3.INSTALLATION AND CONNECTION

8

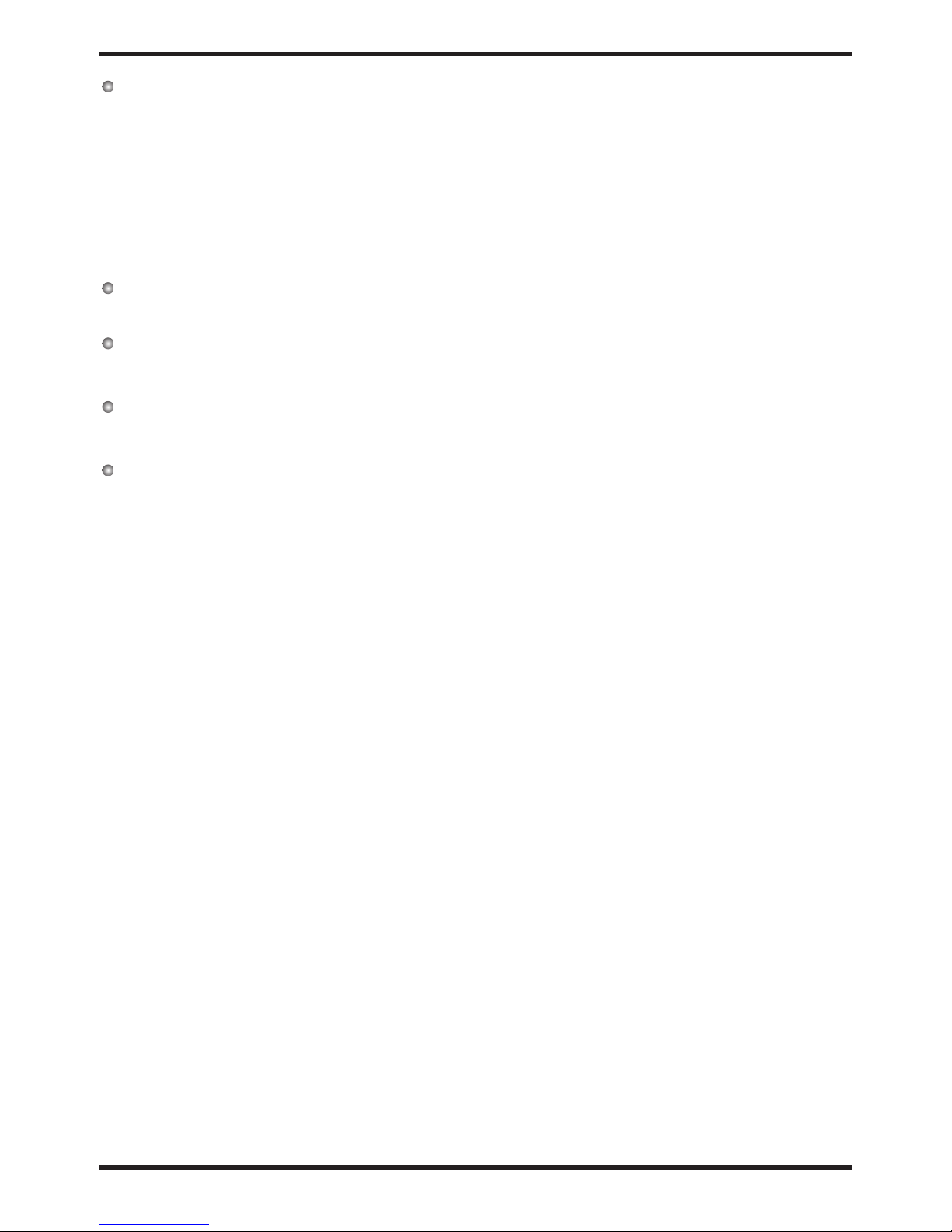

3.4 Swimming Pool Heat Pumps Plumbing

Location: Connect the unit in the pool pump discharge (return) line downstream of all filter

and pool pumps, and upstream of any chlorinators, ozonators or chemical pumps.

Standard model have slip glue fittings which accept 32mm or 50 mm PVC pipe for

connection to the pool or spa filtration piping. By using a 50 NB to 40NB you can plumb 40NB

Give serious consideration to adding a quick coupler fitting at the unit inlet and outlet to allow

easy draining of unit for winterizing and to provide easier access should servicing be

required.

Condensation: Since the Heat pump cools down the air about 4 -5℃, water may condense on

the fins of the horseshoe shaped evaporator. If the relative humidity is very high, this could

be as much as several litres an hour. The water will run down the fins into the basepan and

drain out through the barbed plastic condensation drain fitting on the side of the basepan.

This fitting is designed to accept 20mm clear vinyl tubing which can be pushed on by hand

and run to a suitable drain. It is easy to mistake the condensation for a water leak inside the

unit.

NB: A quick way to verify that the water is condensation is to shut off the unit and keep the

pool pump running. If the water stops running out of the basepan, it is condensation. AN

EVEN QUICKER WAY IS to TEST THE DRAIN WATER FOR CHLORINE - if the is no chlorine

present, then it's condensation.

To pool

From pump

PVC COUPLER

RECOMMENDED(Provided)

CONDENSATION

DRAIN

BARB FTG

The Swimming Pool Heat Pumps exclusive rated flow titanium heat exchanger requires no

special plumbing arrangements except bypass(please set the flow rate according to the

nameplate). The water pressure drop is less than 10kPa at max. Flow rate. Since there is no

residual heat or flame Temperatures, The unit does not need copper heat sink piping. PVC

pipe can be run straight into the unit.

7

3.INSTALLATION AND CONNECTION

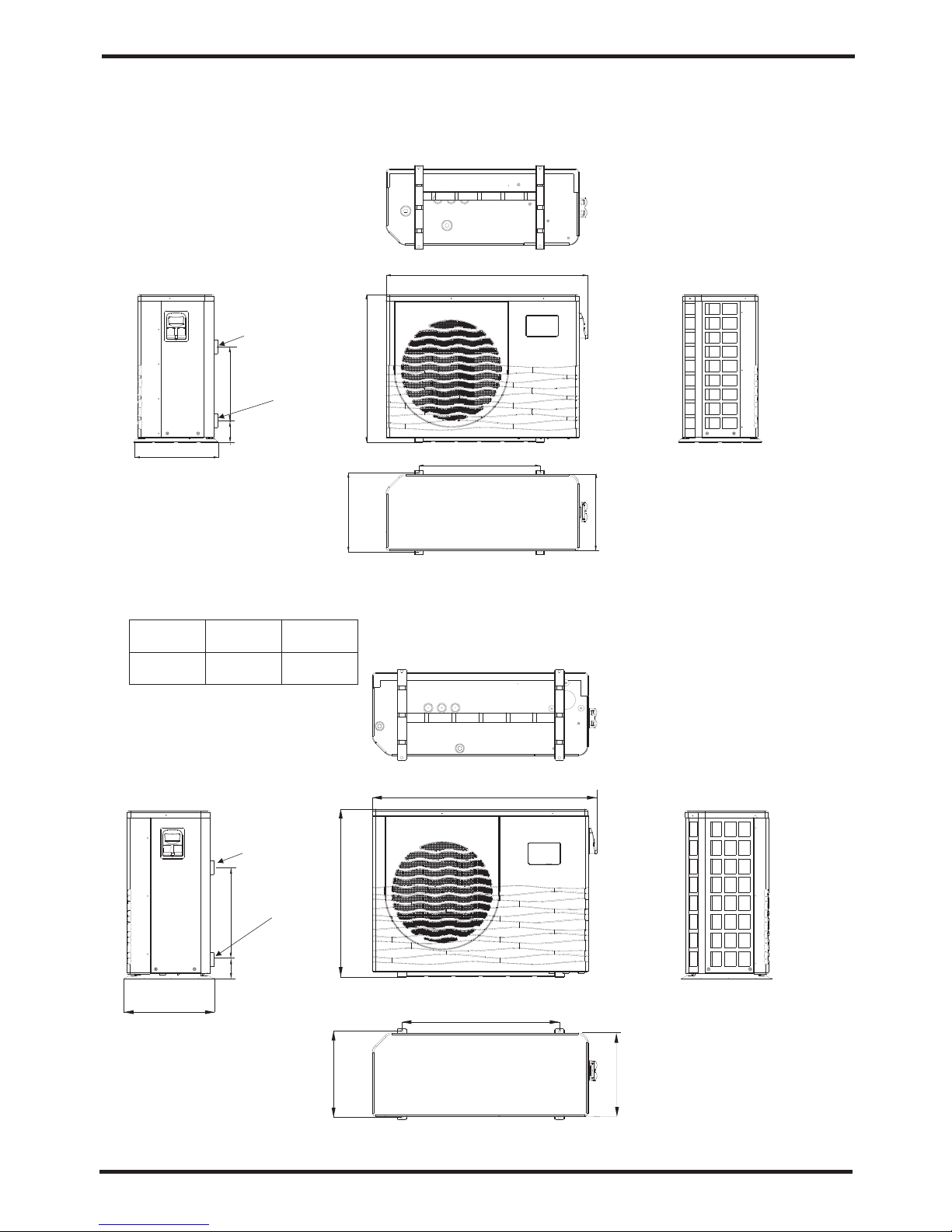

The unit will perform well in any outdoor location provided that the following three factors are

presented:

1. Fresh Air - 2. Electricity - 3. Pool filter piping

The unit may be installed virtually anywhere outdoors. For indoor pools please consult the

supplier. Unlike a gas heater, it has no draft or pilot light problem in a windy area.

DO NOT place the unit in an enclosed area with a limited air volume, where the units

discharge air will be re-circulated.

DO NOT place the unit to shrubs which can block air inlet. These locations deny the unit of a

continuous source of fresh air which reduces it efficiency and may prevent adequate heat

delivery.

3.2 Swimming Pool Heat Pumps Location

Normally, the pool heat pump is installed within 7.5 metres of the pool. The longer the

distance from the pool, the greater the heat loss from the piping. For the most part ,the piping

is buried. Therefore, the heat loss is minimal for runs of up to15 meters(15 meters to and from

the pump = 30 meters total), unless the ground is wet or the water table is high. A very rough

estimate of heat loss per 30 meters is 0.6 kW-hour,(2000BTU) for every 5 ℃ difference in

temperature between the pool water and the ground surrounding the pipe, which translates to

about 3% to 5% increase in run time.

3.3 How Close To Your Pool?

Air inlet

Air outlet

300mm

700mm

300mm

500mm

700mm