OM0306 PAGE 2OF 24 REV 1DECEMBER/2020

Table of Contents

1.0 Packing List.................................................................................................................................. 3

2.0 Precautions for Safe Operation..................................................................................................... 3

2.1 Safety Labels and Precautions............................................................................................................3

2.2 Precautions for Safe Operation..........................................................................................................3

3.0 Product Features.......................................................................................................................... 6

4.0 Usage Precautions ....................................................................................................................... 7

5.0 Product Installation...................................................................................................................... 8

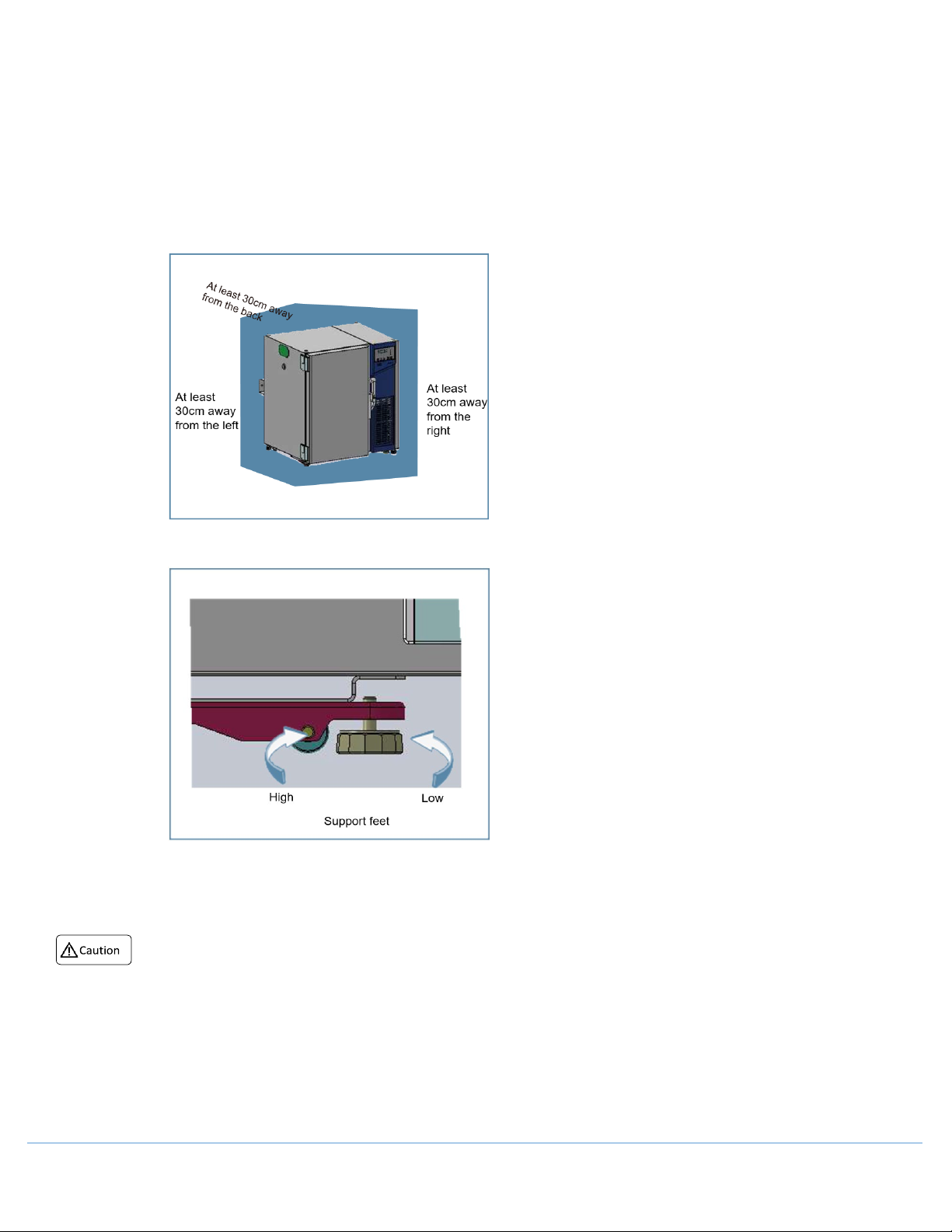

5.1 Installation Environment....................................................................................................................8

5.2 Installation Site ..................................................................................................................................8

5.3 Preparation Before Use......................................................................................................................9

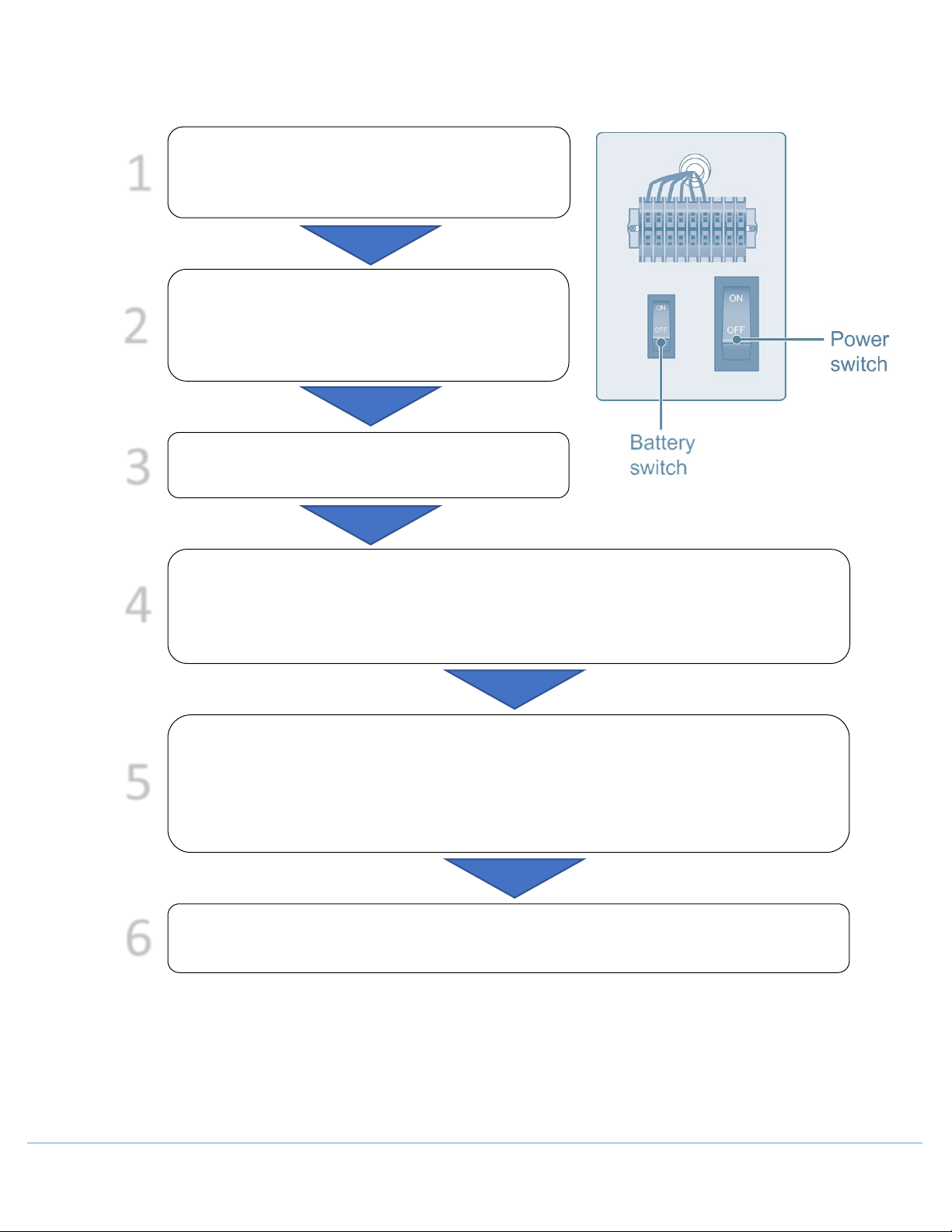

5.4 Initial Startup ...................................................................................................................................10

5.5 Operation after a Power Outage......................................................................................................11

6.0 Refrigerator Components............................................................................................................12

6.1 Control Panel ...................................................................................................................................12

7.0 Operation ...................................................................................................................................13

7.1 Unlocking the Freezer ......................................................................................................................13

7.2 Temperature Setting (TS) .................................................................................................................13

7.3 High Alarm Setting (ALH)..................................................................................................................13

7.4 Low Alarm Setting (ALL) ...................................................................................................................13

7.5 User Parameter Adjustment ............................................................................................................13

7.6 USB Data Export...............................................................................................................................14

7.7 General Setting Notes ......................................................................................................................14

8.0 Display and Alarms .....................................................................................................................15

8.1 Alarm Table......................................................................................................................................16

8.2 Automatic Alarm Recovery Time Setting .........................................................................................17

8.3 Remote Alarm Terminal ...................................................................................................................17

9.0 Cleaning and Maintenance..........................................................................................................17

9.1 Cleaning the Components................................................................................................................17

9.2 Cleaning the Freezer ........................................................................................................................17

9.3 Cleaning the Condenser Filter..........................................................................................................18

9.4 Defrosting the Interior Wall .............................................................................................................18

9.5 Battery Maintenance .......................................................................................................................18

9.6 Freezer Disposal...............................................................................................................................18

10.0 Battery Removal .........................................................................................................................19

10.1 Battery Location...............................................................................................................................19

10.2 Removing the Battery ......................................................................................................................19

11.0 Optional Components .................................................................................................................20

11.1 Storage Shelf and Case.....................................................................................................................20

12.0 Troubleshooting..........................................................................................................................21

13.0 Refrigeration Principle and Circuit Diagram .................................................................................22

13.1 Refrigeration Schematic Diagram ....................................................................................................22

13.2 Circuit Diagram ................................................................................................................................23

14.0 Technical Specifications ..............................................................................................................24

14.1 Specifications ...................................................................................................................................24

14.2 Technical Data..................................................................................................................................24