OleumTech Wio RM4 User manual

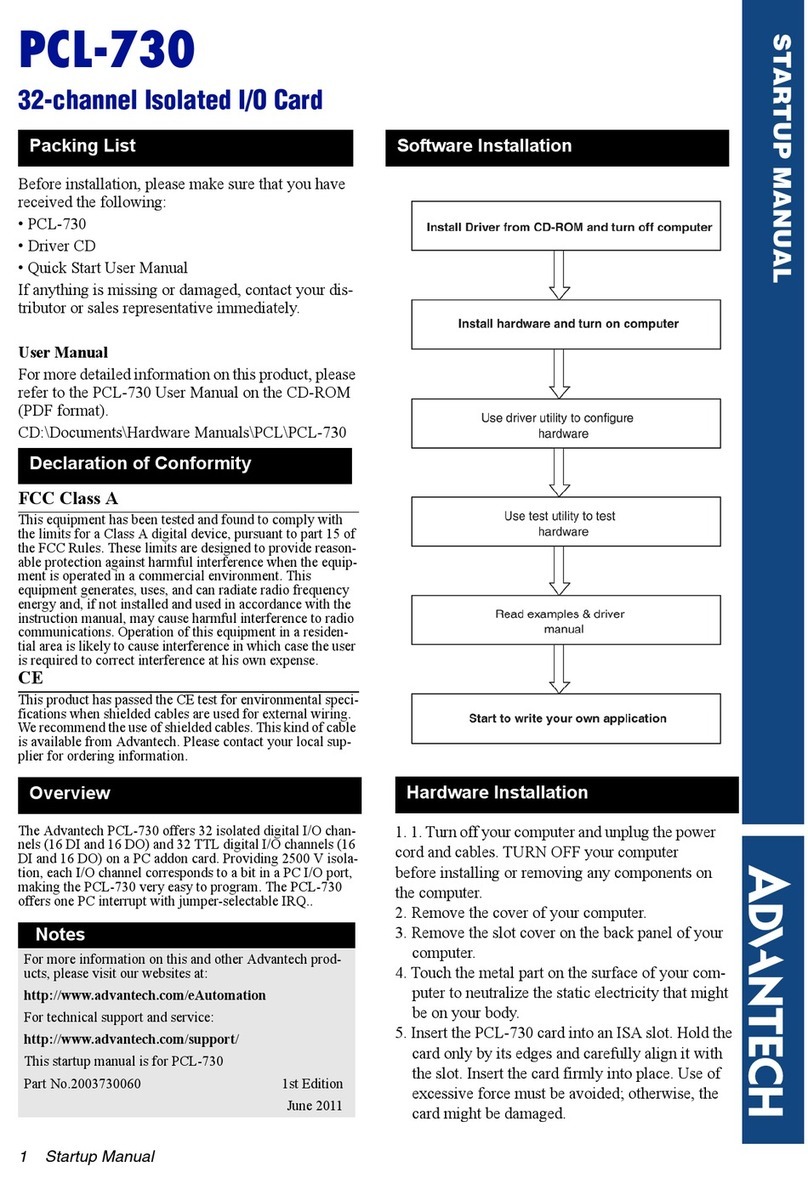

NEMA-Type

Enclosure

9-30 Vdc

(Reverse polarity protecon)

Install antennas

10 above the ground.

Antennas must match

the system’s

Radio Frequency (RF).

Direconal antennas must be

poinng at each other.

Use low loss antenna

cables and connectors.

Installing lightning

arrestors are strongly

recommended.

Make a hole at the boom

of the enclosure to run

wires and cables.

Weatherproof all exterior

connecons and seal all openings

to the enclosure.

6. Installaon

Quick Start Guide

Wireless I/O System - RM4

1. Before You Begin

2. Required Items

- BR-xxxx-RM4 Radio Kit with Onboard I/O

- (2) 9-30 Vdc power sources

- Technician’s screwdriver (flathead)

- (2) 35 mm standard DIN rails (35 x 7.5 mm)

- (2) NEMA 4X-type enclosures for outdoor installaon

- (2) antennas (must match system’s RF type)

- (2) low loss antenna cables, SMA to N (male)

- (2) low loss antenna cables, N to N (male) (oponal)

- (2) lightning arrestors (strongly recommended for outdoors)

- Weatherproofing tape/sealant material

- Wire (solid/stranded AWG 28-12 gauge)

1. The system offers two Tx speeds: 1 sec (def.) or 400 ms

Use the Tx buon to switch between speeds.

2. Device reset: hold down the Tx buon for ~4 seconds unl the

LEDs are exnguished. Power cycling will also reset the device.

Ensure the installaon of the system meets applicable

state and naonal electrical code requirements.

The installaon of the system should only be

performed by a qualified installer.

When connecng the device to an external power supply,

do not exceed the defined voltage: 9-30 Vdc max.

Contains no user serviceable parts. Unauthorized

modificaon to device or supplied accessories may

damage devices and void warranty.

This product is NOT intended for use in hazardous locaons.

Do NOT install or mount on an applicaon with

high vibraon.

The WIO® System must be installed within an

enclosure that requires a tool to access. This is to

prevent inadvertent disconnecon of any of the power

wiring, signal wiring or communicaon cables.

80-3159-001_C

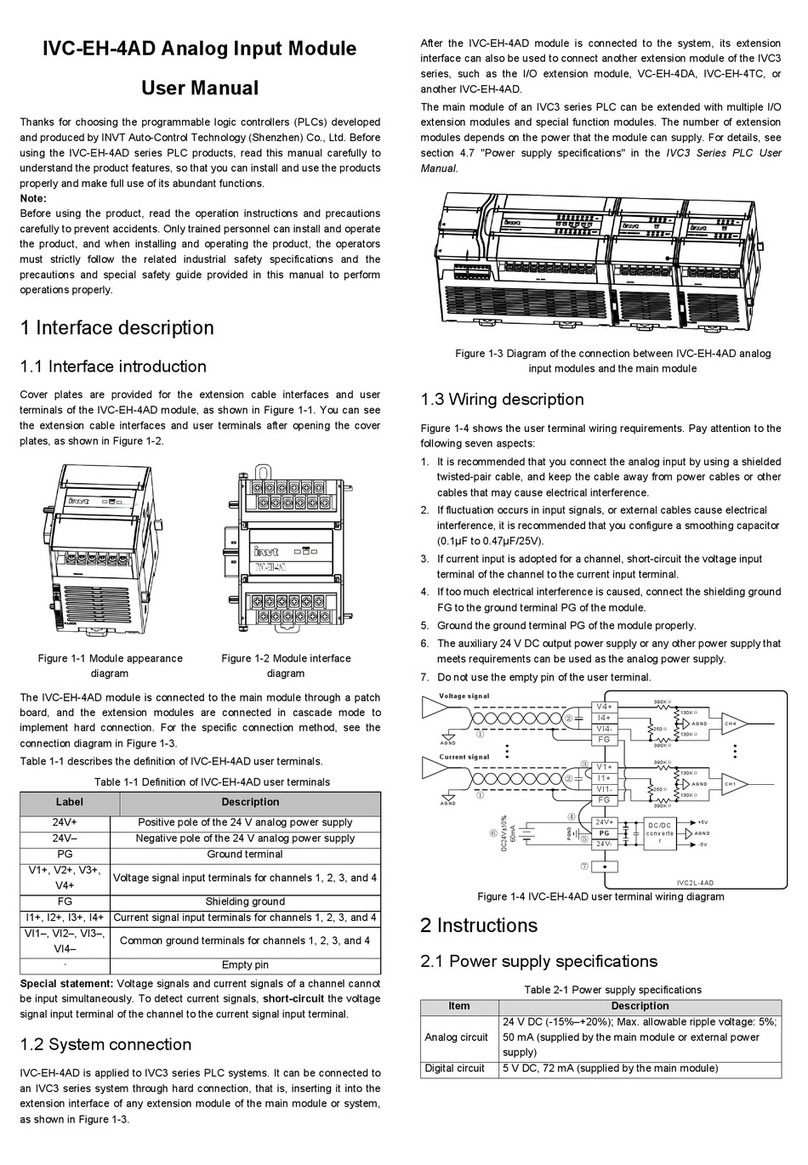

3. Hardware Overview

- Operang temperature range: -40 ˚C to 80 ˚C

7. RF Best Pracces

4. RF Transmission (Tx) Speed / Device Reset

Go to www.wio.oleumtech.com to view or download the

full User Guide for detailed installaon and other

helpful informaon.

RADIO A RADIO B

P1 - Analog Out 1

P2 - Analog Out 2

P4 - Power 9-30 Vdc

P3 - Digital PIO 1/2

Spring-loaded

Latching Clip

DIN Rail Hook

DIP Switches 1-8

SMA Female

P1 - Analog In 1

P2 - Analog In 2

Tx Speed / Reset Buon

Mini-USB

Firmware Upgrade

Diagnosc LEDs RF/PIO

P4 - Power 9-30 Vdc

P3 - Digital PIO 1/2

1. RF Diagnoscs

5. LED Diagnoscs

Flashing Green:

Flashing Yellow:

Solid Yellow:

PIO

RF

Good RF signal: -40 dB (best) to -94 dB

LED flashing speed also indicates

Tx speed.

Weak RF signal: Worse than -94 dB.

RF failure.

2. Digital PIO Diagnoscs

Solid Green:

Solid Red:

Indicates both PIO direcons are

setup correctly.

Indicates when one or both PIO

direcons are setup incorrectly.

Check PIO DIP switches.

www.prosoft-technology.com

1.661.716.5100

1. Perform a RF survey prior to installaon.

2. Use high quality antennas and low loss cables and fings

for achieving the best possible wireless performance.

3. Having a clear line of sight between antennas (Fresnel zone)

is ideal for achieving best RF signal quality.

4. When seng up and installing antennas, avoid walls,

tall buildings, trees, and other solid obstrucons for

improving RF signal quality.

5. Install antennas at least 10 above ground when possible.

6. When using direconal antennas, be sure to point the

antennas at each other and be sure to use correct

antenna orientaon.

7. Be sure to install omni-direconal antennas in vercal posion

or perpendicular to the ground.

8. Be sure that there are no loose connecons.

Securely ghten all cable connecons and wire terminals.

9. Be sure to waterproof all exterior cable connecon using high

quality sealing tape.

10. Once the WIO System is up and running, use the le LED

to diagnose RF health.

13. Transmit Power Seng - 900 MHz Only8. Power Wiring

9. Analog 4-20 mA Inputs, Radio A

This system allows you to control the output states when

RF communicaon failure occurs. When RF is lost for ten

consecuve seconds or more, the system will automacally

drive outputs to their predetermined fail safe states. Use

the dedicated DIP switches to control the fail over behaviors.

1. Analog fail safe modes (DIP 4 and 5 on Radio B)

Applies to both outputs.

11. Digital Programmable I/O (PIO)

1. Digital/discrete input wiring

Only Radio A is equipped with analog inputs.

This system is equipped with two digital programmable I/O.

Using dedicated DIP switches 1 and 2, you can control the

signal direcons independently.

If Radio A = Input, Radio B must = Output and vice versa.

Otherwise, PIO LED will turn red indicang signal direcon error.

Factory default PIO sengs: Radio A = DI ; Radio B = DO

Note that DIP switch posions for In/Out are reversed

on Radio Module A and B.

Must reset device aer modifying any DIP switch sengs.

Be sure to set Fail Safe output mode: Off (default) or On.

The 900 MHz system is equipped with two adjustable

transmission output sengs. Use DIP switch 6 to select

output power. Both Radio Modules must match power.

140 mW (default) or 1 W

14. RF Channel - 900 MHz / 2.4 GHz Only

900 MHz and 2.4 GHz systems offer mulple RF channels

to create beer RF isolaon for beer performance.

Use dedicated DIP switches to set RF channel.

900 MHz system offers channels 0-3 while 2.4 GHz system

offers 0-7 channels.

The RF channel or DIP paern on both Radio Modules

must match. Some examples of how to set RF channel:

15. Using PIO to Monitor RF Health

Using the following logic, you can ulize either PIO channels

to monitor the RF health of the system from a connected

logic controller:

1. Select a PIO channel.

2. Set the PIO signal direcon using DIP switches.

3. Set DO fail safe output mode to off on the output side.

4. On the Radio Module with PIO set as input, place a jumper

wire to e DI to the ground terminal to create “always on.”

5. Tie the output to a logic controller or any device monitoring

the DO state.

6. During normal operang condions, the DO will be on.

7. When the RF communicaon is lost, the system will

de-energize the output to nofy the change in condion.

2. Digital/discrete output wiring

Power - P4

12. Fail Safe Output Operaon

©2019 OleumTech Corporaon. All rights reserved. OleumTech and WIO are registered trademarks of OleumTech Corporaon in the United States.

Specificaons, design, product descripons, and availability subject to change without noce.

9-30 V GNDGND

Reverse Polarity Protecon

10 11 12

DI 2 GNDDI 1

7 8 9

DO 2 GNDDO 1

7 8 9

1. 4-20 mA input wiring - P1 and P2

10. Analog 4-20 mA Outputs, Radio B

4-20 mA output wiring - P1 and P2

Only Radio B is equipped with analog outputs.

SENSOR

N/C

+

9-30 Vdc

N/C

SENSOR

+

_

EXT.

POWER

+

_

S- COMVS

AO 1/2 Fail Safe

Last

Known

Value

<4 mA

AO 1/2 Fail Safe

>20 mA

AO 1/2 Fail Safe

Fail over to Last Know Value (Default) Fail over to Less than 4 mA

Fail over to Greater than 20 mA

>20 mA

AO 1/2 Fail Safe

Fail over to Greater than 20 mA

2. Digital fail safe modes (DIP 3)

Applies to both outputs.

O

DO 1/2 Fail Safe On

DO 1/2 Fail Safe

Fail over to Off (Default) Fail over to On

RF Channel (0-7)

0

0

0

Both Radios

Must Match

Pattern

Channel 0 (Default)

RF Channel (0-7)

0

0

01

Both Radios

Must Match

Pattern

Channel 1

RF Channel (0-7)

0

0

0

Both Radios

Must Match

Pattern

2

Channel 2

RF Channel (0-7)

0

0

01

Both Radios

Must Match

Pattern

2

Channel 3

RF Channel (0-7)

0

0

0

Both Radios

Must Match

Pattern

2

4

Channel 6

RF Channel (0-7)

0

0

0

Both Radios

Must Match

Pattern

1

4

Channel 5

PIO2 GND

INPUT

DI1

Create “alway on”

condion

On = RF OK

Off = No RF

7 8 9

PIO2 GND

Logic

Controller

Example shown using PIO 1

DO1

7 8 9

OUTPUT

Must reset device aer modifying any DIP switch sengs.

3. External Loop Power

2. Internal Loop Power

VS/External Power (min) = 7 Vdc + Max Current (Amp) * Rloop

Rloop = Total Loop Impedance

*A 250 ohm Resistor may be required depending on the design

of the third-party 4-20 mA input module.

250 ohm

Resistor*

Measurement

Electronics

4-20 mA

+

_

PLC Input Module or

Process Controller

N/C

V+GND GND

+_

GND

POWER

SUPPLY

S+

10 11 12

Quick Start Guide

Wireless I/O System -RM4

80-3159-001_C

Accepts Dry Contact (Internal 3.3 Vdc Pull-Up),

Open-Drain (NPN) and Level Output (0 - 30 Vdc Max.)

Input Voltage Threshold:

Signal "H", Vi > 1.85 Vdc

Signal "L", Vi < 1.03 Vdc

Open Drain (NPN) Outputs

Inducve Load (Sink Current): 1A/30 Vdc Max.

Voltage Level Output:

Internal Pull-Up: Signal "H", Vo = 3.3 Vdc

Signal "L", Vo = 0.2 Vdc

Accepts Oponal External Pull-Up, 30 Vdc Max.

Requires 10 K Resistor

Other OleumTech I/O System manuals