1

Heat & Glo • PHFR-PRIMO-48, PHFR-PRIMO-60, PHSI-PRIMO Instructions • 2560-970 Rev. D • 2/19

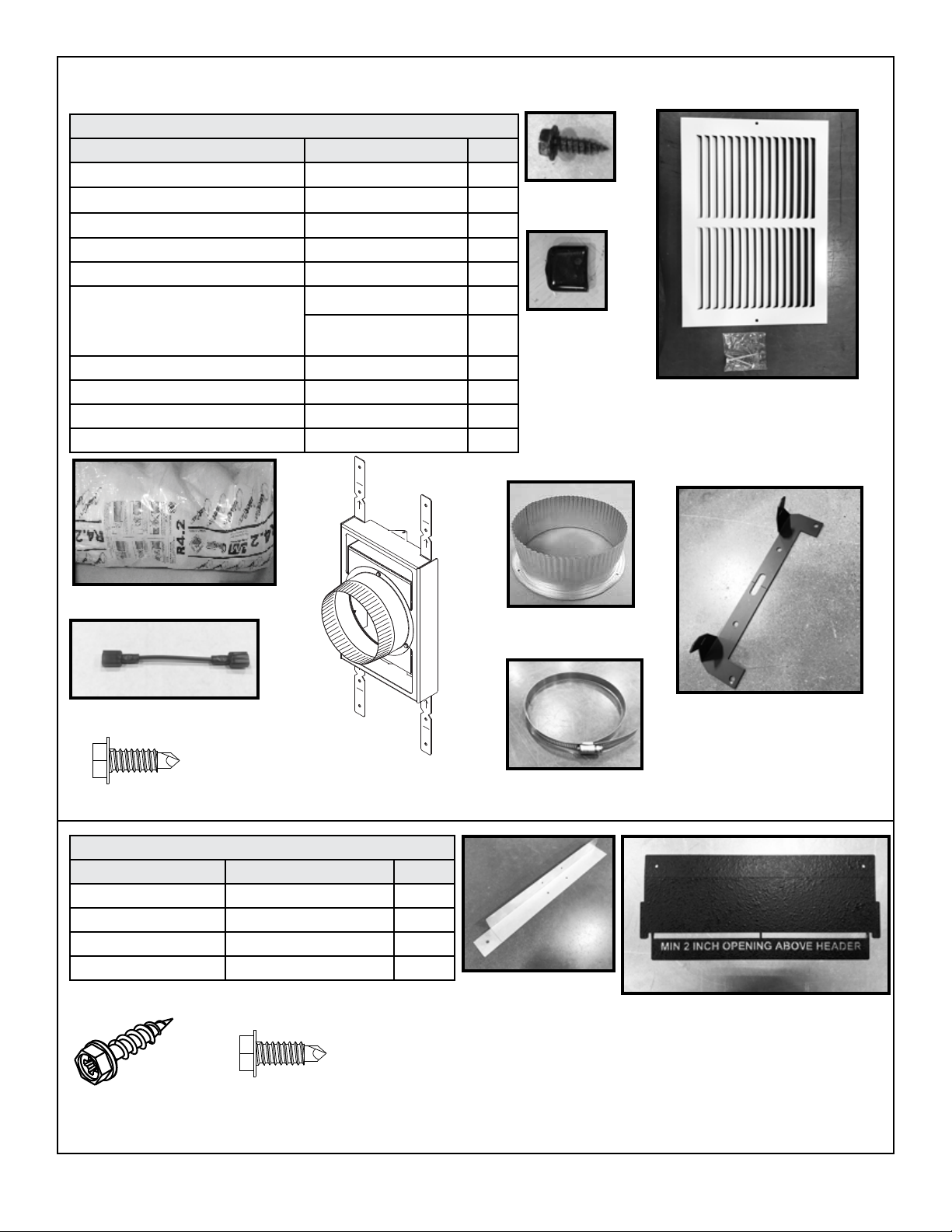

PRIMO Passive Heat PowerFlow™ Heat Management System

Passive Heat - Front Discharge: PHFR-PRIMO-48, PHFR-PRIMO-60

Passive Heat - Side Discharge or Open Top Discharge: PHSI-PRIMO

Models: PRIMO48, PRIMO48ST, PRIMO60, PRIMO60ST

Installation Instructions

Leave this manual with party responsible for use

and operation.

CAUTION! Risk of Cuts, Abrasions or Flying Debris.

Wear protective gloves and safety glasses during instal-

lation. Sheet metal edges are sharp.

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of

burns from the hot viewing glass is provided

with this appliance and shall be installed for

the protection of children and other at-risk

individuals.

CAUTION! Do not install damaged components.

This appliance comes standard with patented

SafeSurfaceTM Glass which keeps the surface temperature

of the barrier glass at a safe level and will still be hot to

the touch when operated for long periods of time.

If the barrier glass is removed, the inner glass temperature

will be very hot and cause burns.

WARNING! Risk of Fire!

• Combustible materials MUST NOT overlap or be placed

behind a decorative front.

• DO NOT apply combustible materials beyond the

minimum clearances. Comply with all minimum

clearances to combustibles as specied. Overlapping

materials could ignite and will interfere with proper

operation of decorative fronts.

If any parts are missing or damaged, contact your dealer before

starting installation. DO NOT install a damaged kit.

Table of Contents

1. Introduction ....................................2

2. Kit Contents....................................3

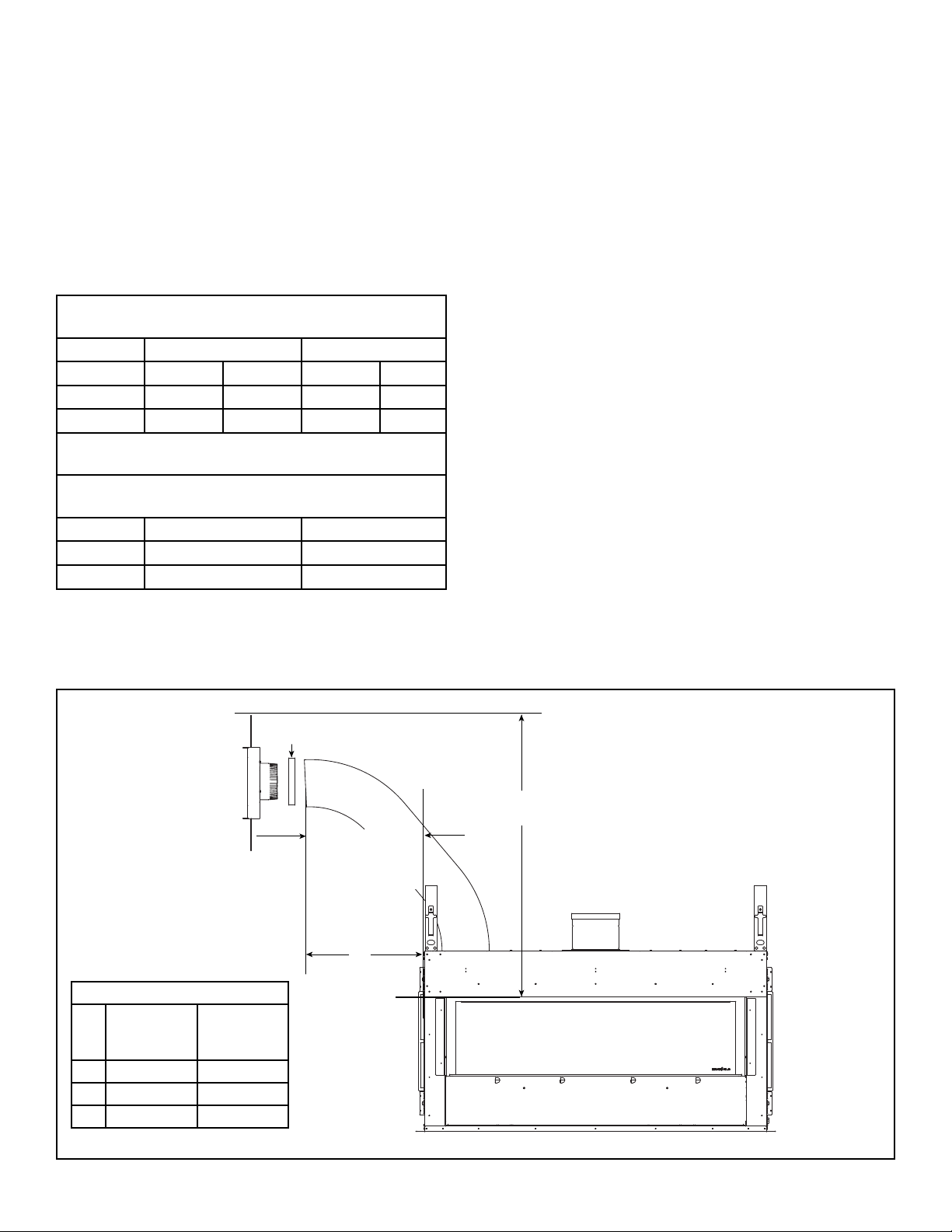

3. Preparation ....................................5

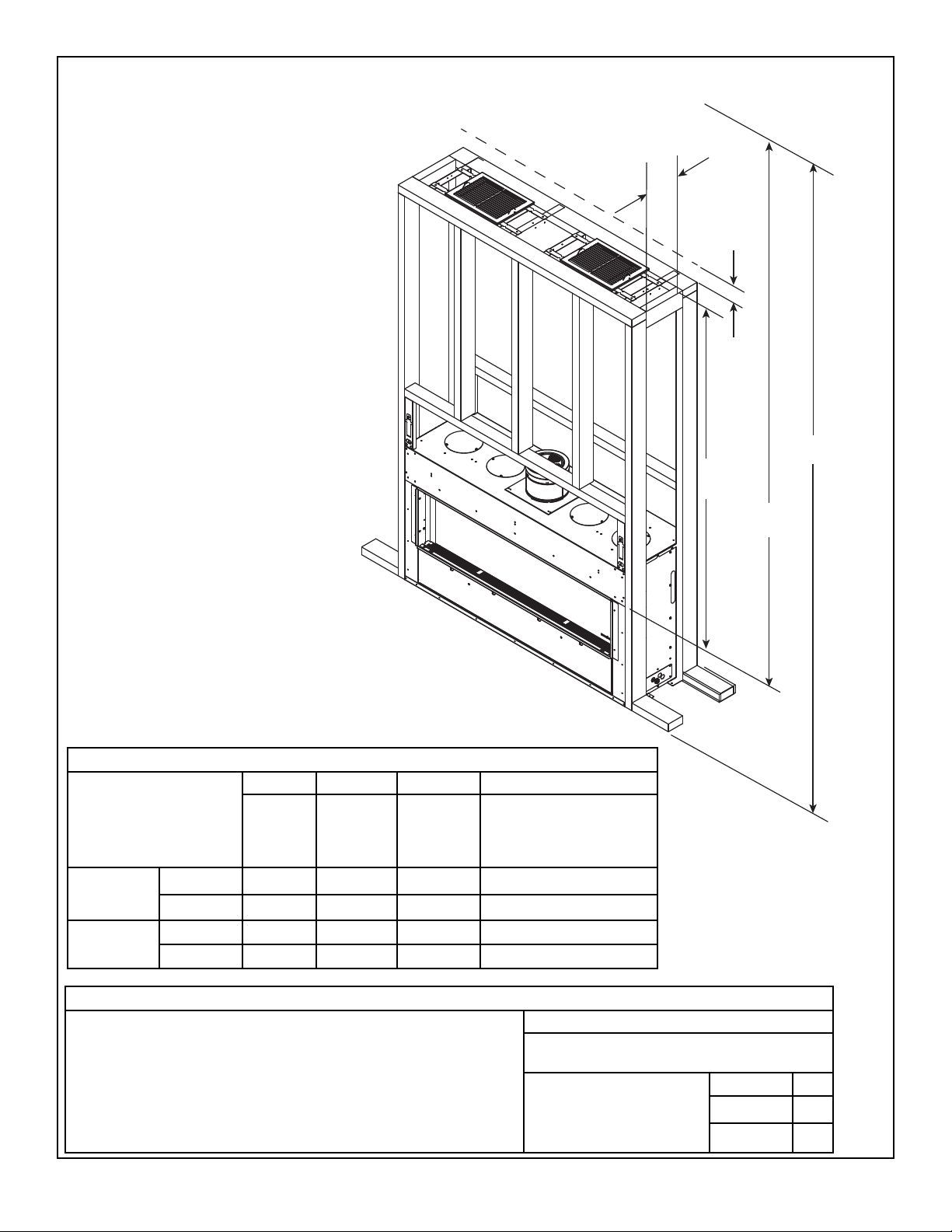

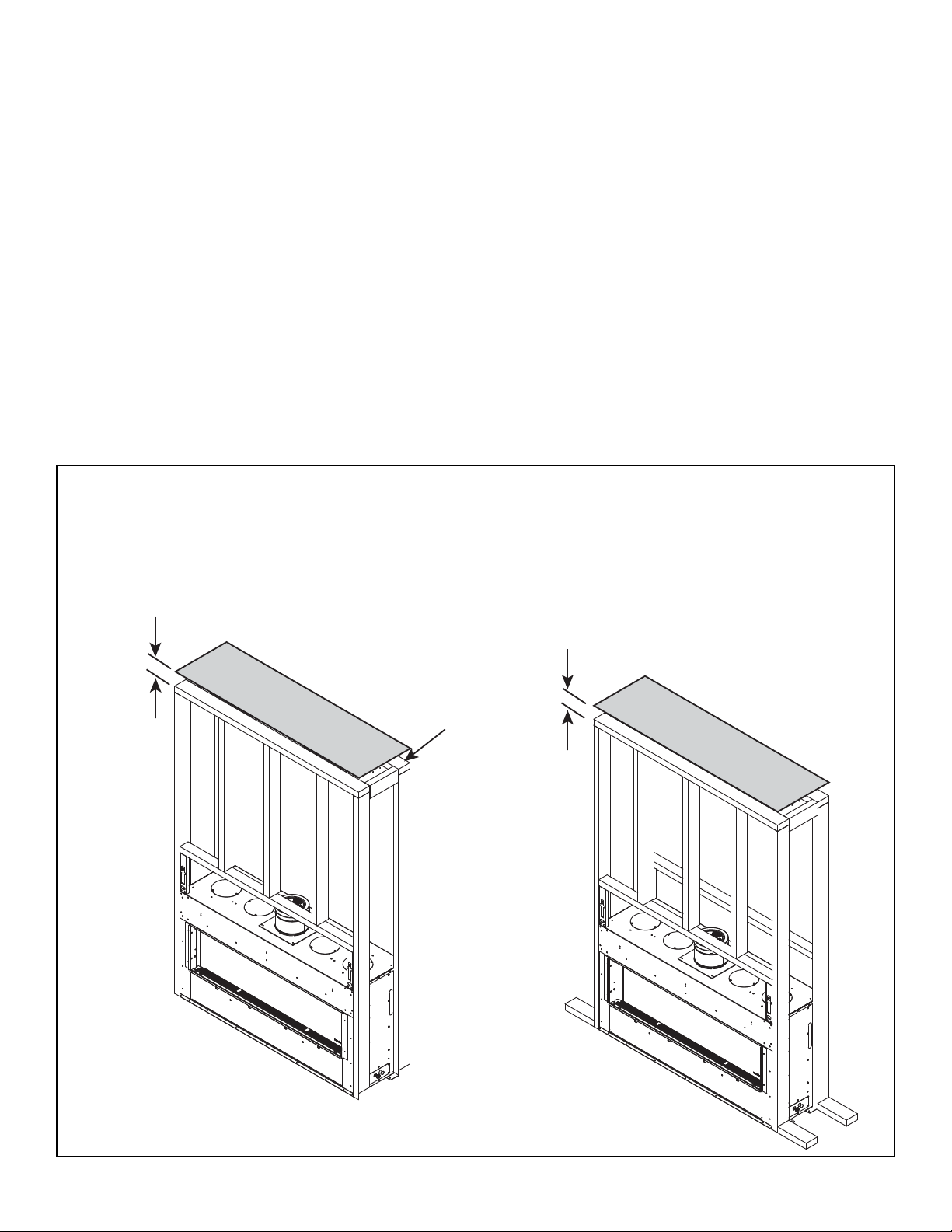

4. Framing ......................................6

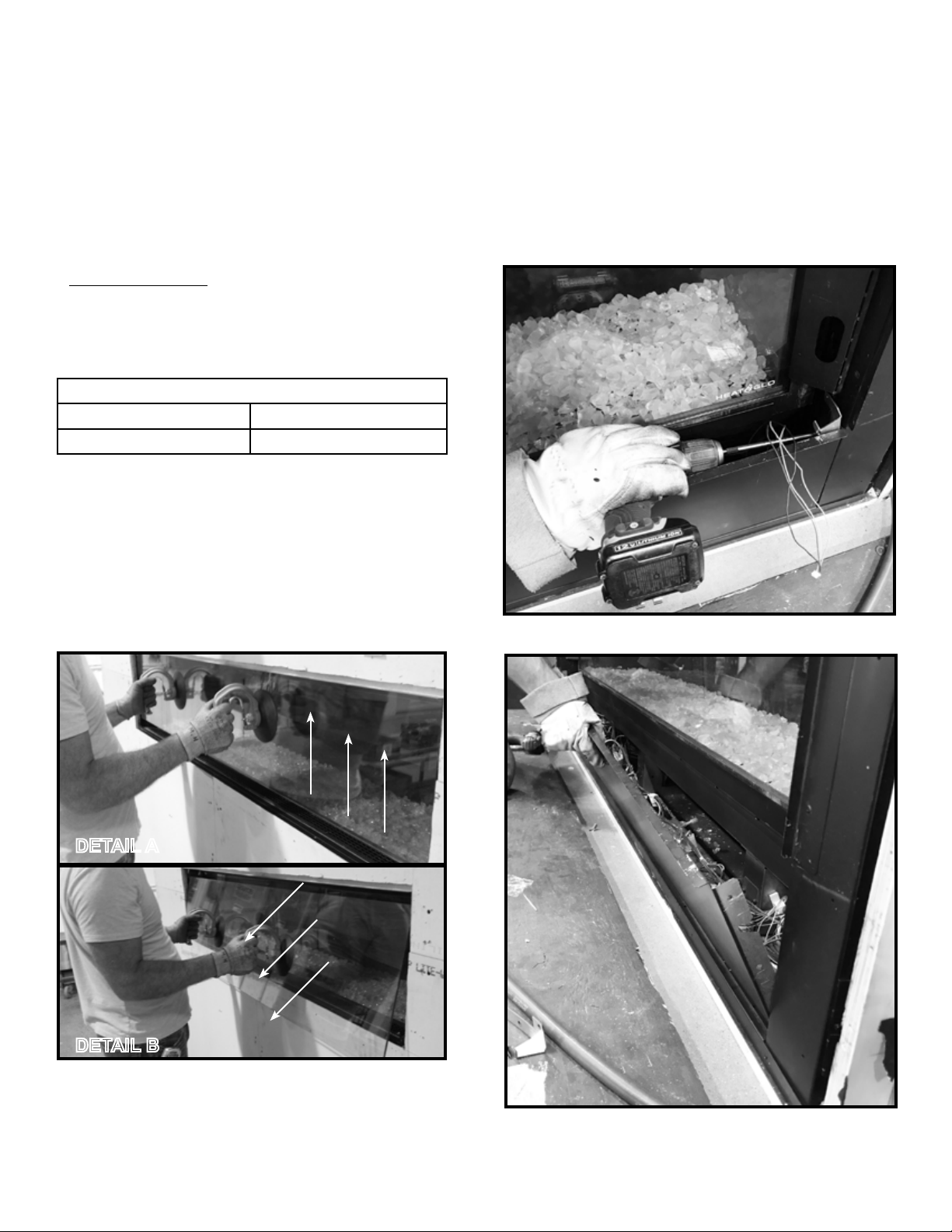

5. Remove Barrier Glass/Bypass Limit Switch and

Glass Mounting Brackets .........................9

6. Installation and Finishing - Front Discharge ..........14

7. Installation and Finishing - Side Discharge ...........20

8. Installation and Finishing - Open Top Discharge .......24

9. Wiring Requirements............................31

10. Maintenance ..................................33