1Safety................................................................................................................................5

1.1 Intended Use.................................................................................................................5

1.2 Safety instructions of the manufacturer .........................................................................5

1.2.1 Disclaimer.................................................................................................................5

1.3 Safety symbols used in this manual ..............................................................................6

1.4 Safety Information for the Operator...............................................................................7

1.4.1 General notes...........................................................................................................7

1.4.2 Qualification of the personnel ...................................................................................7

1.4.3 Personal protective equipment .................................................................................7

1.5 Safety features..............................................................................................................7

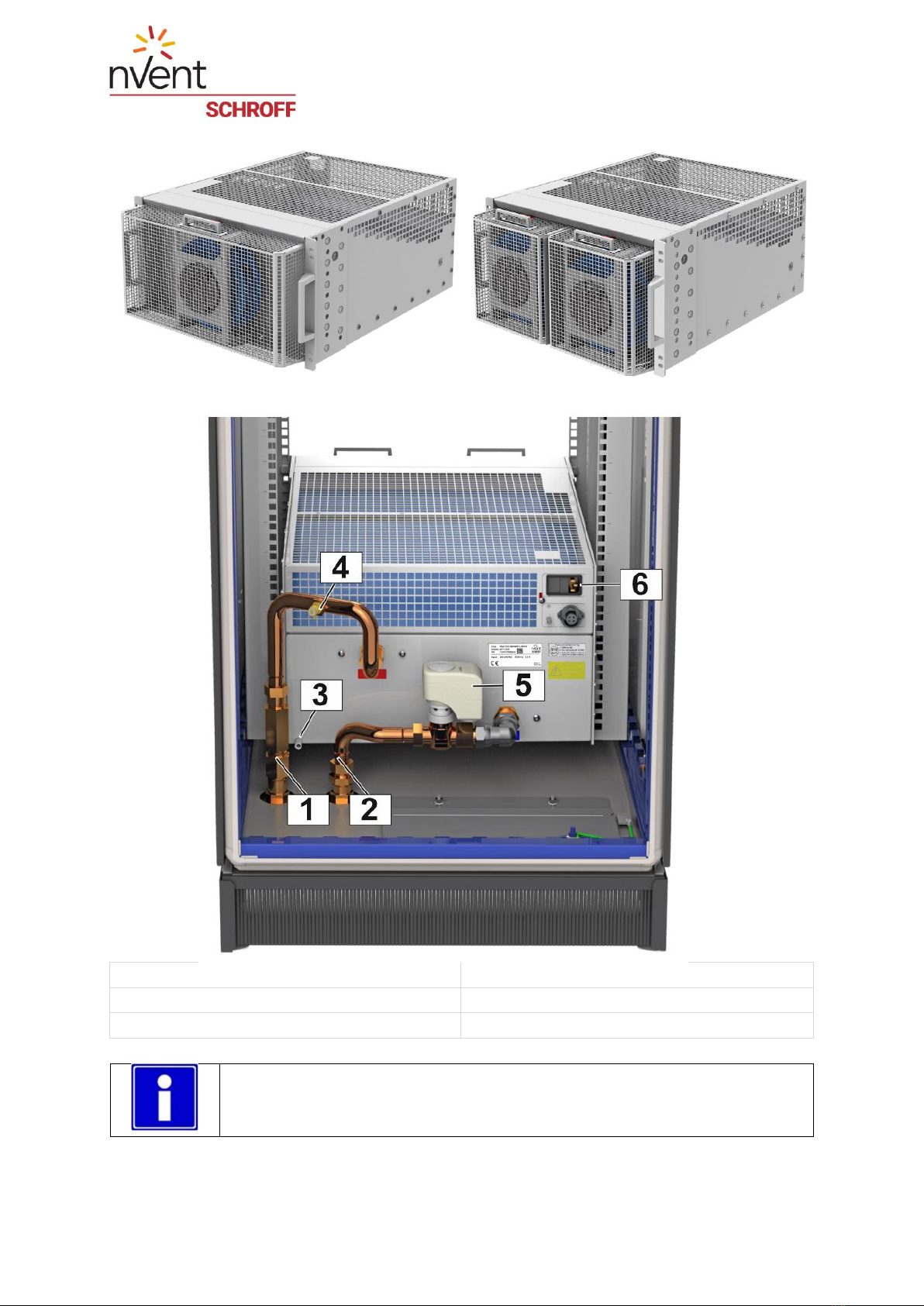

2LHX+ overview.................................................................................................................8

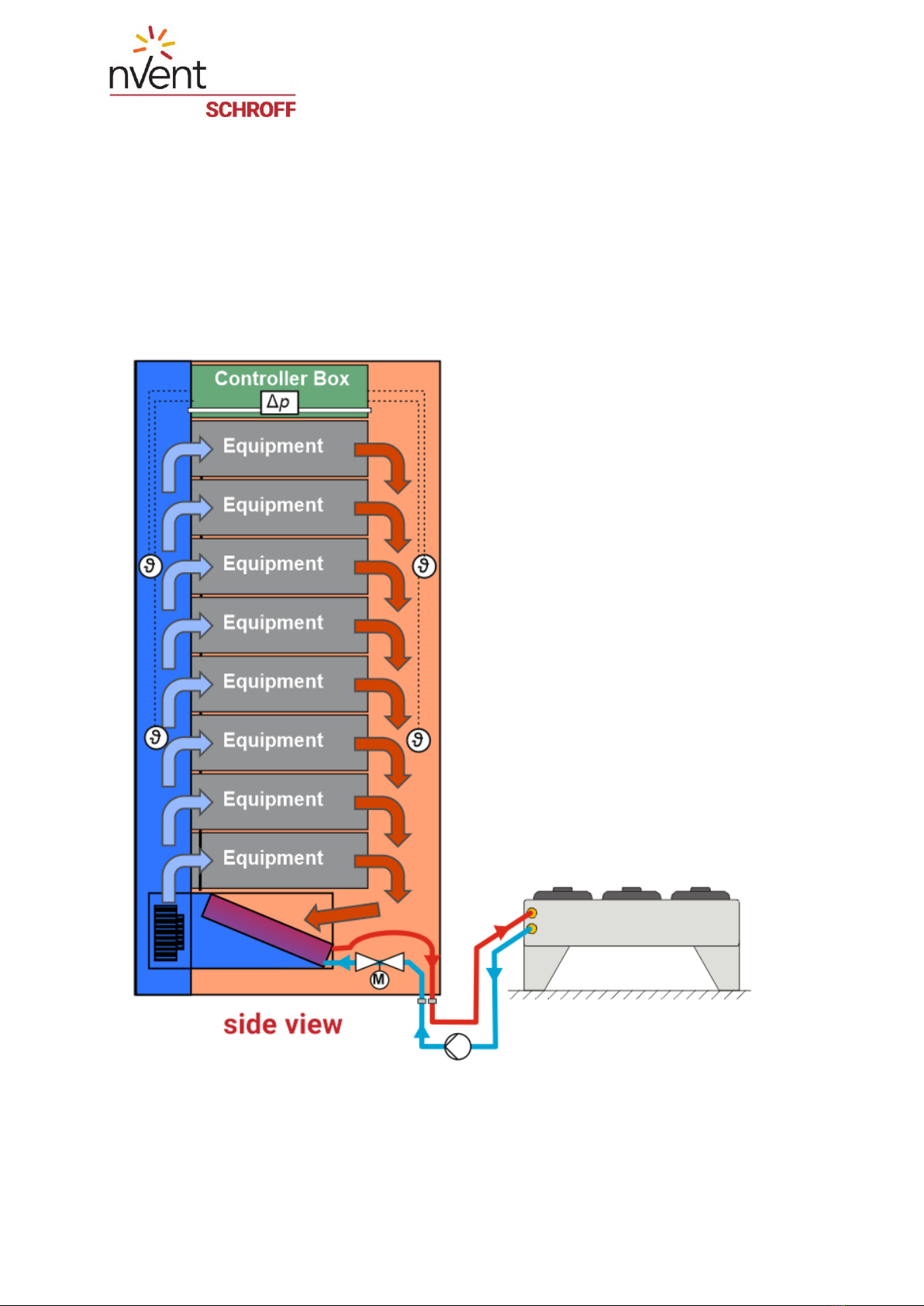

2.1 Functional description .................................................................................................10

2.2 Cooling capacity control..............................................................................................11

3Transport and assembly................................................................................................12

3.1 Safety rules for transport and assembly ......................................................................12

3.2 Unpacking...................................................................................................................13

3.3 Placing the cabinet......................................................................................................14

3.3.1 Lifting the cabinet from the pallet............................................................................15

3.4 Commissioning............................................................................................................16

3.4.1 Connection to the cooling water supply...................................................................17

3.4.2 Requirements for the water quality .........................................................................18

3.4.3 Water connection....................................................................................................19

3.5 Bleeding the cooling module .......................................................................................20

3.5.1 Mains connection....................................................................................................21

3.5.2 Mains inputs ...........................................................................................................22

3.6 Connectors controller box ...........................................................................................23

3.6.1 Plug in/Unplug connectors at the controller box......................................................23

3.7 Initial operation............................................................................................................24

4Monitoring and Configuration.......................................................................................25

4.1 Web Interface..............................................................................................................25

4.1.1 Web interface screens............................................................................................25