Remarks:

The factory only provides the heat pump. Other parts, including a contingent by-pass are to be

provided by the user or installer.

Attention:

Please take the following steps when installing the heat pump:

Each addition of chemicals has to be performed through the conduits located AFTER the heat pump.

Install a by-pass for easy maintenance

Always place the heat pump on a solid base and use the supplied silent blocks in order to avoid

vibrations and noise.

Always keep the heat pump in upright position. If the unit has been tilted, you should wait for at least

24 hours before turning it on.

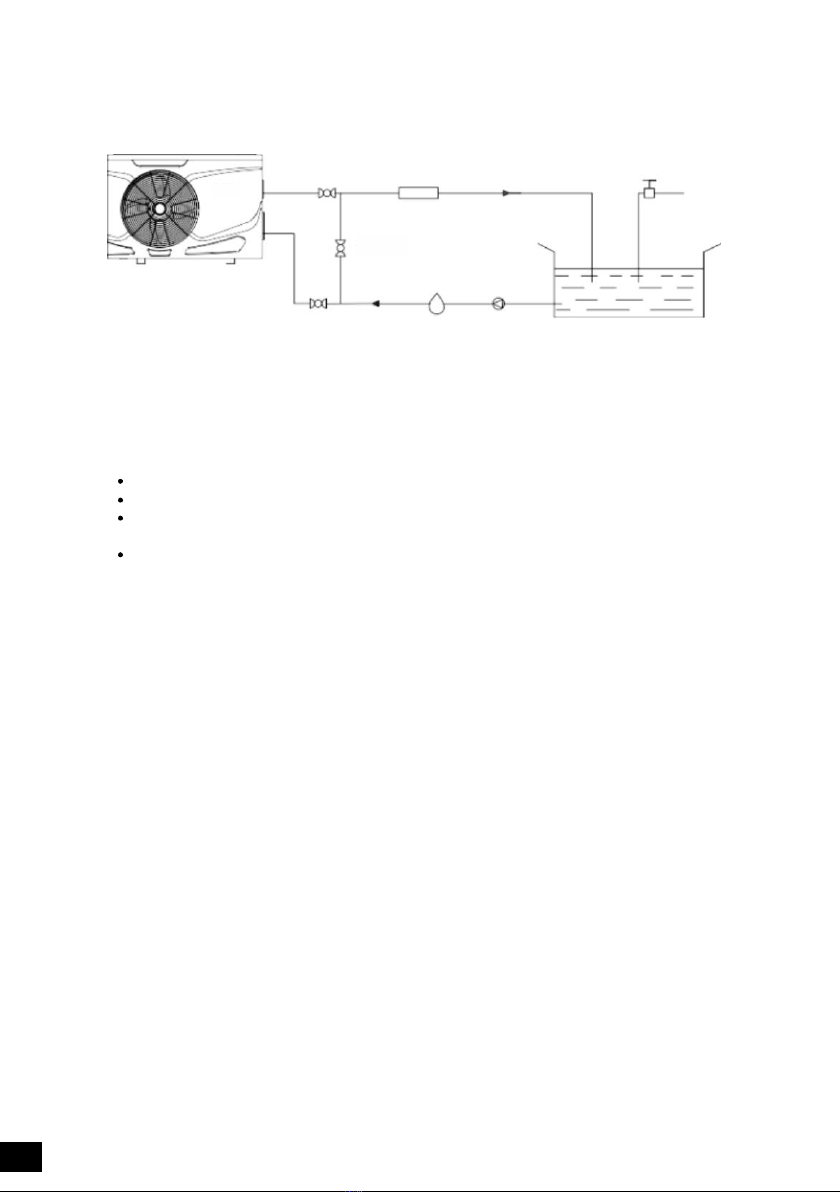

3.3 Piping Installation illustration

Outlet valve Chlorinator Water Valve

Sand lter or other type lter

Water pumpWater inletInlet valve

Water supply

Swimming pool

Bypass valve

3.4 Installation of a check valve

When using automatic chlorine and pH dosage systems, it is of uttermost importance to protect the heat

pump from high concentrations of these chemicals that could corrode the heat exchanger Therefore,

such systems should add the chemicals in the conduits located DOWNSTREAM of the heat pump and

it is recommended to install a check-valve in order to prevent back-ow when there is no water circulation.

Damage to the heat pump caused by disregarding any of these recommendations will invalidate the warranty.

3.5 Electrical Wiring

Important - Although the heat pump is electrically isolated from the rest of the unit, this only

prevents the passage of electricity to or from the pool water. Grounding the unit is still required

to protect yourself from short circuits inside the unit. Make for adequate ground connection.

Check if the electrical mains voltage corresponds with the operating voltage of the heat pump prior to

.

hooking up the unit. It is recommended to use a separate fuse (C-curve) as well as adequate wiring

(see table below). Connect the electrical wires with the terminal block labeled 'TO POWER SUPPLY'

Next to this connection, there is a second terminal block labeled 'TO PUMP', to which the lter pump

(max. 5A/240V) or an electrical relay for a ltration pump can be connected. This connection makes it

possible to control lter pump operation with the heat pump.

However, we do not recommend that you wire the pool circulation pump to the heat pump.Run separate

power supplies to the heat pump and the pool circulation pump. This allows the pool circulation pump to

be put on a time clock and operated for the required time to give adequate ltration for the pool and also

the pool circulation pump can be manually operated when required to backwash the lter etc.

10