NSK Primado2 User manual

1

Read these safety precautions thoroughly before use and operate the product properly.

These indicators are to allow you to use the product safely, prevent danger and harm to you and others. These are classified by degree of danger, damage

and seriousness. All indicators concern safety, therefore be sure to follow them.

These Attachments/Handpieces are to be used exclusively with Primado2, our surgical operation control units.

We recommend that prior to use, you carefully read this document regarding instructions for use, handling method, or maintenance check so that you can

carry on using the Attachments/Handpieces in the future. In addition, keep this operation manual in a place where a user can refer to it at any given time.

Cautions for handling and operation

Class

Degree of Risk

Danger

Hazard that could result in personal death or serious injury if the safety instructions are not correctly

followed.

Warning Hazard that could result in serious injury or damage to the device if the safety instructions are not correctly

followed.

Caution

Hazard that could result in light or moderate injury or damage to the device if the safety instructions are not

correctly followed.

Notice General product specification information highlighted to avoid product malfunction and performance

reduction.

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 1 2017/10/16 11:10:32

2

Intended to use

●Only qualified persons are allowed to use these Attachments/Handpieces for bone operations (bone removal, cutting, perforation and formation).

Danger

●Do not use this product in a room where there is a danger of explosion or in the vicinity of flammable substances. It is especially important not to use this

product on a patient to whom a flammable anesthetic agent (dinitrogen monoxide) has been administered.

●Never disassemble nor tamper with the mechanism. Personal injury, electric shock or fire may result.

Warning

●When operating the product always consider the safety of the patient.

●This is a medical system ; do not allow anybody to use it other than surgeons who are familiar with the procedures. Use this system in accordance with its

intended use and proper method of use.

●This system may be affected when used in rooms with electromagnetic interference and portable or mobile RF communication equipments. Do not use this

system around any equipment that generates electromagnetic waves such as an ultrasonic generator or electrical scalpel. In case equipment generating

electromagnetic waves are used around this system, turn off the Control Unit.

Caution

●U.S. Federal law restricts this device to sale by or on the order of a licensed physician.

●Read these safety cautions thoroughly before use.

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 2 2017/10/16 11:10:32

3

Caution

●The Attachments/Handpieces are not sterilized before delivery. Therefore, be sure to sterilize them prior to use.

●Prior to use, always operate and inspect the device with care for vibration, noise, and heat. If anything unusual is found, do not use. Contact your dealer.

●Should the product function abnormally, cease operation immediately and return the Attachment/Handpiece to your dealer for repair.

●Do not contact the latch or twist collet during rotation.

●Do not allow any impact on to the product. Do not drop the product. Personal injury, abnormal heating and fire may result caused by the internal damage.

●Do not use bent, damaged or deformed burs or drills that are not suitable for the Attachment/Handpiece. The Attachment/Handpiece may not match and it

may break or cause injury/malfunction.

●Always keep bur/drill shanks clean. Dirt or debris in a chuck could cause poor bur/drill concentricity or low chuck retention force.

●Turn off the power when mounting or removing the motor and Attachment/Handpiece. Mounting or removing it with the power on may cause personal

injury due to an unexpected rotation.

●Use new a bur or drill for every surgical operation.

●Do not clean the product with solvents such as thinner or benzine solution. Discoloration or deformation may result.

●The temperature at the tip of the Attachment/Handpiece may reach up to 60°C depending on the environment.

Notice

●The user shall be responsible for maintenance and operation.

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 3 2017/10/16 11:10:32

4

Latch

Irrigation Nozzle

Twist Collet

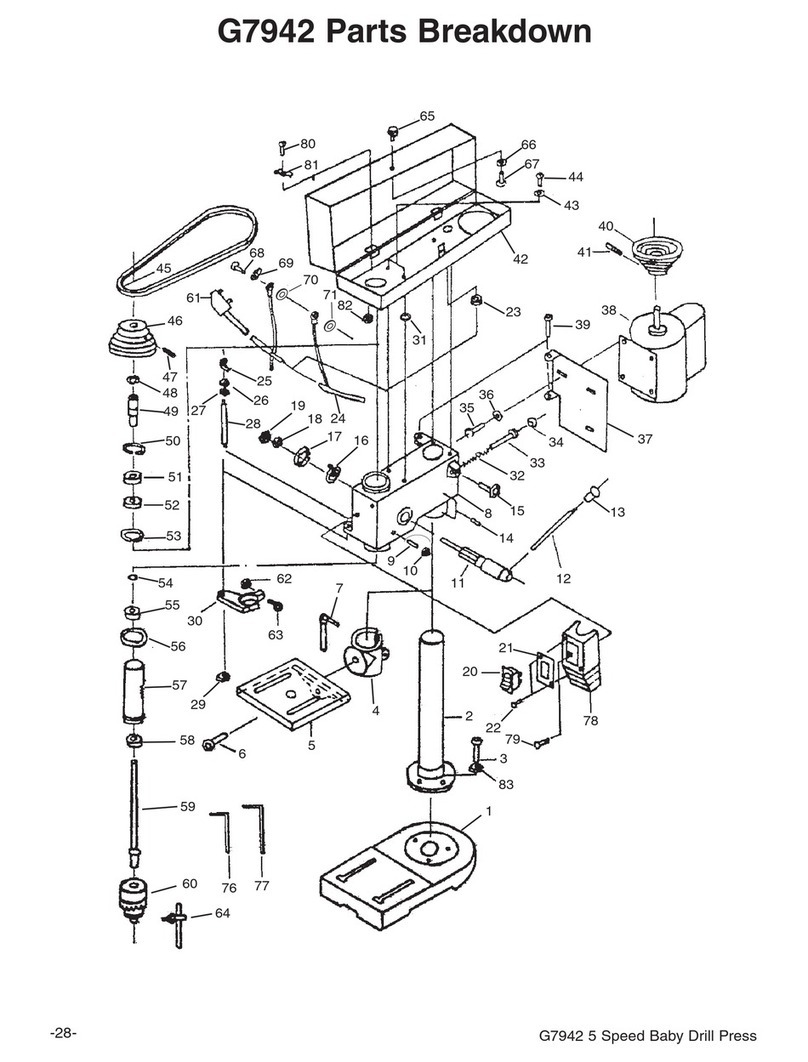

1Parts Names

* The figure shows type PD-CA-16. * The figure shows type PD-2ADM.

<Contra Angle Handpiece> <Drill Handpiece>

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 4 2017/10/16 11:10:33

5

Conduct pre-use checks by the following procedure to confirm that there are no abnormalities.

1) Mount a bur or drill.

2) Operate the Attachment/Handpiece at the rotational speed permissible for bur or drill mounted and confirm that there is no looseness, abnormal vibration,

abnormal heating or abnormal noise. If any abnormality is observed, stop using it and request your dealer for a repair.

3) Ensure there are no abnormalities before use.

2Check before treatment

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 5 2017/10/16 11:10:33

6

Fig. 1

Micromotor

Attachment /

Handpiece

Alignment PinAlignment Hole

1) Push the Attachment/Handpiece into the Micromotor straight without twisting.

2) Turn the Attachment/Handpiece either clockwise or counterclockwise so that the Alignment Pin aligns,

then push it in till it clicks to connect firmly.

* For removing, pull out the Attachment/Handpiece straight without twisting.

●When mounting or removing the Attachment/Handpiece, set the Safety Lock to “OFF” on the Hand Switch of the Micromotor (Micromotor

with Hand Control).

●Refer to the Operation Manual of Micromotor.

●Prior to mounting/removing the Attachment/Handpiece, remove the bur or drill. Otherwise, injury might occur.

●After mounting the Micromotor and Attachment/Handpiece, confirm that they are connected properly.

CAUTION

3Connecting / Disconnecting Motor and Attachment / Handpiece

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 6 2017/10/16 11:10:33

7

●Use only burs and drills specified by NSK. The use of other burs and drills may cause a fault or an accident.

●Use burs and drills that are suitable for the Attachment/Handpiece. The use of unsuitable burs and drills may cause a fault or an

accident.

●After mounting a bur or drill, pull it lightly to confirm that it is securely connected.

●Before use, confirm that the bur or drill does not come off by operating the Attachment/Handpiece.

●Do not operate the Attachment/Handpiece when a bur or a drill is not mounted.

●Remove the bur or drill from the Attachment/Handpiece after the rotation of the Micromotor has completely stopped.

CAUTION

4Mounting and Removing Burs and Drills

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 7 2017/10/16 11:10:33

8

Fig. 2

Fig. 3

OPEN

CLOSE

Contra Angle Handpiece

For the bur, use a commercially available Ø2.35mm contra bur.

<Mounting>

1) Slide the Latch in the direction of “OPEN” (Fig. 2).

2) Match the notch of the bur to the corresponding part of the shaft and push the bur all the way

through (Fig. 3).

3) Slide the Latch in the direction of “CLOSE” to set the bur in place (Fig. 2).

<Removing>

1) Slide the Latch in the direction of “OPEN” to remove the bur.

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 8 2017/10/16 11:10:33

9

Fig. 4

Fig. 5

OPENCLOSE

Drill Handpiece

<Mounting>

1) Turn the Twist Collet in the direction of ‘ ’ until it clicks (Fig. 4).

2) Insert the Bur or Drill through the tip of the Attachment/Handpiece all the way, twisting it slightly

with your fingers.

3) Turn the Twist Collet in the direction of ‘ ’ until it clicks (Fig. 4) to connect the Bur/Drill firmly.

After mounting the Bur/Drill, confirm that it is firmly connected by pulling it lightly.

Chuck Closed Chuck Open

●Insert the Bur/Drill all the way through the Attachment/Handpiece for a firm

connection. If it is not connected firmly, the Bur/Drill may come off during a surgical

procedure and interrupt it.

●When the Bur/Drill is firmly mounted, confirm that ‘ ’symbol and ‘ ’symbol are

aligned.

CAUTION

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 9 2017/10/16 11:10:34

10 Fig. 6

Irrigation Nozzle Irrigation Tube

Contra Angle Handpiece

1) Insert the Irrigation Tube onto the Irrigation Nozzle (Fig. 6).

* Irrigation nozzle is included in Contra Angle Handpiece as standard equipment.

<Removing>

1) Turn the Twist Collet in the direction of ‘ ’ till it clicks (Fig. 4).

2) Pull the Bur/Drill through the tip of the Attachment/Handpiece straight without twisting.

●Mount the Irrigation Nozzle to the Attachment/Handpiece after removing the Bur/Drill.

●Do not use irrigation nozzles other than those specified by NSK.

●Also see the Operation Manuals of Primado2 Control Unit.

CAUTION

5Mounting Irrigation Nozzle

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 10 2017/10/16 11:10:34

11

Fig. 7

Fig. 8

Irrigation Nozzle

Irrigation Nozzle Irrigation Tube

Drill Handpiece

1) Insert the Irrigation Nozzle onto the Bur Guard of the Attachment/Handpiece, making sure the correct

end of the Irrigation Nozzle goes in (Fig. 7).

2) Insert the Irrigation Tube onto the Irrigation Nozzle (Fig. 8).

3) For the related connection and the setting of the Control Unit, see the Operation Manual of Primado2.

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 11 2017/10/16 11:10:34

12

6-1 Preparation before cleaning

1) Remove the Bur/Drill from the Attachment/Handpiece. Dispose the Bur/Drill as it cannot be reused. For the disposal of the commercially available bur,

follow the instructions of its manufacturer.

2) Remove the Attachment/Handpiece from each Micromotor.

3) Confirm that there are no abnormalities or damage or deterioration in its appearance. Confirm that the connection part of the Micromotor is not damaged

or broken.

6-2 Cleaning

1) Clean the surface of each component product, using a lint-free cloth or brush moistened with a neutral detergent for medical treatment. Do not use a

wire brush.

2) Remove the detergent from the surface using a lint-free cloth moistened with distilled, deionized or demineralized water.

●Perform cleansing and sterilization after every use.

●Clean and lubricate the Attachment/Handpiece before autoclaving. Autoclaving the Attachment/Handpiece stained with blood or debris

could cause damage to the Attachment/Handpiece.

●In order to prevent infection, wear a mask, rubber gloves and glasses.

CAUTION

6Cleaning / Sterilization

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 12 2017/10/16 11:10:34

13

6-3 Washing

The Attachment/Handpiece can be washed via Thermo Disinfector.

Disinfect either by using a Thermo-Disinfector or by soaking.

6-3-1 Auto disinfection (It is recommended to use a thermo disinfector compatible with ISO 15883)

The following conditions are recommended for Thermo Disinfector ;

a. Cleaning : at 45°C for 3 minutes

b. Intermediate rinse : At least 1 minute (using distilled, deionized or demineralized water)

c. Thermal disinfecting : at 93°C for 5 minutes (using distilled, deionized or demineralized water)

d. Drying : at least 10 minutes

●Prior to use of Thermo Disinfector, read carefully the Operation Manual of Thermo Disinfector.

CAUTION

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 13 2017/10/16 11:10:35

14 Fig. 9

Attachment /

Handpiece EZ Spray Grip

Release Button

6-3-2 Manual disinfection

1) Soaking : Soak the Attachment/Handpiece in a neutral enzymatic detergent.

Example : For 20 to 30 minutes at 40 to 50°C. (Follow the time and temperature recommended by the manufacturer of the neutral enzymatic detergent)

2) Rinse : Remove debris and detergent from the Attachment/Handpiece by rinsing with distilled, deionized or demineralized water.

3) Drying : Wipe the Attachment/Handpiece dry with a lint-free cloth.

6-4 Lubrication

Lubricate the Attachment/Handpiece using separately sold EZ Spray (Order Code : PD-EZ-M) /E-Type

Spray Nozzle (Order Code : Z019090) and PANA SPRAY Plus (Order Code : Z182600).

1) When using EZ Spray

Push the EZ Spray Grip into the rear part of the Attachment/Handpiece and turn either clockwise or

counterclockwise. When the Alignment Pin clicks into position, the Spray is securely connected.

(Fig. 9)

When using E-Type Spray Nozzle

Insert the E-type Spray Nozzle into the PANA SPRAY Plus.

Insert the E-type Spray Nozzle into the rear part of the Attachment/Handpiece.

2) Spray until the oil coming out of the tip of the Attachment/Handpiece is clear of any debris or foreign

substance (approximately 3 seconds).

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 14 2017/10/16 11:10:35

15

3) Remove the Attachment/Handpiece by depressing the Release Button on the EZ Spray Grip (when using EZ Spray).

6-5 Sterilization

Autoclavable products : Contra Angle Handpiece, Drill Handpiece, Irrigation Nozzle.

We verify the effectiveness of product sterilization under the following conditions.

1) By placing the autoclavable products in a Primado Sterilization Cassette.

2) Autoclave under the following conditions ;

• Pre-vacuum Autoclave : at 134°C for 3 minutes or longer

• Gravity-displacement Autoclave : at 132°C for 15 minutes or longer

●Continue spraying PANA SPRAY Plus until it comes out clear at the tip of the Attachment/Handpiece. Due to its structure, PANA SPRAY

Plus comes out from the tip of the Attachment/Handpiece and the Twist Collet part. To prevent the dispersal of the lubrication oil in the

surrounding area, it is recommended to use a Spray Mist Absorber (Order Code: Y900084).

●Shake the PANA SPRAY Plus well before use.

●After cleaning and prior to sterilization, check the Attachment/Handpiece in the same method as in Step “2. Check before treatment”.

CAUTION

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 15 2017/10/16 11:10:35

16

6-6 Storage

Store the sterilized Attachment/Handpiece in a place where it can be kept sterile until the next use.

●The sterilization parameters are indicated for sterilization and immediate use only.

●Attachment/Handpieces cannot be sterilized using the EOG sterilization method.

●Sterilize Attachments/Handpieces after each patient.

●Do not use a chlorinated cleaner.

●Do not clean Attachments/Handpieces by an ultrasonic cleaning apparatus.

●Do not clean Attachments/Handpieces by a washer sterilizer.

●For detailed information for washing and sterilizing the Micromotor, refer to the Primado2 Micromotor Operation Manual.

CAUTION

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 16 2017/10/16 11:10:35

17

If you are suspecting any faults, check the following once again prior to asking for repair work. If none of these cases is applicable or if the situation does not

improve despite your efforts or measures, the damage could be serious ; call your dealer to fix the problem.

Symptoms Causes/Points of checking Countermeasures

Cannot be connected to the Micromotor. The Alignment Pin is not in position. Turn further till the Alignment Pin aligns, then push

further to connect to the Micromotor.

Abnormality of the Removal part. Contact your dealer.

The Bur or Drill cannot be firmly mounted. The Bur or Drill has not been inserted deep

enough.

Insert the Bur/Drill all the way through.

The Twist Collet/Latch is in ‘OPEN’. After inserting the bur/drill, fasten the Twist Collet/

Latch.

Abnormality of the Twist Collet/Latch. Contact your dealer.

No rotation when the Bur or Drill has been

securely mounted.

The Twist Collet/Latch is in ‘OPEN’. After inserting the Bur/Drill, fasten the Twist Collet/

Latch.

· The bearing has overheated.

· Foreign materials inside.

· The bearing has worn out.

Contact your dealer.

7Troubleshooting

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 17 2017/10/16 11:10:35

18

Symptoms Causes/Points of checking Countermeasures

Overheating (during operation). Continuous operation for a long period of time. Wait until handpiece cools down.

· The bearing has overheated.

· Foreign materials inside.

· The bearing has worn out.

Contact your dealer.

Abnormal vibration and noise.

Bur run-out.

· The bearing has overheated.

· Foreign materials inside.

· The bearing has worn out.

Contact your dealer.

OM-SH0081E_Primado2 Surgical Drill Attachment_EN_for FDA_140124.indd 18 2017/10/16 11:10:35

Other manuals for Primado2

5

Table of contents

Popular Drill manuals by other brands

Ryobi

Ryobi R12DD-LL13S Original instructions

Power works

Power works XB 20V DDG303 Operator's manual

Craftsman

Craftsman CMCD713 instruction manual

Buffalo Tools

Buffalo Tools PS07216 Assembly & operating instructions

XPOtool

XPOtool 64076 Operation manual

Bosch

Bosch GSH 11 E Professional operating instructions