- 2 -

EN

INSTRUCTION MANUAL INDUSTRIAL DISHWASHER

GENERA INFORMATION

This dishwasher is in compliance wi h he provisions curren ly in force concerning safe y. Improper use can cause damage o

people and / or proper y. Before s ar ing he machine, carefully read hese ins ruc ions which con ain impor an informa ion for

ins alla ion and safe y. This manual is an in egral par of he dishwasher.

The dishwasher is only in ended for professional use. I is designed for washing dishes, glasses (cups, pla es, cups, bowls, rays,

cu lery) and in similar areas in he field of food and ca ering and complies wi h in erna ional elec rical and mechanical safe y and

according o EMC s andards.

Personnel opera ing he machine mus be regularly rained. Only rained personnel should use i . The dishwasher is no sui able

for use by minors and persons wi h reduced physical or sensory abili ies, nor by people wi h psychological problems. The use of

he machine by hese people is permi ed only under he supervision of a responsible person. Do no allow children play wi h he

dishwasher.

The manufac urer disclaims any liabili y for damage o persons or proper y caused by disregarding ins ruc ions of his bookle ,

by incorrec use or by in erference wi h any par of he dishwasher. Replace any defec ive par s only wi h new original par s.

This is he only way ha he manufac urer guaran ees he observance of safe y s andards and he correc opera ion of he ma-

chine.

Do no use he dishwasher as a ladder or o suppor people, objec s or animals. Leaning or si ing on he open door could cause i

ipping over and endangering people. Close he door o preven people ripping over i .

Before ins alling his appliance, check ha here are no damages visible. For your safe y, never opera e on a damaged machine.

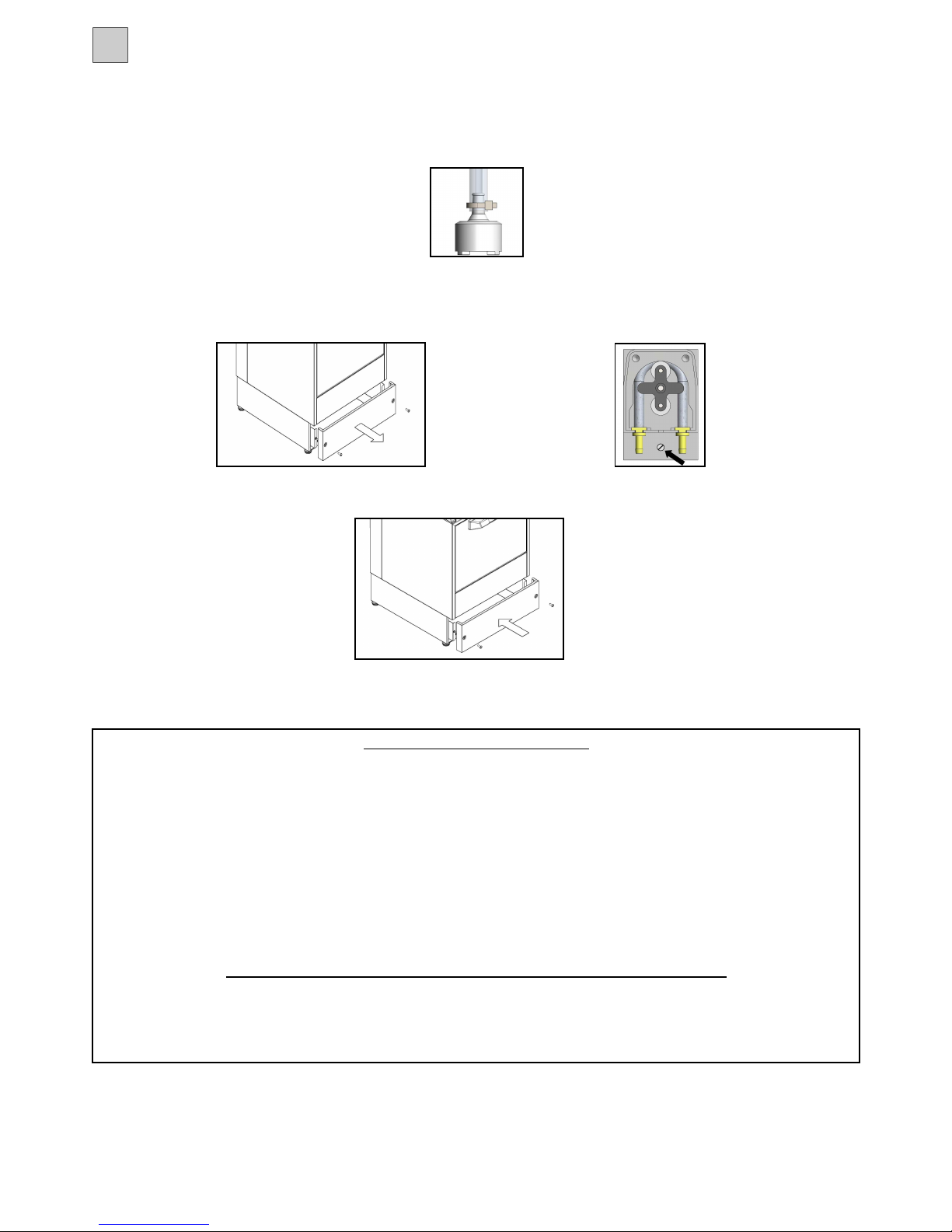

The dishwasher mus be ins alled and repaired only by au horized personnel. Work performed incorrec ly can cause serious haz-

ards o he user, for which he manufac urer is no responsible.

Please ensure ha ear h connec ion as been done correc ly. In case of doub s, have he sys em checked by a qualified echnician.

The manufac urer is no liable for any damages due o he in errup ion or absence of ear h connec ion.

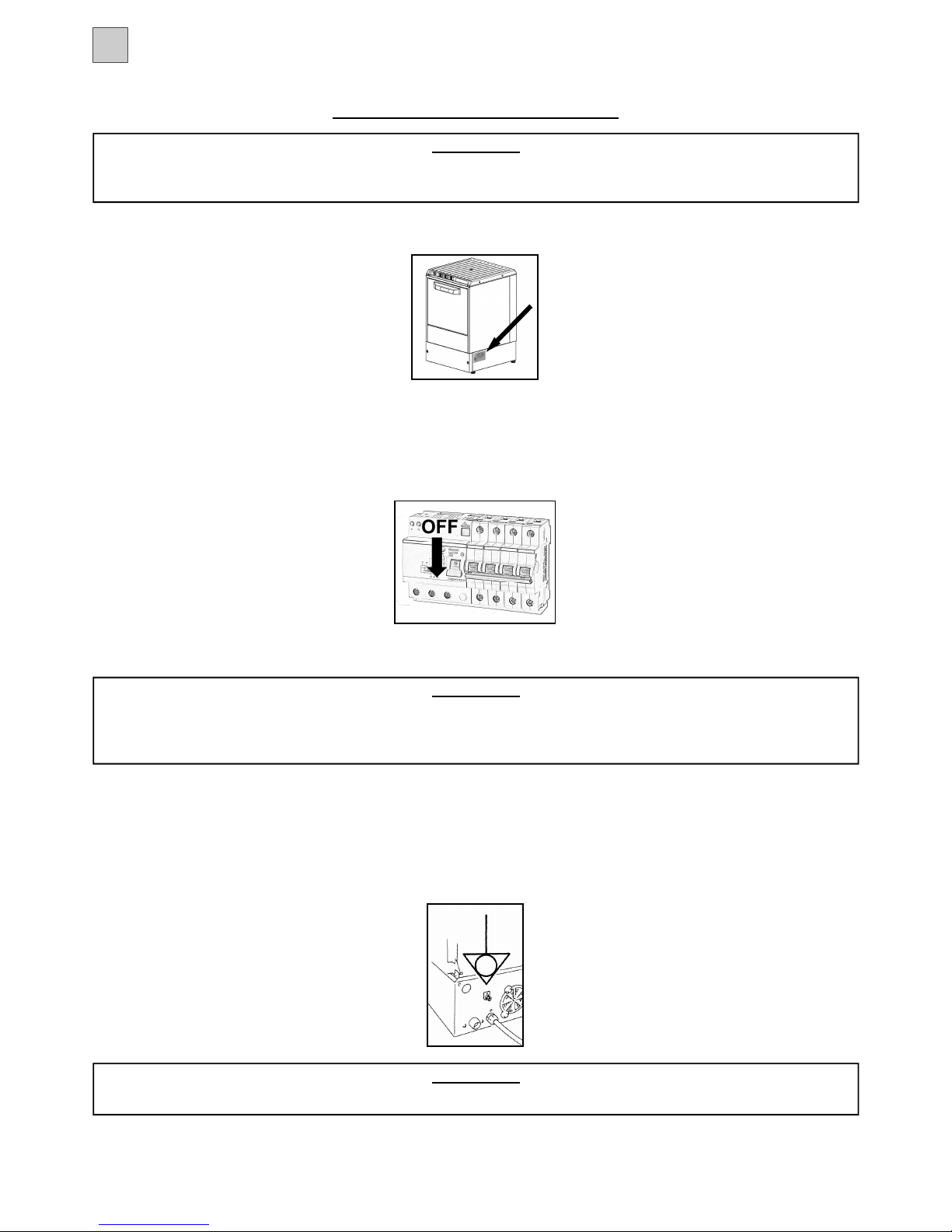

Follow ins alla ion ins ruc ions indica ed in he ins alla ion manual. Prior o an elec rical connec ion, i is necessary o compare

he echnical da a, vol age and frequency indica ed on he machine namepla e wi h hose indica ed on he mains supply. The

elec rical supply da a mus ma ch wi h he machine requiremen s o preven damage on he machine. In case of doub , have he

sys em checked by a qualified elec rician.

Do no connec he machine o he mains wi h ex ensions because hey do no guaran ee he sufficien safe y.

To perform he ins alla ion work or any main enance or repair, disconnec he machine from he mains. Opera e on he machine

only when he isola ing swi ch is off.

Be careful when handling chemical produc s! These produc s, such as de ergen and rinse aid, can be corrosive or irri an . Follow

he safe y regula ions on he packaging! Wear goggles and gloves! Carefully follow he safe y ins ruc ions provided by manufac-

urers. Do no inhale powder de ergen . Inges ing de ergen can cause burns o he mou h and hroa and lead o suffoca ion.

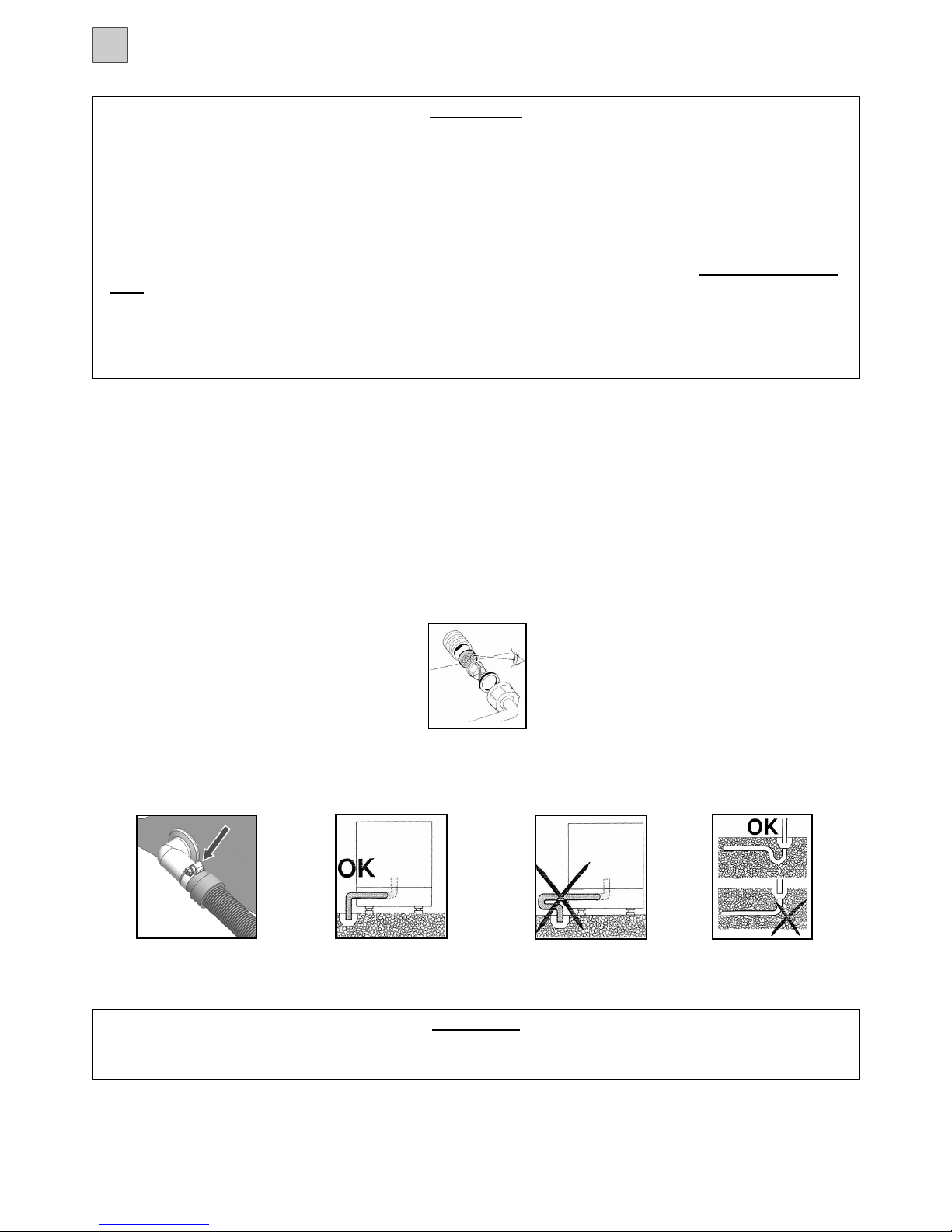

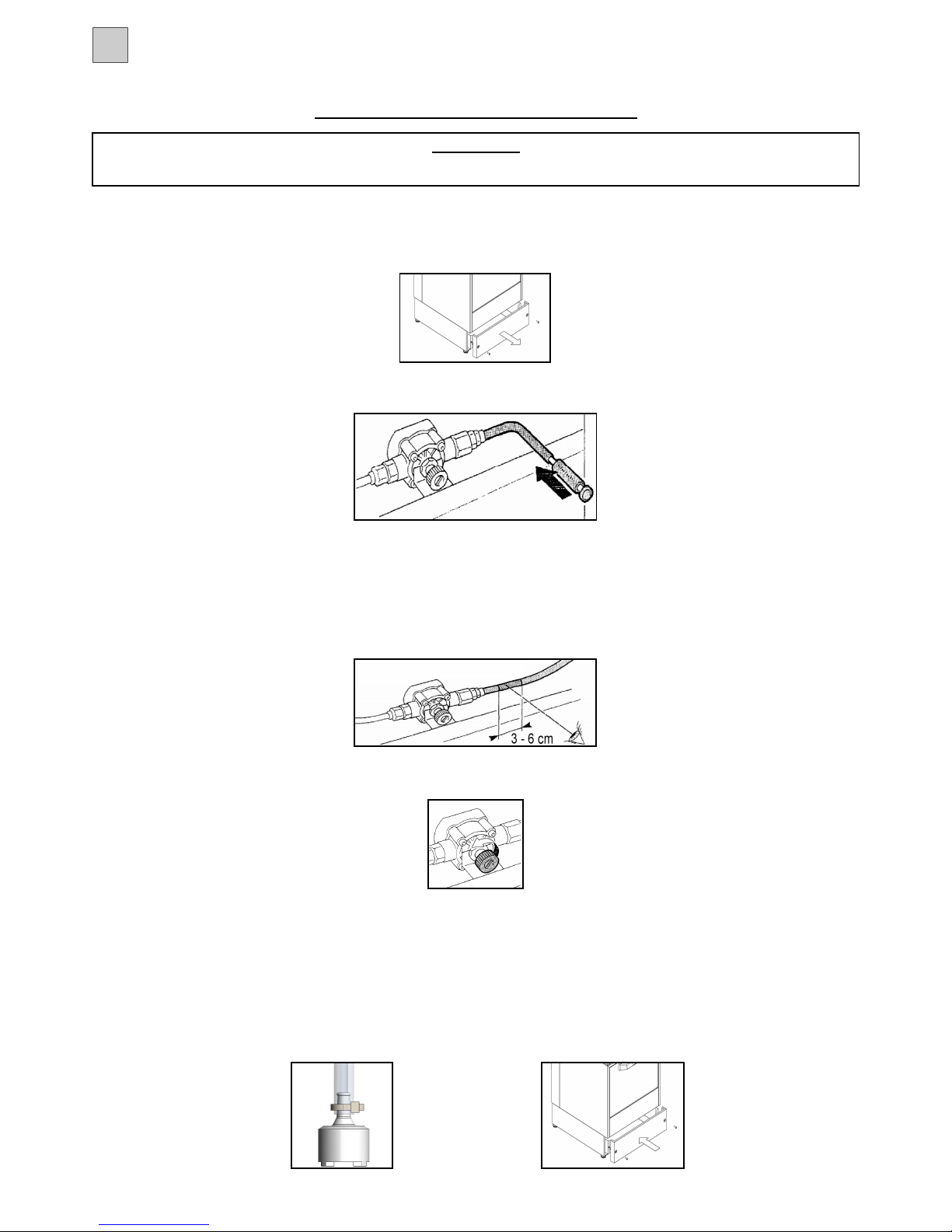

Af er any work done o he wa er supply, purge he wa er pipes o he dishwasher o avoid damaging or clogging he wa er inle

valve.

The machine and he surrounding area should no be sprayed direc ly wi h wa er.

Do no open he door when he machine is opera ing. There is a DANGER of splashing wi h ho wa er. If you open he door a

he end of he cycle , ake care no o ouch he hea ing elemen s loca ed in o he wash ank (danger of burns).