OM0228Page4of99

February/2014

LabgardESEnergySaverClassII,TypeB2LaminarFlowBiologicalSafetyCabinet

ModelsNU‐430‐400/600Operation&MaintenanceManual

TABLEOFCONTENTS

SectionNo.1...........................................................GeneralInformation

SectionNo.2...........................................................Models&Features

SectionNo.3...........................................................Warranty

SectionNo.4...........................................................Shipments

SectionNo.5...........................................................InstallationInstructions

5.1.................................................................Location

5.2.................................................................Set‐upInstructions

5.3.................................................................Exhaust/SupplyAirChecks

5.4.................................................................CertificationTestingMethodsandEquipment

SectionNo.6...........................................................OperatingtheNU‐430

6.1.................................................................BiologicalSafetyCabinetControl

6.2.................................................................OperatingGuidelines

6.3.................................................................OperatingSequence

6.4.................................................................Ergonomics

6.5.................................................................CleaningProcedures

6.6.................................................................HazardousDrugDecontaminationProcedure

SectionNo.7...........................................................GeneralMaintenance

7.1.................................................................Decontamination

7.2.................................................................FluorescentLampBulbReplacement

7.3.................................................................HEPAFilter/MotorReplacement

7.4.................................................................SlidingWindowReplacement&Adjustment

7.5.................................................................AirflowControlSystemSetup&Calibration

7.6.................................................................HEPAFilterLeakTest

7.7.................................................................AirflowSmokePatternTest

7.8.................................................................SiteInstallationAssessmentTests

7.9.................................................................CleanlinessClassificationTestforPharmacyApplication

7.10...............................................................MainControlBoardDescription&Replacement

7.11...............................................................DigitalAirflowSensorDescription&Replacement

SectionNo.8...........................................................ErrorIndicators,Troubleshooting,Option‐Diagnostics&

AirflowSensorPerformanceVerification

SectionNo.9...........................................................RemoteContacts

SectionNo.10.........................................................OptionalEquipment

10.1.................................................................UltravioletLight

SectionNo.11.........................................................Electrical/EnvironmentalRequirements

SectionNo.12.........................................................DisposalandRecycle

Insert..........................................................................ReplacementPartsList

MANUALDRAWINGS

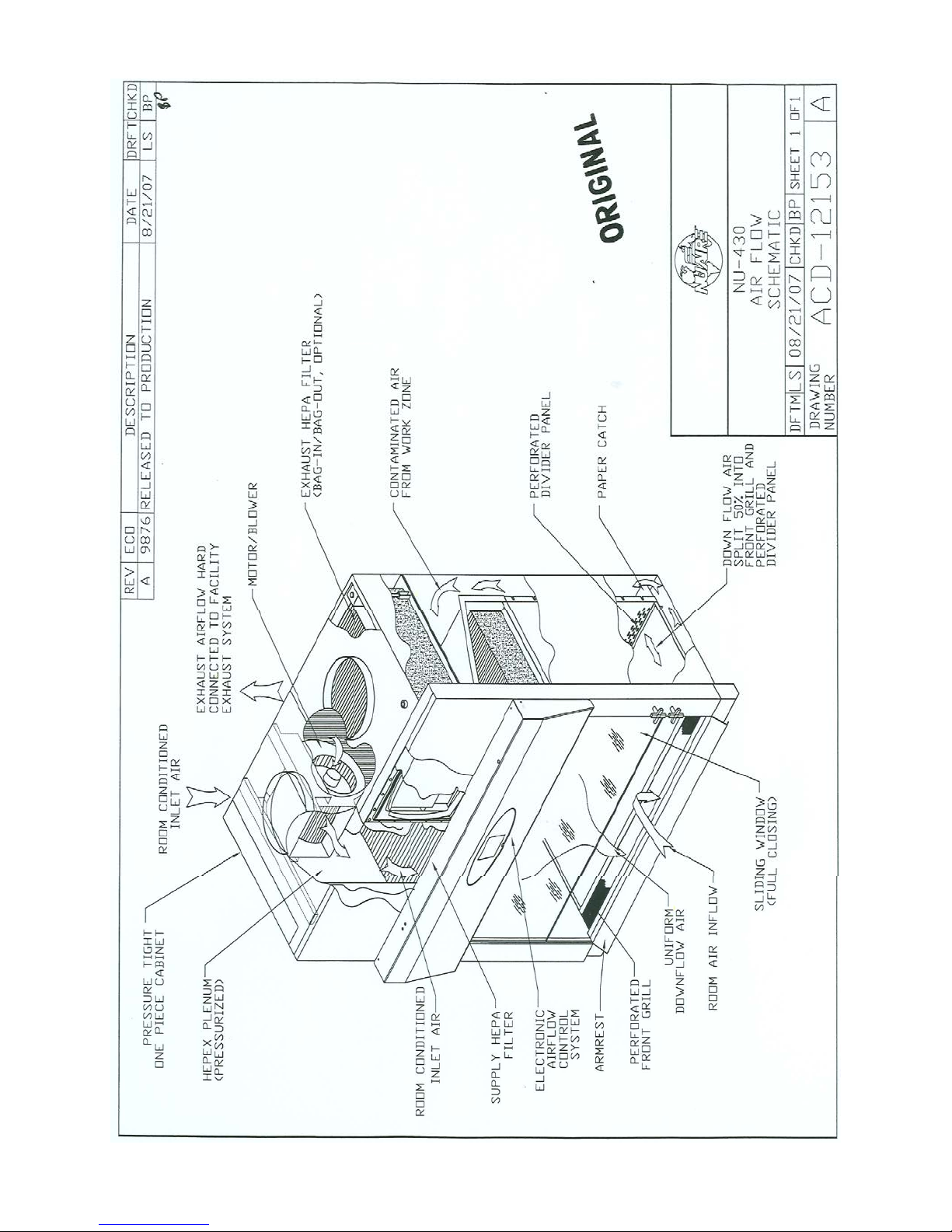

ACD‐12153....................................................NU‐430AirflowSchematic

BCD‐15501.....................................................NU‐430‐400SpecificationDrawing

BCD‐15502.....................................................NU‐430‐600SpecificationDrawing

BCD‐11815.....................................................DrainValveInstallation

BCD‐05572.....................................................ButterflyValveInstallation

BCD‐05660.....................................................BagIn/BagOutProcedure

ASSEMBLYDRAWINGS

BCD‐05147.....................................................BaseStandAssembly

BCD‐05146.....................................................BaseStandStorageCabinetAssembly

BCD‐11817.....................................................ControlCenter&FrontDecorativePanelAssembly

BCD‐11818.....................................................SlidingWindowAssembly&Adjustment

BCD‐14185.....................................................BaseCabinetAssembly

ELECTRICALSCHEMATICS

BCD‐16606(Sheets1‐2)................................NU‐430‐400/600ElectricalSchematic