D860MGB rev04

Sommario

1GENERAL INFORMATION BEFORE INSTALLING ................................................................................. 4

1.1 INTRODUCTION............................................................................................................................... 4

1.2 LIABILITY AND GUARANTEE .......................................................................................................... 4

1.3 SAFETY MEASURES........................................................................................................................ 4

1.4 WARNING ON HOW TO OPERATE................................................................................................. 4

SAFETY ON THE WORKING PLACE....................................................................................... 4

CLEANING................................................................................................................................. 5

INSTALLATION ......................................................................................................................... 5

MAINTENANCE......................................................................................................................... 5

ANTI-POLLUTION MEASURES................................................................................................ 5

1.5 CONTROL OF THE SUPPLIED MATERIAL..................................................................................... 5

1.6 IDENTIFICATION PLATES ............................................................................................................... 5

1.7 FEATURES OF THE MACHINE ROOM ........................................................................................... 6

2TRANSPORT AND STORAGE ................................................................................................................. 6

2.1 GENERAL INFORMATION ............................................................................................................... 6

2.2 PUMP UNITS..................................................................................................................................... 6

2.3 INVERTER......................................................................................................................................... 7

2.4 FLEXIBLE HOSES AND RIGID PIPES............................................................................................. 7

3ASSEMBLING OF THE HYDRAULIC COMPONENTS ............................................................................ 7

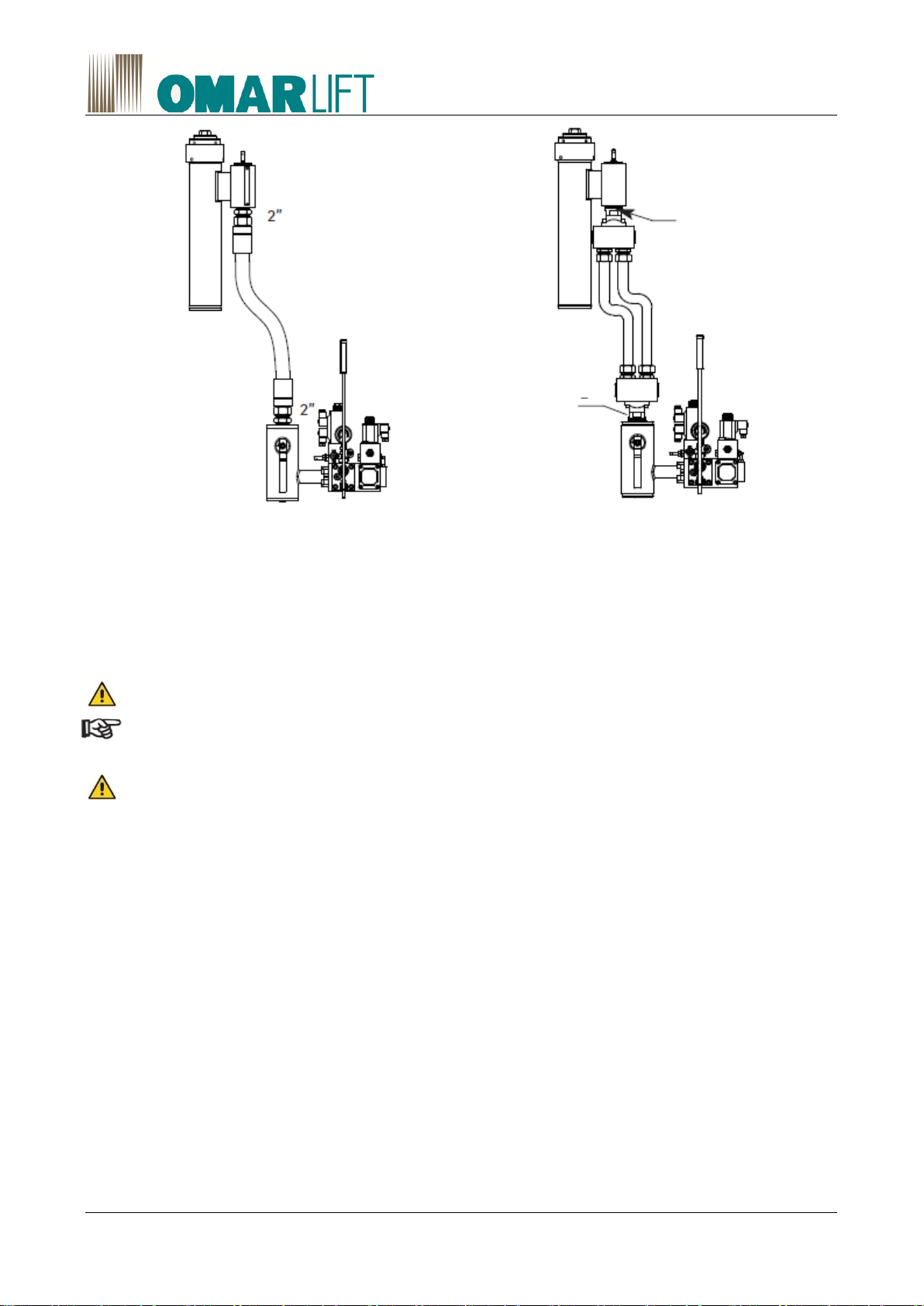

3.1 PUMP UNIT....................................................................................................................................... 7

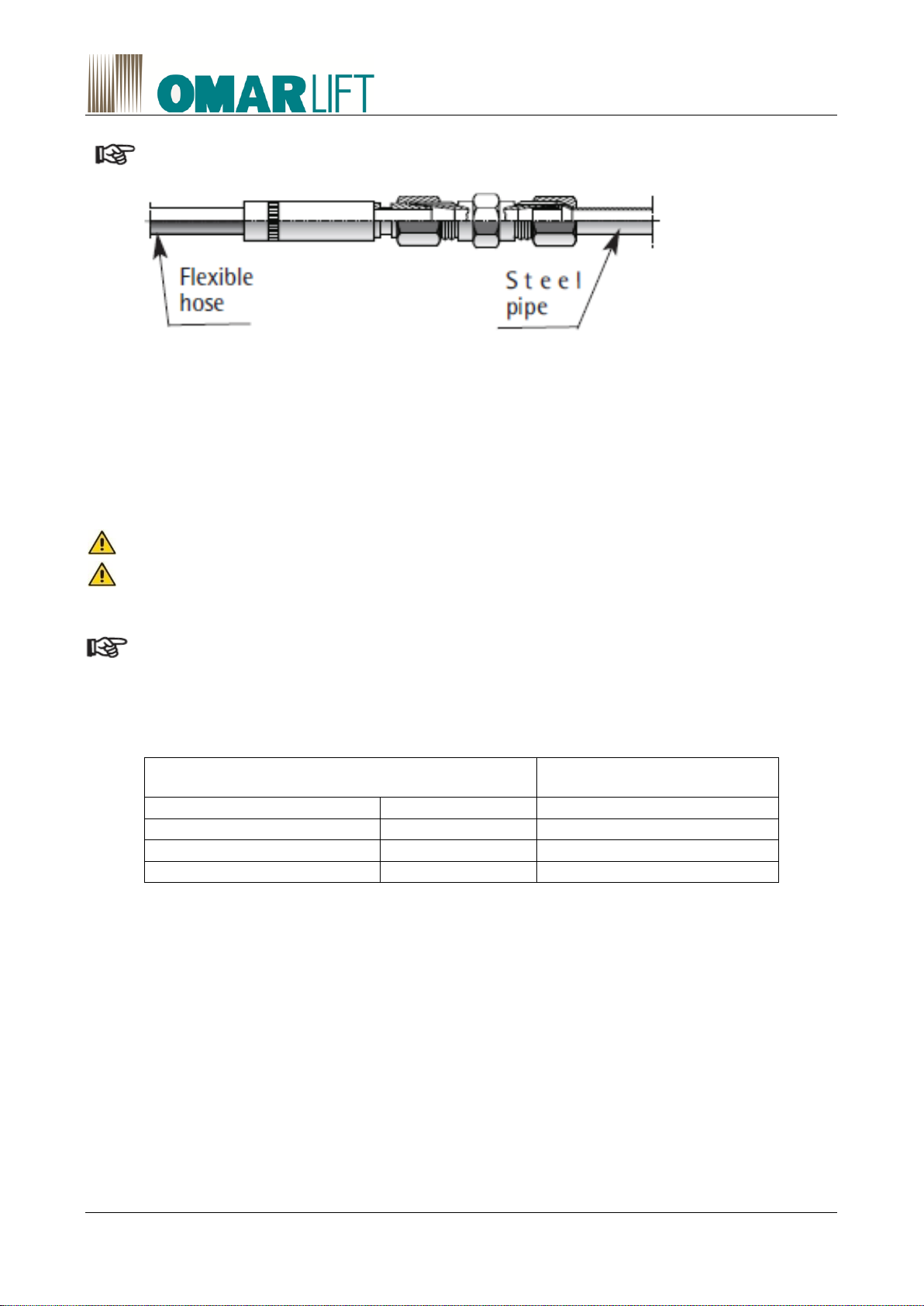

3.2 PIPE AND HYDRAULIC CONNECTIONS ........................................................................................ 7

4ELECTRICAL CONNECTIONS................................................................................................................. 9

4.1 GENERAL REGULATIONS............................................................................................................... 9

4.2 CONNECTION BOX.......................................................................................................................... 9

4.3 ELECTRICAL CONNECTION OF THE THREE-PHASE MOTOR.................................................. 10

4.4 MOTOR PROTECTION WITH THERMISTORS............................................................................. 11

4.5 ELECTRICAL CONNECTION OF THE VALVE GROUP................................................................ 11

4.6 POSITIONING OF THE SHAFT SWITCHES FOR THE DECELERATION DISTANCE................. 12

4.7 ELECTRICAL GROUP INVERTER................................................................................................. 12

INTRODUCTION ..................................................................................................................... 12

WARNING................................................................................................................................ 12

5OIL FOR LIFTS - CIRCUIT FILLING AND AIR PURGING ..................................................................... 13

5.1 CHARACTERISTICS....................................................................................................................... 13

5.2 CHOICE OF THE OIL...................................................................................................................... 13

5.3 CIRCUIT FILLING AND AIR PURGING.......................................................................................... 14

6CONTROLS AND TEST.......................................................................................................................... 16

6.1 CHECK OF THE OIL LEVEL IN THE TANK ................................................................................... 16

6.2 CHECK OF THE MAX. PRESSURE ............................................................................................... 16

6.3 CHECK OF THE START IN UPWARD DIRECTION....................................................................... 16

6.4 CHECK OF THE SEALING OF SEALS AND PIPES ...................................................................... 16

6.5 CHECK OF THE RUPTURE VALVE INTERVENTION................................................................... 17

6.6 CHECK OF THE INSTALLATION AT TWICE THE STATIC PRESSURE...................................... 17

6.7 CHECK OF THE ROD COUNTER-PRESSURE AND HAND WORKING ...................................... 17

6.8 CHECK AND ADJUSTING OF THE HAND PUMP......................................................................... 17

6.9 NOISE.............................................................................................................................................. 17

6.10 MANOMETER SHUT-OFF.............................................................................................................. 18

7ADJUSTING AND TEST OF THE OMARLIFT RUPTURE VALVE......................................................... 18

7.1 GENERAL INFORMATION ............................................................................................................. 18