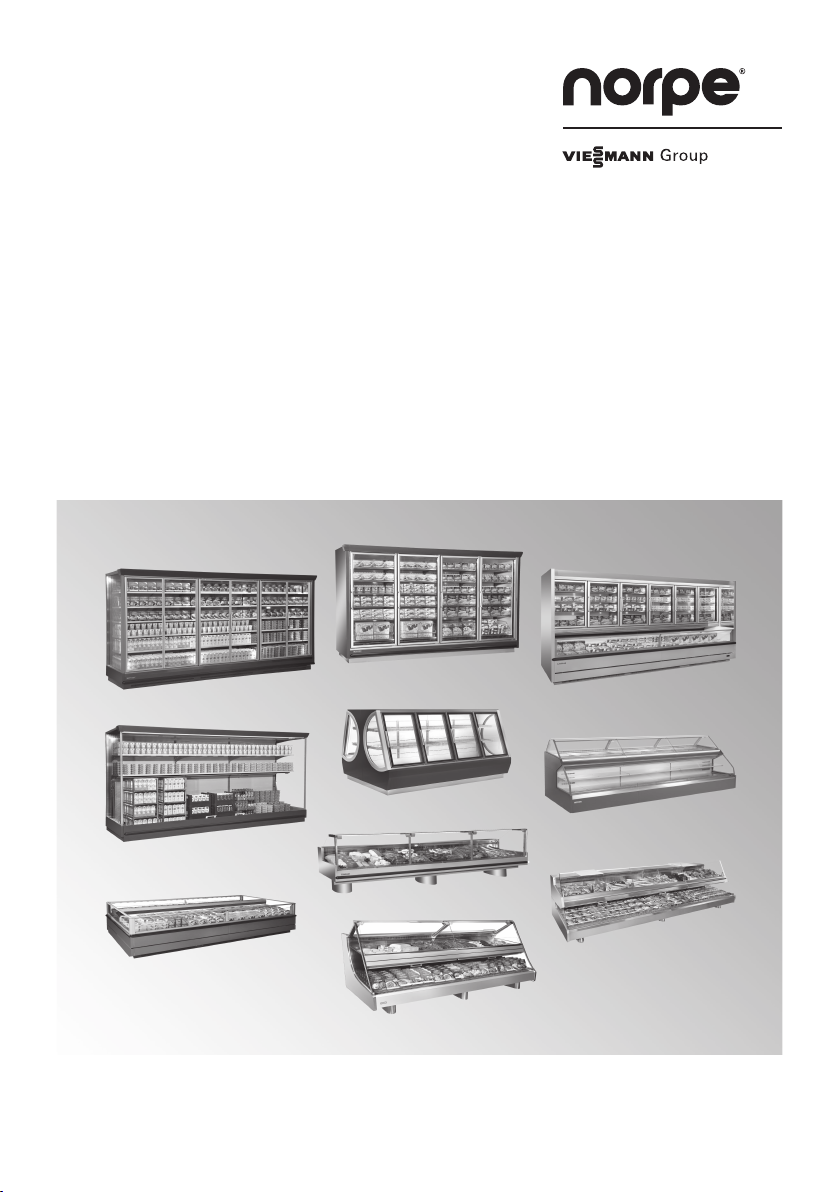

When opening Iconic cabinet doors, note that the opening mechanism is lightened and

the doors open slightly upwards. When the door is opened, the lower corner of the door

ends up further out than it would if the door was in a normal, upright position. This may

result to an unexpected collision. Respectively, the door shuts down softly and slowly.

Do not force or slam the door - instead, let the door close by gravitational force.

Open and close the doors carefully to avoid accidents.

Instruct the customers in the safe use of the doors.

Do not attach any material, for example price tags, on the doors.

WARNING

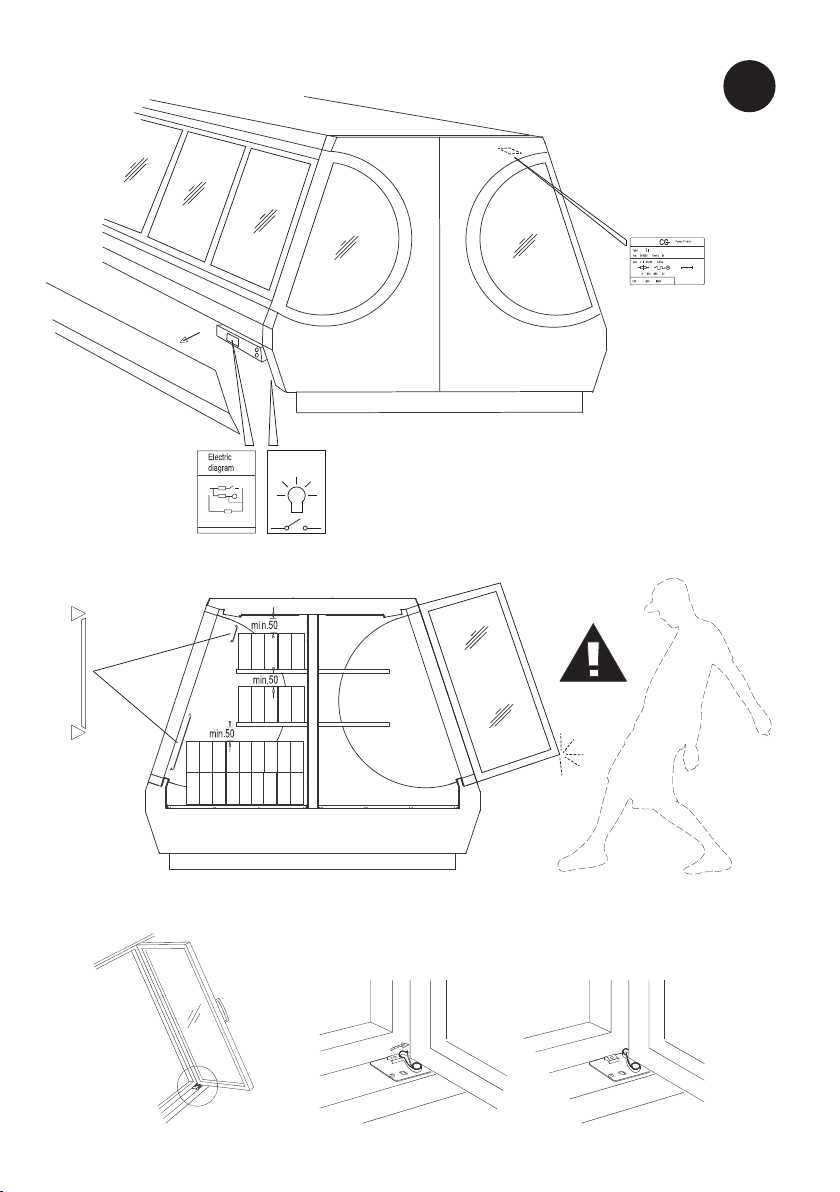

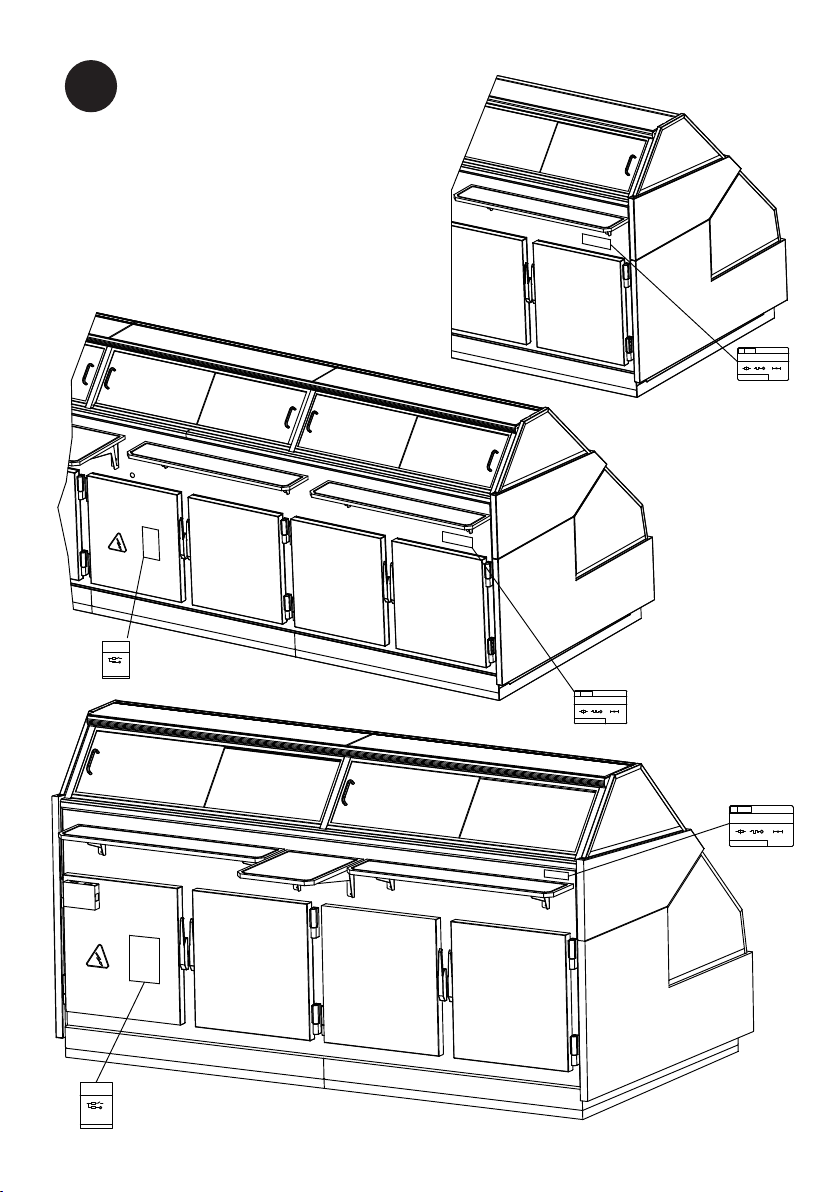

1.9. Gusto SO

Gusto SO serve over and self-service display cabinets are intended for storing and displaying a

wide variety of foods and foodstuffs, including dairy products, processed meat, convenience

foods, salads, processed and semi-processed foods and packed meat. Gusto SO display cabinets

are available for the deep-frozen, refrigerated and warmed products.

Gusto SO display cabinets are supplied for a number of different storage temperature ranges.

The cabinet versions are:

• Cabinet without integrated machinery unit, 0 version, cooling provided by remote refrigeration

equipment.

• Cabinet with integrated machinery unit, M version, provided with local cooling equipment.

•Freezer cabinet, F.

The temperature range in the cabinet is -21..-18° C. The electronic thermostat and light

switch are located in the lower right corner of the cabinet on the service side. The fan

evaporator is located inside the cabinet under the service access covers.

•Heated display counter, H.

The heating equipment for the display counter is comprised of two heating units:

• A heat radiator located in the roof compartment of the cabinet. This radiator is always

switched on when the electric plug is in the wall socket and the main switch (see figure

page 3, figure B2) is turned on. No automated feature disconnects this heating, which

also provides lighting for the cabinet.

• Heating resistors are installed in the base of the storage compartment. Gusto H display

counter has five or seven resistors. The heat output of these resistors is controlled by

a thermostat (see figure page 3, figure C2). The thermostat can be set to the temperature

desired, which is generally +70° C. The maximum setting is +90° C.

The interior surfaces of the cabinet and the lighting/heat radiator shade are

extremely hot. Wear protective gloves.

NOTE

Lift the front glass using both hands. Bring the glass gently to top positionNOTE

Do not push the glass up with force or slam the glass down.WARNING

Make sure that the cabinet version and storage temperature are correct for the products to be

stored.

4Version05/2015

ENGLISH

SM