ENGLISH

35

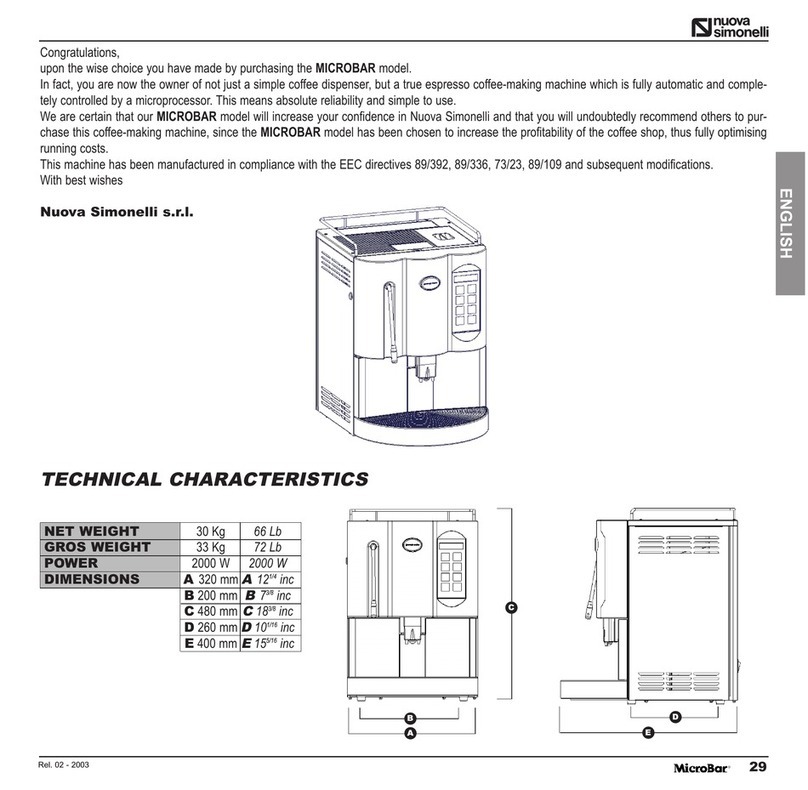

TECHNICAL CHARACTERISTICS . . . . .34

1. DESCRIPTION . . . . . . . . . . . . . . . . . . .37

1.1 ACCESSORIES LIST . . . . . . . . . . . . . . . . . . . . . . . . .38

2.

SAFETY PRESCRIPTION . . . . . . . . . . .39

3. TRANSPORT AND HANDLING . . . . . . .42

3.1 MACHINE IDENTIFICATION . . . . . . . . . . . . . . . . . .42

3.2 TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.3 HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.

INSTALLATION AND PRELIMINARY

OPERATIONS . . . . . . . . . . . . . . . . . . . .43

5. ADJUSTMENTS TO BE MADE BY A

QUALIFIED TECHNICIAN ONLY . . . . . .44

5.1 FILLING BOILER MANUALLY . . . . . . . . . . . . . . . . .44

5.2 PRESSOSTAT/PUMP ADJUSTMENT . . . . . . . . . . . .44

5.3 HOT WATER ECONOMISER ADJUSTMENT . . . . . .45

5.4 CLOCK BATTERY REPLACEMENT

(ONLY FOR THE VIP PLUS VERSION) . . . . . . . . . . .45

5.5 PUSH-BUTTON PANEL REPLACEMENT . . . . . . . . .45

5.6 ELECTRONIC DISPLAYS . . . . . . . . . . . . . . . . . . . .45

6.

USE . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.1 TURNING THE MACHINE ON . . . . . . . . . . . . . . . . .46

6.1.1 AURELIA VIP PLUS . . . . . . . . . . . . . . . . . . . . . . . .46

6.1.2 AURELIA V/ESSE . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.1.3 AURELIA VIP-V/ESSE WITH ELECTRONIC DISPLAYS

(OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.2 SELECTION CONFIGURATION . . . . . . . . . . . . . . . .48

6.3 MAKING COFFEE . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.4 USING STEAM . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.5 MAKING CAPPUCCINO . . . . . . . . . . . . . . . . . . . . .49

6.6 HOT WATER SELECTION . . . . . . . . . . . . . . . . . . . .49

6.7 TIMED STEAM NOZZLE . . . . . . . . . . . . . . . . . . . . .49

7.

PROGRAMMING . . . . . . . . . . . . . . . . . .50

7.1 KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.2 PROGRAMMING AURELIA VIP PLUS . . . . . . . . . . . .50

7.3 PROGRAMMING AURELIA V . . . . . . . . . . . . . . . . . .55

7.4 PROGRAMMING AURELIA ESSE . . . . . . . . . . . . . . .57

8.

CLEANING AND MAINTENANCE . . . . . .58

8.1 SWITCHING OFF THE MACHINE . . . . . . . . . . . . . . .58

8.2 CLEANING THE OUTSIDE OF THE MACHINE . . . . .58

8.3 CLEANING STAINLESS COFFEE-HOLDERS . . . . . . .58

8.4 CLEANING THE UNIT WITH THE AID OF THE

BLIND FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.5 CLEANING FILTERS AND FILTER-HOLDERS . . . . . .58

8.6 RESIN AND SOFTENER REGENERATION . . . . . . .59

9.

AURELIA PLUS MACHINE FUNCTION

MESSAGES . . . . . . . . . . . . . . . . . . . . .60

10. AURELIA V MACHINE FUNCTION

MESSAGES . . . . . . . . . . . . . . . . . . . . .62

11. AURELIA S MACHINE FUNCTION

MESSAGES . . . . . . . . . . . . . . . . . . . . .63

ELECTRIC SYSTEM AURELIA S . . . . . .64

ELECTRIC SYSTEM AURELIA PLUS

Rel 3.xx . . . . . . . . . . . . . . . . . . . . . . . .65

ELECTRIC SYSTEM AURELIA PLUS

Rel 1.xx . . . . . . . . . . . . . . . . . . . . . . . .65

ELECTRIC SYSTEM AURELIA V . . . . . .67

PLUMBING SYSTEM . . . . . . . . . . . . . . .68

INDEX