APPLICATION .................................................................................................................................... 3

PRODUCT REGISTRATION................................................................................................................ 3

DIRECTIONS FOR STORAGE AND HANDLING THE EQUIPMENT.................................................. 3

STORAGE OF THE EQUIPMENT ....................................................................................................... 3

UNCRATING........................................................................................................................................ 3

MOVING THE EQUIPMENT ................................................................................................................ 3

PLACING AND INSTALLING THE EQUIPMENT................................................................................. 4

ELECTRICAL REQUIREMENTS ........................................................................................................ 5

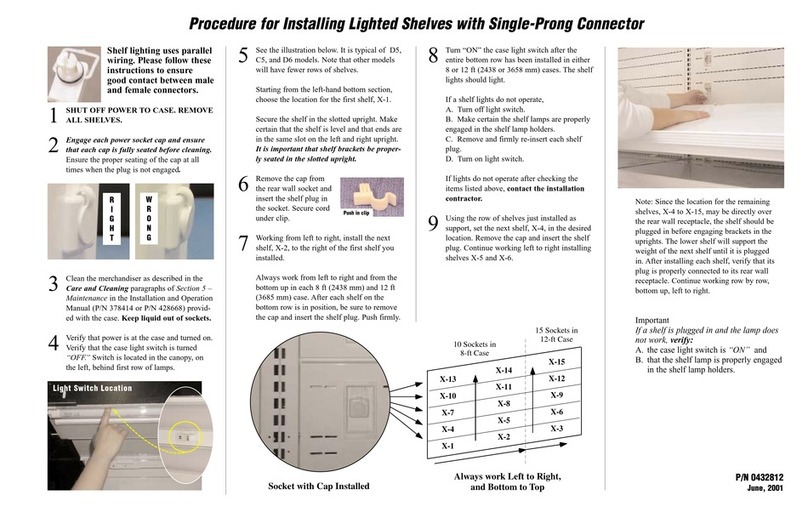

POSITIONING SHELVES..................................................................................................................... 5

PRODUCT LOADING.......................................................................................................................... 5

UNIT OPERATION AND COMPONENTS........................................................................................... 6

ELECTRONIC TEMPERATURE CONTROL:....................................................................................... 6

CAUTION..............................................................................................................................................8

SHELF SPECIFICATIONS................................................................................................................... 8

MAINTENANCEGUIDELINES.........................................................................................................8&9

CLEANING DRAIN LINES.................................................................................................................. 10

STANDARD WARRANTY...................................................................................................................11

TABLE OF CONTENTS

You have selected one of the finest commercial refrigeration units made.

It is manufactured under strict quality controls with only the best quality

materials available. Your Ojeda cooler, when installed correctly and

properly maintained will give you many years of trouble-free operation.

WARNING!

USE THIS APPLIANCE FOR ITS INTENDED PURPOSE AS DESCRIBED IN THIS MANUAL

When using electrical appliances, basic safety precautions should be followed, including the following:

Part Number 100330038 www.ojedausa.com |2

- Use this appliance for its intended

purpose as described in this Owner

Manual.

- is refrigerator must be properly

installed and located in accordance with

the Installation Instructions.

- We strongly recommend that any

servicing be performed by a qualied

individual.

- Do not allow children to climb, stand, or

hang on the shelves in the refrigerator.

ey could damage the refrigerator and

seriously injure themselves.

- Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

- Unplug the refrigerator before cleaning

and making repairs.