OM0300 PAGE 2OF 42 REV 2APRIL/2022

Table of Contents

1.0 Features of the Product................................................................................................................ 3

1.1 Main Functions and Features of the Product ..................................................................................... 3

2.0 Product Details ............................................................................................................................ 3

2.1 Temperature Control .......................................................................................................................... 3

2.2 Safety Control ..................................................................................................................................... 3

2.3 Refrigeration system........................................................................................................................... 3

2.4 Practical design ................................................................................................................................... 4

2.5 VIP ....................................................................................................................................................... 4

2.6 Temperature monitoring function...................................................................................................... 4

2.7 Noise ................................................................................................................................................... 4

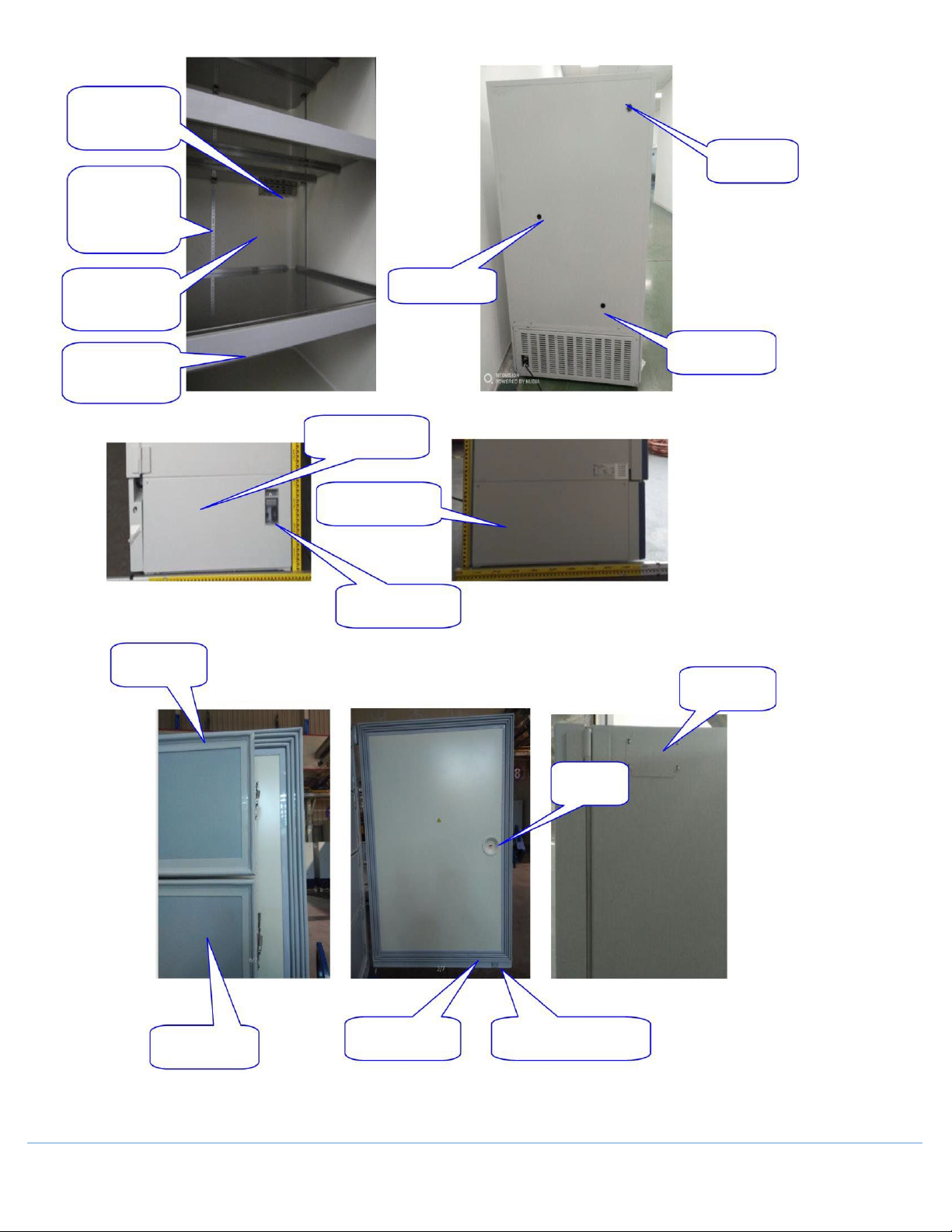

3.0 Parts of the Freezer...................................................................................................................... 5

3.1 Freezer Overview ................................................................................................................................ 5

3.2 Inner Door Components ..................................................................................................................... 6

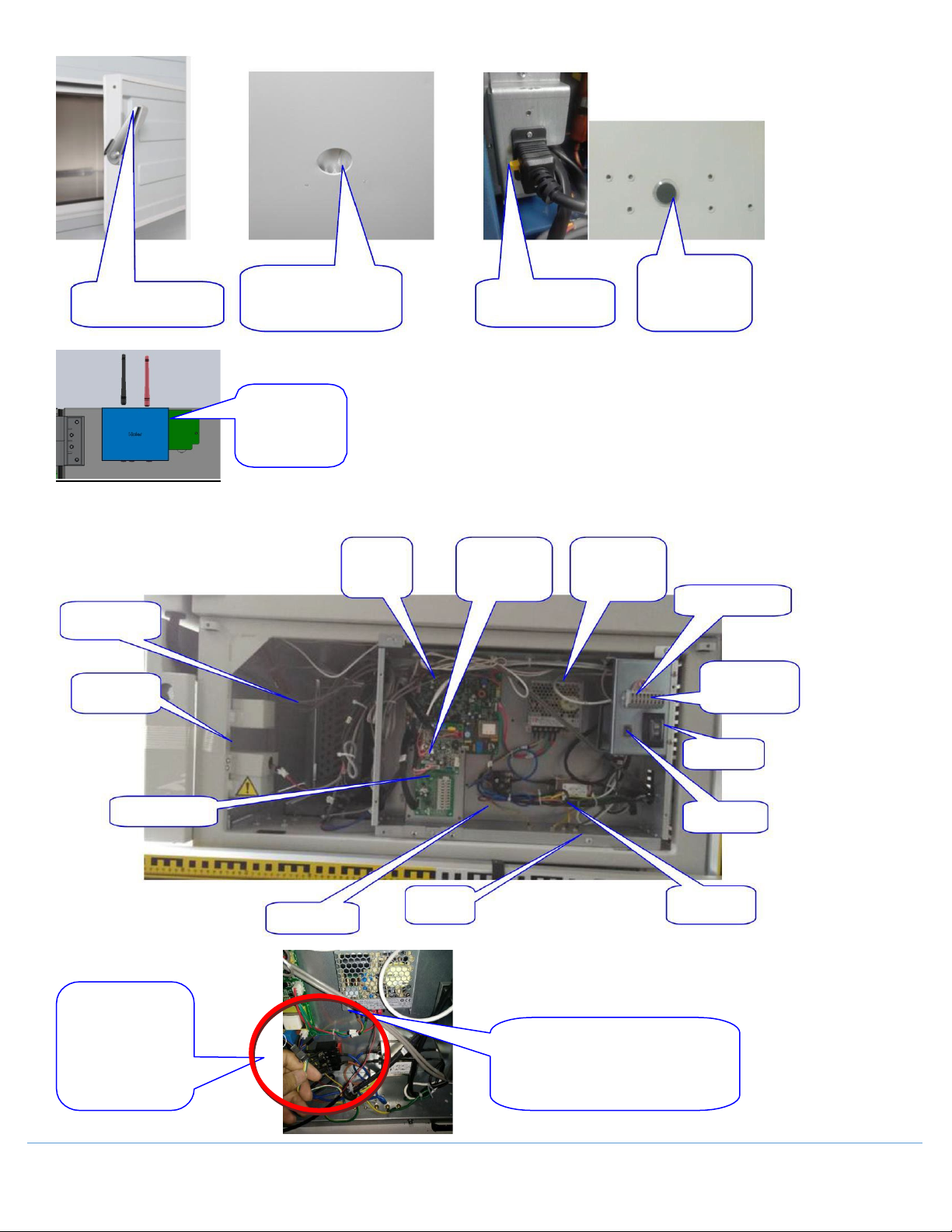

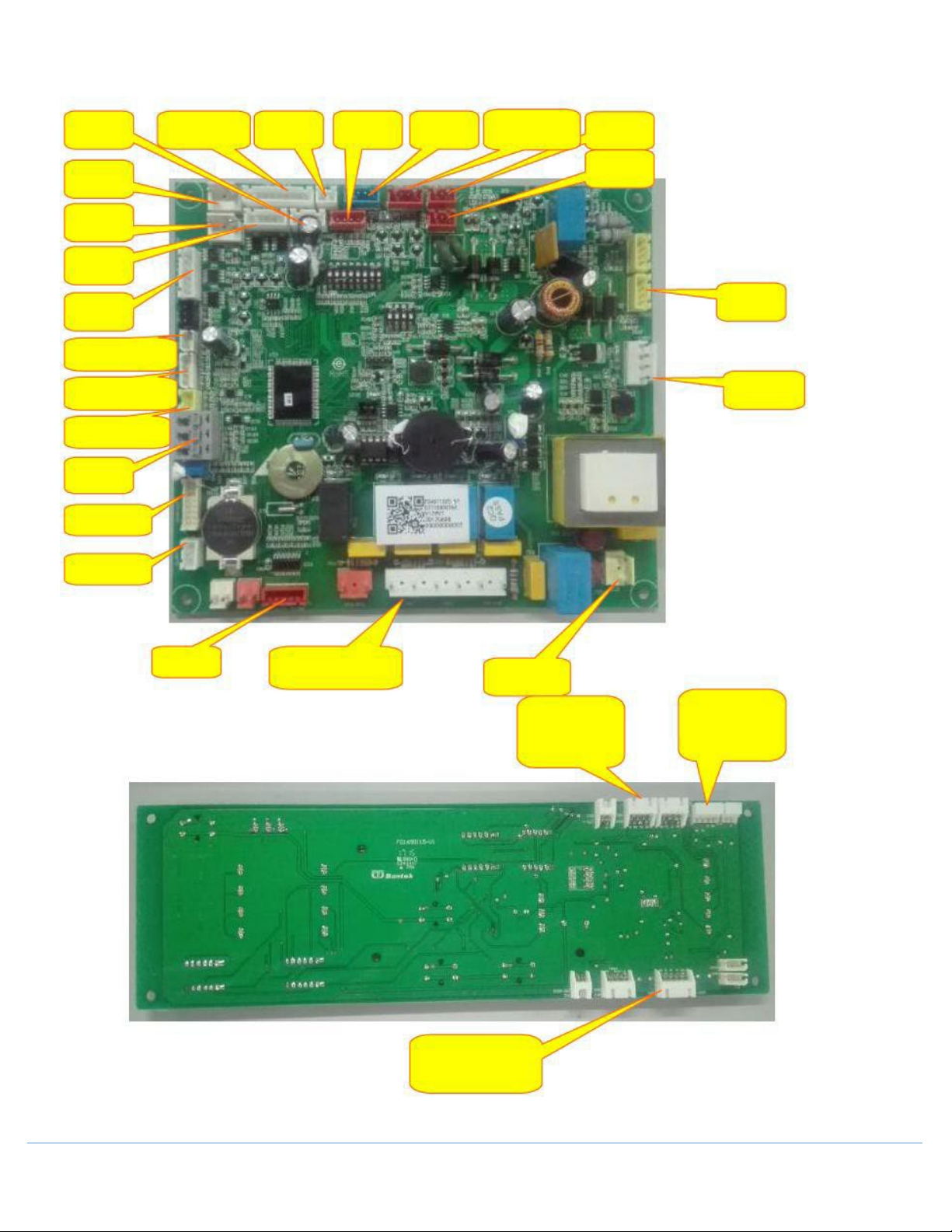

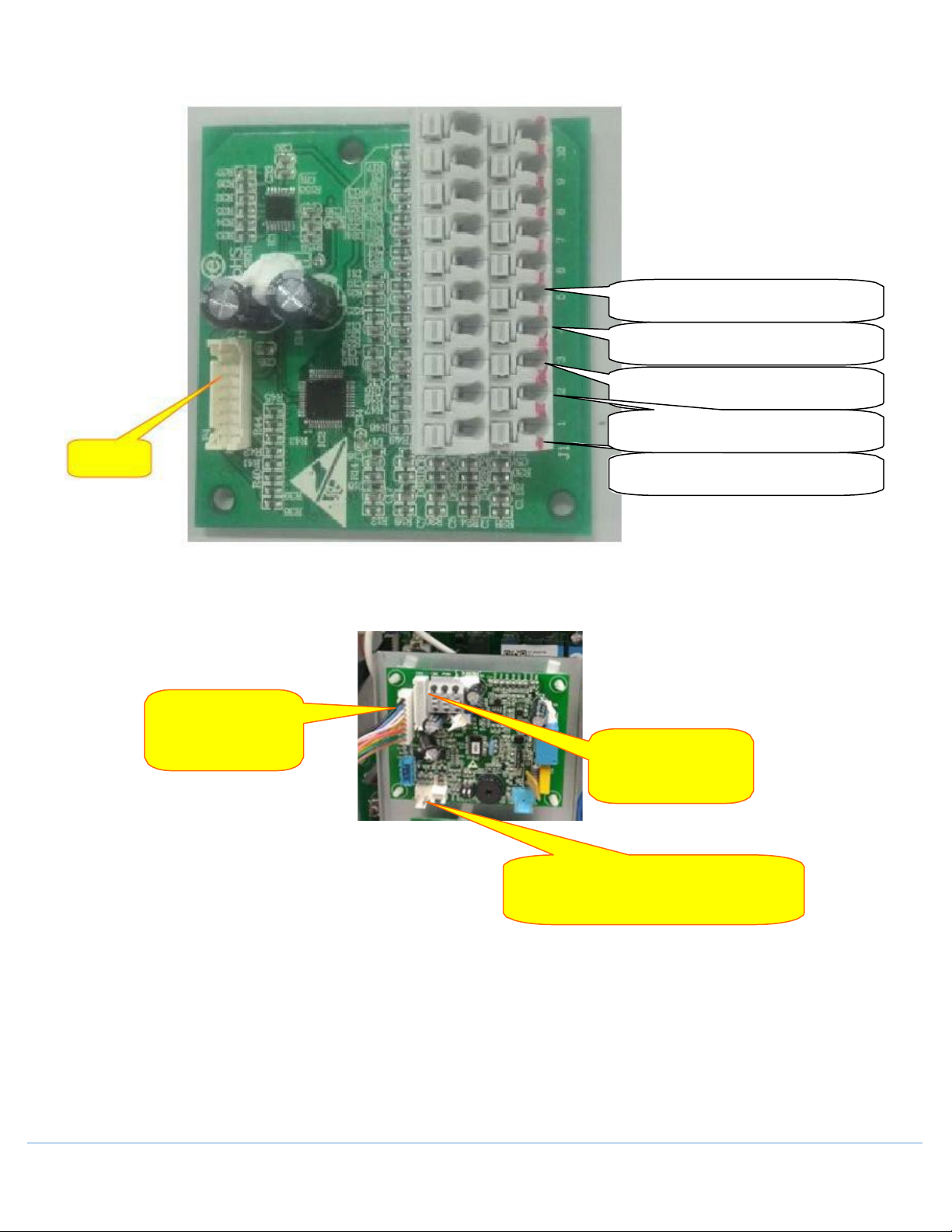

3.3 Electrical Components ........................................................................................................................ 8

3.4 System Structure............................................................................................................................... 12

4.0 Process Overview........................................................................................................................14

4.1 Administrator Permission ................................................................................................................. 14

4.2 Precautions ....................................................................................................................................... 19

5.0 Technical Parameters..................................................................................................................20

6.0 Preventive Measures, Product Use and Daily Maintenance ..........................................................21

6.1 Principle of Ultra-Low Temperature Frequency Conversion Refrigeration ...................................... 21

6.2 Use Method of Ultra-Low Temperature Cabinet .............................................................................. 21

6.3 Working Principle of Pressure Switch ............................................................................................... 22

6.4 Characteristics of Refrigerant ........................................................................................................... 22

6.5 Filling Process of Refrigerant ............................................................................................................ 22

7.0 Refrigeration Schematic and Wiring Diagram...............................................................................25

7.1 Refrigeration Diagram....................................................................................................................... 25

7.2 Wiring Diagram ................................................................................................................................. 26

8.0 Control System ...........................................................................................................................27

8.1 Control of Compressor...................................................................................................................... 27

8.2 Control of Fans.................................................................................................................................. 29

8.3 Battery Control.................................................................................................................................. 29

8.4 Heating Wire Control ........................................................................................................................ 31

8.5 USB Data Download .......................................................................................................................... 31

8.6 Remote Alarm Function .................................................................................................................... 31

9.0 Installation and Disassembly Process...........................................................................................32

9.1 Installation Location.......................................................................................................................... 32

9.2 Handling and Removal of Packaging Materials................................................................................. 32

9.3 Moving the Unit ................................................................................................................................ 33

9.4 Removal of Display Cover ................................................................................................................. 34

10.0 Troubleshooting and Frequently Asked Questions .......................................................................35

10.1 Problems and Possible Solutions ...................................................................................................... 35

10.2 Troubleshooting Table ...................................................................................................................... 36

10.3 High Alarm Processing Method ........................................................................................................ 39

10.4 Low Alarm Processing Method ......................................................................................................... 40

11.0 Diagram and Spare Parts List .......................................................................................................41