Table of Contents

2

3

3

4

6

7

7

7

7

8

8

8

8

10

10

11

12

13

14

16

16

17

17

18

18

18

19

19

20

22

24

24

25

25

26

27

27

General Information .......................................................................................................................................

Safety Rules ...................................................................................................................................................

Wiring diagram ...............................................................................................................................................

Specification Sheet ........................................................................................................................................

Main Features ................................................................................................................................................

Assembly And Set Up ....................................................................................................................................

(1). Control Panel ....................................................................................................................................

(2). Rip Fence ........................................................................................................................................

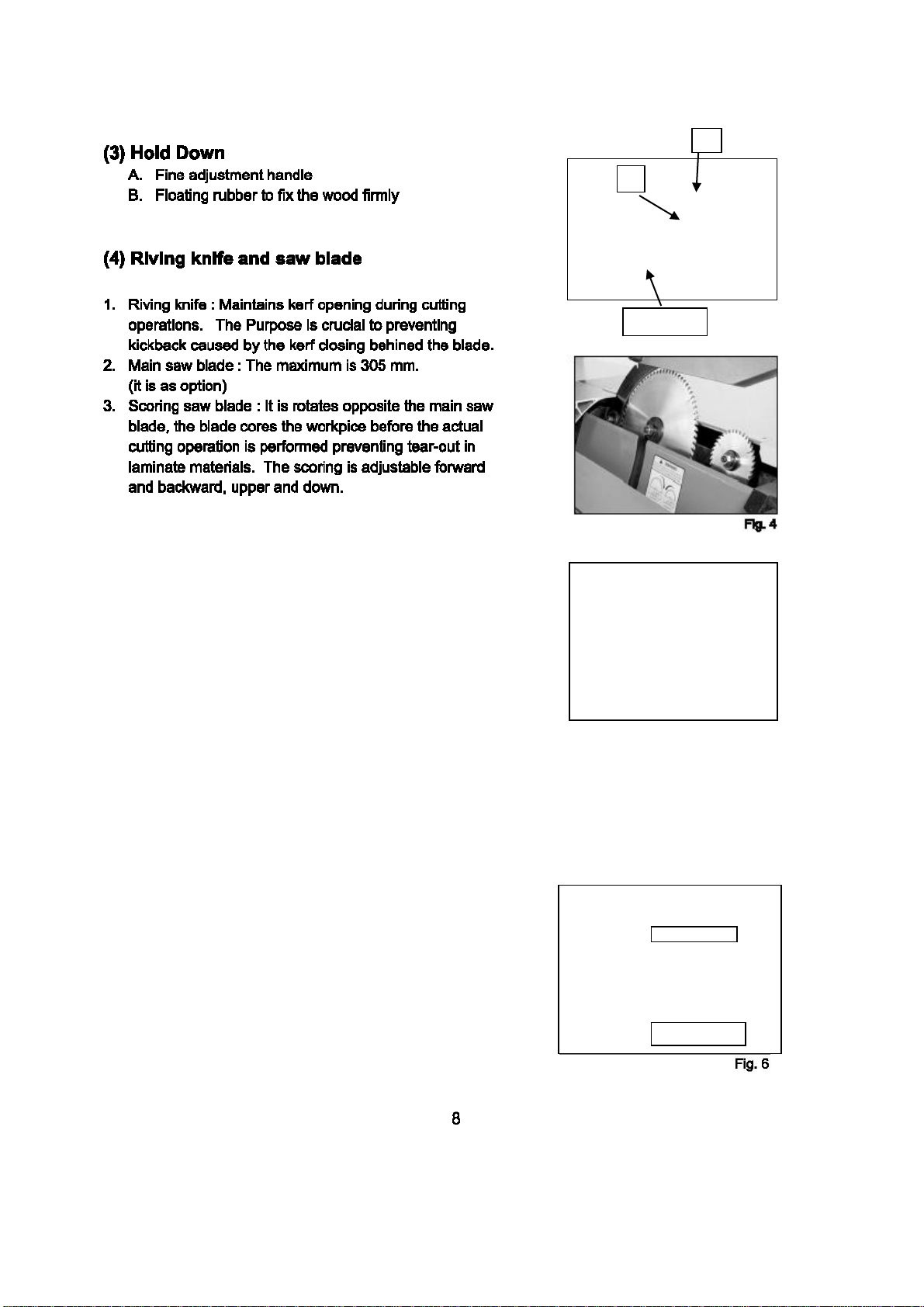

(3). Hold Down .......................................................................................................................................

(4). Riving Knife & Saw Blade ................................................................................................................

(5). Moving & Fixed The Base Unit ........................................................................................................

(6). Extension Table (large & Small) .......................................................................................................

(7). Scale Adjustment ..............................................................................................................................

(8). Rip Fence ........................................................................................................................................

(9). Cross Table ......................................................................................................................................

(10). Cross Fence .....................................................................................................................................

(11). Sliding Table .....................................................................................................................................

(12). Main Blade ......................................................................................................................................

(13). Scoring Blade ..................................................................................................................................

(14). Fence Scale Alignment ....................................................................................................................

(15). Dust Collection .................................................................................................................................

(16). Power Cord ......................................................................................................................................

(17). Test Run ...........................................................................................................................................

Operation .......................................................................................................................................................

(1) Change Main Blade ............................................................................................................................

(2) Riving Knife Adjustment ......................................................................................................................

(3) Change Scoring Blade ........................................................................................................................

(4) Rip Cutting ..........................................................................................................................................

(5) Crosscutting ........................................................................................................................................

(6) Miter Cutting .......................................................................................................................................

(7) Lubrication ..........................................................................................................................................

(8) Replace Belts .....................................................................................................................................

(9) Blade Tilt .............................................................................................................................................

(10) Sliding Table Parallel Adjustment ........................................................................................................

(11) Squaring Crosscut Fence To Blade .....................................................................................................

(12) Trouble Shooting .................................................................................................................................