2. OPERATION

2.1 Operating Principle

The following instructions were compiled to provide you information on how to obtain long

and trouble free use of the machine. Periodic maintenance of the machine is essential.

Read the manual carefully and thoroughly familiarize yourself with the machine and all it’s

functions. Failure to do so may injure yourself or a bystander.

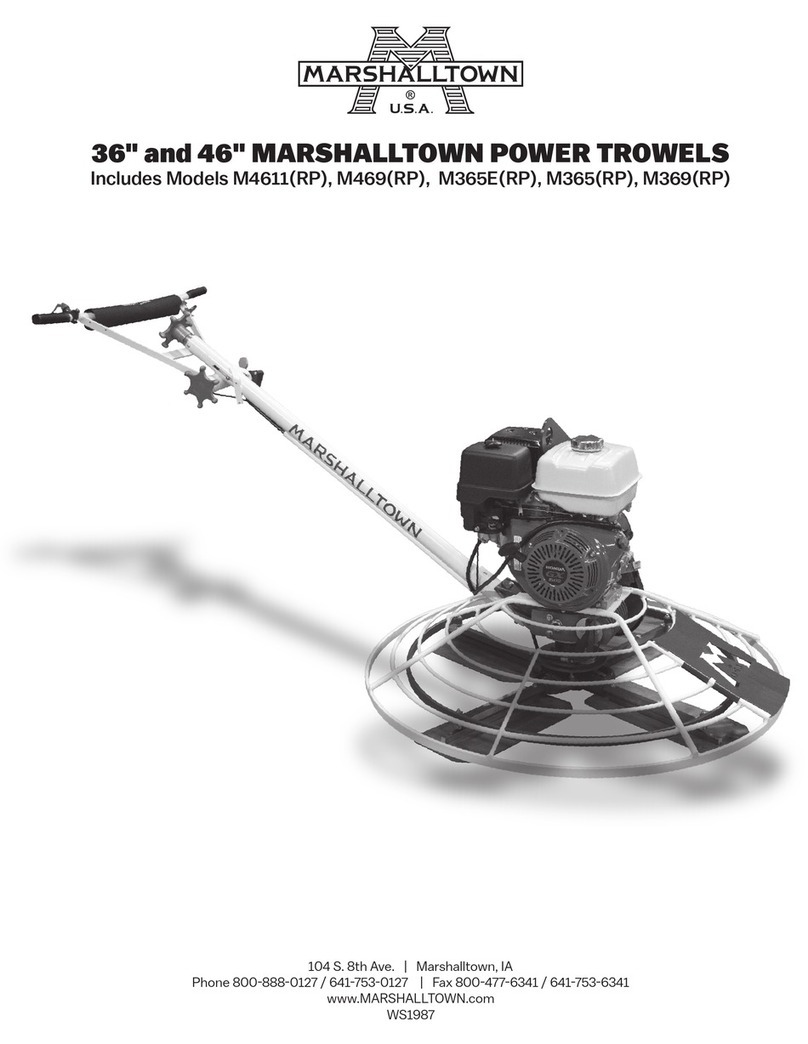

2.2 Application—Standard Features

Your new Power Trowel comes standard with many features to enhance productivity,

performance and safety. Listed below are just a few of these features.

1. Safe Stop Switch—The switching mechanism of this switch should operate freely and should

always be kept in this condition. With the switch in the OFF position, the engine should not

start or run. The purpose of this switch is to stop the engine in a runaway situation, (i.e. the

operator releasing the handle during operation).

2. Adjustable Throttle—Located in a convenient location, this push-pull throttle control can be

set to provide any blade speed from 50 to 130 RPM, and located in place at the desired

operating speed.

3. Bent Arm Adjustable—Allows blades to be adjusted to compensate for bent arms caused by

dropping or mishandling the trowel. Can be easily adjusted on-site for consistent finishing.

4. Heavy Duty Ring Guard—Protects operator and unit while providing lower center of gravity

which contributes to unit stability and performance.

5. Cast Iron Spider—Extra strong for insure alignment. Also contributes to lower center or

gravity for increased trowel performance.

6. Adjustable Handle—Can be positioned to provide comfort and control for any operator’s

height.

7. Tilt Adjustment Knob – adjusts the angle of the blades for different curing stages and

conditions of the concrete. Turning the knob clockwise increases the angle of the blades to

the concrete. Turning the knob counter-clockwise flattens or decreases the angle of the

blades.

2.3 Delivery Checks

Immediately on taking delivery of your new machine and before putting it into service.

Read the operation manual completely—it could save a great deal of unnecessary

expense.Read the engine manual supplied.

Check the general condition of the machine – has it been damaged during delivery?

Check engine oil level.

Check fuel level.

Recommended lubricants are detailed in the Care and Maintenance section.

OPERATION