USER MANUAL

(TERMS OF WARRANTY)

Introduction

User manual of the 2200x0.8 (3050x0.8) folding machine is the basic equipment of the

machine. To meet the requirements of construction companies and sheet metal working

plants we started to manufacture a new model of a manual folding machine with high

reliability, outstanding durability and aesthetic appearance.

Before using this machine, please read this manual carefully. Please follow the instructions

and safety rules when operating this machine. If you find the information included in this

manual unclear please contact your retailer or the manufacturer for assistance.

. Intended use

This folding machine is intended to fold steel sheets in straight lines up to the max. angle of

45° ( 35° for 3-meter folding machine) and max. thickness of 0.8 mm for steels sheets.

2. Safety rules

This folding machine can only be operated by an adult person who has read this manual and

is familiar with the rules for safe work and operation.

When working on the machine observe the basic safety regulations for steel sheet handling,

use personal protective equipment and use the machine as intended. Where the machine is

operated by two persons do not tamper with the movable parts of the machine if you are not

sure that the hands of your partner are outside the working areas of the machine.

The machine should be placed on a stable and even surface with the minimum distance from

a wall or the nearest partition being less than 50 cm to ensure easy and safe operation of the

machine. No bystanders should be in the vicinity of the machine. Keep order by placing the

finished products at a safe distance from the machine.

Do not allow the folding machine to be operated by unexperienced persons. Protect the

working area to prevent the access of children and animals.

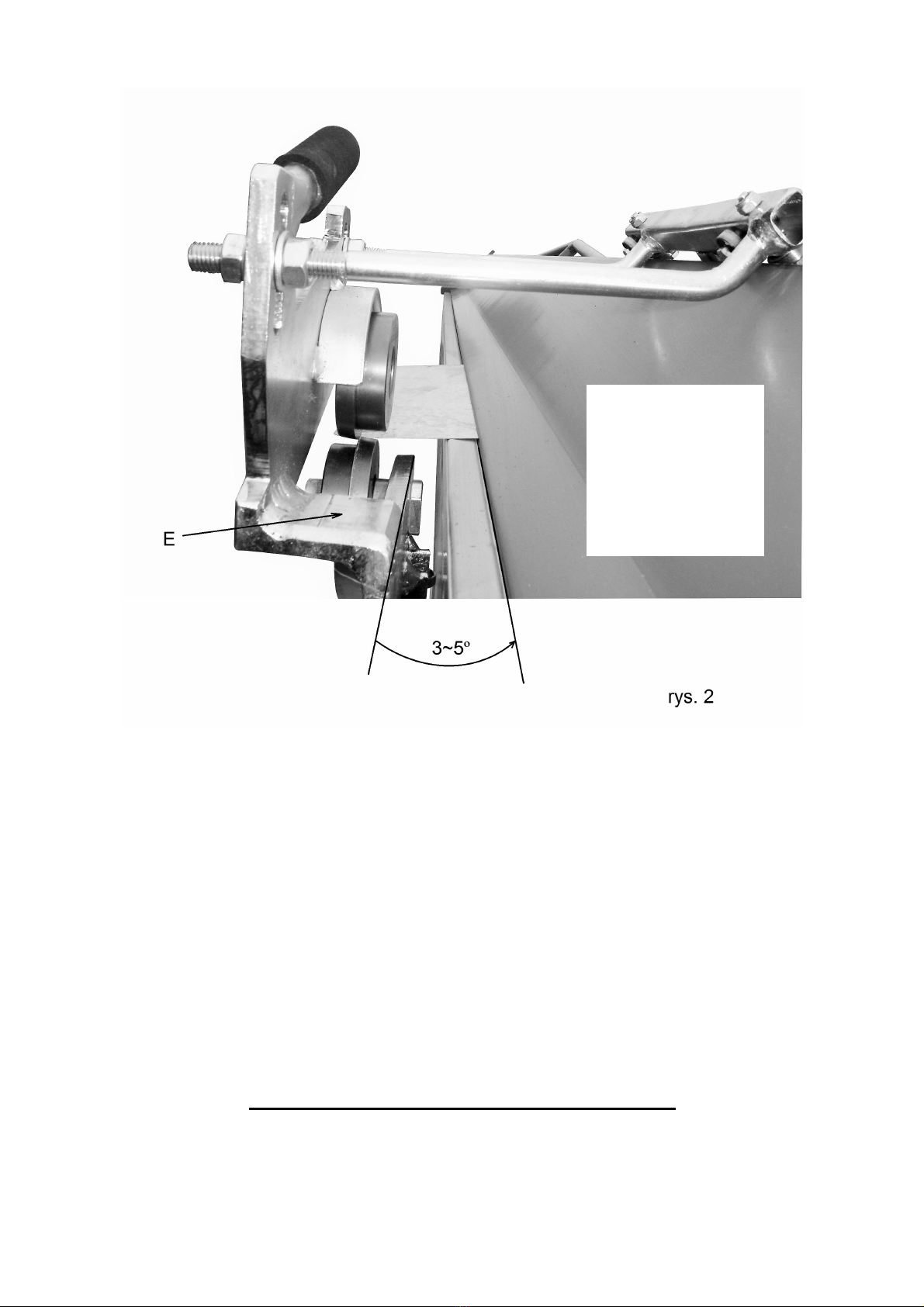

Pay special attention to your fingers as they can be injured by the pressing beam or the

folding beam. To ensure safety the upper beam should always be in extreme positions i.e.

closed or open. To minimize the risk of the pressing beam dropping the machine is equipped

with two gas springs (not applicable to 2.5- and 3-meter folding machines except for

customized machines).

When moving the folding beam, the pressing beam should always be closed.

Any defects or damages found during the operated can be repaired by an authorized person

only or the manufacturer in case of more complicated defects.

The folding machine must not touch food directly and it should not be used in a potentially

explosive atmosphere.