Manual | OMC-150

Status: Final | Not confidential

Table of contents

1Introduction..................................................................................................................... 7

1.1 Utilisation.............................................................................................................................................7

1.2 General arrangement..........................................................................................................................7

1.3 Basic Specifications ............................................................................................................................8

1.4 Theory of Operation ............................................................................................................................8

1.5 Conditions of use.................................................................................................................................8

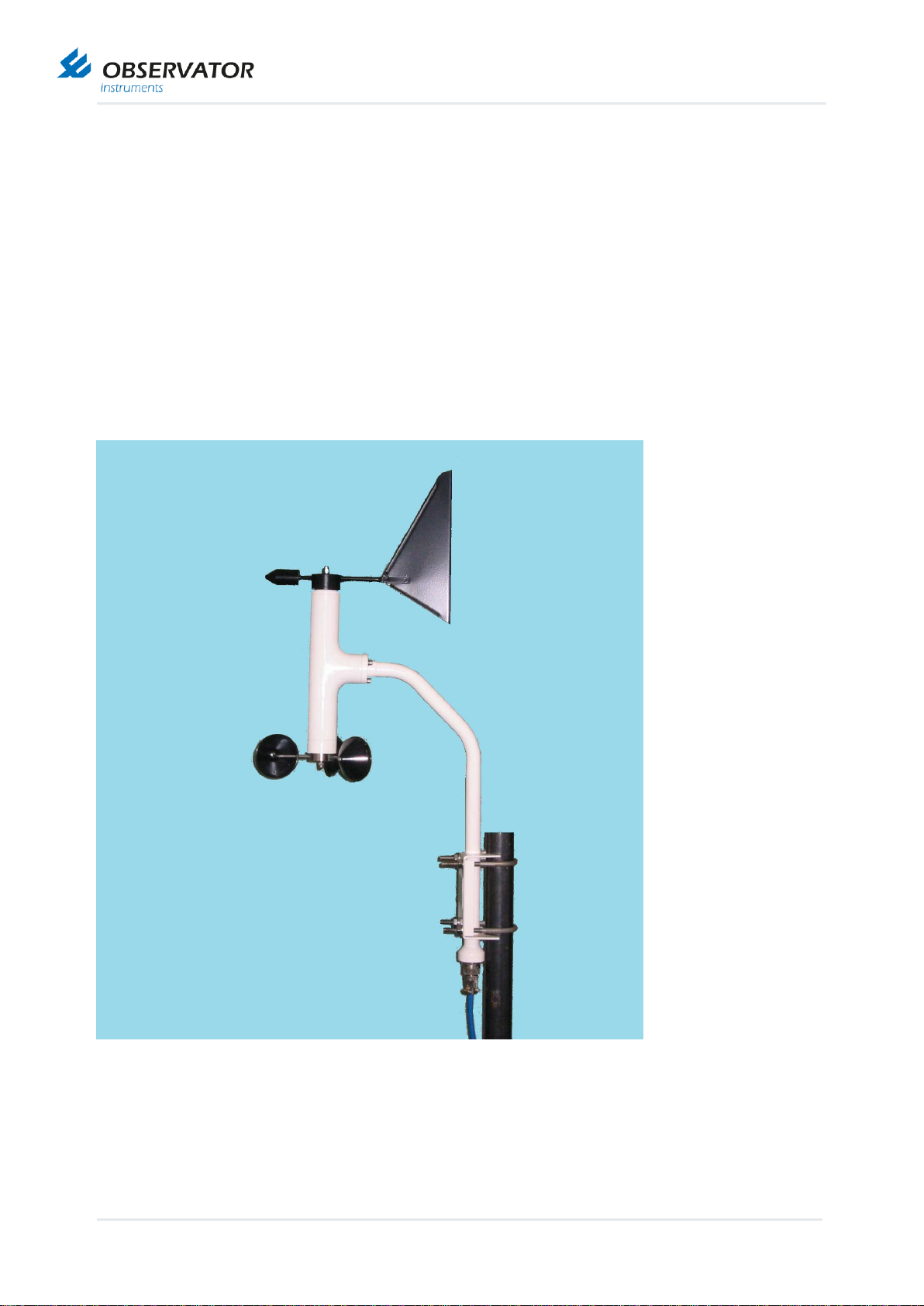

2Description...................................................................................................................... 9

2.1 General................................................................................................................................................9

2.2 Main parts............................................................................................................................................9

2.3 Moving parts........................................................................................................................................9

2.4 Electrical..............................................................................................................................................9

2.5 Layout of a wind system......................................................................................................................9

3Operation........................................................................................................................10

3.1 General..............................................................................................................................................10

3.2 Measurement of wind speed.............................................................................................................10

3.3 Measurement of wind direction .........................................................................................................10

4Safety..............................................................................................................................11

4.1 Safety measures by the design of the OMC-150 anemometer.........................................................11

4.2 System integration - interconnection to the other system components ............................................11

4.3 Required personnel qualification and remaining risks ......................................................................12

5Handling, transportation and storage...........................................................................13

5.1 Handling ............................................................................................................................................13

5.2 Long term storage .............................................................................................................................13

5.3 Reshipping the instrument.................................................................................................................13

6Installation......................................................................................................................14

6.1 Unpacking..........................................................................................................................................14

6.2 Location of the sensor.......................................................................................................................14

6.3 Location of the sensor.......................................................................................................................14

6.4 Mounting / mechanical installation ....................................................................................................14

6.5 Assembly of cup and vane ................................................................................................................15

6.6 Alignment of the wind vane...............................................................................................................16

6.7 Electrical installation..........................................................................................................................17

7Commissioning..............................................................................................................18

8Faults, support, and service..........................................................................................19

8.1 Faults.................................................................................................................................................19

8.2 Support, service and warranty...........................................................................................................20

9Maintenance...................................................................................................................21

9.1 Maintenance schedule (preventive maintenance).............................................................................21

9.2 Removing the OMC-150 anemometer from its location....................................................................21

9.3 Recalibration......................................................................................................................................22