2

03. 09. 20. Document Number 671935Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA |nuaire.co.uk

NEPTUNE T-AT

Installation Manual

1.2 Important Information

This manual contains important information on the safe and

appropriate assembly, transport, commissioning, operation,

maintenance, disassembly and simple troubleshooting of the product.

While the product has been manufactured according to the accepted

rules of current technology, there is still a danger of personal injury or

damage to equipment if the following general safety instructions and

the warnings contained in these instructions are not complied with.

•Read these instructions completely and thoroughly before

working with the product.

•Keep these instructions in a location where they are accessible

to all users at all times.

•Always include the operating instructions when you pass the

product on to third parties.

1.3 Personal Protective Equipment

The following minimum Personal Protective Equipment (PPE) is

recommended when interacting with Nuaire products:

•Protective Steel Toed Shoes - when handling heavy objects.

•Full Finger Gloves (Marigold PU800 or equivalent) - when

handling sheet metal components.

•Semi Fingerless Gloves (Marigold PU3000 3DO or equivalent)

- when conducting light work on the unit requiring tactile

dexterity.

•Safety Glasses - when conducting any cleaning/cutting operation

or exchanging filters.

•Reusable Half Mask Respirators - when replacing filters which

have been in contact with normal room or environmental air.

Nuaire would always recommend a site specific risk assessment by a

competent person to determine if any additional PPE is required.

2.0 INTRODUCTION

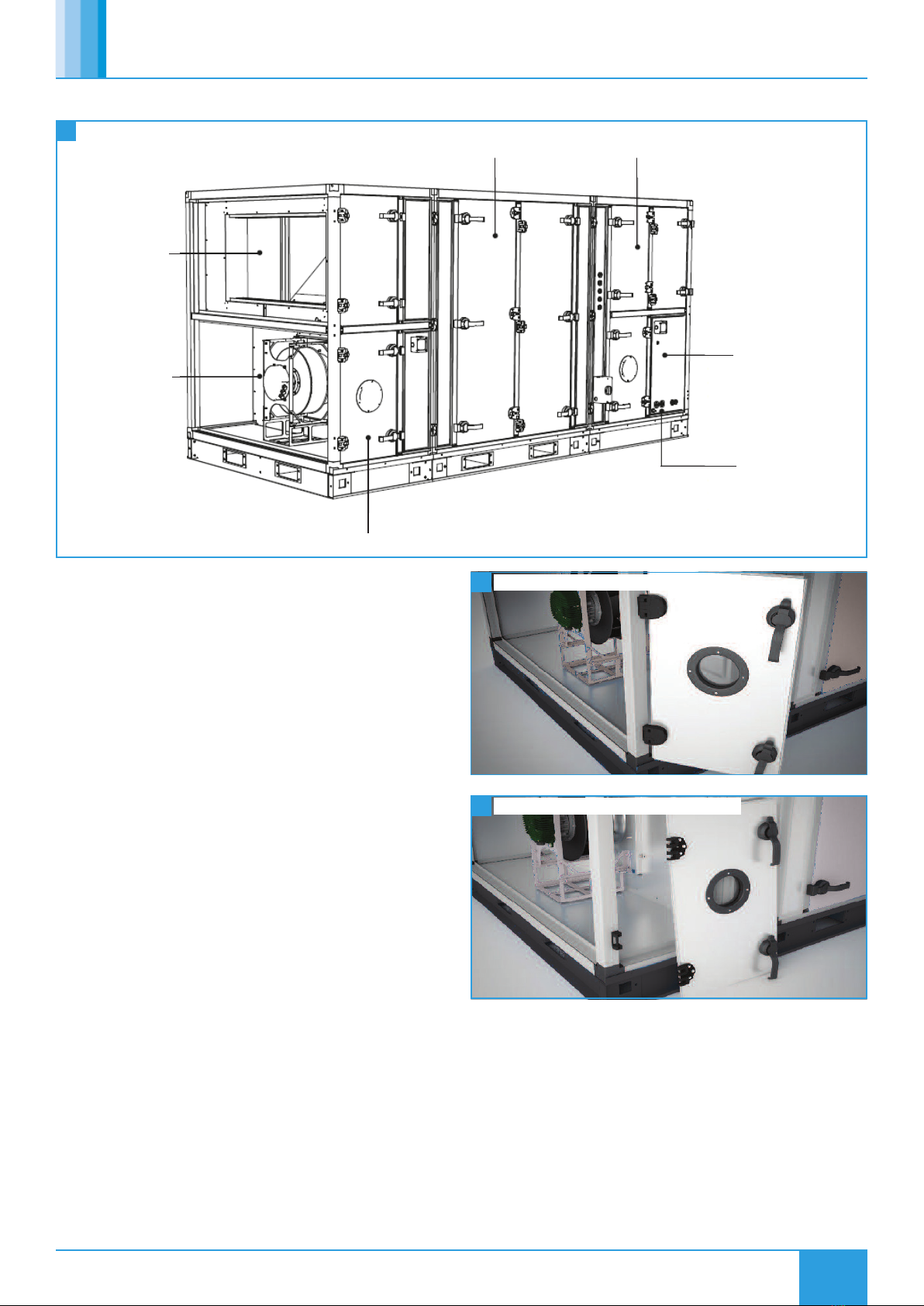

The packaged supply and extract unit shall be manufactured from

Aluzinc corrosion resistant steel, with 50mm double skinned panels

and anodized aluminium frame. All external fittings and fixings shall be

stainless steel, aluminium or non-metallic. All panels and frames will

be of a totally thermally broken design, complying with the following

specification in accordance with BS EN 1886: Mechanical strength, D1;

Leakage class, L2; Thermal transmittance, T3; Thermal bridging, TB3.

Panels and frames will be sealed without the use of silicon, mastic or

other liquid gasket.

An ERP compliant heat exchanger with automatic bypass, complete

with a condensate tray (where cooling is fitted) included. An F7 main

supply filter shall be fitted with an M5 filter bank present on the extract

side. Rails for an additional supply G4 panel filter shall be present with

pressure drop monitoring for maintenance notification included.

Performance optimised backward curved impellers and IP54 EC motors

shall be used to provide low specific fan powers and step less speed

control without tonal noise generation. Fan pressure transducers shall

be fitted (Connect control only) for constant pressure/ flow control and

energy monitoring.

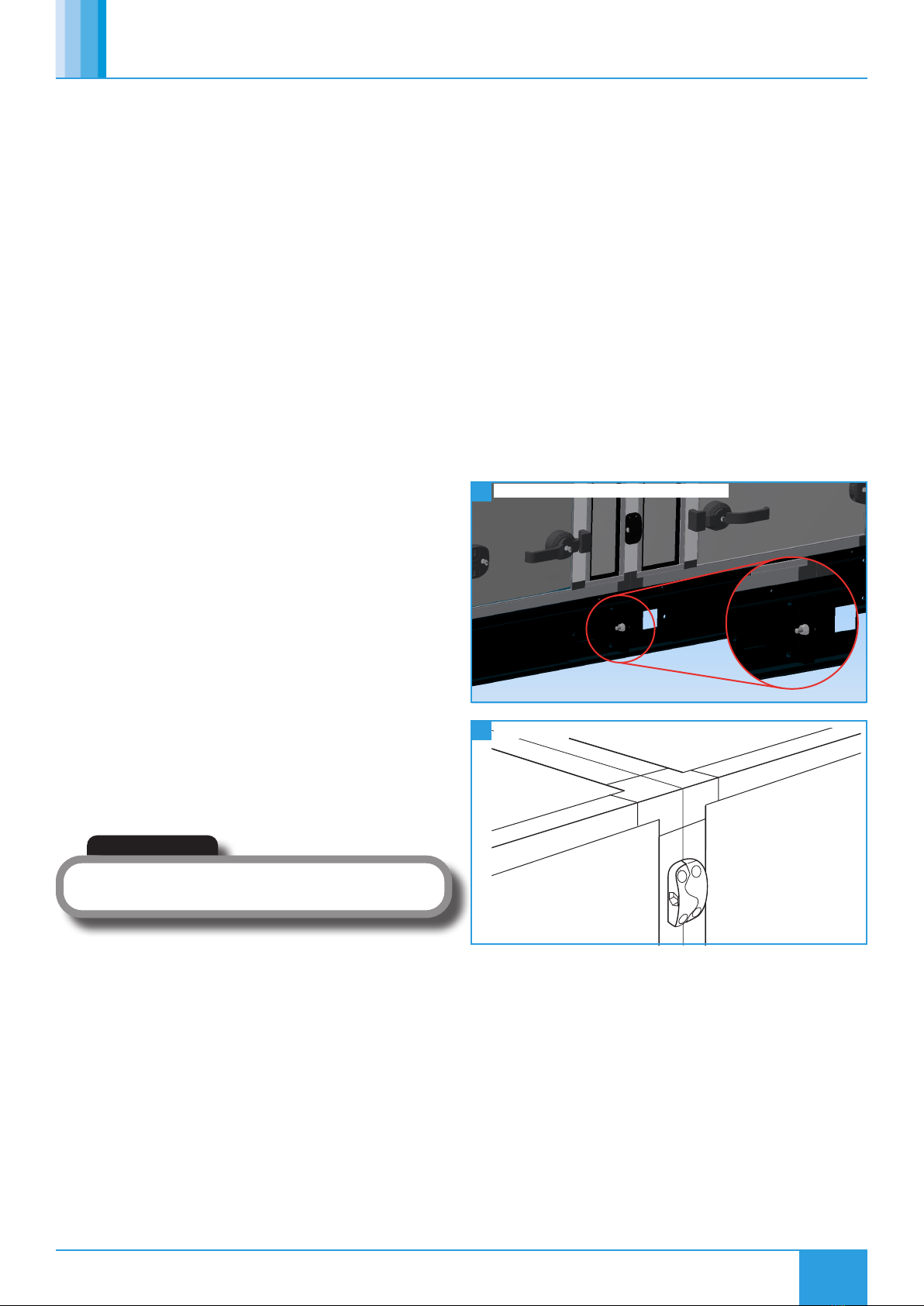

All hinged access panels shall be lockable and removable (with a

common key for all) allowing full maintenance access from the side.

The unit has left (and right option) hand arrangement in direction of

supply air flow.

A LPHW heater battery shall be fitted (on LPHW units). An electric

heater module shall be present (on Electric heater units), complete

with power controller to allow output modulation from the unit

control. A fail-safe auto-reset safety device shall be present.

Structural base frames shall be fitted, powder coated with

covered forklift slots and 50mm square lifting bar holes for site

manoeuvrability. Three axis alignment clamps shall be fitted externally.

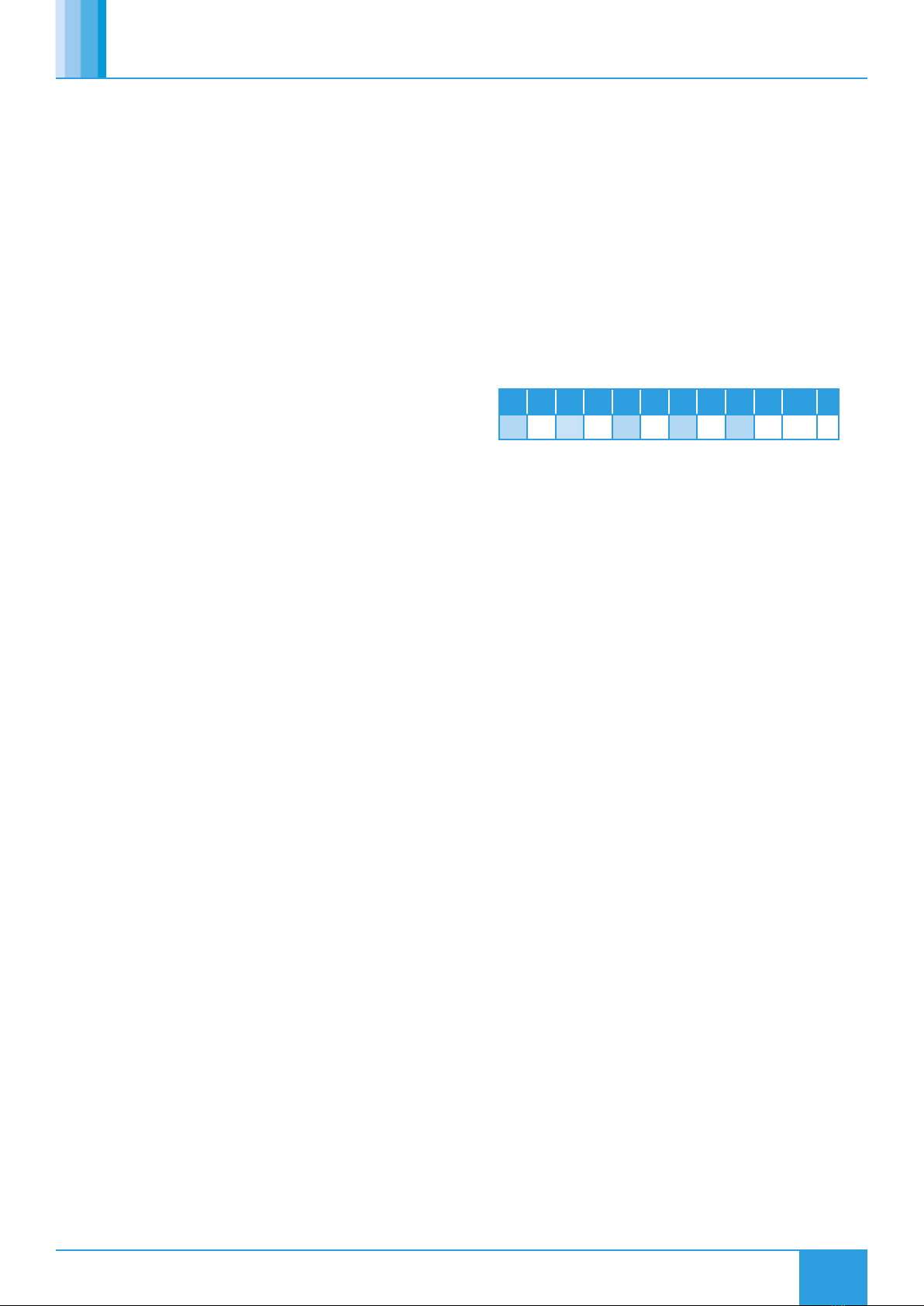

An IP66/67 lockable isolator shall be present for power connection on

main and electric heater modules. Sealing grommets will be present for

control cable access to the unit internals without the need for drilling

on site. Module electrical interconnection shall be made using pre-

fitted plug and socket arrangements.

Modules shall be provided with identification labelling to aid assembly

and QR coded badges to simplify document retrieval via portable

devices.

Autodesk REVIT files shall be provided for Building Information

Modelling and all units shall be based on performance testing carried

out within an AMCA certified test laboratory.

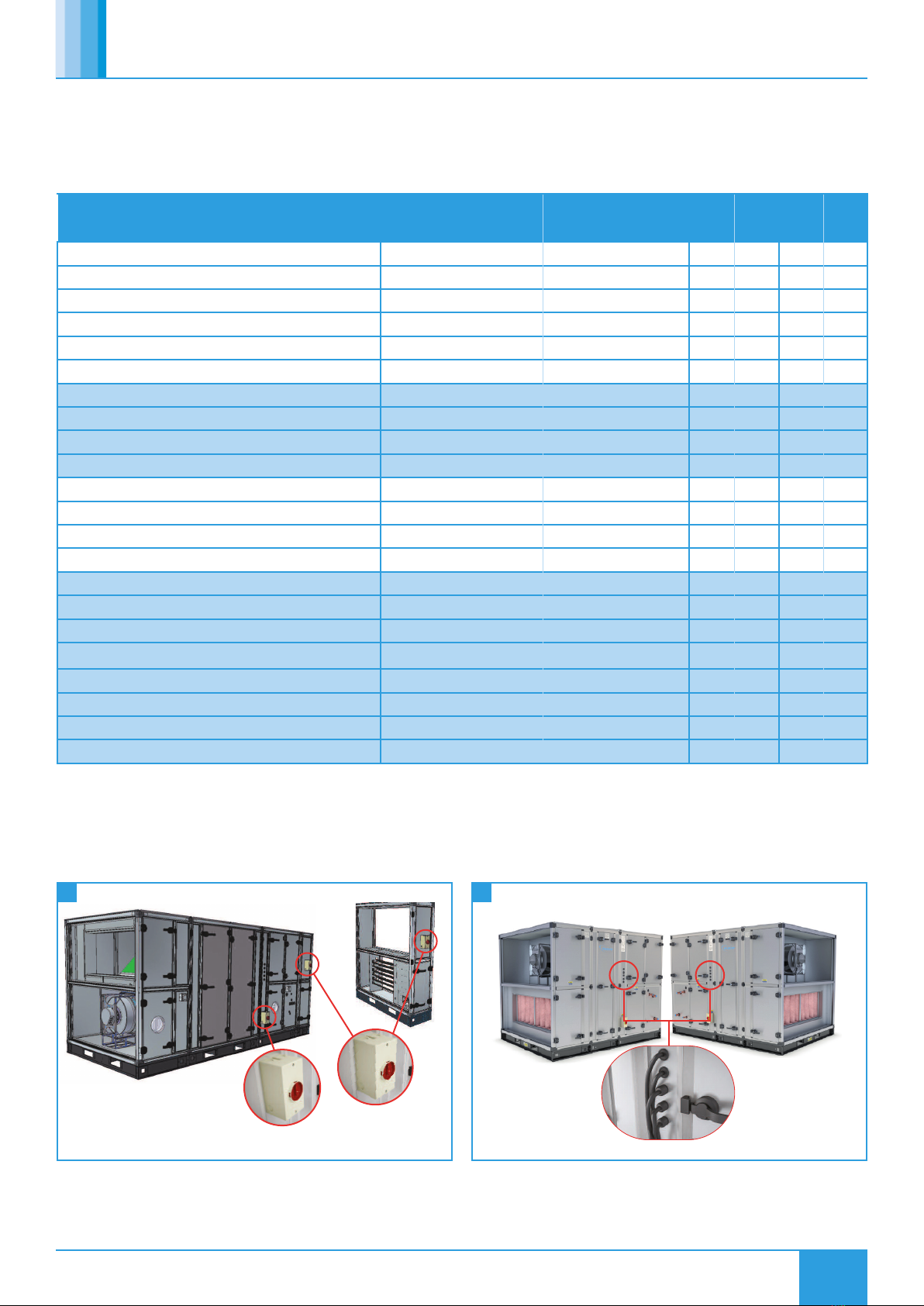

2.1 Code Description:

N 07 T / L R / ES - L WP 4

123/45 / 6 - 7 8 9

1. Range: N = Neptune AHU

2. Unit Size: 07, 12, 17, 22, 32, 42 or 55

3. Heat Recovery Type: T= Thermal Wheel

4. Heating Type: E= Electric (07 - 42 Only)

L = Low Pressure Hot Water (LPHW)

N = No Heating

Cooling Type: C= Chilled Water (CW)

N = No Cooling

X= Reverse Cycle DX (condenser unit

and controls by others)

5. Control Type: AT = Adapt Trend

6. Access Handing L = Left Hand

(in direction of supply R = Right Hand

airflow)

7. Unit Roof: No Affix = Standard Unit (No Roof)

WP = Roof (Factory Fitted)

8. Unit Finish: No Suffix = Standard

4 = Coastal (C4**)

** This units coastal finish has been designed to withstand an External

C4 Atmospheric Corrosivity Category as per BS EN ISO 12944-2:2017

providing that it is installed and maintained as per the manufacturer’s

instructions and general Warranty Guidance Notes found in our

conditions of sale.

3.0 DELIVERY & RECEIPT OF EQUIPMENT

All equipment is inspected prior to despatch and leaves the factory in

good condition. Upon receipt of the equipment an inspection should be

made and any damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be endorsed

by the driver delivering the goods before offloading by the purchaser.

No responsibility will be accepted for damage sustained during the

offloading from the vehicle or on the site thereafter.

All claims for damage and/or incomplete delivery must be reported to

Nuaire within two days of receipt of the equipment.