3

The L16 battery is supplied with a factory fitted

“OCBL-T” fuse (M455323), required for

protection of the internal battery circuitry.

Use of any other fuse type could result in

damage and will invalidate any warranty claim.

IMPORTANT

Pay close attention to Warnings and Cautions in

this manual.

A WARNING describes a condition that may cause

severe personal injury or death if allowed to

happen.

A CAUTION describes a condition that may cause

moderate injury or property damage if allowed to

happen.

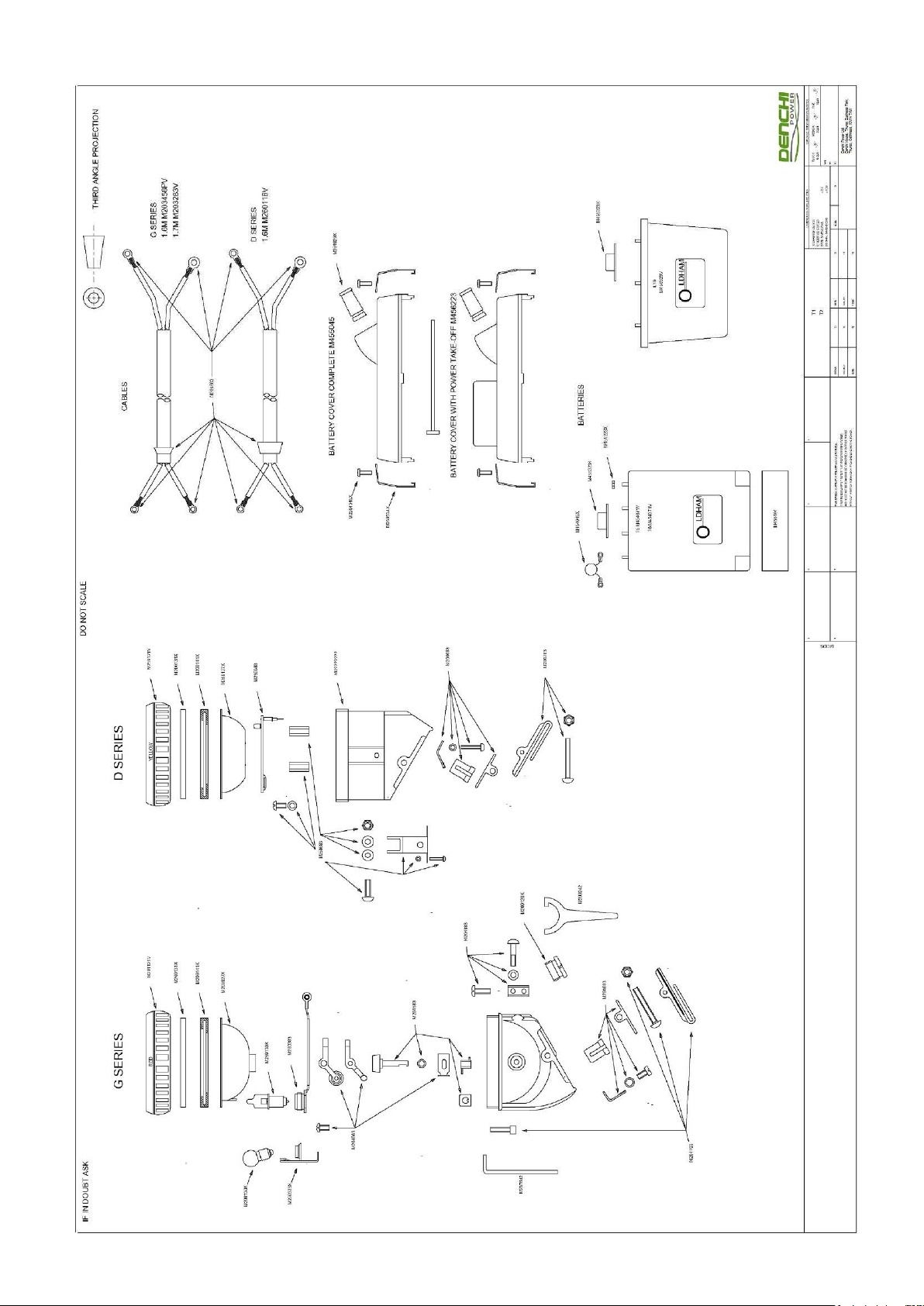

GENERAL DESCRIPTION

The GL9/GL16 cap lamp systems consists of a cap

mounted headpiece powered by a Li Ion battery.

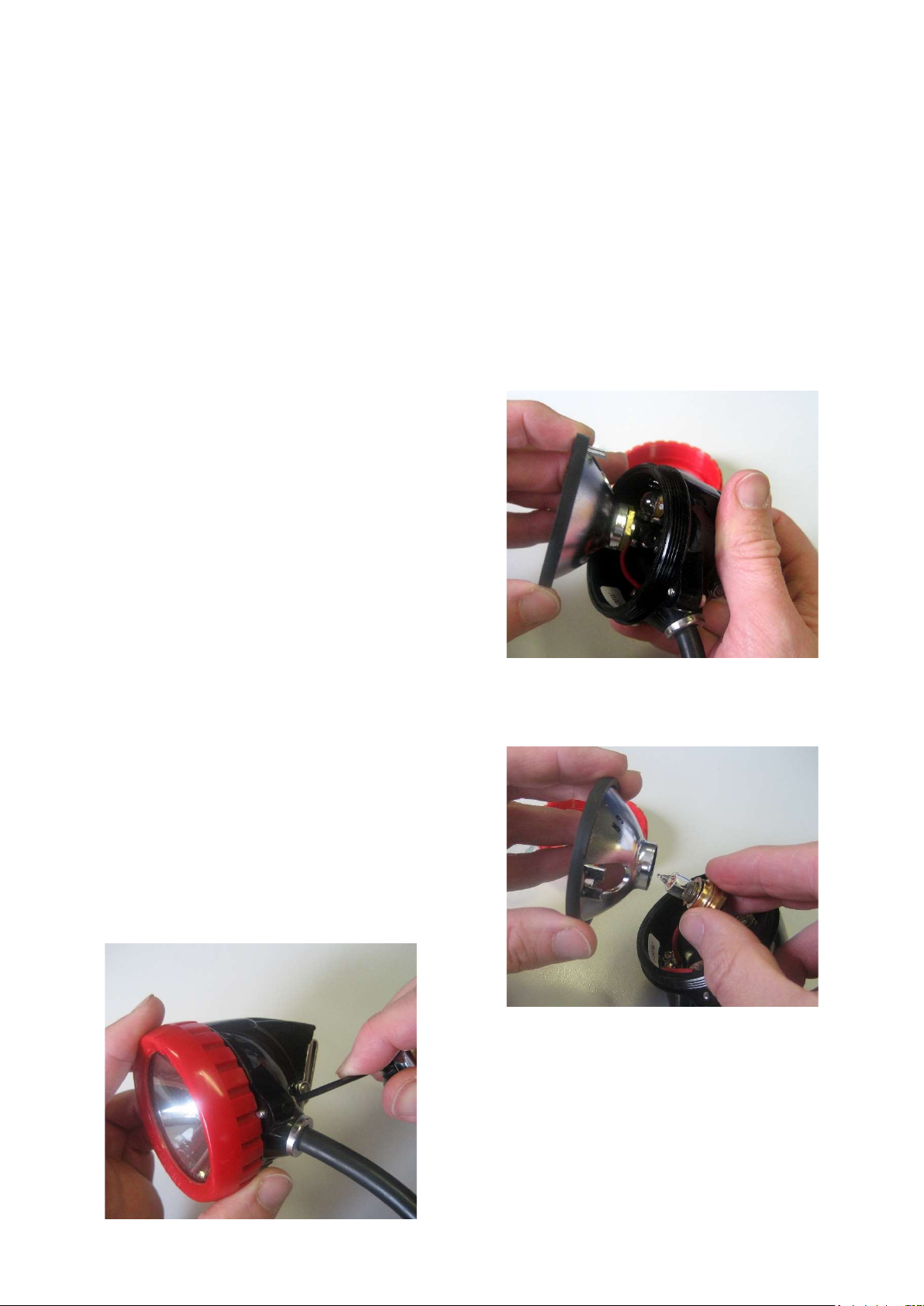

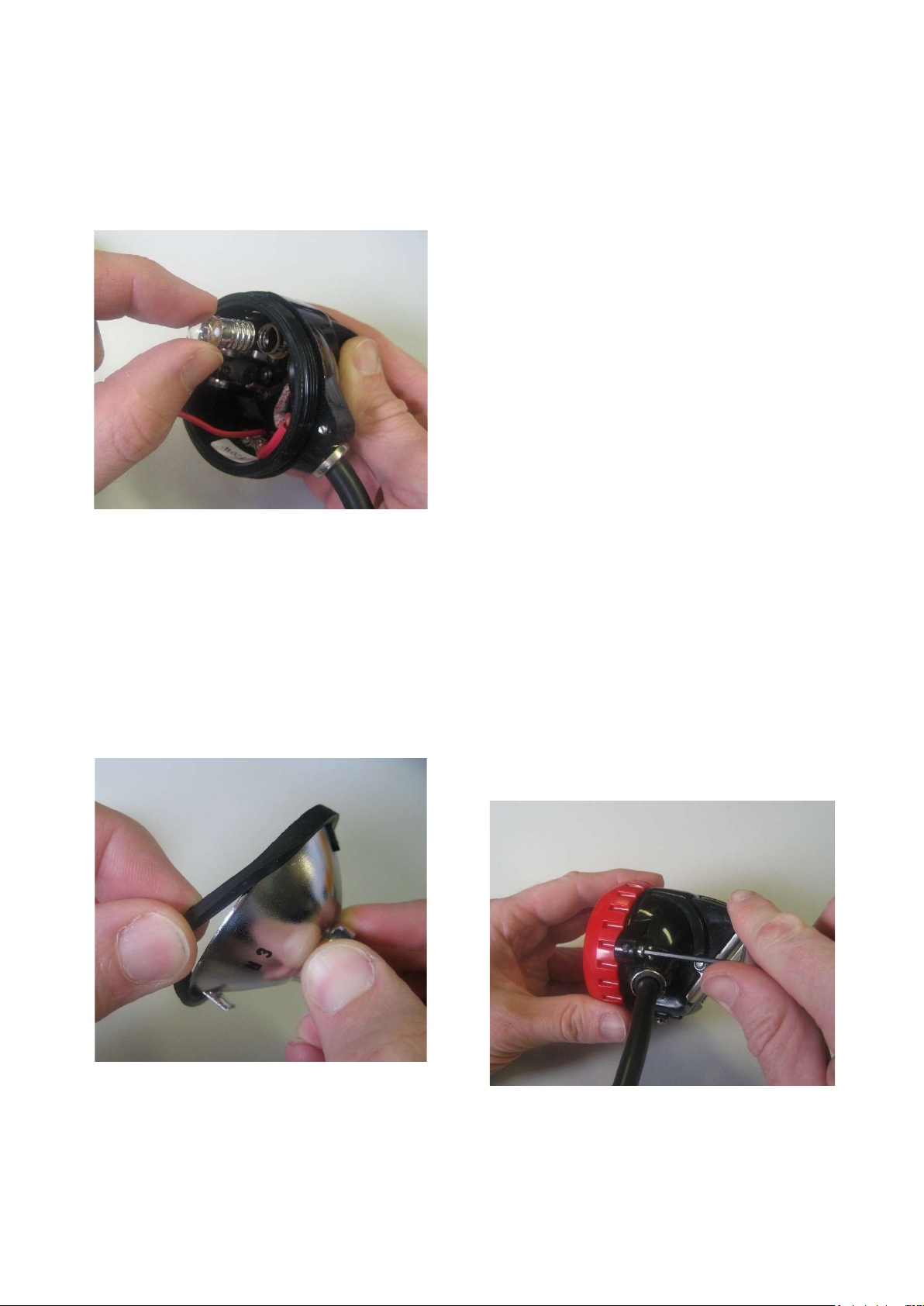

The basis of the headpiece in which some of the

internal connections are integral is as follows:

A selector switch is incorporated, which can switch

on either the large main bulb or the small

secondary bulb. The main bulb is held in the

reflector in a focused position by a screwed bush

from which a lead connects to one of the cable

termination points. The small bulb holder is

positioned at the top of the headpiece, being

connected internally to the cable termination. The

reflector fits over the small bulb and has a rubber

gasket around the rim to seal against the

headpiece lens.

PREPARING THE GL9 or GL16 CAP LAMP FOR

FIRST TIME USE

The battery is packaged separately to the lamptop

and needs to be connected before use.

Tool kit required is M614830

NOTE: THE BATTERY IS TRANSPORTED IN A

PARTIALLY CHARGED CONDITION - EVERY

BATTERY MUST BE FULLY CHARGED

BEFORE FIRST USE.

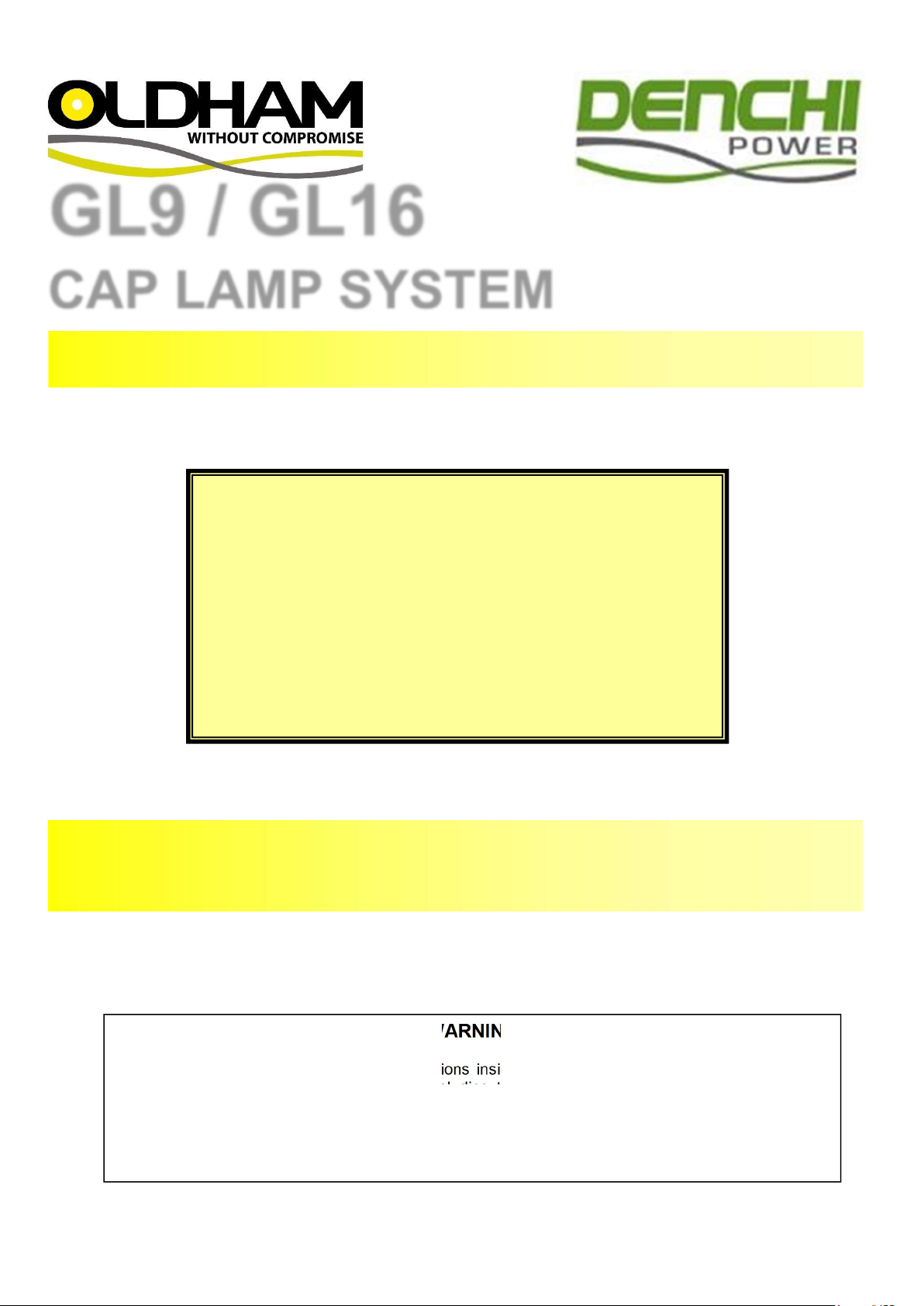

Remove the battery from the shipping box and

check for damage. The battery is supplied with the

encapsulated fuse fitted, terminal nuts and

washers.

Remove the nut and washer from the positive end

of the fuse (marked +). Place the ring terminal of

the red wire onto the terminal post, replace the

spring washer and nut, and tighten to 0.5Nm.

Remove the nut and washer from the negative

terminal (not connected to the fuse) and place the

ring terminal of the black wire onto the terminal

post, replace the spring washer and nut, and

tighten down to 0.5Nm.

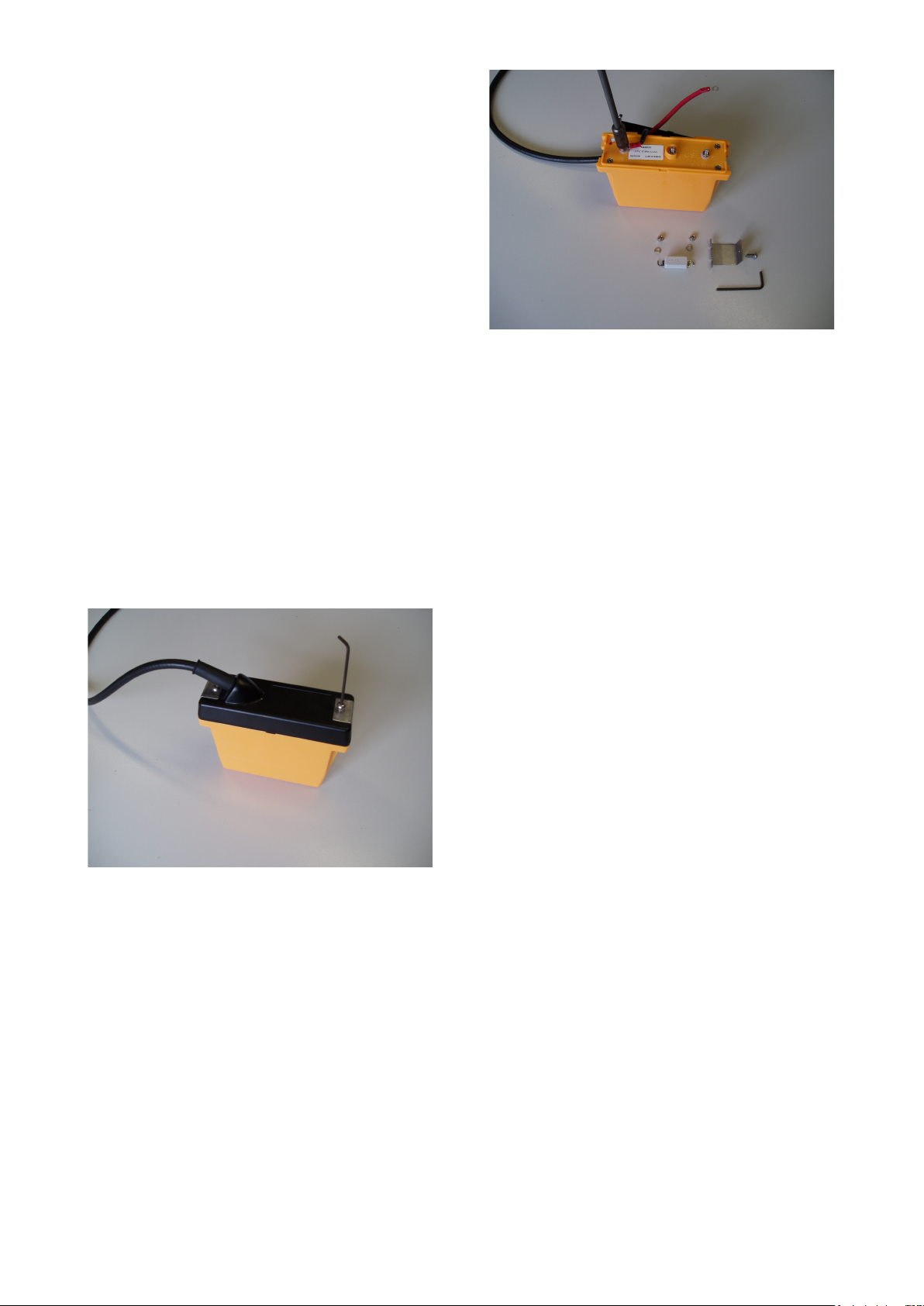

Hook the cable exit end of the battery cover onto

the battery.

Check that the cables are not trapped under the

edge of the cover then press down into position.

Secure the cover in place with the clip and M4

mushroom head socket screw.

Battery charging

WARNING

Li Ion batteries must only be charged on a

specific charger with a Li Ion charge profile. If

the battery is charged on a standard GT

caplamp charger the battery will be damaged.

For charger information and how to convert

existing charger software please consult the

Caplamp Charger Manual.

Every battery must be charged before it is used for

the first time.

Never discharge completely!