PROGRAMMING OF PREHEATING (PHASE NO. 1)

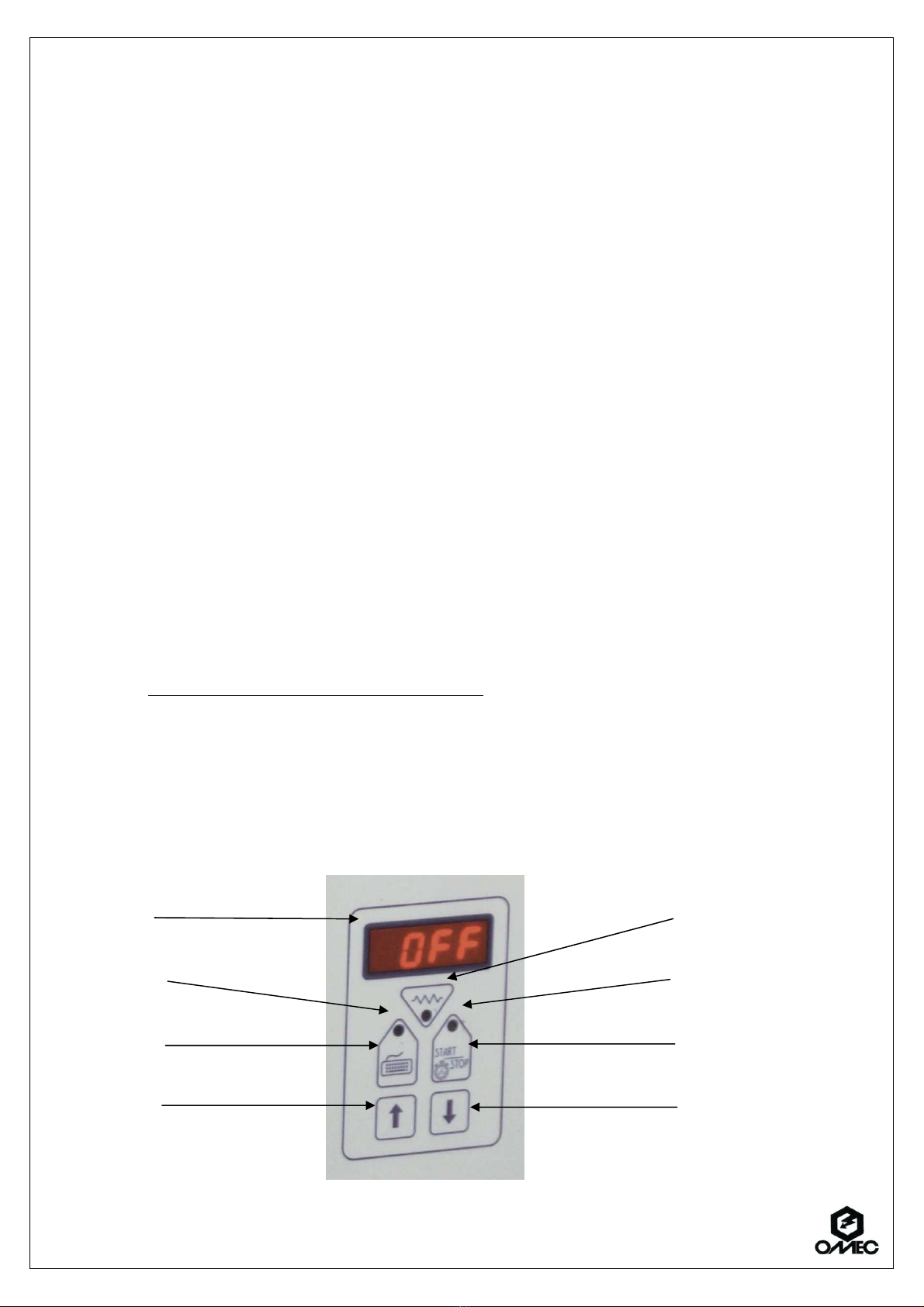

Press

key to program.

The words “Ph.1”, “°C” and the last programmed preheating temperature value will appear in

sequence on the display.

The red led of

key will start flashing intermittently during all preheating programming.

The change f this parameter (programming range 0/100°C) is done by using

key (to increase

value) and

key (to decrease value).

By keeping pushed one of the two keys (

or

)for a time shorter than 2 seconds, the change of

parameter will be by one step corresponding to 1 °C a press.

For a rapid change the operator has to keep one of the two keys (

or

)pushed for a time

longer than 2 seconds. In this case the change of parameter will be by 10 steps correspondent to

a 10 °C a second until the release of the key.

In case a value equal to 0 is set this phase is by-passed (no parameters are considered for this

phase) and cycle starts from phase 2 directly.

Press

key to confirm entry.

The word “rAtE” and the last programmed speed rising value will appear in sequence on the

display.

The modification of this parameter (programming range 0/FULL=max. speed) is done by using

key

(to increase value) and

key (to decrease value).

By keeping pushed one of the two keys (

or

)for a time shorter than 2 seconds, the change of

parameter will be by one step corresponding to 1 °C a press.

For a rapid change the operator has to keep one of the two keys (

or

)pushed for a time

longer than 2 seconds. In this case the change of parameter will be by 10 steps correspondent to

a 10 units per second until the release of the key.

It is advisable never to set a value lower then 13 otherwise the heating will be too slow (while

setting this value always consider the quantity of water inside the tank: the more water there

is in the tank the slower will be the heating up).

In case the operator wants to heat the water as fast as possible, the rising speed to be set on

FULL (heating element always active).

Press

key to confirm entry.

The word “Hr.Mn” followed by the last programmed holding time will appear on display.

Four numbers separated by a dot will appear on the display.

The two still numbers on the left side of the dot show the hours, while the flashing numbers on

the right side of the dot show the minutes.

The first parameter to change are the hours.

The modification of this parameter (programming range 00/20 hours) is done by using

key (to

increase value) and

key (to decrease value).

By keeping pushed one of the two keys (

or

)for a time shorter than 2 seconds, the change of

parameter will be by one step corresponding to 1 hour a press.

For a rapid change the operator has to keep one of the two keys (

or

)pushed for a time

longer than 2 seconds. In this case the change of parameter will be by 10 steps correspondent to

a 10 hours a second until the release of the key.

Press

key to confirm entry and to go to programming of minutes.

On display now you will see the two numbers on the right side of the dot (showing minutes)

still, while the two numbers on the left side of the dot (showing hours) flashing.

The modification of this parameter (range of programming 00/59 minutes) is done by using

key

(to increase value) and

key (to decrease value).

By keeping pushed one of the two keys (

or

)for a time shorter than 2 seconds, the change of

parameter will be by one step corresponding to 1 minute a press.

- Page 4/9 -