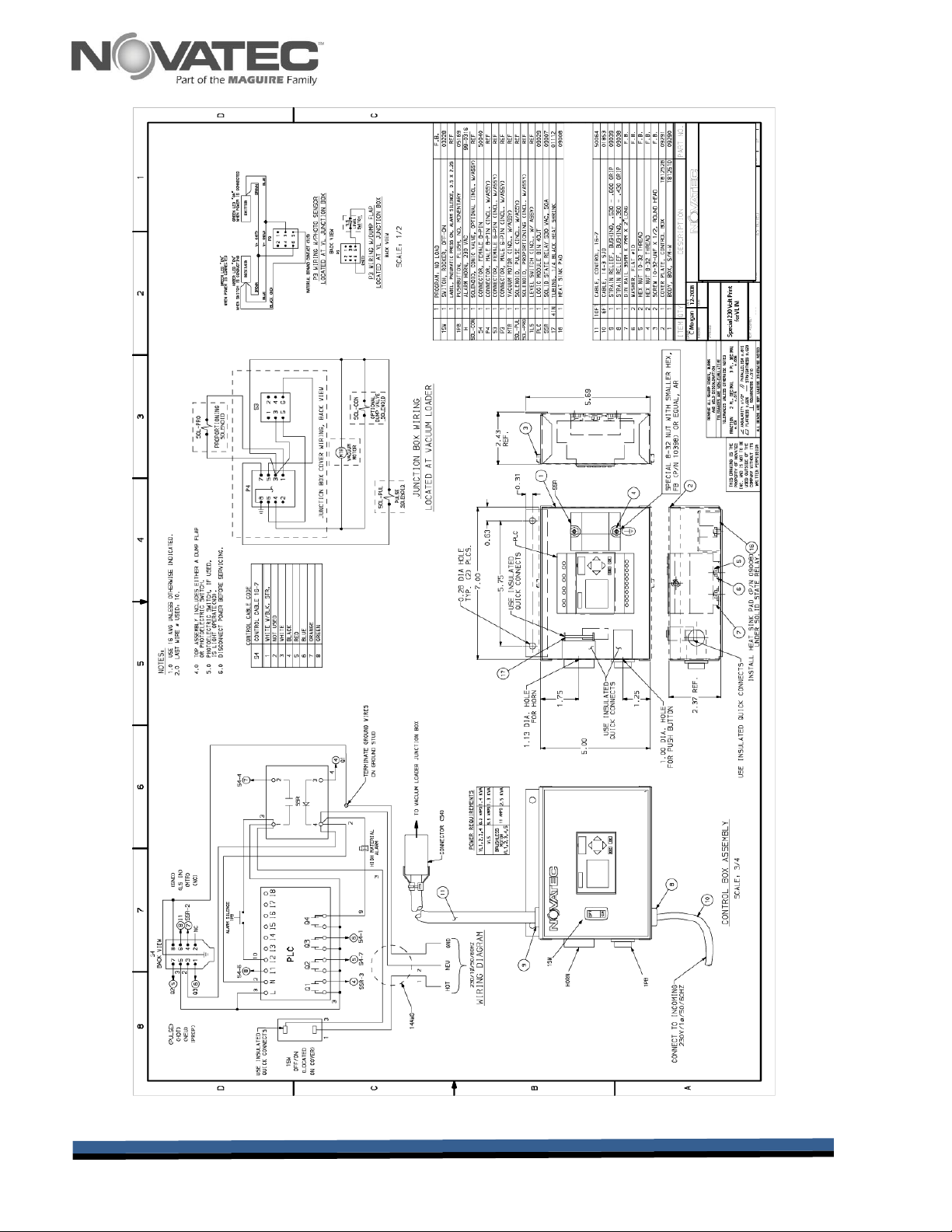

13- ELECTRICAL DRAWINGS.....................................................................................................19

14-VL SERIES LOADER PARTS LIST.........................................................................................21

15-VLP SERIES LOADERS PARTS LIST ....................................................................................22

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

4

1- PRINCIPLE OF OPERATION

NOVATEC vacuum loaders utilize a powerful motor to create a vacuum, which draws material into

a chamber. After the load time setting has expired, the vacuum motor is turned off and the

negative pressure in the chamber is relieved. Material in the chamber then falls through the

bottom, past the flapper while compressed air is pulsed through the filter to dislodge any

contaminants or fines that may have accumulated. This cycle is repeated as many times as

necessary, until the unit is shut off by the rise of the conveyed material in the area below the

loader which trips the level switch, removing the ‘demand’ signal.

Machine mounted units do not have a demand switch actuated by the discharge flapper valve, but

instead utilize a remote sensor for demand. The sensor is attached to an adjustable bracket that

slides along the length of a clear sight tube serving as a Just-in-Time (JIT) material hopper

mounted between the machine throat and loader discharge. The sensor height on the site tube

determines the level of material that triggers a demand for more material and a new load cycle.

The sensor may be either a capacitance style, with sensitivity adjustment, or a pair of

photoelectric sensors, an emitter and a receiver.

The bottom flange is normally supplied undrilled to allow the customer to drill the appropriate

mounting pattern for a particular machine.

2- UNPACKING AND INSPECTION

NOVATEC Vacuum loaders are shipped complete, with all controls for automatic operation. The

only utilities required are a 115 or 220 volt power supply (depending on voltage of control), and

clean, dry compressed air at approximately 80 PSI.

After receipt of the unit, completely inspect it for damage. Although the units are packaged

securely, vibration and mishandling during transit can cause damage.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

5

3- VL SPECIFICATIONS

NOVATEC VL Series vacuum loaders are completely automatic self-cleaning vacuum loaders

designed to convey virgin pellets and regrind materials from storage containers to drying hoppers

or directly to process machines.

Machine Mount Models with a sight glass are available as standards for all VL and VLP models.

Each unit is shipped complete with all controls for immediate operation, and include a hardware

package. The hardware package includes 15 feet of flexible vacuum hose, hose clamps and a

material pick up lance.

Options:

Additional tubing and fittings (Rigid tubing, elbows, bolted couplers, etc.)

Alternate sight glass sizes are available for most Machine Mount models.

220/1/50-60 Volt Power

Brushless Motor for VL-38

Accessories:

asVR-MM-8

asVR-MM-12

asVR-MM-16

8 lb. Sight Glass Conversion Kit

12 lb. Sight Glass Conversion Kit

16 lb. Sight Glass Conversion Kit

Conversion Kit to increase sight glass capacity for

VL & VLP-12 and -19 models. Includes base, borosilicate

glass, top adapter plate and discharge valve.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

6

NOVATEC VLP Series vacuum loaders operate in a similar manner to the VL’s, but are designed

to convey free flowing powders.

4- VLP SPECIFICATIONS

Options:

Additional tubing and fittings (Rigid tubing, elbows, bolted couplers, etc.)

Alternate sight glass sizes are available for most Machine Mount models.

220/1/50-60 Volt Power

Brushless motor for VLP-38

Accessories:

asVR-MM-8

asVR-MM-12

asVR-MM-16

8 lb. Sight Glass Conversion Kit

12 lb. Sight Glass Conversion Kit

16 lb. Sight Glass Conversion Kit

Conversion Kit to increase sight glass capacity for

VL & VLP-12 and -19 models. Includes base, borosilicate

glass, top adapter plate and discharge valve.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

7

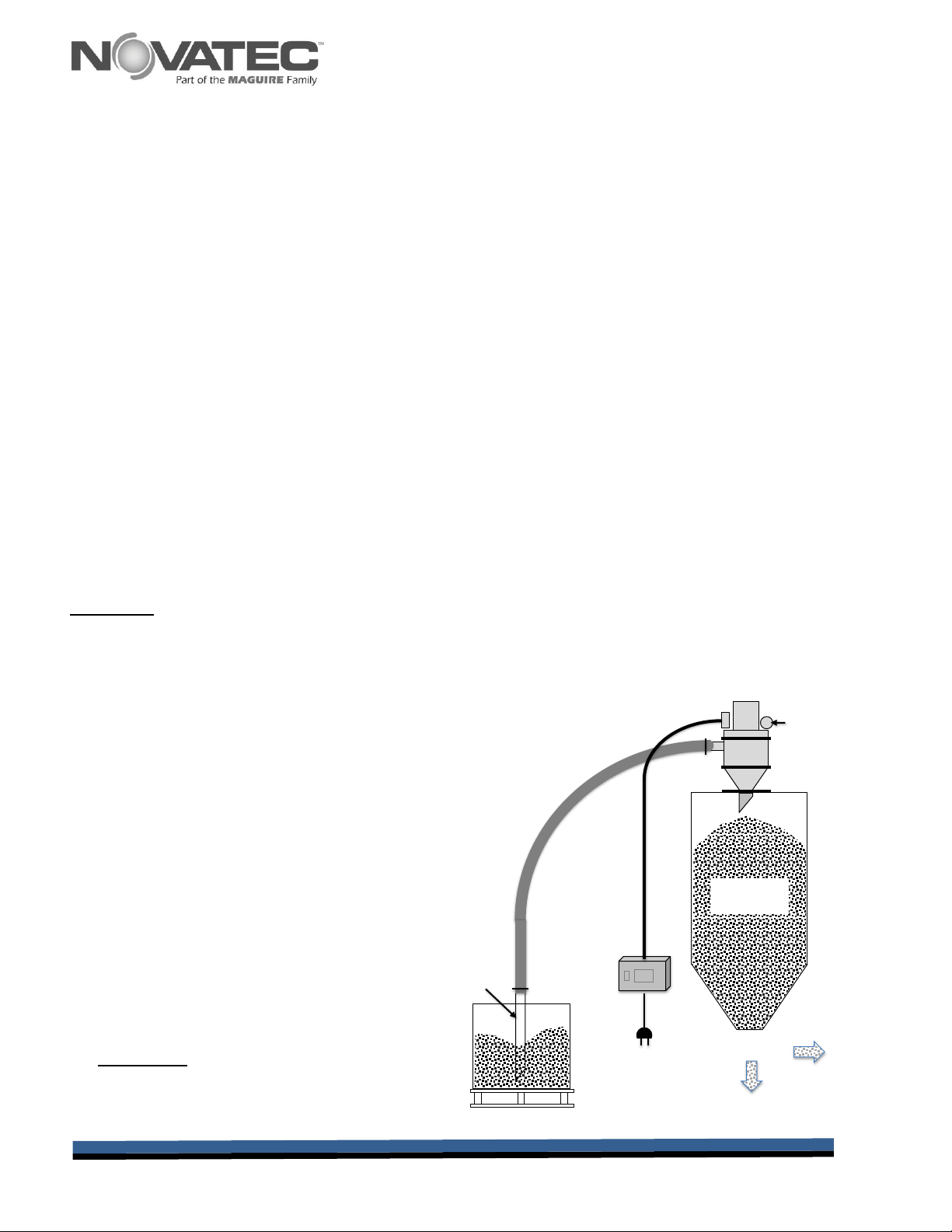

5- LOADER INSTALLATION

Mount the loader body to the hopper lid, positioning it so that the material inlet is directed towards

the material pick up point. Make sure the dump valve flapper plate has enough room to freely

operate. Secure the loader to the hopper lid with captive bolts or clamps to ensure a safe

installation with no chance of hardware vibrating loose.

On machine mounted units, the bottom flange is usually supplied undrilled to allow a range of

mounting patterns and hardware choices. A gasket is used to provide a tight seal between the

loader base and the machine throat.

Ensure a tight seal when securing the loader to the hopper or machine. This is particularly

important for VLP units that will be conveying powder. The conveying line should be horizontal

and/or vertical, using a 90 degree radius bend for directional changes, and it should be as direct

as possible with no slope. All line connections should be vacuum tight. Rigid conveying tubing

should be properly supported by the installer to provide a safe and secure installation. Use

flexible material handling hose to connect the material pick-up lance or vacuum take-off box to the

conveying line. The flexible hose should be only as long as needed, since excess hose will

reduce loader efficiency.

Connect a clean, dry compressed air supply line to the filter on the accumulator tank. The

minimum requirement for effective filter cleaning is 80 PSI.

CAUTION:

1. DO NOT EXCEED 125 PSI. COMPRESSED AIR.

2. PROPER SUPPORT OF ALL CONVEYING LINES AND A SECURE MOUNTING OF THE

HOPPER LOADER IS NECESSARY FOR A SAFE INSTALLATION.

5.1 CONTROL INSTALLATION

The VL/VLP control box may be

mounted in a location that is convenient

for the operator, making sure that the

control cable will extend to the junction

box on the lid of the hopper loader.

The power and connections cables

should be carefully routed away from

hot components or surfaces and away

from high voltage lines that may

produce undesirable electrical noise.

Connect the control to the power source

as required by the nameplate located

on the side of the loader control box.

CAUTION: FOLLOW ALL

NATIONAL and LOCAL

ELECTRICAL CODES.

To machine or

other destination

VL or VLP

Vacuum Loader

Loader

Control

Power

Source

Flex Hose

(supplied) and/or

rigid tubing

Pick-up Lance

Material

Destination

Material

Source

Compressed Air

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

8

6- OPERATION OVERVIEW

Pressing the OFF/ON switch will start the vacuum motor, creating vacuum suction through the

conveying line, to the pick-up wand and the loader will load material into the loader’s vacuum

chamber for an adjustable length of time.

When the load time is completed, the vacuum motor will stop, allowing material in the vacuum

chamber to relax and flow through the dump valve to the hopper or machine below.

Simultaneously, the filter will be cleaned with pulses of compressed air blown down through the

filter media. The dump time and the number of pulses used to clean the filter are adjustable.

Load and dump/pulse cycles will continue until the drying hopper, surge bin or machine hopper

below the loader is full, at which time loaded material will either hold the dump valve flapper open

or trigger a sensor, placing the system in a holding mode. As material is consumed by the

process and flows from the hopper below the loader, the material level will fall, the flapper will

close or sensor will be uncovered, and the loader will begin to load automatically again, to keep

the hopper full.

NOTE: Once the vacuum motor starts, a loading cycle will continue through the load, dump, and

pulse cycles, even if the dump flapper is held open. The loader control senses a full condition

only after the completion of the dump/pulse cycle.

7- NO-LOAD ALARM FEATURE

The No-Load alarm feature monitors the dump flapper on hopper mounted units, to assure it

opens as it should by material discharging after loading. If the flapper does not open 3 seconds

after the dump sequence has started, the no load alarm on the side of the control will sound. On

machine mounted units, the No-Load alarm monitors the photo-eye demand sensor on the glass

base to determine if loaded material interrupts the sensor path.

The alarm horn can be silenced with the silence pushbutton on the side of the control.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

9

No-Load Alarm Horn

Alarm Horn Silencer

8- ADJUSTING the LOADER CONTROL

The VL and VLP series

loaders from NOVATEC

employ a Siemens brand, model LOGO! Mini-PLC

Control for loading functions. The control is housed

in a rugged enclosure and is factory programmed for

functions related to vacuum loading.

NOTE: The user may adjust certain parameters of

the control to fine tune their loader’s operation, but

changing settings other than

those listed can damage

control operation.

The control is equipped with a small LCD screen that displays operating and programming

prompts, plus pushbuttons to aid in selecting parameters and making changes. A No-Load alarm

horn is located on the side of the enclosure along with a silence button.

Instructions listed here are repeated on the control face for ease of use.

8.1 TO CHANGE LOADING PARAMETERS

Press ESC key.

Select SET PARAM and press OK.

Use arrow buttons to select parameter from this list.

Press OK. Make changes by selecting desired digit.

Increase or decrease setting with up/down arrows.

When complete, press OK. Press ESC twice to exit.

8.2 PARAMETERS EXPLANATION

Motor-on Time (B3 T), measured in seconds, is the amount of time the vacuum motor will run to

load material into the loader’s vacuum chamber. Too little time will result in insufficient loading

and will shorten motor life with too many start/stop cycles. Too much time will pack the loader full

of material, prematurely blinding the filter and possibly clogging the conveying line. This setting

should be adjusted over the course of several normal loading cycles to ‘just fill’ (but not overfill)

the loader’s vacuum chamber. NOTE: VLP series powder loaders include an extended body to

house the cartridge filter(s). Loaded material should not be allowed to be filled up into this

extended hopper area. It is intended only as a housing for the filter cartridges(s), not a hopper for

collecting loaded material.

Dump Alarm Time (B4 T), measured in seconds, is the pause time between the completion of

Motor On Time and movement of the discharge flapper. This time setting drives the No-Load

alarm feature by determining if material was actually loaded and dumped, but prevents false

alarms from slow moving material discharge. This setting may be increased if nuisance alarms

occur from slow moving material (IE: fluffy regrind) that is typically slow to evacuate the loader. It

may be decreased if the No-Load alarm is too slow to respond to your material supply needs

(IE: frequent shortages of material flow).

PARAMETERS:

Motor-on Time B3 T

Dump Alarm Time B4 T

Dump Time B5 T

Blowback Count B11

Prop Valve A Time B16 T

Prop Valve B Time B18 T

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

10

Dump Time (B5 T), measured in seconds, is the setting for how long the loader will remain at rest

after loading, to allow material to evacuate the loader. This setting may be increased in case the

material is very slow moving and/or to provide an extended OFF period for the loader (IE: if the

loader is used to off-load a granulator).

Blowback Count (B11), is the number of blowback pulses that occur following loading for the

compressed air system to clean the filter(s). Compressed is blown down through the filters in the

opposite direction of the vacuum loading air, blasting collected fines and dust from the filter media

and into the loaded material. Typically, more blasts will clean the filters better and extend the

time between manual filter cleaning and provide more efficient loading. However, compressed air

is expensive and too many blasts waste this resource. Also, blasts that extend beyond the dump

sequence may actually be strong enough to create dusting issues around the loader.

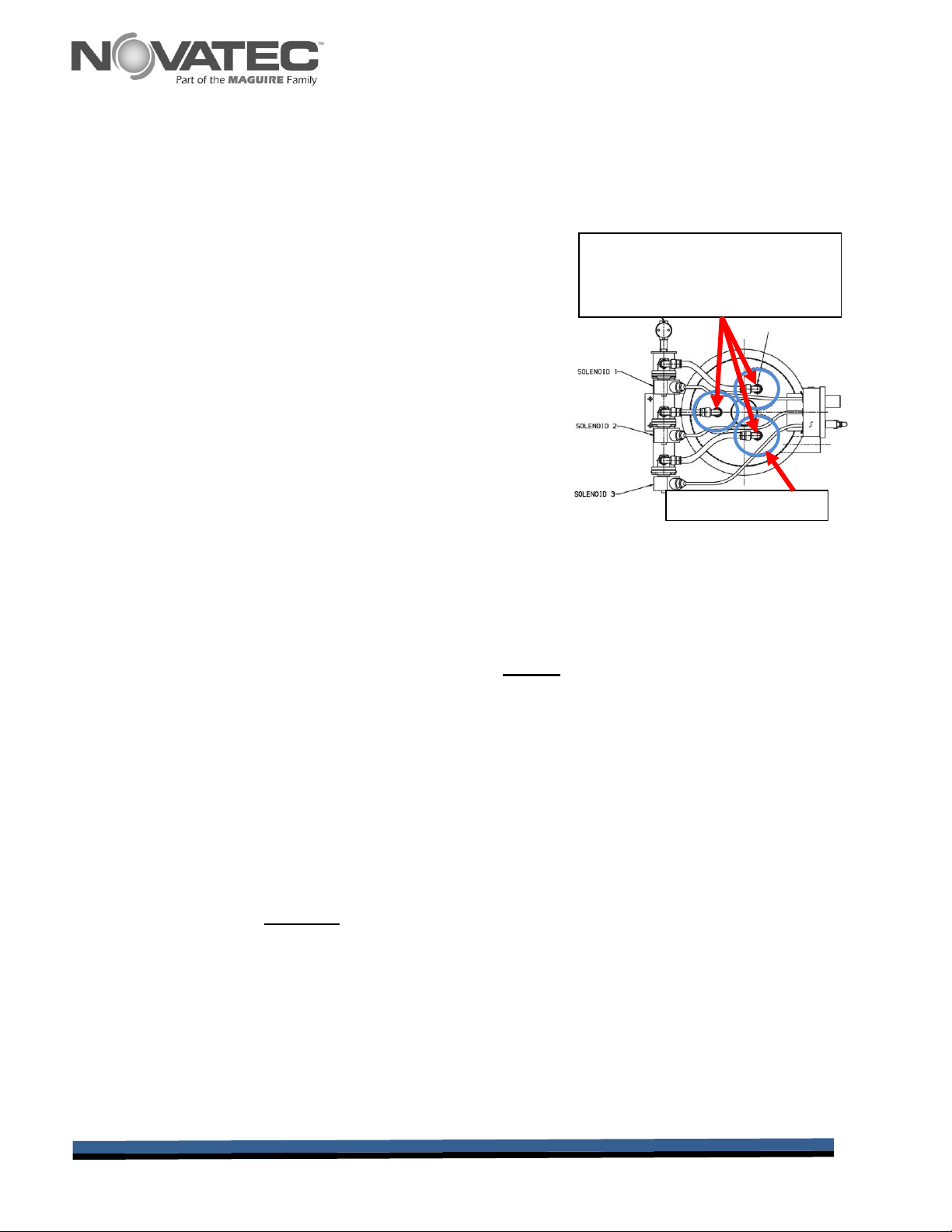

Prop Valve A Time (B16 T) and Prop Valve B Time (B18 T), each measured in seconds, is the

amount of time dedicated to the loading of two materials with the use of an optional, external

Proportioning Valve. The Proportioning Valve is installed on the material inlet of the VL or VLP

loader (see separate instructions, accompanying the valve) and shuttles internal plungers

between allowing A (typically virgin) and B (typically regrind) materials to be loaded during the

course of the Motor-On time. Time setting A counts down during loading at which time the valve

switches to allow the B time setting to take over. A and B will repeat until the Motor-on time

expires.

Short A and B time settings will allow multiple ‘layers’ of virgin and regrind materials to be loaded

for rough ‘mixing’ of the two materials during loading. However, short cycles require each flow of

material to start, then stop, possibly resulting in very little material being conveyed to the loader.

Trial and error settings of Motor-on time and A and B times are suggested to optimize these

settings.

9- USE OF PROPORTIONING VALVES

Proportioning valves are a convenient method for introducing regrind into the process while

vacuum loading of virgin material. The proportioning valve is typically installed onto the material

inlet of the receiver and is connected to the central control system, or an accessory control

specifically designed for proportioning valve operation.

Note that a proportioning valve should never be relied upon for accurate mixing of two materials,

but are only a process convenience for loading a second material (typically regrind). An ideal use

of a proportioning valve is emptying a granulator of reground material, in quantities known to not

exceed the limitations or specifications of the process.

If requirements for the proportioning

require more accuracy, consult with

your supplier regarding the use of a

blender in lieu of a simple

proportioning valve.

Solenoid: Connection to control

and connection to compressed

air supply.

Material #1 inlet,

typically Virgin

Material #2 inlet,

typically Regrind

Material Outlet, connected

to receiver Inlet

External Proportioning Valve

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

11

10- INITIAL START UP

For optimum loader operation, adjust the load time so that the vacuum chamber is almost

completely full at the end of the load cycle. Do not allow the chamber to overfill. NOTE: VLP

series powder loaders include an extended body to house the cartridge filter(s). Loaded material

should not be allowed to be filled up into this extended hopper area. It is intended only as a

housing for the filter cartridges(s), not a hopper for collecting loaded material.

Adjust the dump time so that it is only 1 to 2 seconds longer than the time necessary to

completely empty the chamber. The number of pulses needed to clean the filter depends upon

the material being conveyed. Clean, virgin pellets require minimum filter cleaning while very dusty

regrind or powder may necessitate a maximum filter cleaning sequence. Adjust the pulse cycle

so the filter(s) remain clean. A mid range setting is suggested as a starting point.

10.1 CONVEYING NOTES

Materials, which contain a large percentage of fines or powder, may require increased filter

cleaning. This can be achieved by the following technique.

A) Set the load time to minimum.

B) Set the dump and pulse time to maximum.

C) Increase the compressed air pressure. CAUTION: DO NOT EXCEED 125 PSI.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

12

Remove

Clamping Ring

Carefully

Remove Motor

Lid

11-MAINTENANCE

CAUTION: Disconnect electrical power and compressed air supplies before any type of

loader maintenance.

Typical maintenance for self-contained vacuum loaders consists of two main areas: Filter

cleaning and motor brush replacement.

11.1- VL Series - FLAT FILTER CLEANING:

VL Series loaders are typically used for conveying virgin pellets and/or regrind. The amount of

dust within the conveyed materials will determine the frequency of necessary manual filter

cleaning.

NOTE: Although the blowback system of the VL loaders will extend the operational life of the filter

media, it cannot be relied upon alone. Frequent checks of the filter accompanied by thorough

manual cleanings are required, in addition to cleanings during material changes to prevent cross

contamination.

The filter media may be removed for

inspection and cleaning by unclamping the

ring clamp of the lid, directly below the

motor. If necessary, unplug the control

cable and disconnect the air line.

Carefully remove the motor lid and expose

the flat filter directly below the lid. The filter may now

be removed for inspection and cleaning.

Vacuum cleaning the bottom of the filter is recommended to remove

collected resin debris, dust and fines. If compressed air is used, be sure to

wear goggles and blow from the top (coarse screen side) of the filter down

through the filter media. Never bang the filter against a hard surface to dis-

lodge debris. Distortion of the media or sealing ring can result.

Once clean, thoroughly inspect the filter for severe wear, holes, tears and material abrasion. Any

break in the filter media indicates the need for new filter. Do not attempt to repair the media.

Remember that the filter protects the vacuum motor and holes or any kind of leakage through the

filter can allow material to pass into and through the motor, severely shortening the motor’s life,

possibly creating a fire hazard and sending material dust into the air around the loader. In

addition, examine the sealing ring around the filter media. This ring provides the vacuum seal

between the motor lid, the filter and the loader body. The ring must be smooth, clean and intact

to provide a suitable seal for vacuum sealing. Replace the filter if the seal is not in perfect shape.

Once cleaning/inspection is complete, the filter may be reinstalled by

placing it on the flat rim of the loader body (cloth DOWN and coarse

screen UP) and placing the motor lid down upon it and centering the filter

between the two. Replace the clamp and tighten. With newly installed

filters, the clamp may need to be adjusted to provide a vacuum-tight and mechanically firm seal.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

13

Vacuum Cleaning

of filter(s) exterior

is recommended

If compressed air

is used, blow down

through inside of to

outside.

VLP Cartridge

Filter

11.2- VLP Series - CARTRIDGE FILTER CLEANING:

VLP Series loaders are typically used for conveying free flowing powder materials. For this task,

they are equipped with higher capacity cartridge filters. The amount of dust within the conveyed

materials will determine the frequency of necessary manual filter cleaning.

NOTE: Although the blowback system of the loader will extend the operational life of the filter

media, it cannot be relied upon alone. Frequent checks of the filter accompanied by thorough

manual cleanings are required, in addition to cleanings during material changes to prevent cross

contamination.

CAUTION: Disconnect electrical power and compressed air supplies before any type of loader

maintenance.

The cartridge filter(s) may be removed for inspection and cleaning by unclamping the ring clamp

of the lid, directly below the motor. If necessary, unplug the control cable and disconnect the air

line. Carefully remove the motor lid and expose the cartridge filter mounting plate directly below

the lid. The cartridge filter mounting plate, with the cartridge filter(s) installed below it may now be

carefully removed for inspection and cleaning.

If only light cleaning of the cartridge filter(s) is required,

the filter(s) may remain installed onto the filter plate and

cleaned in place. However, full removal and thorough

cleaning of each cartridge is highly recommended.

Vacuum clean the outside of the filter(s) to remove collected resin debris,

dust and fines. If compressed air is used, be sure to wear goggles and blow

from the inside of the filter(s) down through and out of

the filter media. Never bang the filter(s) against a hard

surface to dis-lodge debris. Distortion of the media or

sealing ring(s) can result.

Once clean, thoroughly inspect the filter(s) for severe wear, holes, tears and

material abrasion. Any break in the filter media indicates the need for new

filter cartridge. Do not attempt to repair the media. Remember that the filter

protects the vacuum motor and holes or any kind of leakage through the filter can allow material

to pass into and through the motor, severely shortening the motor’s life, possibly creating a fire

hazard and sending material dust into the air around the loader. In addition, examine the sealing

ring around the top of each filter cartridge. This seal provides the vacuum seal between the

cartridge filter and the filter mounting plate and must be fully intact. Replace the cartridge if this

seal is not perfect.

NOTE: Polyester filter cartridges, supplied as standard with all NOVATEC VLP loaders are

washable to extend their life. Use only clean water, sprayed at medium pressure through the

media from the inside out to remove dust and debris. The cartridge must be thoroughly dried

before being put back into service. A commercial drying device may be used, or the cartridge can

be thoroughly drained of water and water droplets and left to dry for no less than 24 hours.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

14

IMPORTANT: Make sure that

each blow down jet on the lid must

be centered over a cartridge filter

for effective blowback action.

Cartridge Filters (3)

Once each cartridge is cleaned, completely dry and inspected, it may be re-installed onto the filter

mounting plate in the same fashion it was removed. Examine the filter mounting plate to be sure

it is intact and its perimeter seal is smooth and clean since it will form a vacuum tight seal

between the motor lid, the filter mounting plate and the loader body. Replace the seal if it is not in

perfect shape.

Once filter cartridge(s) are mounted to the filter mounting

plate, it may be reinstalled by placing it on the flat rim of

the loader body with the cartridges down inside the

loader body. At this point, it is critical that each

cartridge filter is located directly below a blowback

nozzle that cleans it during the blowback sequence

(this step not required for single cartridge units). By

viewing the motor lid and the blowback nozzles on the

underside of it, the filter plate may be rotated into

proper position prior to placing the motor lid down upon

it and centering the filter between the two. Each blow

down jet on the lid must be centered over a cartridge

filter for effective blowback action. Replace the clamp

and tighten. With newly installed filter plate seals, the clamp may need to be adjusted to provide

a vacuum-tight and mechanically firm seal.

11.3- VACUUM MOTOR BRUSH REPLACEMENT

Brushes should be examined for wear and changed before the brush holder or non-brush

components touch the commutator of the motor. Estimated brush life is approximately 300

running hours under normal operating conditions. See next page for detailed brush changing

instructions. To achieve best performance, new brushes should be seated on the commutator

before full voltage is applied. The motor manufacturer recommends the following procedure:

After brush change, apply 50% to 70% of rated voltage for thirty minutes to accomplish the

seating. The motor will return to full performance after thirty to forty-five minutes of operating at

full rated voltage. The motor must not be run with the vacuum inlet sealed off.

Direct application of full rated voltage after changing brushes will cause arcing, commutator

pitting, and reduced overall life. However, if reduced voltage is unavailable; connecting two

motors of similar rating in series for thirty minutes will accomplish the proper brush seating.

CAUTION: Disconnect electrical power before any type of loader maintenance.

Removing the vacuum motor from the loader lid is recommended prior to changing brushes.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

15

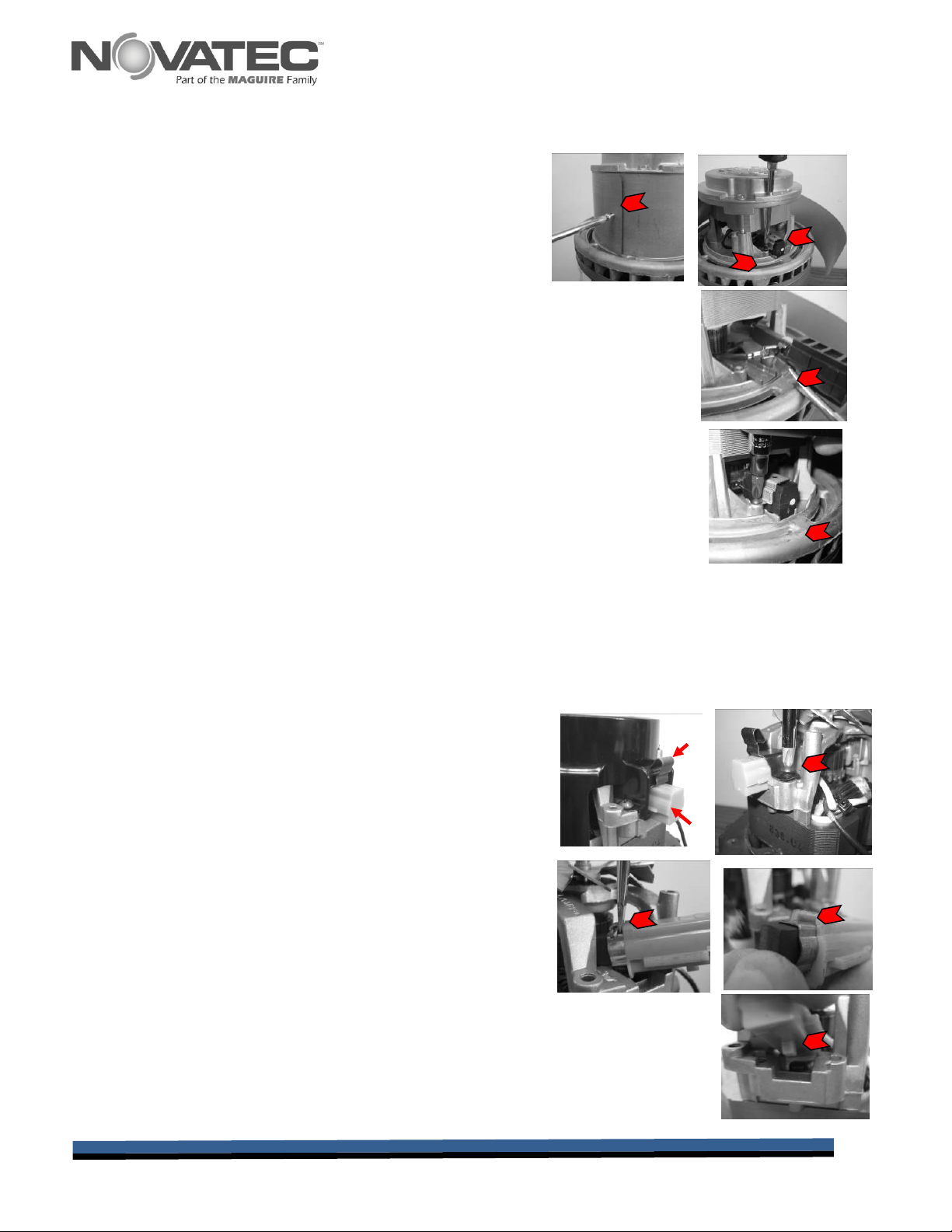

11.4- VL-12 through VL-38 and VLP-12 through VLP-38 MOTOR BRUSH

REPLACEMENT

1. Remove metal band from mid-section of motor

by unscrewing the sheet metal screw in the

side. Pull the cover back away from the motor,

sliding it gently over the wires that pass through

the grommet opposite the screw. The brushes

are visible inside, towards the base of the

motor.

2. Remove the screws on each side of each brush that hold the

brush retaining clip. A screwdriver may be inserted through the

holes in the top of the motor to aid in this process. Remove the

clip carefully to be sure nothing drops into the motor fan housing

opening towards the middle of the motor.

3. The brush is contained within a plastic holder and is connected to

the electrical lead through a spade lug terminal. Gently pull or pry

the lug off the brush holder taking care to not damage the lead or

the lug.

4. New brush may be installed by reversing the above steps. When

securing the brush in the motor housing with the retainer clip, be

sure the brush is properly nested in the motor frame before

securing the screws.

5. Repeat steps 2 thru 4 for the adjacent brush.

6. Replace the metal band onto the mid-section, while carefully routing the wires through the

grommet. It is notched to fit in only one position. Secure with single screw. Reinstall

cover over motor.

11.5- VL-5, VLP-5 MOTOR BRUSH REPLACEMENT

Remove metal cover from motor.

1. Remove plastic shield from top of motor by

squeezing the top of each spring clip (A) while

prying the cover up away from colored brush

holder (green-120 volts, red-220 volts). Cover

can be worked up and off, one side at a time.

Take care to not break small positioning stubs

and grip tabs (B) on the plastic cover.

2. Remove two black screws that hold down brush

retaining clip. Once removed, brush will be

released, but still connected to the short

electrical lead. Use caution to avoid damaging

the lead.

3. Pry electrical lug out of the brush holder in the direction of the motor

armature, taking care to not separate the wire from the lug.

4. New brush may now be connected to the electrical lead by reversing

this procedure. Push the lug firmly between the brass brush holder

and its plastic housing.

1

2

3

4

A

B

1

2

3

4

5

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

16

5. Reinstall new brush into motor housing and replace the retaining clip. Be sure to properly

seat the nub on the bottom of the brush holder into the motor housing groove.

6. Repeat steps 2 thru 5 for the adjacent brush.

7. Replace the plastic shield on top of the motor by aligning it on top of the motor and pushing

down until the spring clips on each brush snap into place.

8. Reinstall metal cover over motor.

11.6- MOTOR REPLACEMENT

Disconnect all power from the loader system. Disconnect the motor wiring from the junction box

located on the lid of the chamber. Remove the three springs that clamp the motor to the lid. The

motor can now be removed. Check the gasket that seals the vacuum motor to the lid and renew if

necessary. Reverse the above steps to install the vacuum motor. Connect power and verify that

the system is operating correctly.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

17

12- TROUBLESHOOTING

Most loader problems are a result of a dirty filter, air leaks or improper adjustments. These items

should be checked before assuming equipment failure.

Problem Investigate

Motor will not run A, B, C, H, and L

Inadequate or no vacuum D, E, F, G, J

Inadequate or no material flow D, E, F, and G, I, K

Motor runs but proportioning solenoid not operating L

CHECK CONDITIONS SOLUTION

A. Power Supply No voltage or voltage incorrect Check incoming power supply

voltage at outlet

B. Stop/Start Switch No voltage through switch Replace switch

C. Vacuum motor No voltage at motor See A,B, & L

D. Filter Filter dirty Replace filter

(Also see G & J)

E. Air Ducts Obstructed Remove obstruction

F. Leaks in system Air leaking into system Replace gaskets & repair

leaks as necessary

G. Blowback air Increase pressure

pressure incorrect Low pressure (not to exceed 125 psi)

H. Limit switch No voltage through switch Replace switch

I. Load Time Chamber not filling sufficiently Increase load time

Chamber over-filling Decrease load time

J. Pulse rate Insufficient to clean filter Increase rate

K. Dump time Insufficient to allow complete Increase time

emptying of chamber

L. Pulse solenoid Correct voltage at solenoid Replace solenoid

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

18

13- WARRANTY –NOVATEC, INC. - Effective Date 4-10-2013

NOVATEC, INC. offers COMPREHENSIVE PRODUCT WARRANTIES on all of our plastics auxiliary equipment. We

warrant each NOVATEC manufactured product to be free from defects in materials and workmanship, under normal

use and service for the periods listed under “Warranty Periods”. The obligation of NOVATEC, under this warranty, is

limited to repairing or furnishing, without charge, a similar part to replace any part which fails under normal use due to

a material or workmanship defect, within its respective warranty period. It is the purchaser’s responsibility to provide

NOVATEC with immediate written notice of any such suspected defect. Warranted replacement parts are billed and

shipped freight pre-paid. The purchaser must return the suspect defective part, freight prepaid and with identifying

documentation to receive full credit for the part returned. NOVATEC shall not be held liable for damages or delay

caused by defects. No allowance will be made for repairs or alterations without the written consent or approval of

NOVATEC.

The provisions in equipment specifications are descriptive, unless expressly stated as warranties. The liability of

NOVATEC to the purchaser, except as to title, arising out of the supplying of the said equipment, or its use, whether

based upon warranty, contract or negligence, shall not in any case exceed the cost of correcting defects in the

equipment as herein provided. All such liability shall terminate upon the expiration of said warranty periods. NOVATEC

shall not in any event be held liable for any special, indirect or consequential damages. Commodities not

manufactured by NOVATEC are warranted and guaranteed to NOVATEC by the original manufacturer and then only

to the extent that NOVATEC is able to enforce such warranty or guaranty. NOVATEC, Inc. has not authorized anyone

to make any warranty or representation other than the warranty contained here. Non-payment of invoice beyond 90

days will invalidate the warranty. A renewed warranty can be purchased directly from NOVATEC.

Please note that we always strive to satisfy our customers in whatever manner is deemed most expedient to overcome

any issues in connection with our equipment.

Warranty Period:

Note: All warranty periods commence with the shipment of the equipment to the customer.

VL & VLP Series Loaders = 2 Years

Exclusions:

Routine maintenance/replacement parts are excluded from the warranty. These include, but are not limited to: hoses,

desiccant, filters, filter elements, wiper seals, gaskets, dew point sensors, infrared lamps, motors, internal solenoids,

fuses and motor brushes. Use with abrasive materials will void the warranty of any standard product. Wear resistant

options may be available to extend usable service life with abrasive materials. NOVATEC reserves the right to limit the

warranty if the customer installs replacement parts that do not meet the specifications of the original parts supplied by

NOVATEC.

*Specific Exclusions:

1. NovaDrier warranty is void if coalescing filters are not replaced on a 6-month or yearly basis (per instruction manual)

and/or membrane has been exposed to ozone.

2.Touch screen controls on NovaWheel dryers have a 2-year warranty. All other controls have a 1-year warranty

3. NovaVac Dryer -The ability of the canisters to hold vacuum will be compromised if the vacuum seal edge is

damaged from mishandling. We do not warranty canisters damaged from improper handling. We do, however,

warranty the seals.

4. LOAD CELLS on our WSB’s are covered by NOVATEC standard warranty as long as they have not been damaged

from improper handling.

5. Velocity Control Valve warranty is voided if unit is placed in direct material flow.

This warranty shall not apply to equipment:

1. Repaired or altered without written approval of NOVATEC unless such repair or alteration was, in our judgment, not

responsible for the failure

2. Which has been subject to misuse, negligence, accident or incorrect wiring by others

3. Warranty is void if processing rates exceed manufacturer-recommended levels or if damage is caused by

ineffective power isolation and/or power spikes/sags or incorrect installation.

NOTE: All conditions and content of this warranty are subject to changes without notice.

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

19

14- ELECTRICAL DRAWINGS

VL/VLP Series

115 V. LOGO Control

Wiring Diagram

© NOVATEC, Inc. 2013 All Rights Reserved VL-VLP IM 4-12-2013

20

VL/VLP Series

230 V. LOGO Control

Wiring Diagram

This manual suits for next models

9

Table of contents