-

-

-

1)

2)

3)

4)

5)

6)

7)

Soggetto a modifica senza preavviso! Subject to change without notice!

8)

9)

10)

11)

2.5 Cylinders in three pieces

1)

Pagina/Page D842MGB.006

Data/Date 09.2008

Versione/Issue 1

Hydraulic cylinders

Operating instructions

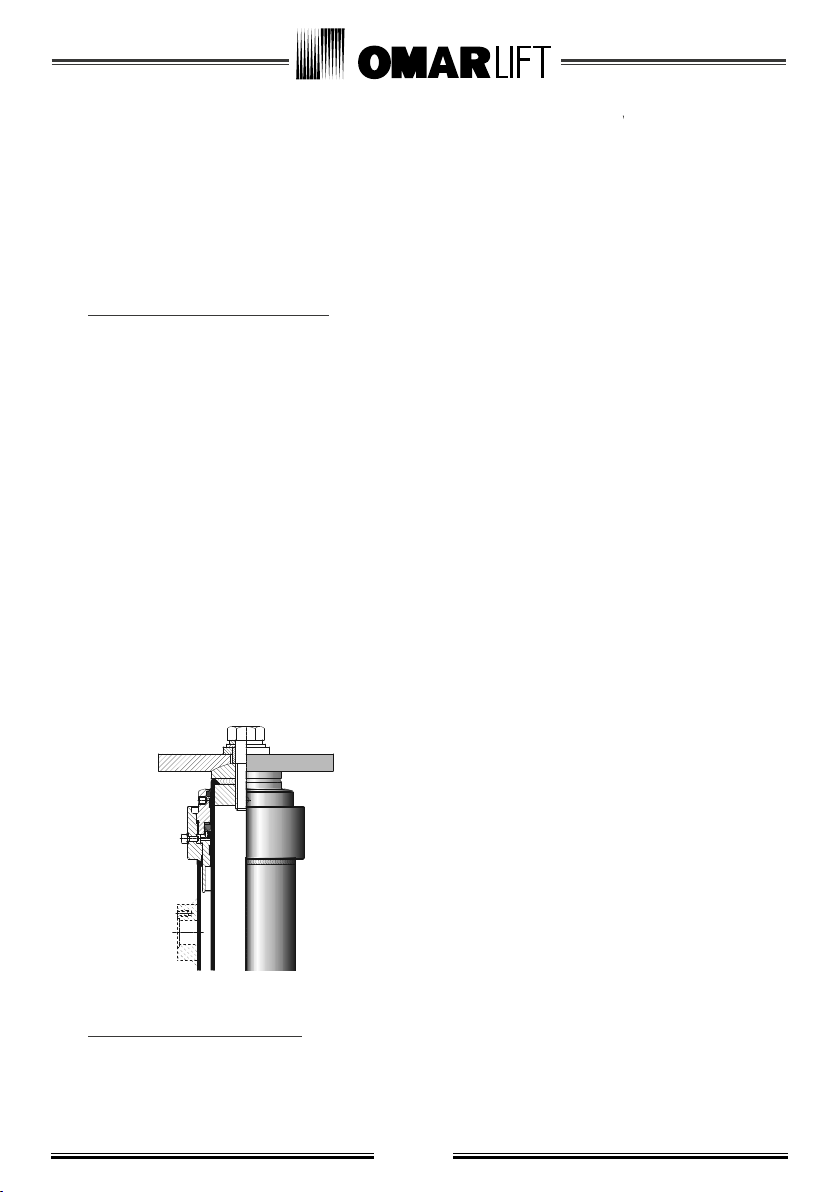

It is necessary, after having removed the protection

hoods, to put some rubber stripes between the rod

and the cylinder, in order to avoid damages to the

rod. These stripes have to be fixed well to the screws

of the flanges and have to be removed just before

closing the square flanges of the cylinder.

Follow the next operating instructions for the assembling

of the two pieces (see drawing n. 4):

Put the lower part of the cylinder in a perfect vertical

position and fix it, unscrew the screws that fix the

protection hood to the flange on the cylinder head.

Draw out the rod for a length of around 1/2 metre, fix the

special wrench or other tools well protected by rubber or

similar material. Then take the protection hoods away.

Remove the potection rubber on the upper half of the

rod.

Check if the upper block stirrup is present and if it

is fixed through the M30 screw.

Disassemble the rod protection hood unscrewing the

fixing screws.

Lift the upper half of the cylinder with an hoist

fastening it to the holed plates welded on the head.

Let the rod draw out paying attention to avoid scriping

and knocks to the cylinder.

Block the rod of the upper half with a screwer or with

another tool insulated with rubber, without making it

come out of the head which contains the seals.

The block stirrup of the rod has to be removed only

when the operation has finished.

Remove grease and clean the male and female threads,

avoiding that the solvent contacts the OR of the joint.

Control carefully that there are no bruises neither

on the threads nor on the joint. If necessary, get rid

of them.

Control that the OR of the joint is not damaged and is

well greased.

Lower the upper half of the cylinder and slowly

approach the threads without harsh movements.

Control the alignment and completely screw

without using the thread-locking liquid.

If there are any difficulties with screwing, unscrew

immediately, control the threads and try again.

After having completely screwed the two halves, unscrew

by 4/5 turns, apply the thread-locking liquid on the screw

(not on the OR), quickly screw again, checking that the

red paint signs are aligned (max tolerance 4/5 mm).

Remove the screwers and control by hand that the

joint of the rod is perfect all around, without bruises

and steps. If necessary, smooth with fine abrasive

paper (grain 320-400).

Check that the OR of the lower flange is perfect and

positioned in its own housing. Clean the two flanges.

Pull the two square flanges closer, matching the pin

with the hole. Then screw the four screws that block

the flanges, tighting crosswise.

The upper half of the cylinder in two pieces has a rod

which is longer than the cylinder, so it is possible to fix

the screwer to the rod without disassembling the cylinder.

The two joints of the cylinder in two pieces are

hermetically closed by two metal hoods which act as a

protection and packaging during the transport.

In case of three pieces cylinders, we advice to proceed as

follows:

In the first step, assembly the cylinder lower part with

the intermediate one, considering these two parts as

being one cylinder in two pieces. To facilitate this

operation, the intermediate part jacket can be completely

unthreaded and put back after having assembled the first

two parts.

OMAR LIFT

Pagina/Page D842M2L.006

Data/Date 09.2008

Versione/Issue 1