Page 9

Model NG2 Revision 210798A

Check that the Low Gas Pressure switch is set to

minimum. Fit a manometer or other approved pres-

sure measuring instrument to the test point on the

downstream side of the gas valve. Open the up-

stream manual isolating valve approximately 15 to

20 deg and switch on the burner. With the fan

running, make a mental note of the pressure and

look for an increase in pressure during the ignition

stage. If no increase in pressure is detected then

increase the governor setting and restart the burner.

Note that it may be necessary to re-cycle the burner

a few times to purge air from the pipework. When

the flame is established, the flame relay is ener-

gised by the flame detection circuit and the burner

continues to run on main flame.

Make a quick visual check on the flame stability

and if it is O.K. then slowly open the manual gas

valve to the fully open position whilst checking for

excessive CO. Adjust the combustion air setting if

necessary to maintain the combustion figures within

acceptable limits.

Setting Main Flame Gas Rate

With the manometer still attatched, the main flame

gas rate can be set. Adjust the governed pressure

to that shown in the Gas Governor Settings table.

Check the gas flow rate at the meter. Ensure that

other appliances served by the same meter are iso-

lated when the flow tests are carrried out. Adjust-

ments to the governor setting can now be made to

obtain the required flow rate.

Combustion Air Settings

With the gas flow rate set and the burner running

with stable flame, the flue gases can be checked

for C02 and 02with suitable combustion testing in-

struments. Acceptable figures are given in the Al-

lowable Combustion Analysis table. For safety rea-

sons, the CO should not exceed 93 ppm. To

achieve good combustion efficiency, or if the CO

content is exceeded, adjustments to air and gas

can be made whilst the burner is on main flame.

To adjust the air flow, loosen the retaining screw

on the rotary air strap situated on the right hand

side of the burner. To increase the flow of air, turn

the air strap anti-clockwise as viewed from the right

hand side. To decrease combustion air flow, turn

the rotatry strap clockwise. Tighten the retaining

screw after each adjustment.

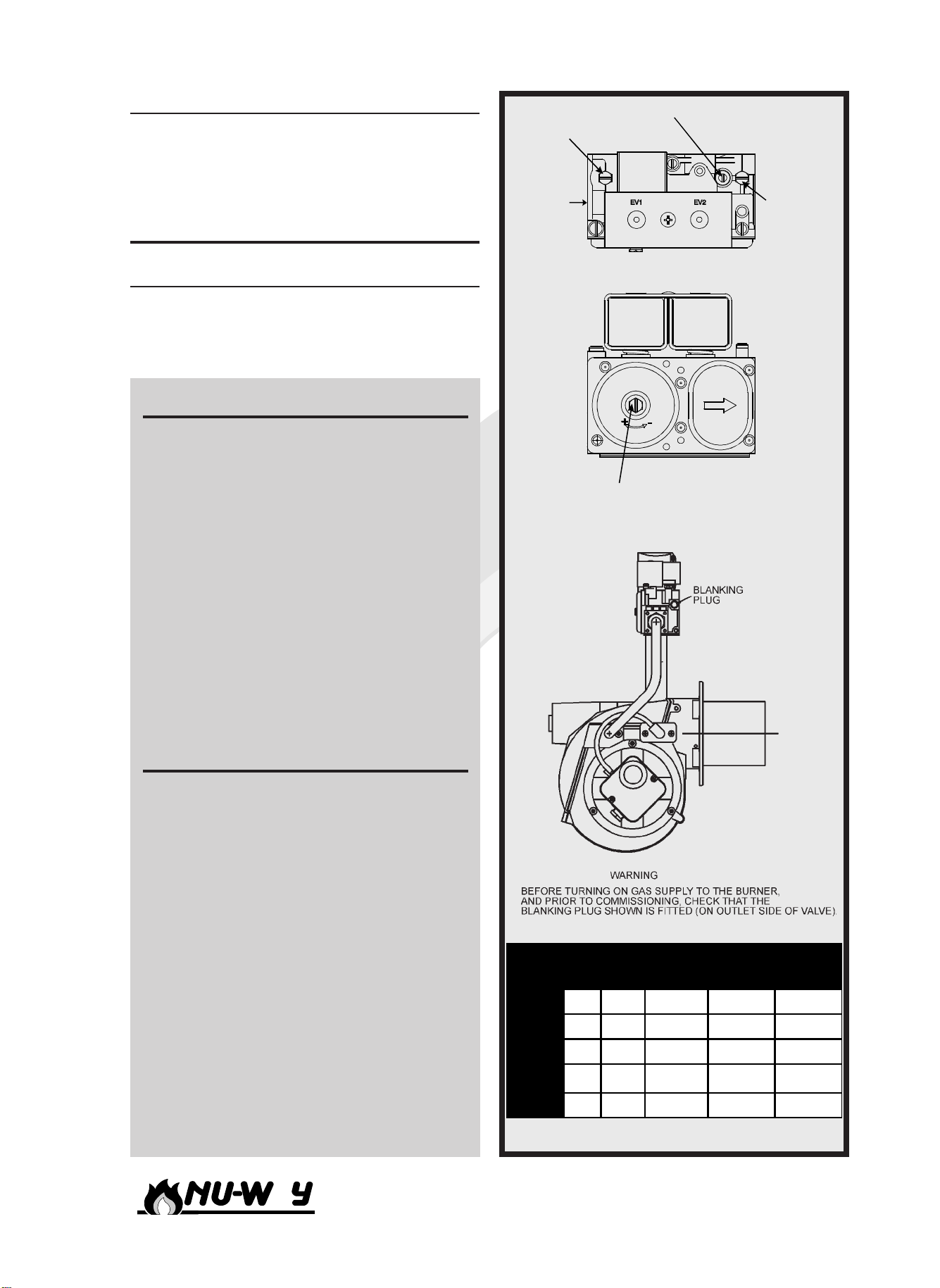

Setting The Step Start Facillity

The step start is used to reduce the gas rate during

the ignition period, therefore ensuring a smooth

quiet light up. Re-start the burner and note the

quality of ignition. If the light up is heavy, reduce

the amount of start rate gas by turning the adjust-

ing screw anti-clockwise. If the light up is weak,

then increase the amount of start rate gas by turn-

ing the adjusting screw clockwise. Repeat until a

satisfactory setting is achieved.

Important

After each adjustment, gas flow rate and flue gas

analysis should be re-checked.

Always

Use approved test equipment (Continually moni-

toring electronic equipment is recommended).

Never

Rely on a visual inspection of the flame as a guide

to combustion quality.

Air Pressure Switch Setting

Isolate the burner and remove the air pressure

switch cover. Switch on the electrical supply and

allow the burner to establish main flame. Slowly

turn the adjustment dial on the air pressure switch

clockwise until the flame is extinguished and the

burner locks out. Turn the dial one division anti-

clockwise and reset the burner control. The burner

will restart and continue its cycle to the main flame

condition or lock out. If the burner locks out re-

peat the adjustment procedure once per burner

cycle until main flame is established. Recheck the

performance and then turn the dial a further two

divisions anticlockwise. Switch off the burner and

replace the air pressure switch cover.

Low Gas Pressure Switch Setting

The low gas pressure switch is wired in series with

the appliance controlling instruments and will cause

the burner to effect a safety shut down if a loss of

inlet gas pressure is detected.

Gas Type %CO2 %O2

Min Max Min Max

Natural 99.5 3.5 5

L.P.G. 10.5 11 3.5 5

Allowable Combustion Analysis