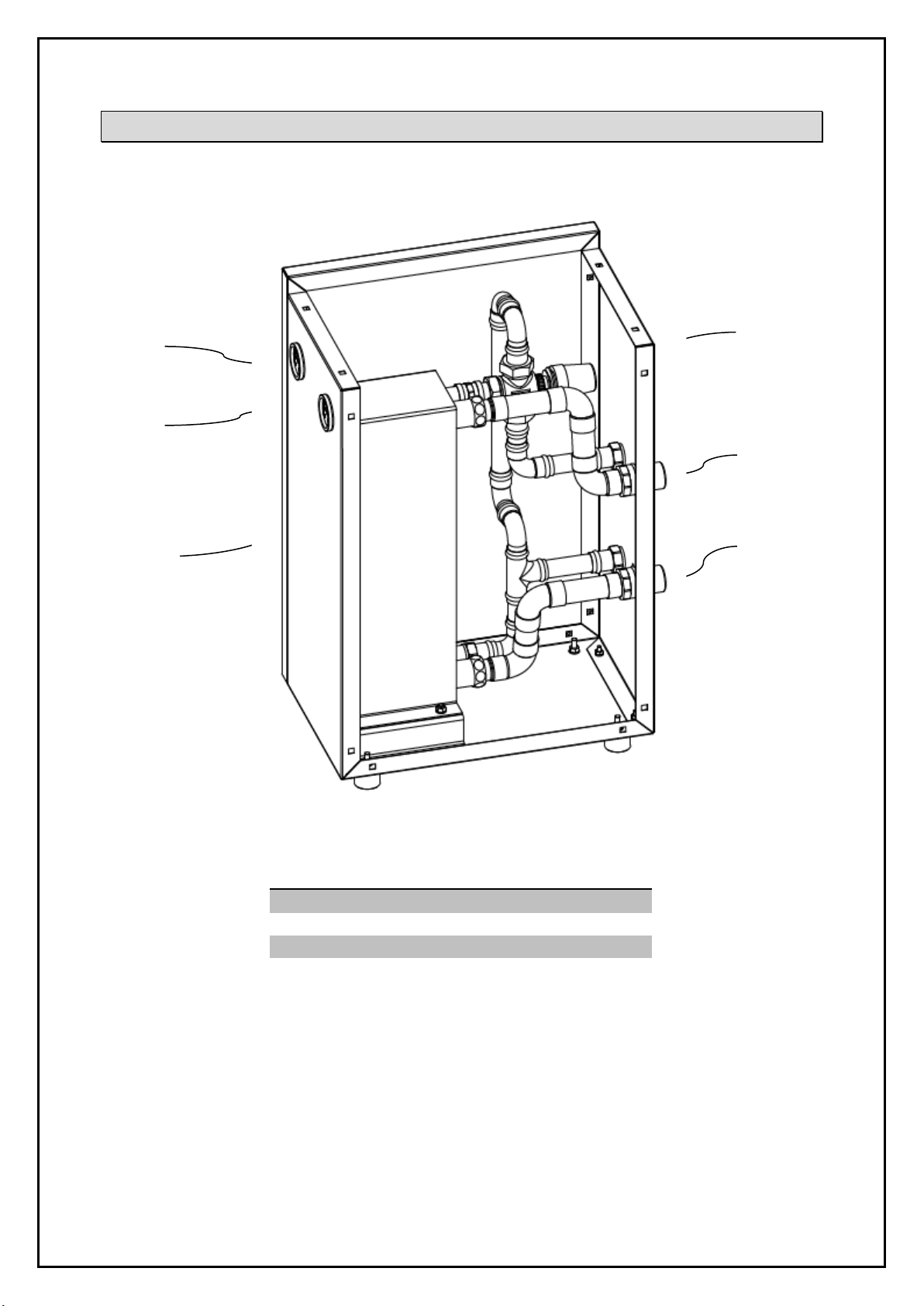

AirWatt - Installation and operating manual

Introduction

External heat recovery system AirWatt is intended for professional use. This user manual

provides all necessary information for dimensioning, installation, safe operation and

maintenance. It should be read thoroughly and carefully. Obey all safety instructions.

Manual should be conserved through entire lifetime of device. Regular and correct

maintenance and regular safety checks are required for long and trouble free operation.

Installation and use may be subject of local laws and directives which must be obeyed. For

any further information or in case of doubt contact manufacturer. Manufacturer will not be

held responsible for any defects, which are consequence of misinterpreting user manual

instructions, unprofessional installation or disobeying local laws and directives.

General safety instructions

Warning!

Operating this device may be dangerous, if following instructions are

not obeyed. In addition to this manual instructions from compressor

manufacturer must also be observed.

AirWatt unit was designed and manufactured in accordance with all health and safety

requirements of EU.

•All personnel involved at installation, operating and maintenance of this device must

reed and fully understand this included instructions.

•Installation and assembly of the unit can only be performed by authorized personnel

of company Omega Air d.o.o. Ljubljana.

•Device may only be used in accordance to this manual.

•Personnel must always wear personal protective equipment.

•Do not use this device, if there are present any signs of damage or defect.

•Always turn of compressor, lock the power supply and depressurize the system,

before performing any kind of work on device or installation.

•Device must have installed limiting elements, which prevent operating outside

specified parameters.

•It is forbidden to approach device under operation.

Installation and maintenance work on the device my only be carried by authorized and

trained professional.

•It is forbidden to alter the device or its construction in any way.

•Before maintenance depressurise the system.

•Use only original spare parts.

•Use the device only for the purpose for which it was originally designed.